In the realm of portable energy solutions, a thorough comprehension of vital elements and their configurations is crucial for optimal functionality. This knowledge not only enhances performance but also aids in efficient troubleshooting and maintenance. A clear visualization of these components can significantly simplify the process of identifying potential issues.

Exploring the intricate relationships among various pieces reveals how they interact to create a reliable source of power. Each section plays a pivotal role, and understanding their arrangement contributes to overall efficiency. A detailed examination facilitates deeper insights into operational mechanics and offers a pathway to resolving common challenges.

As you delve into the specifics, you’ll discover that having access to accurate layouts allows users to make informed decisions when it comes to repairs and replacements. This ultimate guide aims to provide clarity and enhance your expertise in managing and maintaining these essential tools.

Understanding Onan 4000 Generator Basics

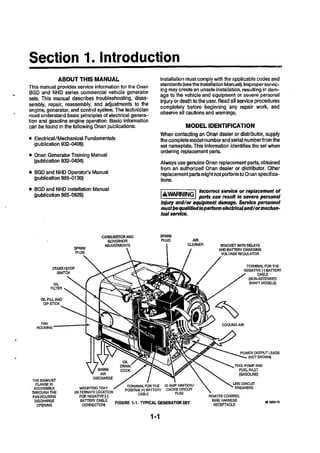

Familiarity with the fundamental components of a portable power source is essential for effective operation and maintenance. Recognizing how various elements function together not only enhances performance but also prolongs lifespan. This section aims to clarify key concepts related to this specific model, ensuring users can maximize efficiency.

