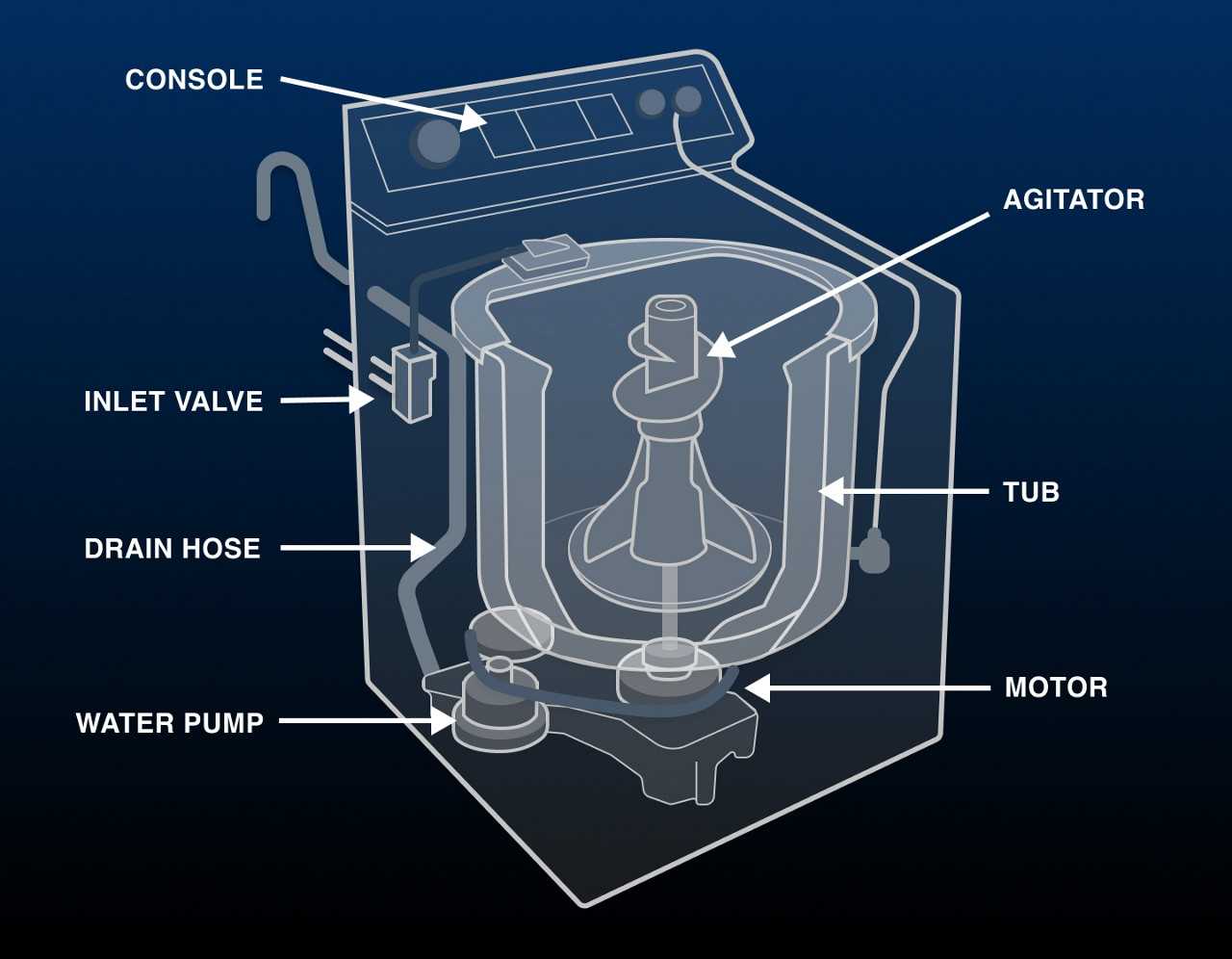

Understanding how various elements work together in home appliances can significantly improve their efficiency and prolong their lifespan. One essential household device is designed to handle clothing maintenance, ensuring fabric care with precision. Gaining knowledge about its internal structure offers insight into troubleshooting and maintenance.

Each unit is built with several interconnected elements, including systems responsible for air circulation, temperature regulation, and moisture detection. Identifying these components allows users to optimize the performance and address potential issues before they become serious.

