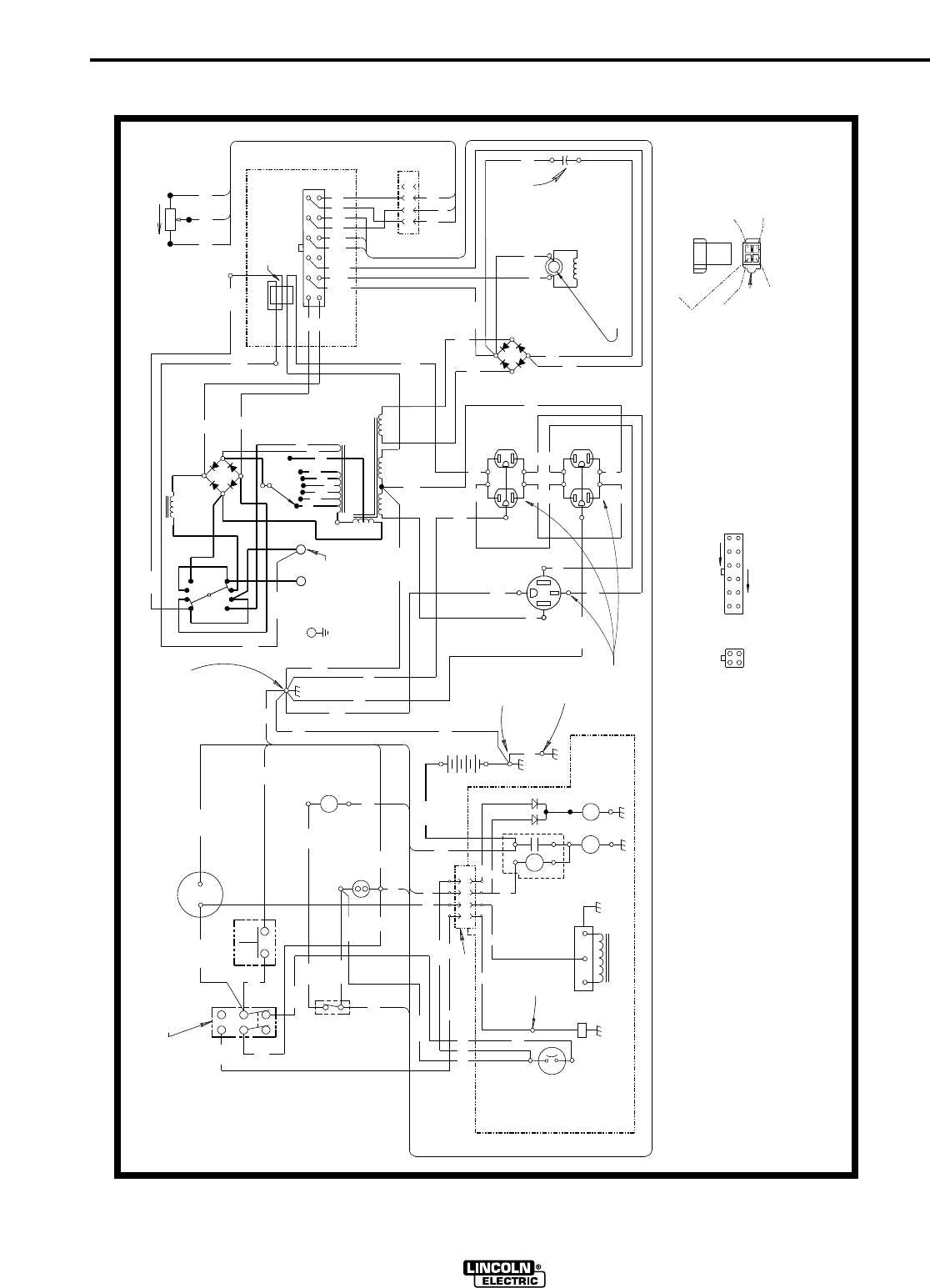

In the realm of machinery and equipment maintenance, grasping the intricacies of assembly layouts is crucial for optimal performance and longevity. Knowledge of how various elements interact and function together not only enhances repair efficiency but also aids in troubleshooting potential issues. This exploration sheds light on the significance of familiarizing oneself with the comprehensive arrangement of components in welding devices.

