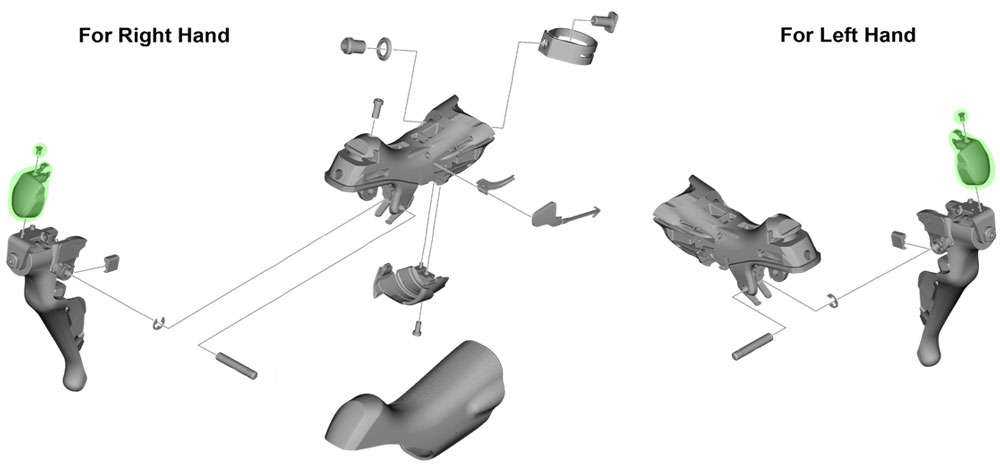

In the world of cycling, smooth and precise transitions between gears are essential for optimal performance. The complex system responsible for changing gears consists of multiple interconnected elements that work together to provide seamless operation. Each part plays a crucial role in ensuring the rider can adjust to different terrains and speeds effortlessly.

Key mechanical elements within the gear system are designed to function harmoniously. These components, while intricate, are engineered to enhance durability and reliability. Understanding their functions can help in maintenance and adjustments, ensuring that the system continues to perform at its best over time.

Whether for routine upkeep or specific repairs, familiarizing oneself with the mechanical layout of these elements provides invaluable insights. With this knowledge, cyclists can address potential issues, ensuring longevity and efficiency of their riding experience.