This guide delves into the intricate design of a popular household appliance, helping enthusiasts and repair professionals recognize individual elements and their functions. With a better understanding of these internal mechanisms, maintaining and repairing these devices becomes a more straightforward task.

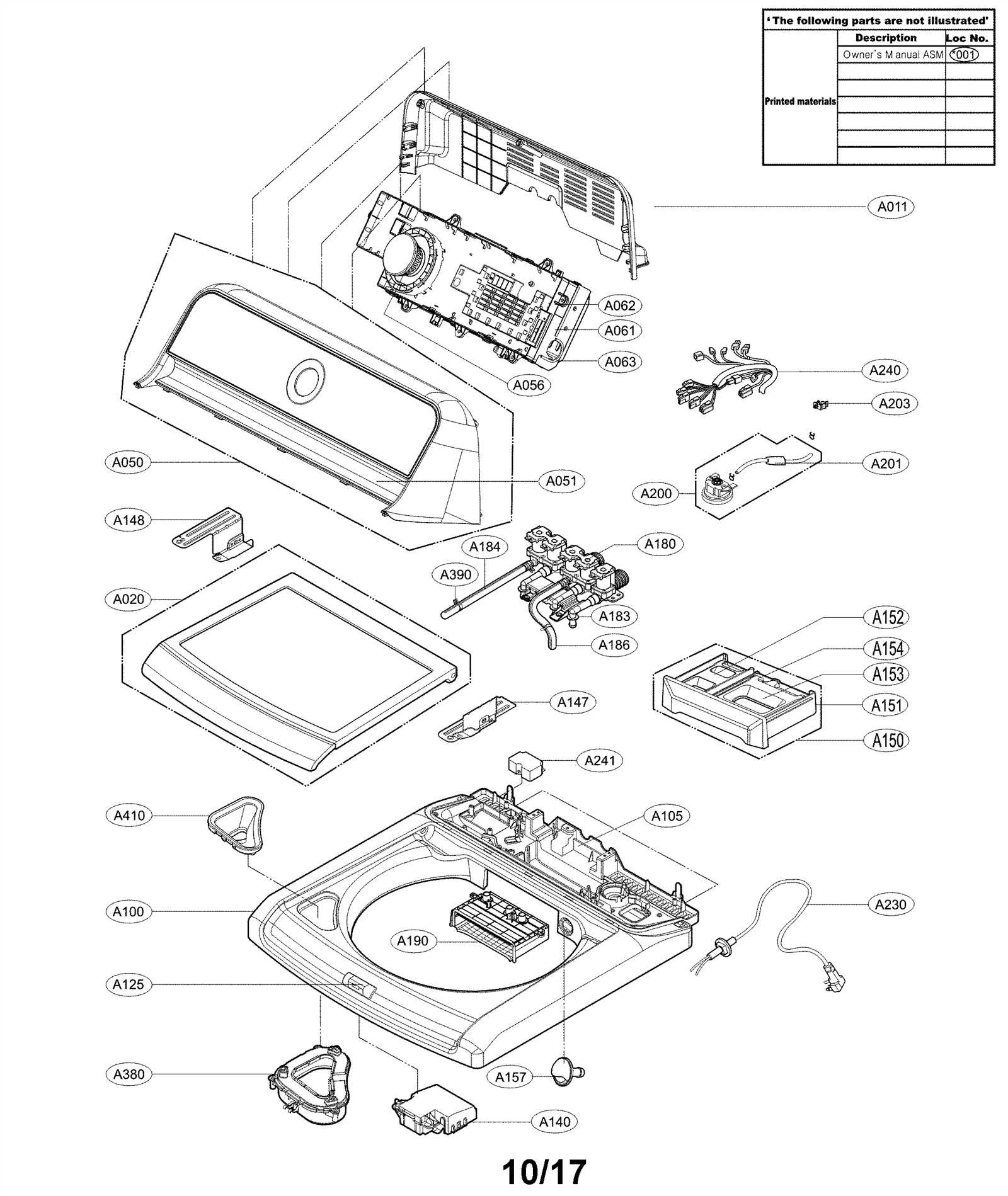

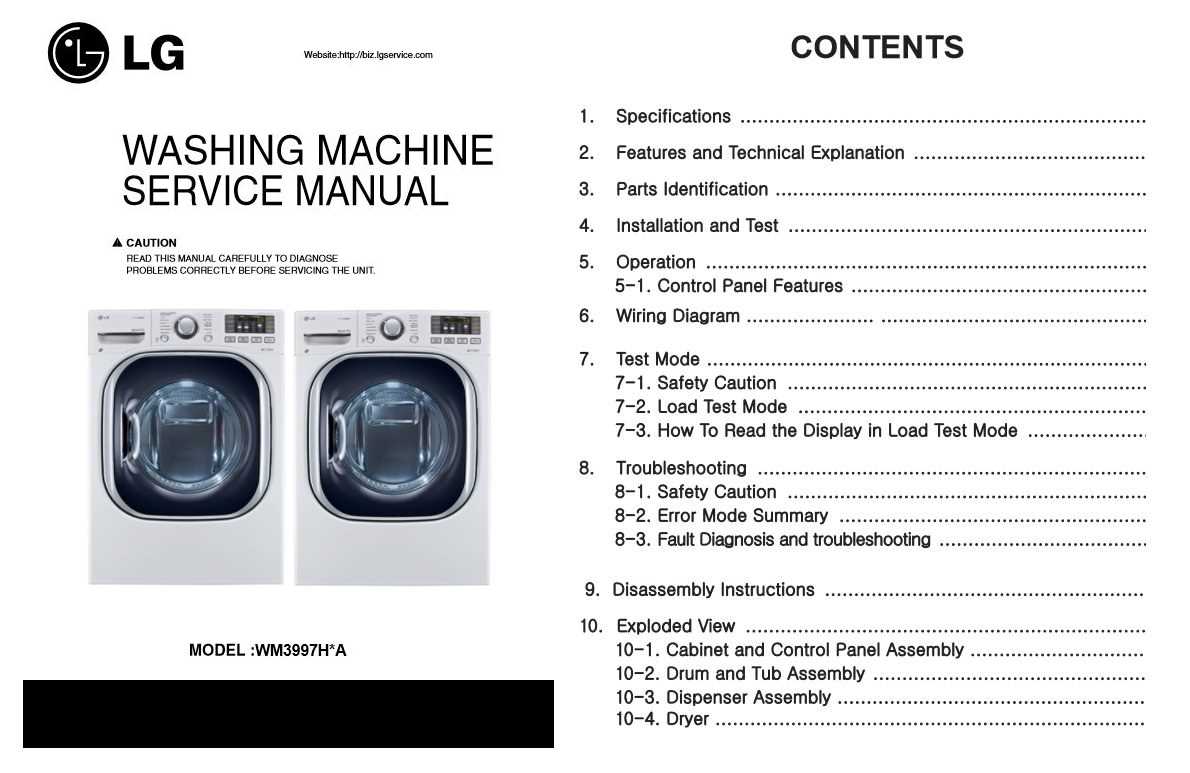

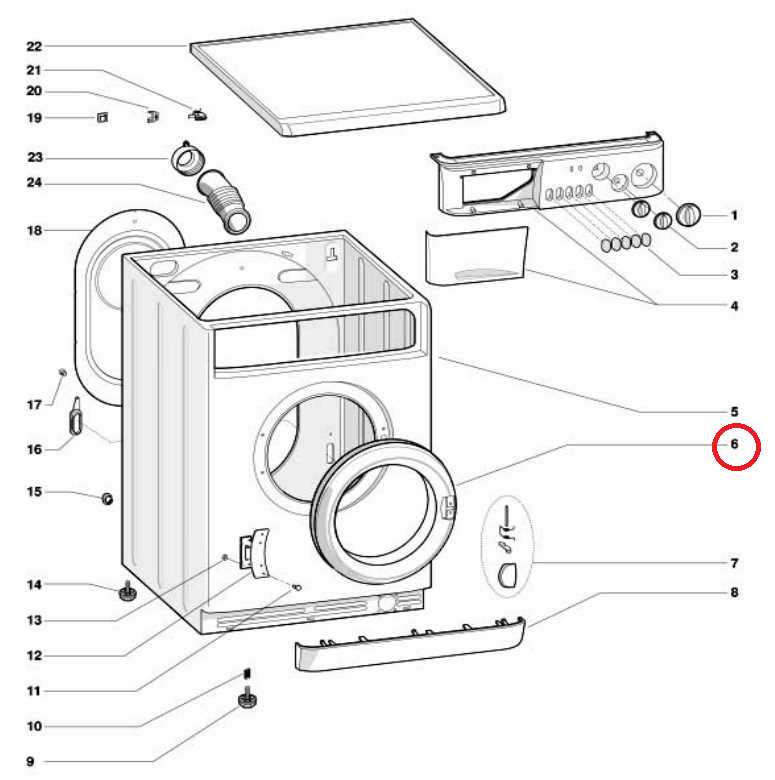

LG Front Load Dryer Parts Diagram

Understanding the structure and components of a household appliance helps ensure proper maintenance and repair. Each element inside the machine plays a crucial role in delivering efficient operation and longevity.

Key Internal Elements

The system consists of several interconnected modules responsible for heat generation, airflow, and control. Heating units ensure optimal temperature levels, while ventilation pathways keep the air circulating smoothly to dry fabrics effectively. The device also includes sensors to monitor performance and safety.

Maintenance and Common Repairs

Key Components of the LG Dryer

Each appliance is made up of essential elements that work together to ensure smooth operation and long-lasting performance. Understanding these components can help users maintain the equipment properly and identify issues when they arise.

Heating Element: This component is responsible for producing the necessary warmth to effectively dry fabrics, ensuring optimal results for various materials.

Control Panel: The interface allows users to adjust settings, choose cycles, and monitor the appliance’s

Understanding the Control Panel Functions

The control panel serves as the main interface for operating the appliance, allowing users to manage various settings and features. Each button and display area has a specific purpose, helping to customize the machine’s performance according to individual preferences.

- Power Button: Turns the appliance on or off, making it ready for use.

- Cycle Selector: Allows users to choose from multiple operation modes for different fabric types and care needs.

- Temperature Control: Adjusts

Door Assembly and Latch System

The structure of the door and its locking mechanism ensures secure closure and smooth operation. These components are designed to align precisely, preventing accidental openings and maintaining proper internal conditions during use.

Door Frame: This part supports the overall structure and connects to the hinges, allowing stable movement. A well-fitted frame ensures durability and seamless opening or closing.

Hinges: The hinges enable smooth motion, holding the door in place and minimizing wear over time. They also help in

