The functionality of a marine engine relies on the seamless interaction of various elements. Recognizing these components and their arrangement is crucial for effective maintenance and troubleshooting. By exploring the intricate layout of an engine’s structure, users can gain valuable insights into its operation and identify potential issues that may arise during use.

Each section of the assembly serves a distinct purpose, contributing to the overall performance and efficiency of the vessel. Knowledge of these individual parts enables operators to make informed decisions regarding repairs and replacements. Whether one is a seasoned technician or a novice enthusiast, familiarizing oneself with the configuration enhances understanding and encourages proactive management of the engine.

In the following sections, we will delve deeper into the various components, providing a comprehensive overview of their functions and interrelations. This exploration will equip readers with the necessary information to maintain their engines and ensure their longevity in the water.

Understanding Mercury Optimax Engine Parts

This section delves into the components of a specific marine propulsion system, highlighting their roles and interactions. A thorough comprehension of these elements is crucial for effective maintenance and performance enhancement.

Key components typically found in this type of motor include:

- Powerhead: The heart of the engine, where combustion occurs.

- Fuel System: Responsible for delivering the right amount of fuel to the combustion chamber.

- Cooling System: Ensures optimal operating temperatures to prevent overheating.

- Exhaust System: Directs exhaust gases away from the engine, enhancing efficiency.

- Drive Unit: Converts the engine’s power into propulsion for the vessel.

Each of these components plays a vital role in ensuring smooth operation. Regular inspections and maintenance are recommended to keep these systems functioning optimally.

Understanding how these elements work together not only aids in troubleshooting but also enhances the overall performance and longevity of the propulsion system. Being aware of common issues associated with these components can help in proactive maintenance efforts.

Overview of Optimax Technology

This section delves into an advanced propulsion system that has revolutionized the marine industry. Designed to enhance efficiency and performance, this innovative mechanism integrates cutting-edge engineering principles to deliver a superior boating experience.

Key features of this technology include:

- Enhanced fuel efficiency through precision fuel management

- Reduction in emissions, contributing to environmental sustainability

- Improved acceleration and overall responsiveness

- Advanced diagnostics systems for real-time performance monitoring

The implementation of this technology has enabled vessel owners to enjoy longer trips with less environmental impact. Its ability to provide optimal power while minimizing fuel consumption showcases the strides made in modern marine engineering.

In summary, the benefits of this propulsion system highlight the importance of innovation in creating reliable and efficient marine solutions.