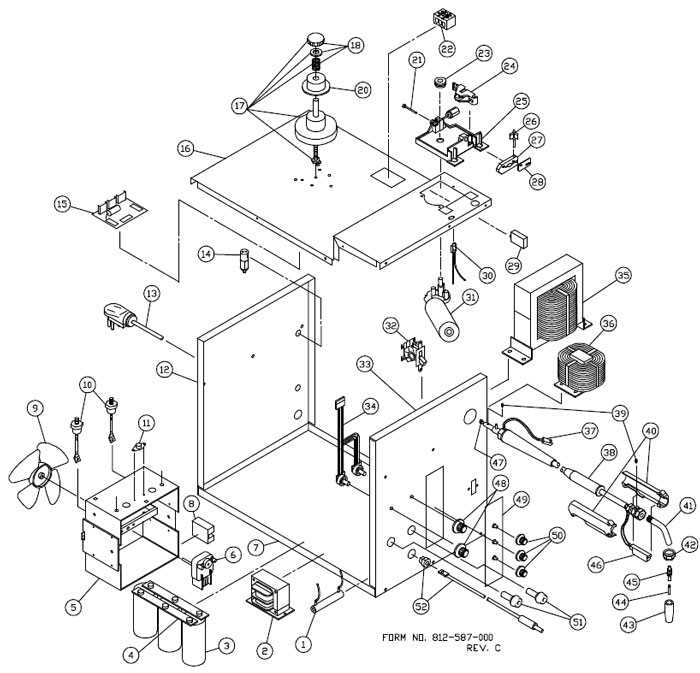

Detailed visual representations serve as invaluable tools for technicians and enthusiasts alike. They provide clarity, ensuring that every piece is correctly identified and understood. By studying these layouts, one can develop a more profound appreciation for the engineering behind these machines, leading to improved handling and maintenance practices.

Moreover, comprehending the configuration of components can significantly reduce downtime during repairs. A systematic approach to identifying and addressing specific parts allows for quicker resolutions and minimizes disruption in workflows. In the following sections, we will delve deeper into these essential layouts, uncovering their roles and importance in the world of welding technology.

Understanding Lincoln Ranger 225 Components

This section explores the intricate elements that comprise a portable welding machine, highlighting their functions and significance. By familiarizing oneself with these components, users can enhance their operational efficiency and troubleshoot more effectively.

Key Elements

- Power Source: Converts electrical energy into usable power.

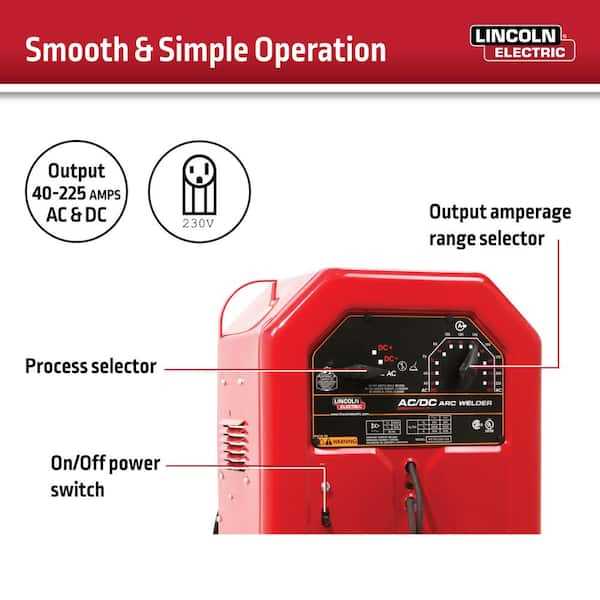

- Control Panel: Interface for adjusting settings and monitoring performance.