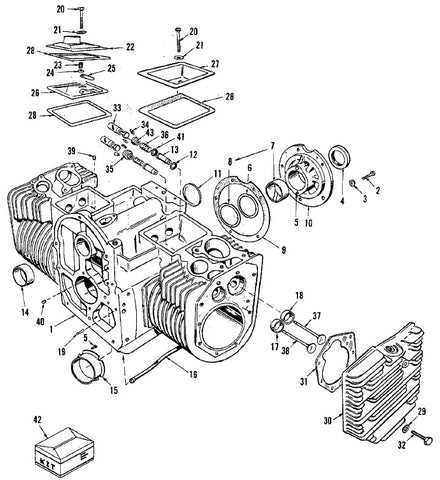

Key Components

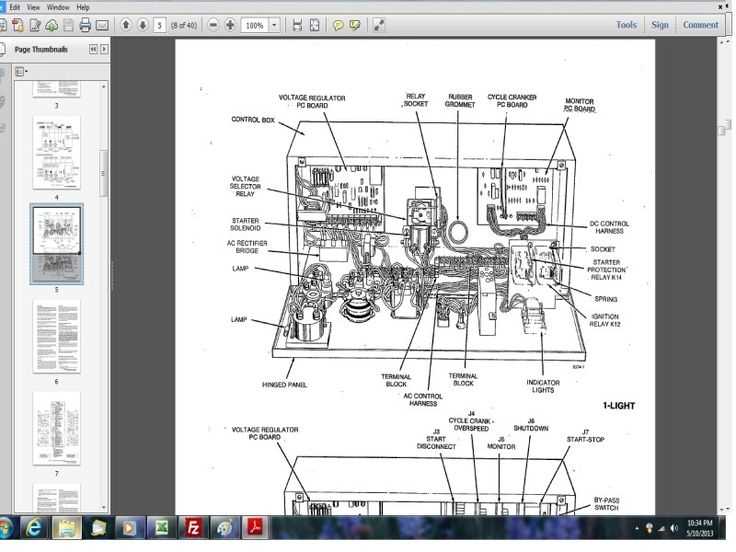

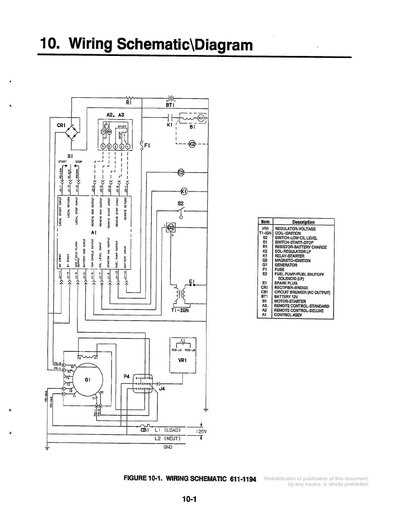

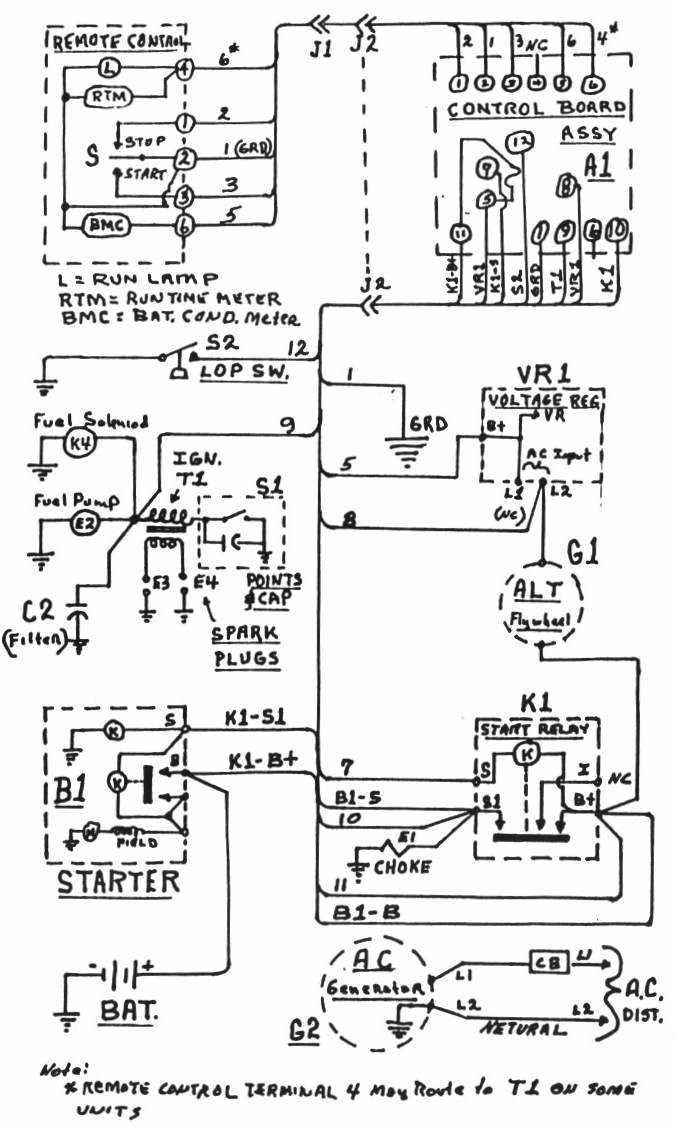

Central to any power unit are the essential components, including the engine, alternator, and control panel. Each part plays a vital role in converting fuel into electrical energy, while the control system manages output levels and safety features. Understanding these elements facilitates troubleshooting and repairs.

Operational Principles

Effective operation relies on the harmonious interaction between the internal mechanisms and user inputs. By grasping how the fuel system, cooling mechanism, and electrical output work in tandem, operators can make informed decisions during usage, ensuring reliable performance in various applications.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations of these elements provide clarity, making it easier for users to identify, locate, and address issues. This ultimately enhances the efficiency and longevity of the equipment.

Accurate illustrations serve as a guide, enabling technicians to follow procedures precisely. They also simplify the ordering process for replacements, ensuring that the correct items are obtained without confusion. This attention to detail not only saves time but also reduces the risk of errors during repairs.

Moreover, such visuals are essential for training purposes, allowing new users to familiarize themselves with the machinery’s layout and functions. Ultimately, having access to comprehensive visual resources fosters a deeper understanding and promotes better care of the equipment.

Common Issues with Onan Generators

Understanding frequent complications with these power units can enhance their longevity and performance. Owners often encounter various malfunctions that can hinder functionality, and recognizing these issues is crucial for effective maintenance.

- Fuel Problems: Contaminated or old fuel can lead to poor performance.

- Electrical Failures: Issues with wiring or connections can cause inconsistent power output.

- Overheating: Inadequate ventilation or low oil levels may result in overheating.

- Starting Difficulties: Problems with the ignition system can prevent startup.

- Noisy Operation: Unusual sounds may indicate internal wear or damage.

Regular inspections and timely repairs can mitigate these challenges, ensuring optimal operation.