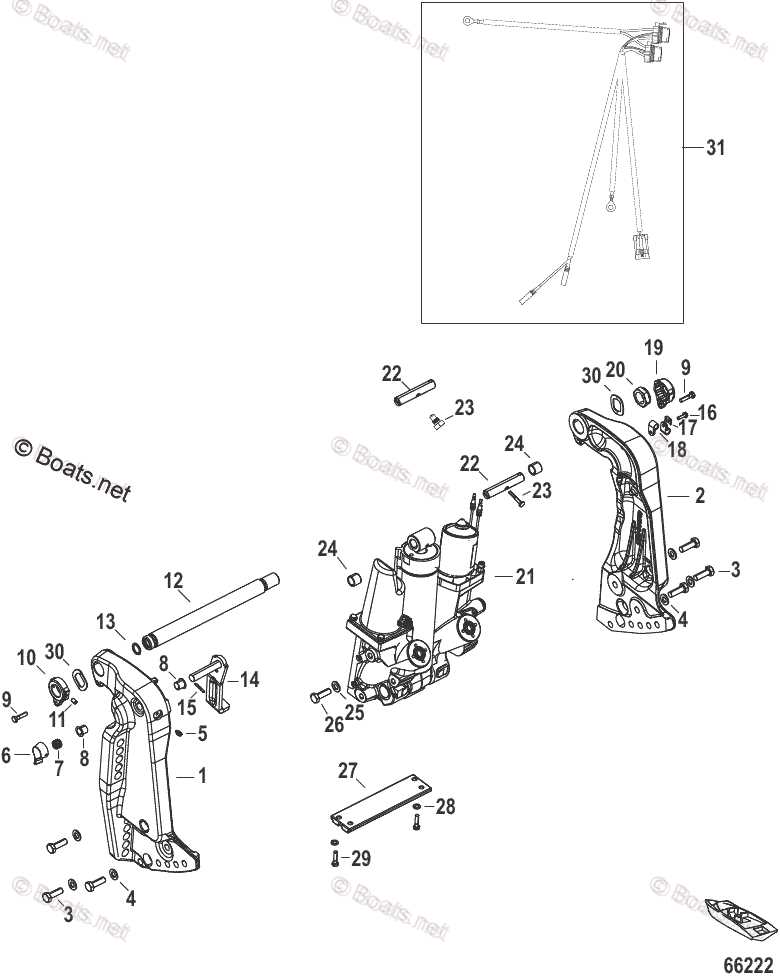

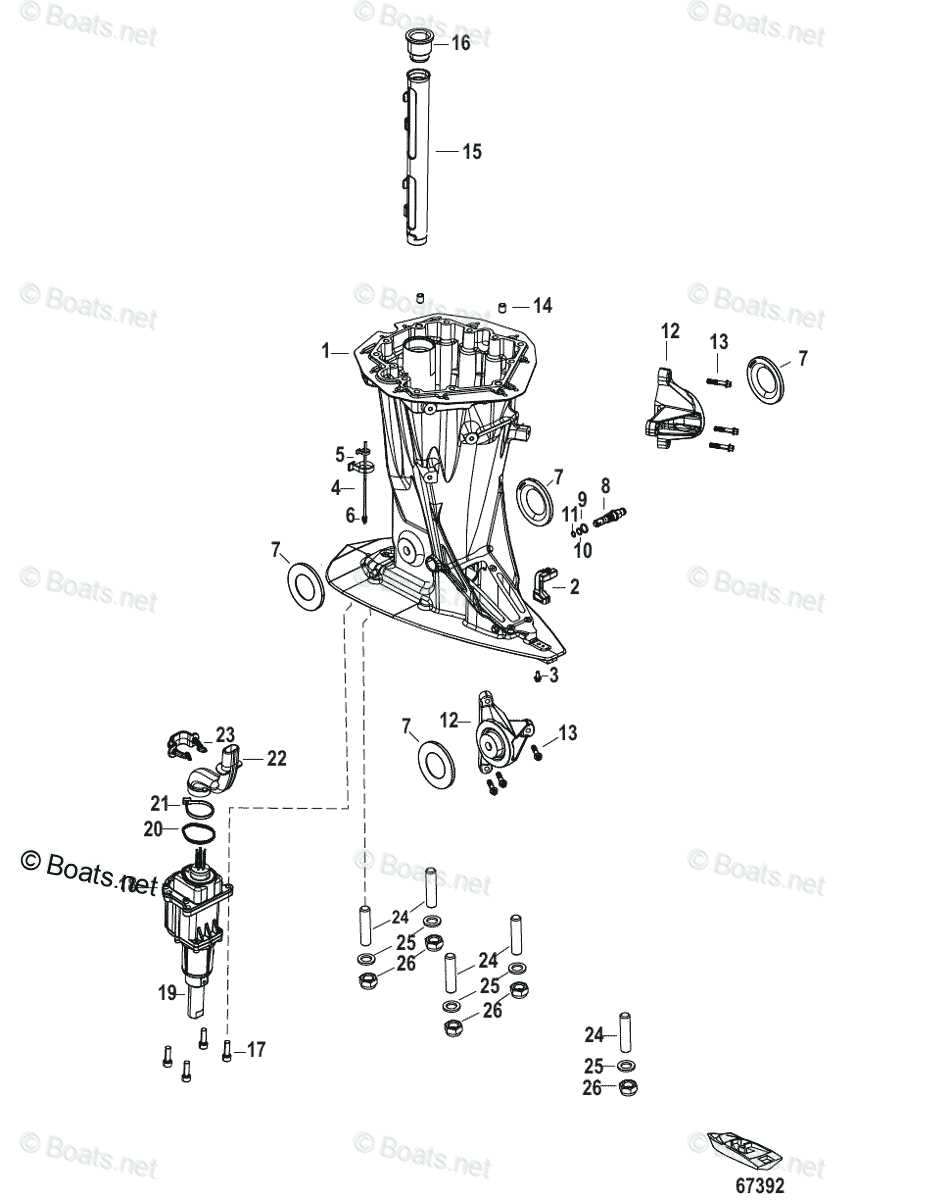

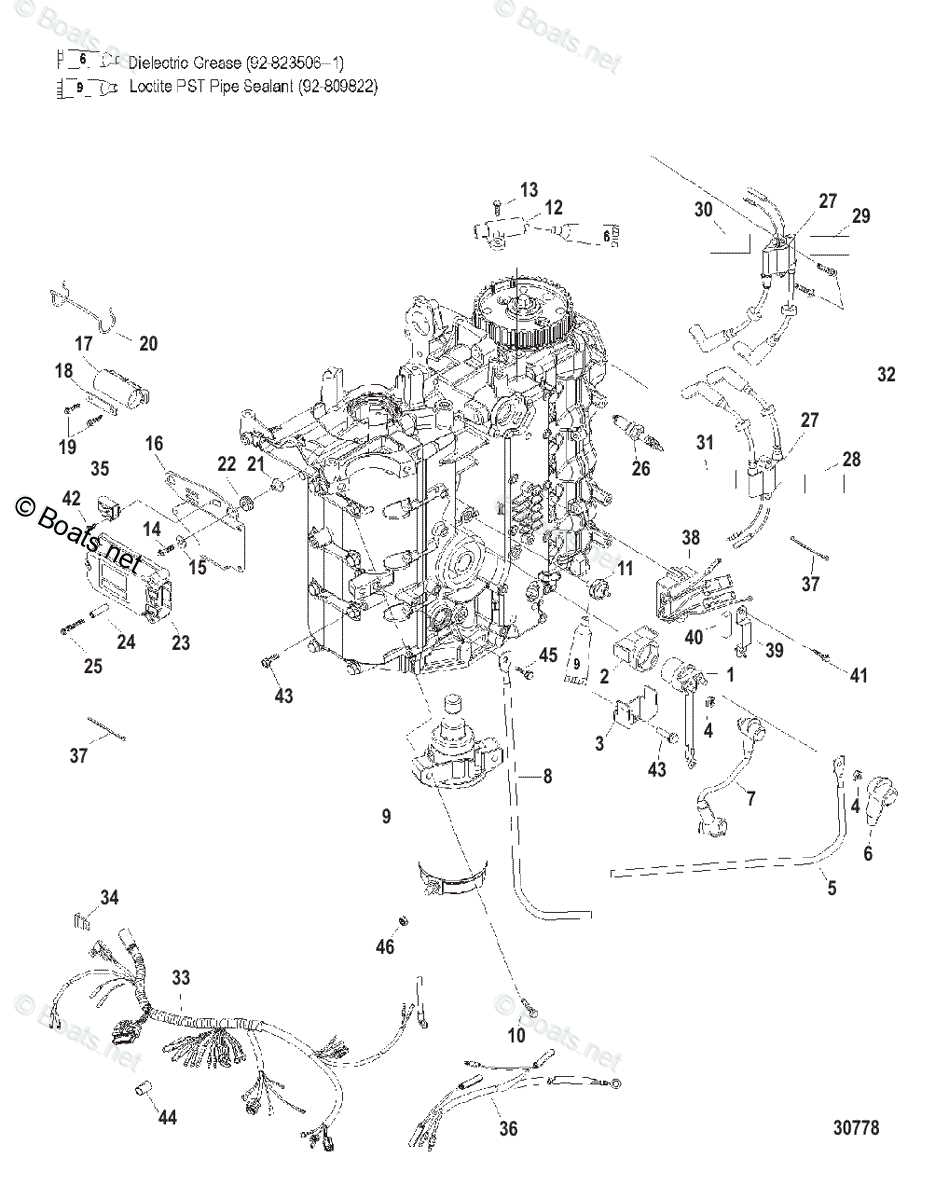

Importance of Parts Diagrams

Understanding the layout of components in any mechanical system is crucial for effective maintenance and repair. These visual representations serve as essential tools for technicians and enthusiasts alike, facilitating a clearer comprehension of how each element fits together and functions within the larger assembly.

Benefits of Visual Representations

- Enhanced clarity for identifying individual components

- Improved troubleshooting processes

- Streamlined repair and replacement procedures

- Facilitated training for new technicians

Key Features of Effective Visual Layouts

- Detailed labeling of each item to avoid confusion

- Clear depiction of connections and interdependencies

- Comprehensive coverage of all relevant sections

- Accessibility in both digital and print formats for ease of use

Key Components of Mercury Optimax

This section outlines the essential elements that contribute to the efficient operation of high-performance marine engines. Understanding these components is crucial for maintenance and repair, ensuring optimal performance on the water.