- Cooling System: Maintains optimal temperature during operation.

- Welding Gun: The primary tool for delivering the welding arc.

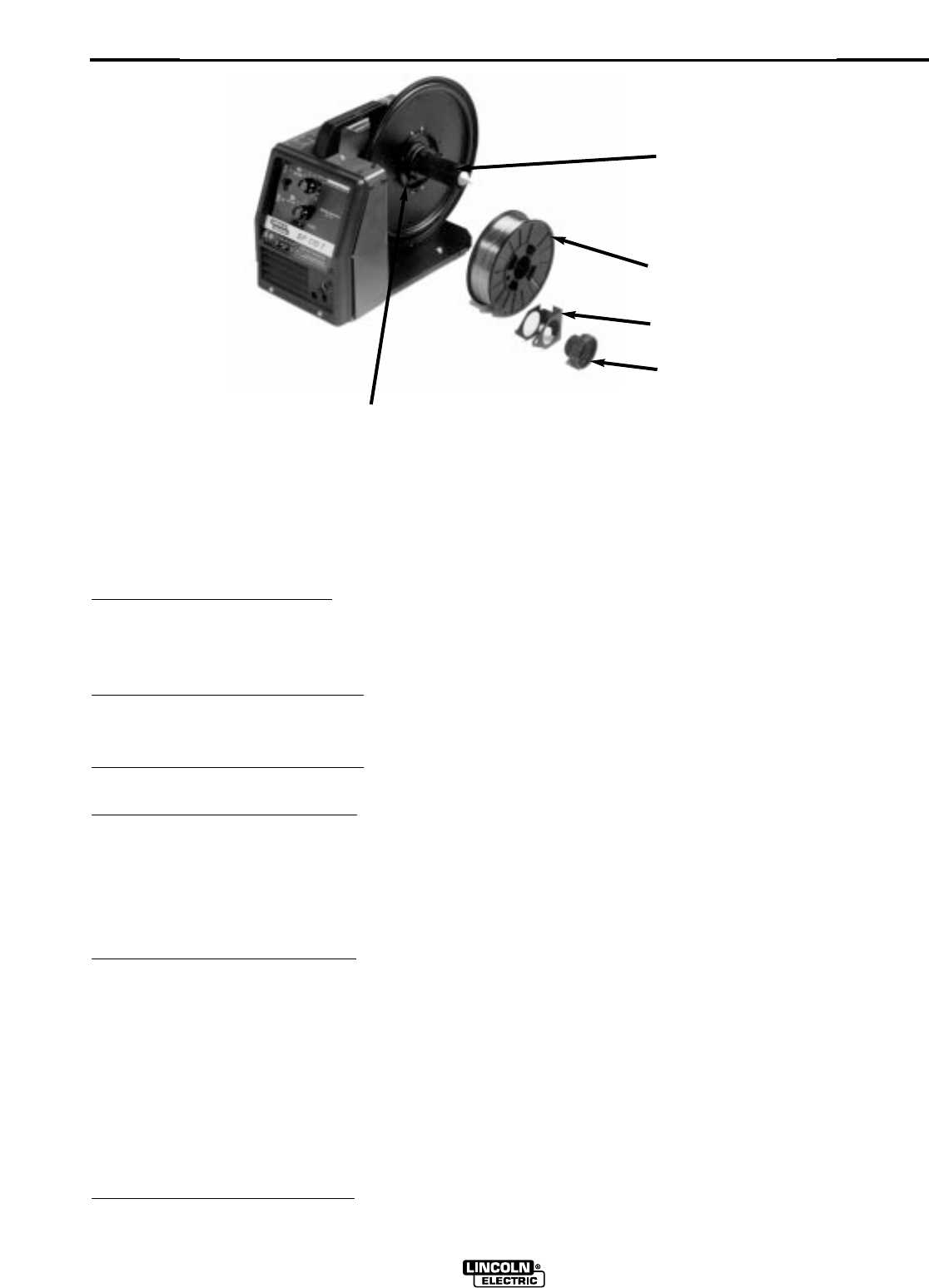

- Wire Feeder: Supplies welding wire consistently for uninterrupted use.