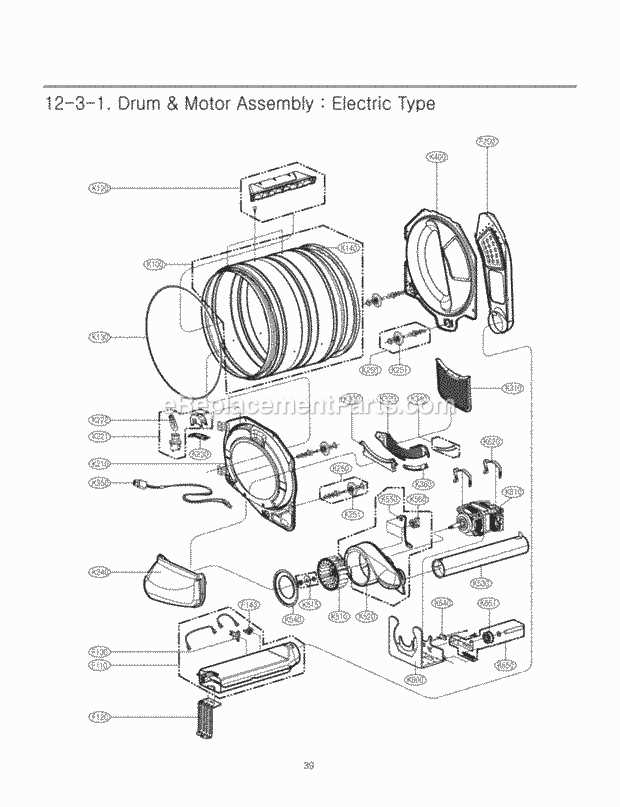

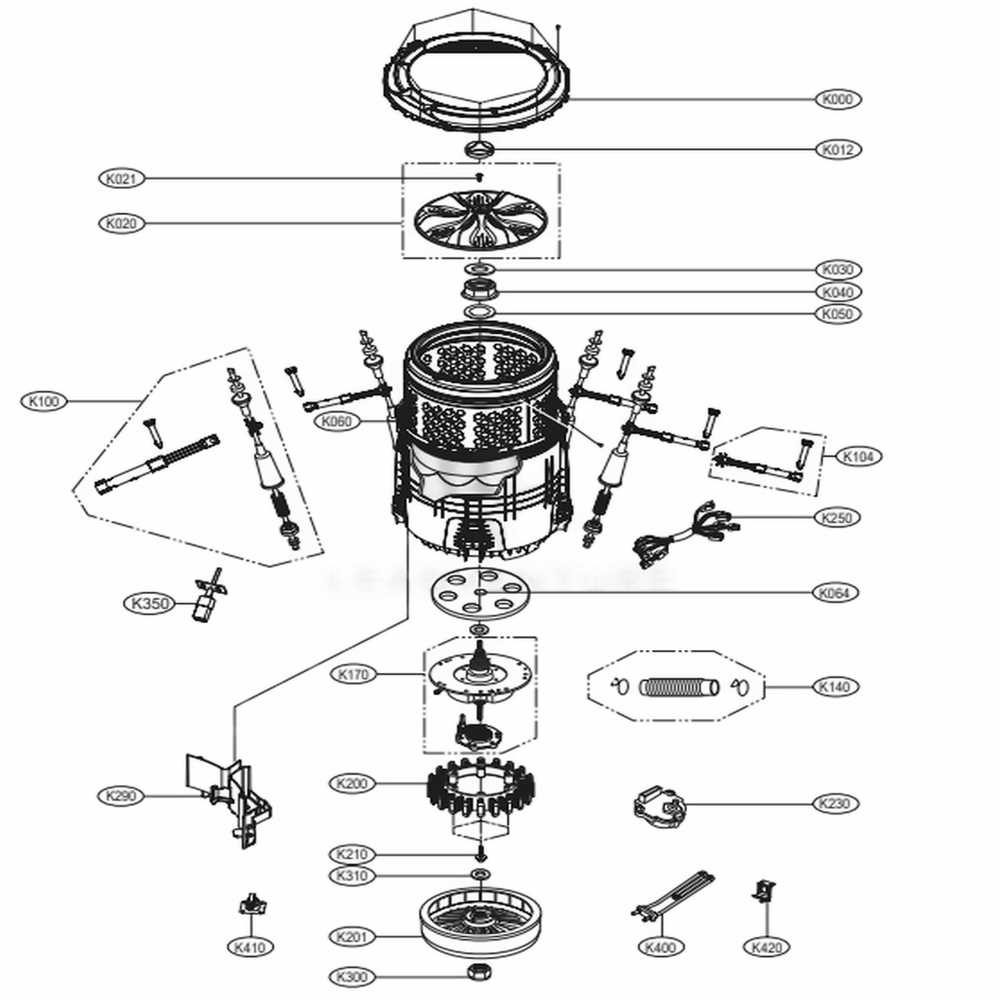

Motor and Drum Operation Explained

The coordinated work of the motor and drum ensures smooth performance during each cycle. This system relies on precise movement and stable rotation to achieve optimal results, keeping the internal mechanisms functioning seamlessly.

The motor plays a critical role by generating the necessary power to initiate rotation. It drives the belt connected to the drum, setting the entire assembly in motion. Without this synchronization, the equipment would struggle to maintain its rhythm and efficiency.

Proper drum operation depends not only on motor activity but also on tension maintained by pulleys and belts. This allows the drum to spin evenly, ensuring consistent performance across different settings and workloads.

In case of disruptions, such as worn

Heating Element Location and Function

The heating component is a vital part of any appliance that utilizes heat to facilitate its operation. Understanding where this element is situated and how it functions can enhance the overall efficiency of the machine.

Typically, the heating element is positioned in a designated area within the appliance’s structure, ensuring optimal heat distribution. Its location may vary depending on the design and model, but generally, it can be found in the following areas:

- Near the rear panel, allowing heat to flow through the drum efficiently.

- Integrated into the housing for streamlined performance.

- In proximity to the airflow system to maximize heating effectiveness.