Some of the fundamental elements include:

- Fuel System: Responsible for delivering the appropriate mixture of fuel and air to the combustion chamber.

- Ignition System: Provides the necessary spark for combustion, crucial for engine start-up and overall efficiency.

- Cooling System: Maintains optimal operating temperatures by circulating coolant and dissipating heat.

- Exhaust System: Channels exhaust gases away from the engine, minimizing emissions and improving performance.

- Lubrication System: Ensures smooth operation by reducing friction between moving parts and preventing wear.

Each of these components plays a vital role in the overall functionality of the engine. Regular inspection and maintenance of these elements can significantly enhance longevity and performance.

Reading the Parts Diagram Effectively

Understanding a visual representation of components is essential for anyone looking to maintain or repair their equipment. This guide focuses on how to interpret such illustrations efficiently, ensuring clarity in identifying and sourcing various elements. With the right approach, you can streamline your troubleshooting and maintenance tasks.

Begin with Familiarization: Before diving into the illustration, take a moment to familiarize yourself with the overall layout and organization. Components are often categorized in a logical manner, allowing for easier navigation.

Utilize the Legend: Most illustrations come with a legend or key that explains symbols and notations used. Refer to this guide frequently to understand the context of different elements and their corresponding labels.

Zoom In on Details: Pay attention to smaller parts, as they may have specific annotations that could be easily overlooked. A closer examination can reveal critical information about each component’s role and connection points.

Cross-Reference with Documentation: It’s beneficial to cross-reference the visual guide with any available manuals or specifications. This practice enhances comprehension and helps to clarify any uncertainties regarding functionality and compatibility.

Take Notes: While analyzing the illustration, jot down notes about key components and any relevant measurements or specifications. This habit aids in quick reference and reduces the chances of error during repairs or replacements.

Ask for Assistance: If you encounter difficulty interpreting certain parts, don’t hesitate to seek advice from experts or forums. Engaging with a community can provide valuable insights and tips for effective understanding.

Common Issues and Solutions

In any mechanical system, certain challenges may arise that can affect performance and reliability. Identifying these problems early and understanding how to address them is crucial for maintaining optimal functionality. This section explores frequent complications encountered in various machinery and provides practical solutions to rectify them.

Understanding the common issues that can arise is the first step in effective troubleshooting. Below is a table summarizing typical challenges along with their corresponding solutions.

| Issue | Solution |

|---|---|

| Overheating | Check coolant levels and inspect for blockages in the cooling system. Ensure proper airflow around the unit. |

| Unusual Noises | Inspect for loose components and ensure that moving parts are properly lubricated. |

| Difficulty Starting | Examine the ignition system and battery condition. Ensure connections are secure and clean. |

| Reduced Power Output | Check fuel supply and filter for obstructions. Inspect air intake for blockages. |

| Frequent Stalling | Assess the fuel system for leaks or contamination. Review electrical connections for integrity. |

Maintenance Tips for Optimax Engines

Proper upkeep is essential for ensuring the longevity and efficiency of your marine propulsion system. By adhering to regular maintenance practices, you can prevent issues and enhance performance. This section provides key recommendations for keeping your engine in optimal condition.

Regular Inspection

Conduct frequent evaluations of your engine to identify any signs of wear or damage. Check for leaks, corrosion, and loose connections. A proactive approach helps address potential problems before they escalate, ensuring a smoother operation.

Fuel System Maintenance

Keep the fuel system clean and free of contaminants. Replace filters as recommended and ensure that the fuel is fresh. Regularly inspect fuel lines for any signs of degradation. Maintaining the fuel system contributes to better performance and reliability, allowing for efficient combustion.

Cooling System Care

The cooling system plays a vital role in preventing overheating. Regularly check coolant levels and inspect hoses for leaks or cracks. Flush the system as needed to remove any buildup. Effective cooling ensures optimal engine temperatures, promoting longevity and performance.

Identifying Replacement Parts Easily

Finding the right components for your equipment can often be a daunting task, especially when dealing with various models and specifications. Understanding how to navigate through the selection process can save time and ensure the right fit for your needs. This section provides insights into effectively identifying the necessary items without the confusion of complex terminology.