Maintenance Tips

- Regularly inspect connections for wear and tear.

- Clean the cooling system to prevent overheating.

- Test the control panel functionality before each use.

- Replace worn-out components promptly to maintain performance.

Key Parts of Lincoln Ranger 225

Understanding the essential components of a portable welding machine is crucial for efficient operation and maintenance. Each element plays a vital role in ensuring the device performs optimally, contributing to its reliability and effectiveness in various tasks. Below is a breakdown of the primary components that make up this robust equipment.

| Component | Description |

|---|---|

| Power Source | This element provides the necessary energy to the welder, converting input electricity into usable output for welding operations. |

| Control Panel | The interface that allows users to adjust settings, monitor performance, and ensure safe operation during welding tasks. |

| Cooling System | A mechanism that prevents overheating by dissipating heat generated during operation, ensuring longevity and efficiency. |

| Welding Torch | The tool used to direct the welding arc and manage the welding process, crucial for achieving quality welds. |

| Chassis | The sturdy frame that houses all components, providing structural integrity and portability for easy transport. |

How to Read Parts Diagrams

Understanding visual schematics is crucial for effective maintenance and repair tasks. These illustrations provide an organized representation of components, making it easier to identify and locate each piece within a complex assembly.

Key Elements to Focus On

- Labels: Each element is often numbered or labeled, which corresponds to a list detailing specifications.

- Lines and Connectors: Observe how elements are connected; this indicates their functional relationships.

- Legend: A legend may explain symbols used, ensuring clarity in interpretation.

Steps for Effective Reading

- Identify the main assembly in the illustration.

- Follow the numbered components to their descriptions.

- Refer to the legend for any unfamiliar symbols.

- Use the schematic to plan your approach for any repairs or replacements.

