The construction of a vehicle’s frontal assembly is a crucial aspect of its overall design, playing a significant role in both functionality and aesthetics. This section delves into the various elements that constitute this area, highlighting their importance and how they interrelate. A comprehensive grasp of these components is essential for both maintenance and enhancement of vehicle performance.

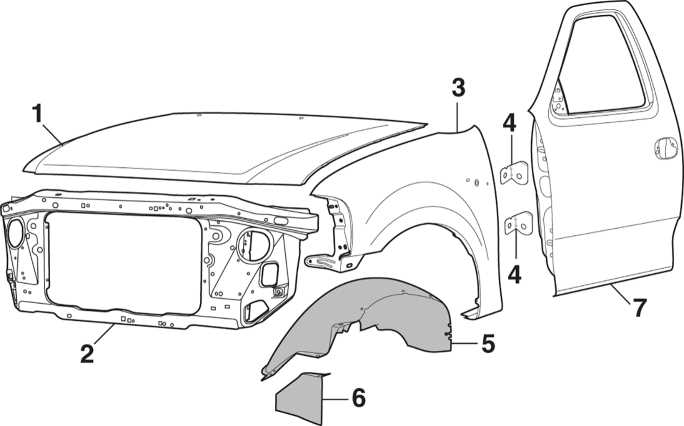

In examining the structural elements that contribute to the front section, one can appreciate the intricate engineering that ensures durability and efficiency. From the mounting brackets to the cosmetic enhancements, each component serves a specific purpose, contributing to the vehicle’s operational integrity. Understanding these aspects not only aids in repairs but also empowers enthusiasts to make informed modifications.

Furthermore, a detailed exploration of the assembly will unveil the potential for personalization and upgrades. Whether it involves replacing worn-out items or enhancing the appearance with aftermarket additions, knowledge of the underlying structure is vital. By dissecting the components involved, owners can navigate the complexities of customization, ensuring that their vehicle meets both performance standards and personal preferences.

The components located at the front of a vehicle play a critical role in ensuring optimal performance, safety, and aesthetics. These elements work together to provide stability, support, and a streamlined appearance. Understanding their significance is essential for any vehicle owner or enthusiast.

Key Functions

- Safety: These components are vital for maintaining the structural integrity of the vehicle, helping to protect occupants in the event of a collision.

- Handling: They contribute to the overall handling characteristics, influencing steering responsiveness and ride quality.

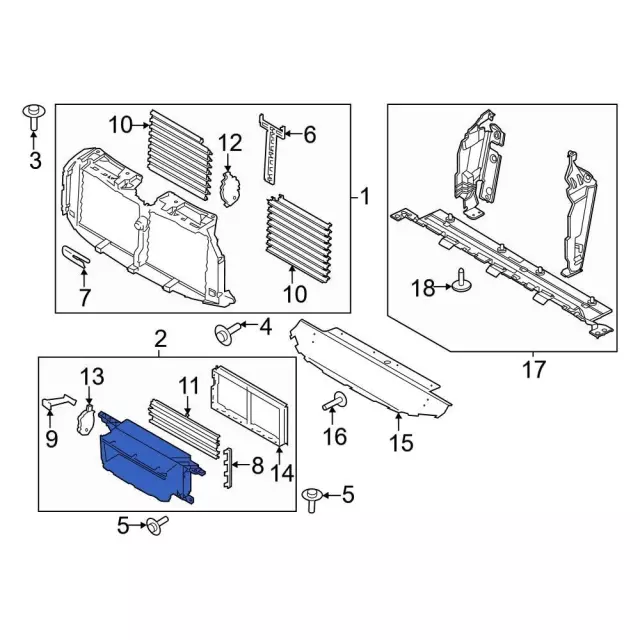

- Aerodynamics: Properly designed elements help reduce drag, improving fuel efficiency and enhancing performance.

- Aesthetic Appeal: These components significantly influence the visual appeal, allowing for customization and personal expression.

Maintenance Considerations

- Regular Inspections: Routine checks can identify wear and tear, preventing more significant issues down the line.

- Timely Replacements: Replacing damaged or worn elements promptly ensures safety and performance remain at optimal levels.

- Quality Parts: Utilizing high-quality replacements can enhance durability and effectiveness, contributing to the vehicle’s longevity.

Common Issues with Front End Assembly

The assembly located at the vehicle’s front is crucial for overall performance and safety. It plays a significant role in maintaining stability and handling. However, several common problems can arise, affecting both functionality and comfort. Understanding these issues can help in timely maintenance and repair, ensuring a smoother driving experience.