How to Read Diagrams Effectively

Understanding visual representations is crucial for successful interpretation and application. Grasping the layout and components can enhance your ability to troubleshoot and assemble various systems. By mastering the symbols and connections, you can streamline your workflow and avoid common pitfalls.

| Tip | Description |

|---|---|

| Familiarize with Symbols | Learn the meanings of common symbols to quickly identify elements. |

| Follow the Flow | Trace the connections to understand how components interact. |

| Use a Key | Refer to the legend or key to clarify any uncertainties. |

| Break It Down | Divide the representation into sections for easier comprehension. |

| Practice | Regularly engage with various illustrations to build familiarity. |

Essential Components of the Onan 4000

This section delves into the crucial elements that contribute to the functionality and efficiency of a compact power source. Understanding these key components is vital for maintaining performance and ensuring longevity. Each element plays a specific role, and together they create a reliable energy solution for various applications.

Engine: At the heart of the system lies the engine, responsible for converting fuel into mechanical energy. Its design focuses on durability and efficiency, making it a cornerstone of reliable operation.

Alternator: This component is essential for transforming mechanical energy into electrical energy. The alternator’s performance directly influences the quality and stability of the output power, making it a critical part of the overall system.

Control Module: The control module serves as the brain of the unit, managing operations and ensuring that all systems function harmoniously. It monitors performance and regulates the power output to meet demand.

Fuel System: The fuel system plays a pivotal role in delivering energy to the engine. Its efficiency can significantly affect performance, highlighting the importance of regular maintenance and checks.