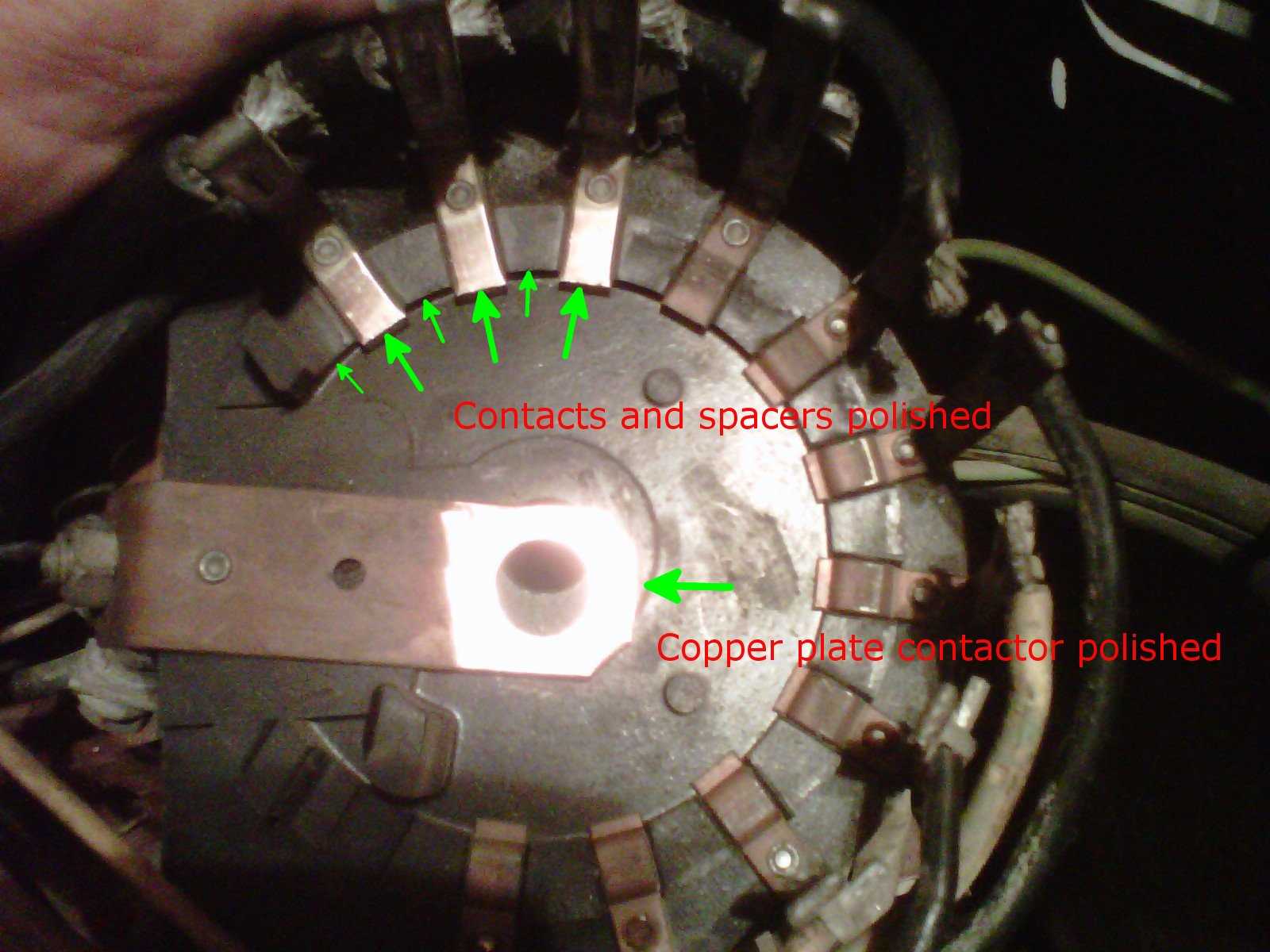

Common Issues with Ranger 225 Parts

When working with equipment, certain components may frequently present challenges that can affect performance and efficiency. Understanding these issues is crucial for maintenance and repair, ensuring longevity and optimal functionality of the machinery.

Frequent Malfunctions

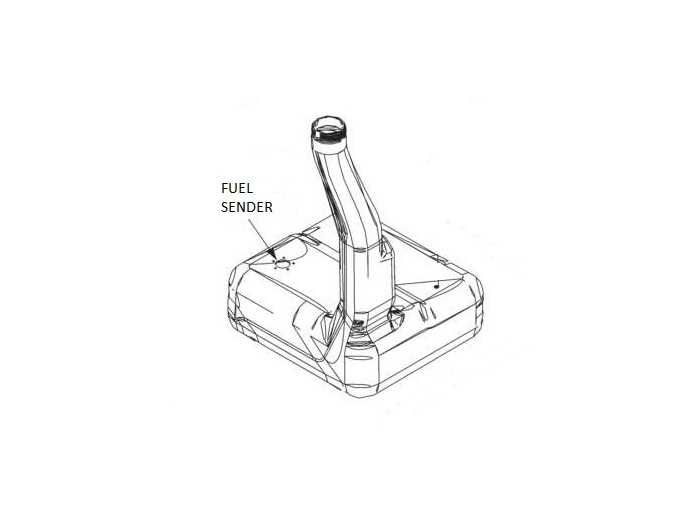

Several elements are prone to wear and tear due to continuous use. Common malfunctions often include failures in electrical systems, leaks in fluid lines, and mechanical breakdowns in movable parts. Recognizing these issues early can save both time and resources.