This component plays a crucial role in generating the necessary warmth to dry fabrics effectively. It operates by converting electrical energy into heat, which is then circulated throughout the interior of the appliance. This process involves several key functions:

- Heating air that passes over the element before entering the drying chamber.

- Maintaining consistent temperatures to ensure thorough drying of items.

- Supporting the overall drying cycle by working in conjunction with other mechanisms.

In summary, the heating component’s strategic location and essential functions contribute significantly to the efficiency and performance of the appliance, making it a critical aspect of its design.

Lint Filter Structure and Cleaning Tips

The lint filter is a crucial component in maintaining optimal performance and efficiency in your appliance. It serves to trap loose fibers and debris that detach from garments during the drying process. Regular maintenance of this element is essential not only for enhancing the drying efficiency but also for preventing potential hazards.

Understanding the Lint Filter Design

This filter typically features a mesh or perforated design that allows air to pass through while capturing lint. It is usually located near the door or at the top of the appliance. The construction ensures that the air circulation remains unobstructed, which is vital for effective moisture removal from fabrics.

Cleaning Procedures

To maintain optimal functionality, it is recommended to clean the lint filter after every use. Start by gently removing the filter from its compartment. Use your hands or a soft brush to remove the collected lint, ensuring not to damage the mesh. For a deeper clean, rinse the filter under warm water and allow it to dry completely before reinserting it. This routine not only prolongs the lifespan of your appliance but also enhances its overall performance.

Blower Fan Role in Air Circulation

The blower fan is a crucial component in ensuring effective air movement within various appliances. Its primary function revolves around facilitating the distribution of heated air, promoting optimal drying conditions. By generating airflow, the blower fan significantly enhances the efficiency of the system, contributing to a quicker and more uniform drying process.

Importance of Airflow

Airflow plays a vital role in maintaining the performance of the appliance. A well-functioning blower fan ensures that warm air reaches all areas, preventing moisture accumulation and promoting thorough drying. This not only improves the appliance’s efficiency but also helps to extend the lifespan of the device.

Impact on Energy Efficiency

Efficient airflow provided by the blower fan can lead to reduced energy consumption. When the air circulates effectively, the appliance does not have to work as hard to achieve desired drying results. This optimization translates to lower utility bills and a more environmentally friendly operation.

Function Benefit Circulates warm air Enhances drying efficiency Prevents moisture build-up Promotes appliance longevity Reduces energy usage Lower utility costs Moisture Sensor for Efficient Drying

The moisture sensor plays a crucial role in optimizing the drying process, ensuring that garments are thoroughly dried while conserving energy. By accurately detecting the humidity levels within the chamber, this component helps achieve ideal drying conditions, preventing over-drying and preserving fabric quality.

How the Moisture Sensor Works

This sophisticated device operates through the following mechanisms:

- Humidity Detection: It measures the moisture content in the air, allowing the system to determine when the load is adequately dried.

- Signal Processing: Upon detecting the desired moisture level, the sensor communicates with the control unit, adjusting the drying time accordingly.

- Energy Efficiency: By stopping the cycle when optimal dryness is reached, it reduces unnecessary energy consumption.

Benefits of Using a Moisture Sensor

Incorporating a moisture sensor into the drying system offers several advantages:

- Enhanced fabric care by preventing damage from excessive heat.

- Improved energy savings due to reduced drying times.

- Consistent drying results, ensuring that all items are uniformly treated.

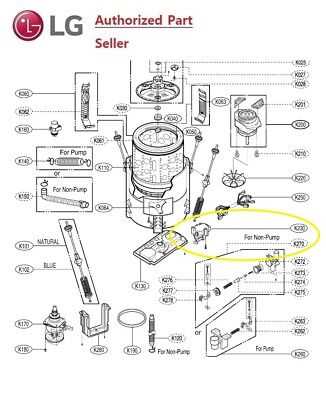

Wiring Harness and Electrical Connections

The wiring assembly plays a crucial role in the functionality of any appliance, ensuring the efficient transmission of electrical signals. Understanding the layout and components of this system is essential for troubleshooting and maintenance. This section delves into the significance of the wiring harness and its connections, highlighting their impact on overall performance.

Components of the Wiring Assembly

The wiring assembly comprises various elements, including connectors, terminals, and wiring that link different functional units. Each component must be correctly aligned to facilitate proper electrical flow, which is vital for the appliance’s operation. Misalignments or damage to these parts can lead to malfunctions, making familiarity with their arrangement essential for any repair work.