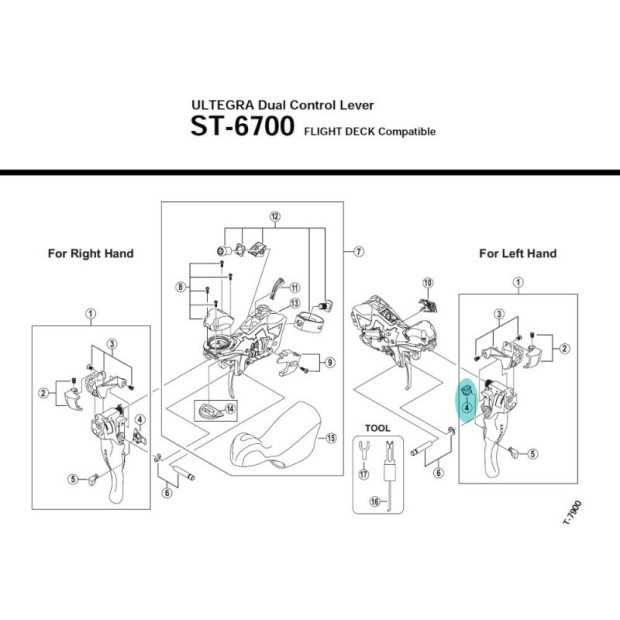

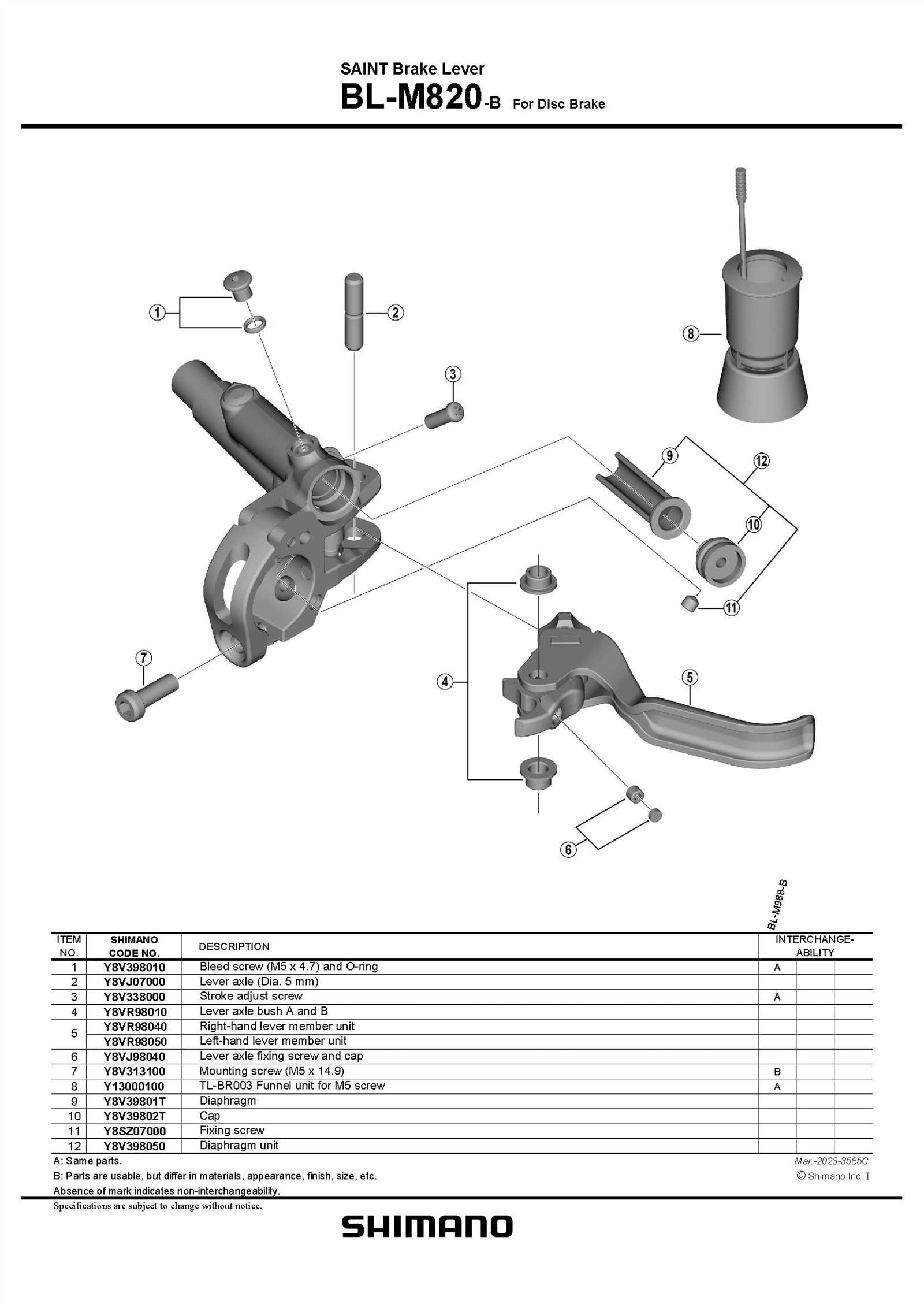

Shimano Shifter Components Overview

The gear control system consists of various interconnected elements designed to provide smooth and reliable gear changes. Each component plays a specific role in ensuring accurate performance, allowing the rider to maintain momentum and control in varying conditions.

| Component | Function | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lever | Used to change the gears by pulling or pushing, allowing for quick shifts. | ||||||||||||||||||||||||||||||

| Cable | Transmits force from the control mechanism to adjust gear positions. | ||||||||||||||||||||||||||||||

| Housing | Protects the cable and ensures smooth movement during shifts. | ||||||||||||||||||||||||||||||