Wear and Tear on Components

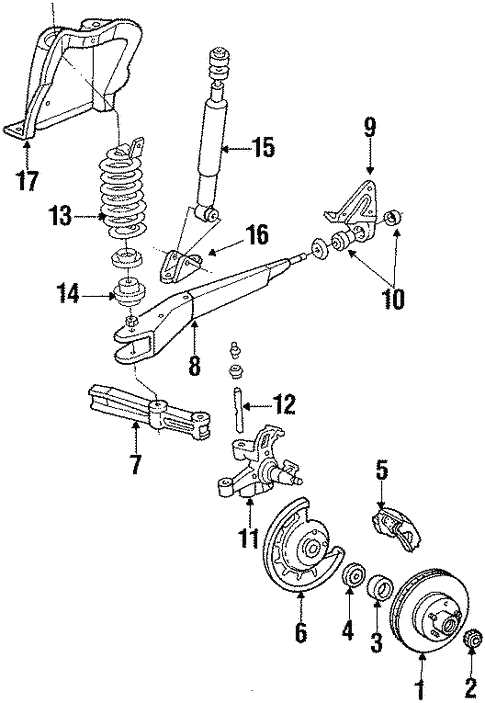

One of the most prevalent issues involves the gradual deterioration of various components. Items such as bushings, ball joints, and tie rods can experience wear over time, leading to misalignment and handling difficulties. Regular inspections can help identify these problems early, allowing for preventive measures before they escalate.

Alignment Issues

Misalignment is another frequent concern, often resulting from hitting potholes or curbs. This can cause uneven tire wear and affect the vehicle’s handling. Correct alignment is essential for even tire wear and optimal fuel efficiency. Proper maintenance practices and timely adjustments can mitigate these issues and prolong the life of the assembly.