Maintenance Tips

Regular upkeep is essential in preventing potential problems. It’s advisable to conduct routine inspections and replace worn components proactively. Additionally, proper lubrication and cleaning can enhance the lifespan of critical elements.

| Component | Common Issue | Solution |

|---|---|---|

| Electrical System | Intermittent failure | Inspect connections; replace faulty wiring |

| Fluid Lines | Leakage | Replace seals; check for cracks |

| Movable Parts | Sticking or jamming | Clean and lubricate regularly |

Essential Tools for Maintenance

Regular upkeep of equipment requires a well-equipped toolkit to ensure optimal performance and longevity. Having the right instruments not only simplifies tasks but also enhances efficiency and safety during maintenance activities.

Wrenches are fundamental for tightening and loosening fasteners, while screwdrivers are essential for handling various types of screws. An adjustable wrench offers versatility for different sizes, making it indispensable.

Additionally, a quality multimeter is crucial for electrical diagnostics, enabling precise measurements of voltage and current. Lubricants and cleaning solutions should not be overlooked, as they maintain the moving parts and prevent wear and tear.

Finally, having a good toolbox or storage solution ensures that all these tools are organized and easily accessible, promoting a smooth maintenance process.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a challenging task, yet it is crucial for maintaining optimal performance. Understanding where to search for these items can save you both time and money. Various sources are available, each offering distinct advantages in terms of availability, pricing, and customer service.

Online Retailers

Numerous online platforms specialize in offering a wide range of components. Websites such as dedicated industrial suppliers or general marketplaces provide detailed catalogs that make it easy to locate the required items. Before purchasing, ensure you check customer reviews and ratings to gauge reliability and service quality.

Local Supply Stores

Visiting nearby shops can also yield favorable results. Local distributors often have knowledgeable staff who can assist you in finding exactly what you need. Additionally, they may carry complementary items that you might not have considered. Establishing a relationship with these retailers can lead to better deals and insider knowledge about upcoming sales.