| Index Mechanism | Ensures precise gear alignment and

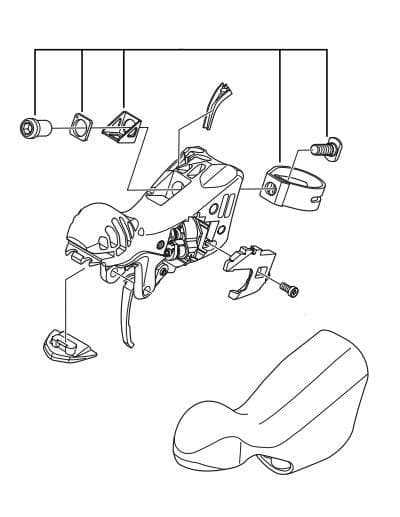

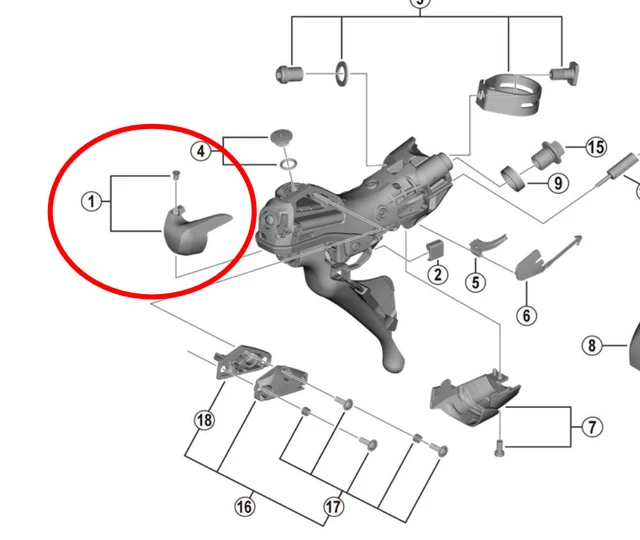

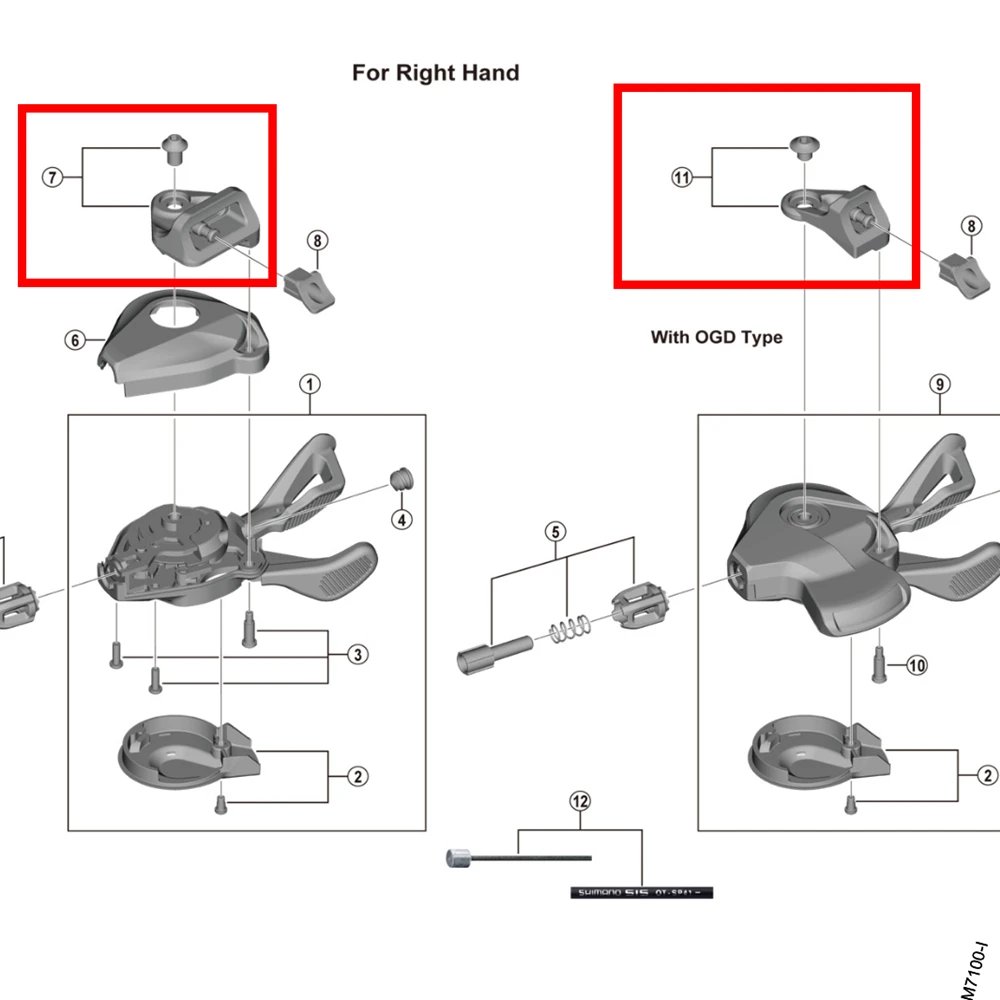

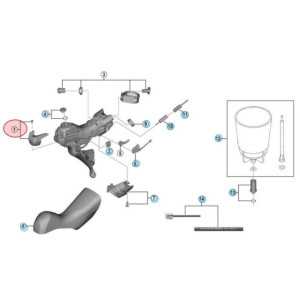

Internal Mechanism BreakdownThe internal mechanism consists of several interconnected components that work together to provide smooth functionality. These elements allow for precise control, ensuring seamless performance. Understanding how these parts interact is essential for maintenance and troubleshooting.