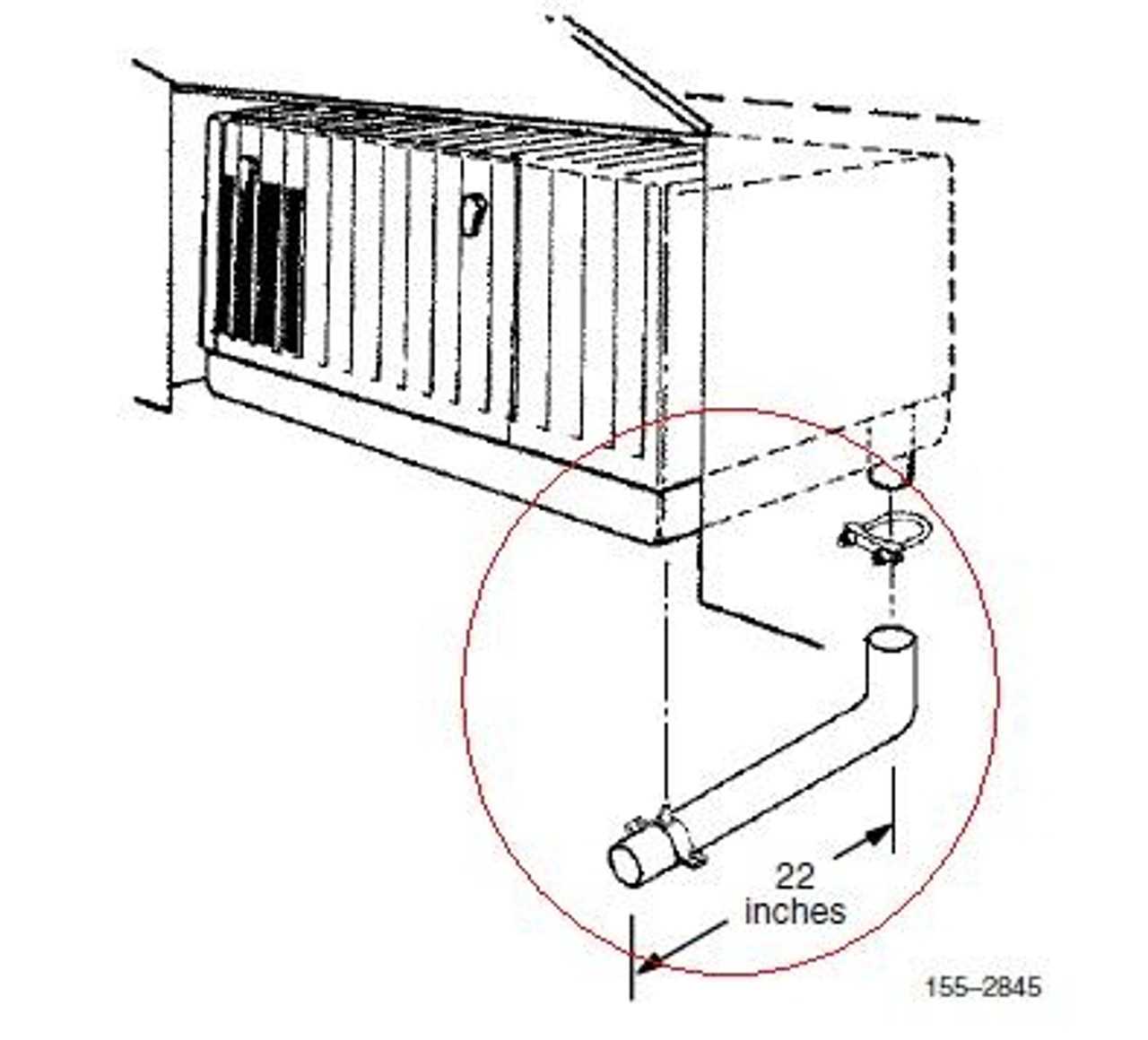

Cooling System: Effective temperature management is essential for optimal operation. The cooling system prevents overheating, ensuring that all components operate within their ideal temperature range.

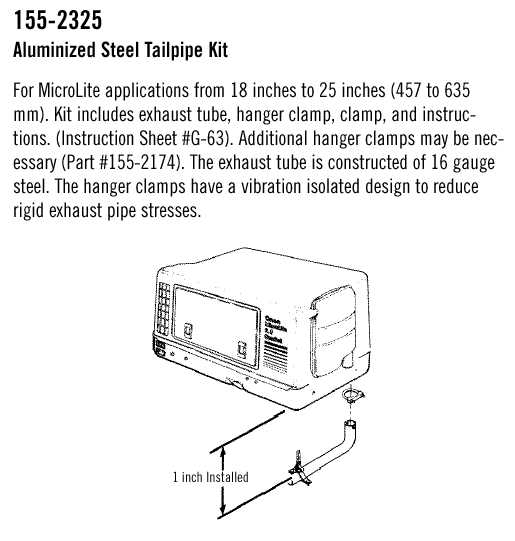

Exhaust System: This component is vital for safely expelling gases produced during operation. A well-designed exhaust system minimizes environmental impact while maintaining efficiency.

In summary, each element within this compact power unit is integral to its overall functionality. Regular maintenance and understanding of these components can lead to enhanced performance and extended service life.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention. By following key maintenance practices, you can significantly extend its operational life and enhance performance.

Regular Inspections: Conduct routine checks to identify wear and tear early. Look for signs of damage, leaks, or unusual sounds, which can indicate potential issues.

Keep It Clean: Maintaining cleanliness is essential. Dirt and debris can affect functionality, so make it a habit to clean surfaces and components regularly.

Check Fluid Levels: Regularly monitor and replenish fluids, including oil and coolant, to ensure optimal operation. This prevents overheating and reduces friction.

Replace Filters: Change air and fuel filters as recommended. Clogged filters can hinder performance and lead to unnecessary strain on the system.

Service Schedule: Follow a consistent service schedule. Adhering to manufacturer recommendations helps maintain reliability and performance.

Implementing these practices can greatly enhance the lifespan of your equipment, ensuring it runs smoothly for years to come.

Where to Find Replacement Parts

Locating components for machinery can be a straightforward process if you know where to look. Numerous resources are available for sourcing high-quality items, whether for maintenance or repairs. Understanding these options is essential for ensuring the longevity and efficiency of your equipment.

Online Retailers: One of the most convenient places to start is with online shops that specialize in equipment components. Many of these platforms offer extensive catalogs, allowing you to search by model or type.

Local Dealers: Visiting a nearby dealer can provide personal assistance and immediate access to necessary items. These establishments often carry a range of products and can help identify specific needs.

Salvage Yards: For those seeking cost-effective solutions, salvage yards can be a treasure trove. You might find functional components at a fraction of the new price, perfect for budget-conscious individuals.

Manufacturer Websites: Always check the official website of the machinery’s manufacturer. They often provide direct links to authentic components, ensuring compatibility and quality.

Forums and Community Groups: Engaging with online communities dedicated to equipment maintenance can yield valuable insights. Members often share recommendations for trusted suppliers and may even offer parts for sale.

By exploring these avenues, you can effectively source the items needed to keep your machinery operating at its best.