To simplify the process, it’s beneficial to familiarize yourself with the common elements and features of your equipment. Utilizing a systematic approach can help streamline the search for replacements, making it easier to locate what you need. Below is a table that outlines essential aspects to consider when seeking out substitutes.

| Feature | Description |

|---|---|

| Model Number | Each item typically has a unique identifier that aids in precise identification. |

| Compatibility | Ensure that the chosen component is suitable for your specific model. |

| Specifications | Review detailed measurements and attributes to match with your requirements. |

| Manufacturer | Consider parts from reputable manufacturers to guarantee quality and reliability. |

| Reviews | Consult user feedback to gain insights into performance and satisfaction. |

By focusing on these key factors, the process of locating necessary components becomes more straightforward, reducing frustration and ensuring optimal operation.

Where to Find Genuine Parts

Locating authentic components for your engine is crucial for maintaining optimal performance and longevity. Using reliable sources ensures that you receive high-quality replacements that meet the required standards. Below are some effective ways to find these essential items.

Authorized Dealers

One of the most dependable options for sourcing genuine components is through authorized dealerships. These establishments provide:

- Access to manufacturer-approved products

- Expert advice from trained professionals

- Warranty coverage on purchased items

Online Retailers

The internet offers a plethora of platforms specializing in marine equipment. When shopping online, consider the following:

- Check for customer reviews to gauge reliability.

- Verify that the retailer is recognized by the manufacturer.

- Look for return policies to ensure satisfaction.

By exploring these avenues, you can confidently acquire the components necessary for your vessel’s upkeep.

Advantages of Using Original Components

Utilizing authentic components in machinery and equipment brings numerous benefits that enhance performance and longevity. These original elements are specifically designed to fit perfectly and work in harmony with the system, ensuring optimal functionality and reliability.

One significant advantage is the assurance of quality. Original components undergo rigorous testing and adhere to strict manufacturing standards, which minimizes the risk of defects and failures. This reliability translates into reduced downtime and maintenance costs, ultimately leading to a more efficient operation.

Moreover, using genuine components often results in better performance. They are engineered to match the specifications of the equipment, providing improved efficiency and effectiveness. This compatibility ensures that the machinery operates at its best, delivering superior results compared to substitutes.

Additionally, choosing original components can enhance resale value. Equipment maintained with genuine parts tends to be more attractive to potential buyers, as it signals a commitment to quality and proper maintenance practices. This can lead to a higher return on investment when it comes time to sell or upgrade the equipment.

Finally, using authentic components often comes with better customer support and warranty coverage. Manufacturers typically offer extensive assistance for their original products, ensuring that users have access to necessary resources and information when needed. This support can be invaluable in troubleshooting and maintaining equipment efficiently.

Aftermarket Parts: Pros and Cons

When considering alternatives to original components, it is essential to evaluate their advantages and disadvantages. Many enthusiasts turn to these replacements as a cost-effective solution, while others remain cautious about potential impacts on performance and longevity. Understanding both sides can help consumers make informed choices that align with their needs.

One significant benefit of these alternatives is the potential for cost savings. Often, these replacements come at a fraction of the price of original items, making them accessible for those on a budget. Additionally, a wide range of options may be available, allowing consumers to choose from various brands and specifications that might better suit their preferences.

However, quality can be a concern. Not all alternatives are created equal, and some may lack the durability or performance standards set by the original manufacturers. This disparity can lead to premature wear or even failures, resulting in more expenses in the long run. Furthermore, compatibility issues might arise, causing further complications during installation or use.

In summary, while alternatives to original components offer attractive benefits such as affordability and variety, potential buyers should remain cautious. Careful research and consideration of quality are crucial to ensuring a positive experience with these replacements.

Upgrading Your Optimax Engine

Enhancing the performance and efficiency of your marine propulsion system can significantly improve your boating experience. By implementing various modifications and upgrades, you can achieve better speed, fuel economy, and reliability. This section will explore several key areas to consider for improving your engine’s capabilities.

Performance Enhancements

- Installing a high-performance exhaust system can increase airflow, leading to improved power output.

- Upgrading the fuel injection system ensures a more precise fuel delivery, enhancing efficiency and responsiveness.

- Consider tuning the engine’s software for optimized performance based on your specific usage needs.

Maintenance and Care

- Regularly inspect and replace filters to maintain optimal airflow and fuel quality.

- Utilize high-quality lubricants and fluids to protect internal components and ensure smooth operation.

- Schedule routine check-ups with a qualified technician to identify and address potential issues before they escalate.

By focusing on these upgrades and maintenance practices, you can significantly enhance your propulsion system’s performance, ensuring a more enjoyable and efficient time on the water.