Each part plays a crucial role in the overall performance, and their proper alignment is essential for long-lasting durability. Lever Design and Functionality

The design of the lever plays a crucial role in ensuring smooth operation and control. By focusing on ergonomics and precision, the mechanism allows for easy handling, delivering consistent performance in various conditions. The form and structure are tailored to provide a comfortable grip and effective use with minimal effort. Key Components

Various elements of the lever contribute to its overall functionality. Each part works in harmony, ensuring that the user can operate the mechanism efficiently and without strain. Below is a breakdown of the main components involved:

The diverse array of materials ensures that each component can withstand the demands of various riding conditions while maintaining reliability and functionality over time. Trigger Mechanism Efficiency

The performance of a control system relies heavily on the effectiveness of its activation components. These elements play a crucial role in how smoothly and precisely the adjustments are made, directly impacting the overall functionality of the device. Understanding the mechanisms that enhance operational efficiency is essential for achieving optimal results. Design and Materials significantly influence the responsiveness and durability of these components. High-quality materials ensure longevity and consistent performance under varying conditions. Additionally, innovative designs can reduce friction, allowing for quicker and more accurate responses. Adjustment Precision is another vital aspect that affects overall efficiency. Fine-tuning mechanisms that allow for micro-adjustments enhance user experience, making it easier to achieve desired outcomes. This precision not only improves functionality but also contributes to greater satisfaction in use. Ultimately, enhancing the efficiency of these activation elements leads to a more enjoyable and effective interaction with the system, providing users with the reliability they expect in critical situations. Gear Indicator AssemblyThe gear indicator assembly plays a crucial role in the functionality of a transmission system. This component allows users to easily determine the current gear selection, enhancing the overall riding experience by providing important feedback. A well-designed indicator contributes to smoother shifts and better control, making it an essential part of any transmission setup.

Shifter Grip DesignThe design of the grip plays a crucial role in enhancing user experience and performance. A well-thought-out grip ensures comfort and control, allowing the user to navigate effortlessly through various conditions. The choice of materials and shapes can significantly influence the overall handling and responsiveness of the mechanism. Ergonomics is a key factor in grip design, as it directly impacts how easily a user can engage with the device. By considering the natural positioning of the hand, designers can create grips that minimize strain during prolonged use. This leads to improved efficiency and satisfaction. Texturing also contributes to the effectiveness of the grip. The right surface finish can enhance friction, preventing slippage and ensuring a secure hold even in challenging environments. This aspect is essential for maintaining precision and confidence in operation. Common Wear and Tear PointsOver time, certain components of a transmission system may experience significant deterioration due to frequent use and environmental factors. Identifying these areas is crucial for maintaining optimal performance and extending the lifespan of the device. One of the primary locations for wear is the mechanism that engages and disengages the gears. This part often faces high stress, leading to gradual wear that can affect responsiveness. Regular inspections can help detect any early signs of wear, allowing for timely adjustments or replacements. Another common area of concern involves the cable housing. Exposure to moisture and dirt can lead to corrosion or fraying, which impedes smooth operation. Keeping this area clean and well-lubricated is essential for ensuring proper functionality. Finally, the interface points where components connect can also suffer from wear. These contact areas may develop slippage or misalignment, impacting the overall efficiency of gear shifting. Regular maintenance and adjustments can help mitigate these issues, ensuring a seamless experience. Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your gear-changing mechanism requires regular attention and care. By implementing simple maintenance practices, you can significantly extend the lifespan of your equipment, ensuring a smoother and more reliable performance. Regular Cleaning: Keep the components clean by removing dirt and debris after every ride. Use a gentle brush and a suitable cleaning solution to prevent buildup that could hinder functionality. Lubrication: Apply an appropriate lubricant to moving parts to reduce friction and wear. Make sure to wipe off excess lubricant to avoid attracting more dirt. Inspecting for Wear: Periodically check for any signs of wear or damage. Look for frayed cables or worn-out mechanisms, and replace them promptly to avoid further complications. Proper Adjustment: Ensure that all components are correctly aligned and adjusted. Regular tuning can help maintain optimal performance and prevent unnecessary strain on the system. Store Properly: When not in use, store your equipment in a dry place to protect it from moisture and temperature extremes, which can accelerate deterioration. By following these essential tips, you can enhance the performance and longevity of your gear-changing system, allowing for a more enjoyable riding experience. |