Maintenance and Troubleshooting

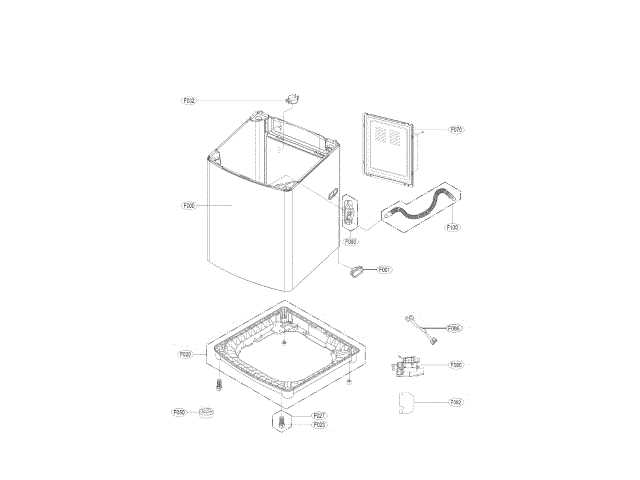

Exhaust Duct and Venting Setup

Proper installation of the ventilation system is crucial for efficient operation and safety. The ductwork serves to direct warm, moist air outside, preventing damage and maintaining optimal performance. This section outlines essential considerations and steps for effective setup.

When planning the exhaust system, keep the following factors in mind:

- Material: Use rigid metal ducts for durability and better airflow.

- Length: Minimize the length and number of bends in the duct to ensure efficient air movement.

- Vent Location: Position the exhaust vent in a suitable location that allows unobstructed airflow.

- Sealing: Ensure all joints are properly sealed to prevent air leaks.

Follow these steps for effective installation:

- Measure the distance from the appliance to the exterior wall.

- Cut the duct to the required length, ensuring it is straight with minimal bends.

- Attach the duct to the exhaust outlet securely.

- Route the duct to the external vent, ensuring it is properly supported and does not sag.

- Connect the duct to the vent and seal all connections with appropriate materials.

Regular maintenance of the venting system is equally important. Periodically check for lint buildup and ensure the exterior vent is not obstructed to maintain optimal airflow.

Replacing Belts and Pulleys in the Dryer

Maintenance of essential components is crucial for the efficient operation of your appliance. Among these components, belts and pulleys play a significant role in facilitating movement and ensuring proper functioning. This section will guide you through the process of replacing these vital parts, enabling your machine to operate smoothly once again.

Identifying Signs of Wear

Before proceeding with the replacement, it is important to recognize the signs indicating that the belts or pulleys may need attention. Common symptoms include unusual noises, a decrease in performance, or visible damage to the components. Addressing these issues promptly can prevent further complications.

Replacement Procedure

To successfully replace the belts and pulleys, follow these steps:

Step Description 1 Unplug the appliance from the power source to ensure safety. 2 Remove the outer casing to access the internal mechanisms. 3 Carefully detach the worn belts and pulleys from their respective mounts. 4 Install the new components, ensuring they are aligned correctly. 5 Reassemble the casing and reconnect the appliance to the power source. Following these steps will help ensure your machine operates efficiently and extends its lifespan. Regular checks and timely replacements are key to maintaining optimal performance.

Common Issues with LG Dryer Parts

Appliances often encounter various challenges that can hinder their efficiency and performance. Understanding the common problems associated with these devices is essential for effective troubleshooting and maintenance. In this section, we will explore typical complications that may arise, affecting the overall functionality and reliability.

Symptoms of Malfunctioning Components

When certain components fail or underperform, users may notice a variety of signs indicating an issue. These can range from unusual noises to inadequate drying capabilities. Identifying these symptoms early on can help prevent further damage and reduce repair costs.

Frequent Component Failures

Some elements are more prone to failure due to their frequent use. Understanding which components typically experience issues can aid in timely interventions and replacements. Below is a table summarizing common problematic components and their symptoms.

Component Common Symptoms Heating Element Insufficient heat or no heat Thermostat Overheating or inadequate drying Drum Roller Unusual noise or drum not turning Belt Drum not spinning or slipping