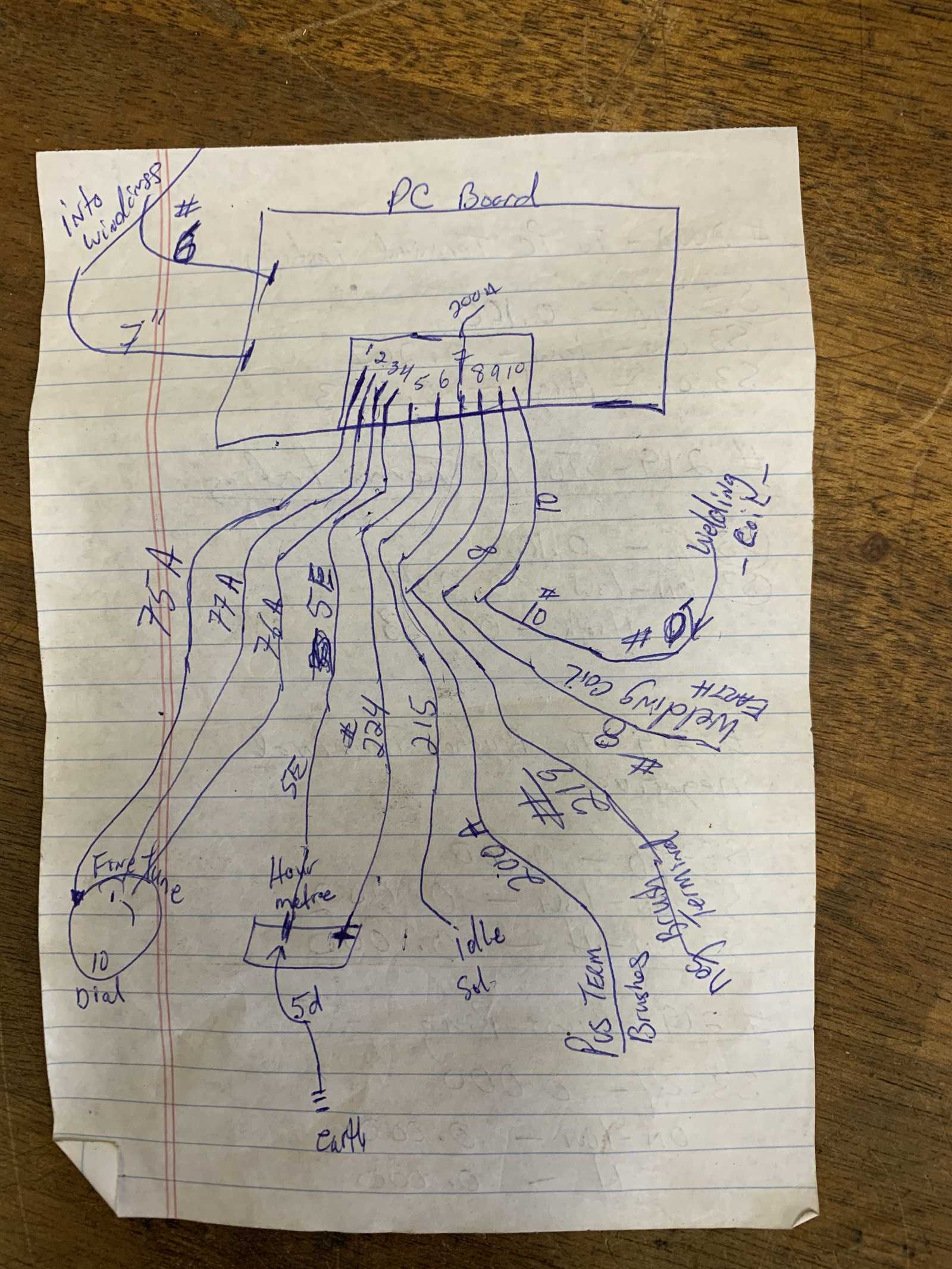

Identifying Electrical Components Easily

Recognizing electrical components can be a straightforward task with the right approach. A solid understanding of basic elements and their functions is essential for anyone working with electronic devices. By familiarizing oneself with common components, you can enhance troubleshooting skills and ensure efficient repairs.

To aid in the identification process, here is a brief overview of typical electrical components and their characteristics:

| Component | Function | Visual Characteristics |

|---|---|---|

| Resistor | Limits current flow | Cylindrical shape, colored bands |

| Capacitor | Stores electrical energy | Small cylinder or rectangular box |

| Diode | Allows current to flow in one direction | Small, cylindrical or rectangular; often with a stripe |

| Transistor | Acts as a switch or amplifier | Three leads, usually in a plastic or metal case |

| Inductor | Stores energy in a magnetic field | Coiled wire, often in a cylindrical shape |

By mastering these fundamentals, you can quickly pinpoint the components in any electrical setup, streamlining your maintenance and repair tasks effectively.

Benefits of Regular Parts Inspection

Routine examination of machinery components plays a crucial role in maintaining operational efficiency and longevity. By ensuring that each element functions correctly, potential issues can be identified and addressed before they escalate, saving both time and resources.

Enhanced Performance

Consistent evaluation of components leads to optimal performance. When parts are in good condition, equipment operates more smoothly, resulting in increased productivity. Regular checks allow for fine-tuning, ensuring that machinery runs at peak efficiency.

Cost Savings

Preventive inspections can significantly reduce repair costs. Early detection of wear and tear prevents minor issues from becoming major failures, which can be expensive and time-consuming to rectify. Additionally, well-maintained equipment often consumes less energy, contributing to lower operational costs.

| Benefit | Description |

|---|---|

| Improved Safety | Regular checks minimize the risk of accidents caused by malfunctioning equipment. |

| Extended Lifespan | Timely maintenance enhances the durability of machinery, delaying the need for replacements. |

| Increased Reliability | Routine assessments foster confidence in equipment performance, reducing unexpected downtimes. |

Upgrading Your Lincoln Ranger 225

Enhancing your welding machine can significantly improve its performance and longevity. By focusing on specific components, you can achieve better efficiency and results tailored to your needs.