Differences Between Models Explained

Understanding the variations among different units is essential for effective maintenance and repair. Each model offers unique features and specifications that cater to various needs and applications. Here, we explore the key distinctions to help users make informed choices.

- Power Output:

- Some units provide higher wattage, suitable for larger appliances.

- Others focus on efficiency for smaller devices.

- Fuel Type:

- While some operate on gasoline, others may use diesel or propane.

- Each fuel type affects performance and operational costs.

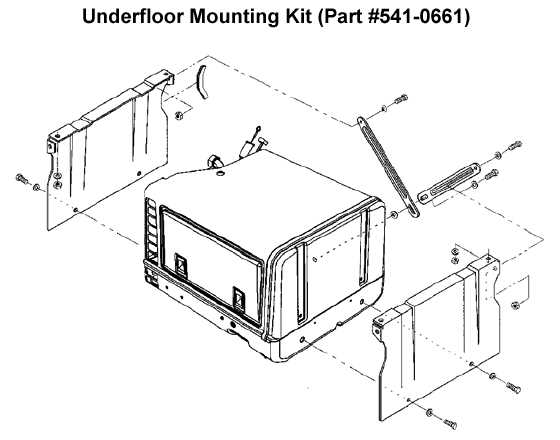

- Size and Portability:

- Compact models are designed for easy transport.

- Larger models often provide more power but are less mobile.

- Control Features:

- Advanced models may include digital interfaces for monitoring.

- Basic units typically feature manual controls.

- Noise Levels:

- Some variations are engineered for quieter operation, ideal for residential use.

- Others may produce higher noise levels, suited for outdoor activities.

Recognizing these differences can enhance the user experience and ensure optimal performance for specific applications.

Step-by-Step Repair Guide

This guide provides a systematic approach to troubleshooting and restoring functionality to your energy-producing unit. By following these outlined steps, you can efficiently identify and resolve common issues, ensuring optimal performance and longevity.

Identifying the Problem

Begin by assessing the symptoms exhibited by the device. Pay attention to unusual noises, irregular power output, or failure to start. Document each observation, as this will aid in diagnosing the underlying issue.

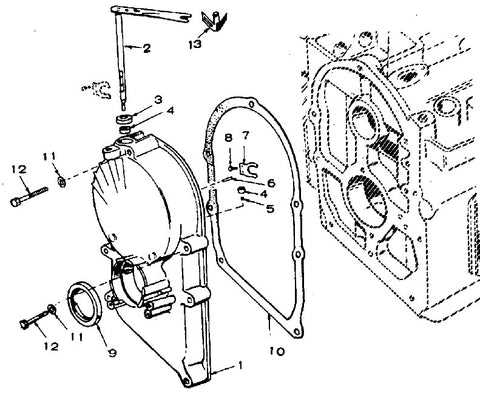

Disassembling the Unit

Once you have pinpointed potential issues, carefully dismantle the equipment. Use appropriate tools and take note of the arrangement of components. Labeling parts can prevent confusion during reassembly, ensuring that everything is returned to its original state.

Safety Precautions When Servicing

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Proper precautions should be taken to create a secure working environment. Familiarity with safety protocols can significantly reduce the risk of harm while performing necessary tasks.

Before beginning any servicing work, consider the following guidelines:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and safety shoes.

- Disconnect all power sources to avoid electric shock or accidental start-up.

- Work in a well-ventilated area to minimize exposure to harmful fumes.

Additionally, adhere to these essential practices:

- Read the operation manual thoroughly before starting any repairs.

- Keep your workspace organized and free of clutter to prevent tripping hazards.

- Use the correct tools for the job to avoid damaging components or causing injury.

Finally, always ensure that you have a clear understanding of the equipment’s layout and components. When in doubt, consult a professional to guarantee safe handling and effective maintenance.

Upgrading Your Generator Performance

Enhancing the efficiency and output of your machine can lead to significant improvements in overall functionality. By focusing on key components and making strategic upgrades, users can experience better reliability and longevity.

- Regular maintenance is essential for optimal operation.

- Consider upgrading to high-quality fuel systems for improved combustion.

- Installing a more efficient exhaust system can enhance airflow and reduce noise.

- Switching to advanced control panels allows for better monitoring and management.

- Utilizing upgraded battery technology can ensure consistent power supply.

By prioritizing these enhancements, you can delve into the ultimate performance potential of your equipment, ensuring it meets your needs effectively.