First, consider investing in a more efficient cooling system. An upgraded cooling mechanism can prevent overheating during prolonged use, ensuring consistent operation.

Next, explore higher quality electrodes and wires. Using superior materials can enhance the quality of your welds and reduce the likelihood of defects.

Additionally, upgrading the control panel can offer more precise settings and improve user experience. Modern interfaces provide better feedback, allowing for more accurate adjustments.

Finally, ensure that all internal components are in top condition. Regular maintenance and upgrades to the electrical systems can lead to improved reliability and performance over time.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance is crucial to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks and promote a more efficient working atmosphere.

- Always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and steel-toed boots.

- Ensure that the workspace is well-ventilated to avoid inhaling harmful fumes.

- Keep a first aid kit readily available in case of minor injuries.

- Disconnect power sources before starting any repair to prevent electrical shocks.

Being aware of your surroundings is equally important. Always maintain a tidy workspace to minimize tripping hazards and keep tools organized.

- Inspect tools and equipment for any defects before use.

- Follow manufacturer instructions and guidelines carefully.

- Do not work alone; have a colleague nearby in case assistance is needed.

- Take regular breaks to prevent fatigue, which can lead to mistakes.

By prioritizing safety, you not only protect yourself but also ensure that the repair process runs smoothly and efficiently.

Maintaining Optimal Performance Levels

Ensuring peak functionality in equipment is crucial for efficiency and longevity. Regular upkeep and monitoring are essential to prevent issues and enhance overall effectiveness. This section outlines key practices to achieve and sustain high operational standards.

Routine Inspection

- Conduct regular visual checks for wear and tear.

- Listen for unusual sounds during operation.

- Inspect connections and components for stability.

Proper Maintenance

- Clean equipment thoroughly to prevent buildup.

- Lubricate moving parts as recommended.

- Replace worn or damaged components promptly.

By implementing these strategies, users can delve deeper into maintaining their machinery and achieving the ultimate performance results.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their maintenance, providing clarity for users seeking to enhance their knowledge and ensure optimal performance. Understanding these elements is essential for effective troubleshooting and upkeep.

What should I do if I can’t find a specific component?

If a particular element is elusive, consider checking various suppliers or online platforms that specialize in machinery and tools. Additionally, consulting user manuals or technical support can often yield helpful guidance and alternative options.

How can I ensure the quality of the components I purchase?

To guarantee high standards when acquiring elements, it’s advisable to choose reputable vendors known for their reliability. Look for reviews and ratings from other users, and opt for brands that provide warranties or guarantees for their products.

Expert Tips for DIY Repairs

Embarking on repair projects can be both rewarding and challenging. With the right knowledge and tools, you can tackle various tasks around your workspace efficiently. Understanding the intricacies of your equipment and utilizing practical techniques will enhance your confidence and skill set.

1. Gather Essential Tools: Before starting any repair, ensure you have all the necessary instruments at hand. A well-equipped toolbox saves time and reduces frustration during the process.

2. Study the Manual: Familiarize yourself with the equipment’s manual. This document contains invaluable information regarding assembly, disassembly, and maintenance procedures that can streamline your repairs.

3. Take Notes and Photos: Document your disassembly process by taking notes and photographs. This practice helps you remember the order of components and ensures a smoother reassembly.

4. Prioritize Safety: Always prioritize your safety by wearing appropriate protective gear. Gloves, goggles, and masks can prevent injuries and ensure a safe working environment.

5. Seek Online Resources: Utilize online forums and video tutorials for additional guidance. Many experienced individuals share their insights, which can provide useful tips for common issues.

6. Test Components: After completing your repairs, test all components thoroughly. This step verifies that everything functions as intended and helps identify any remaining issues.

By following these expert tips, you can enhance your repair skills and tackle projects with greater ease and confidence.