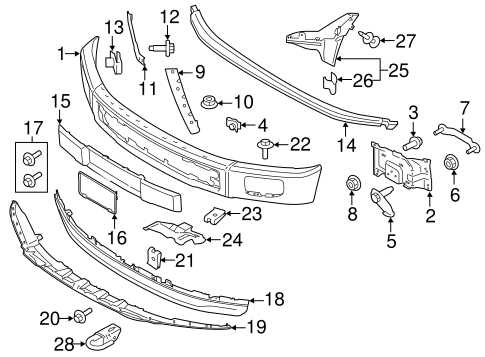

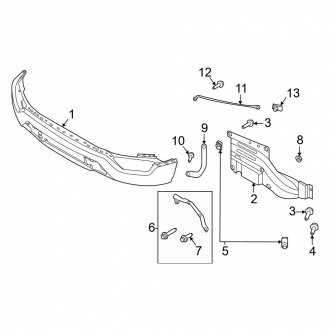

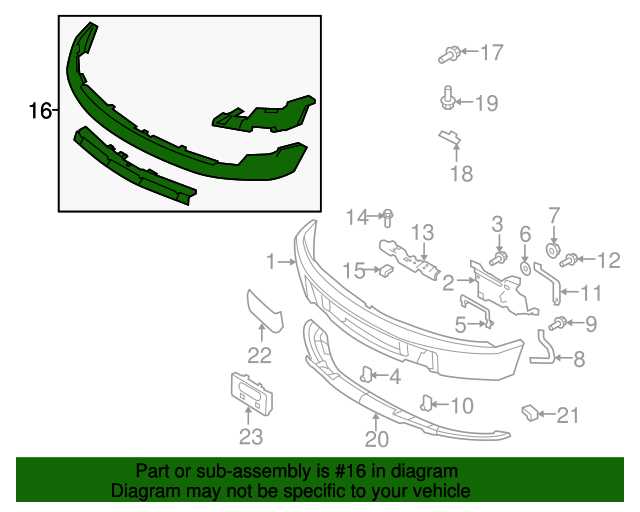

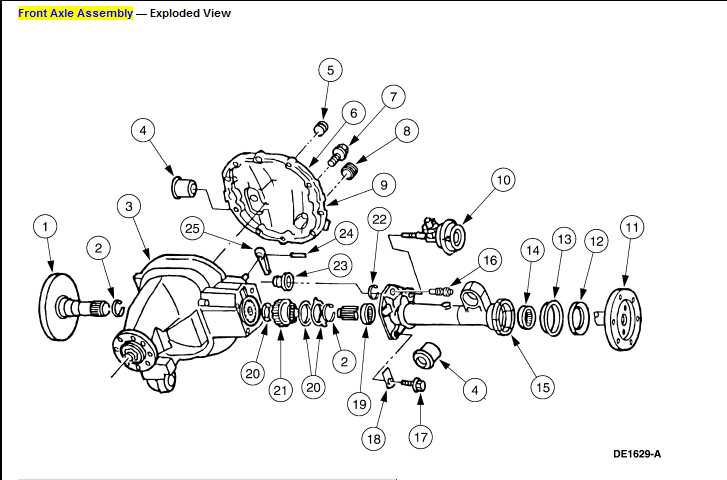

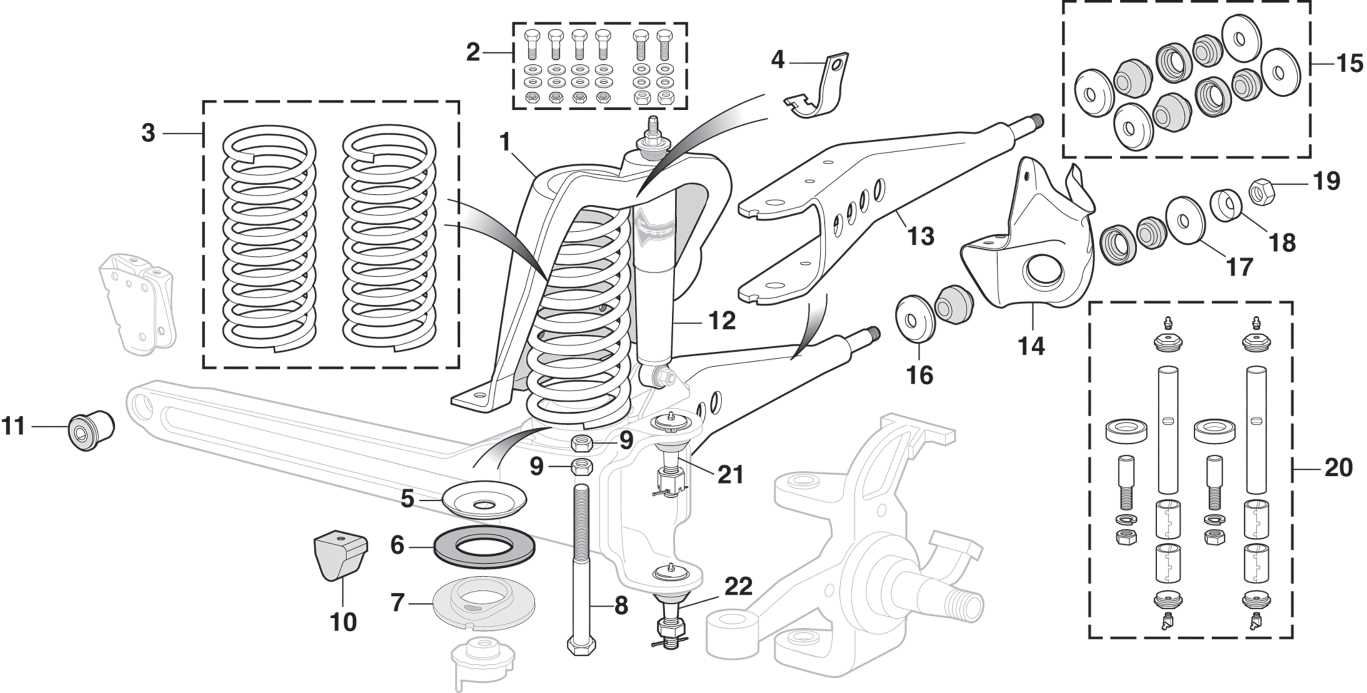

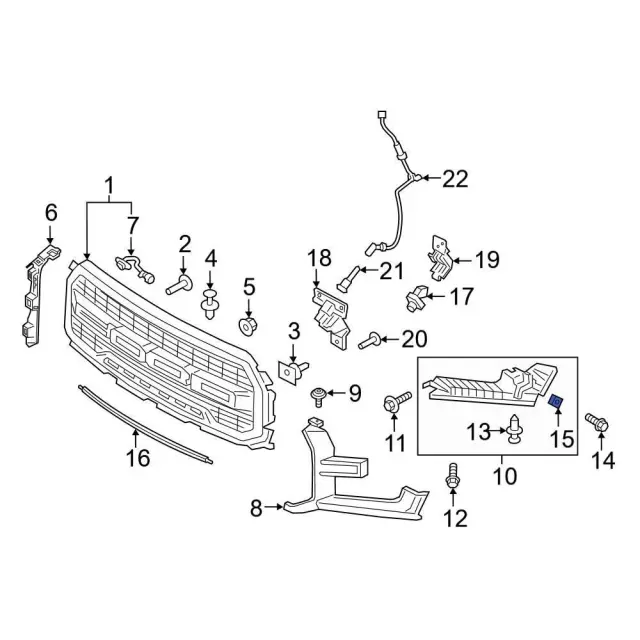

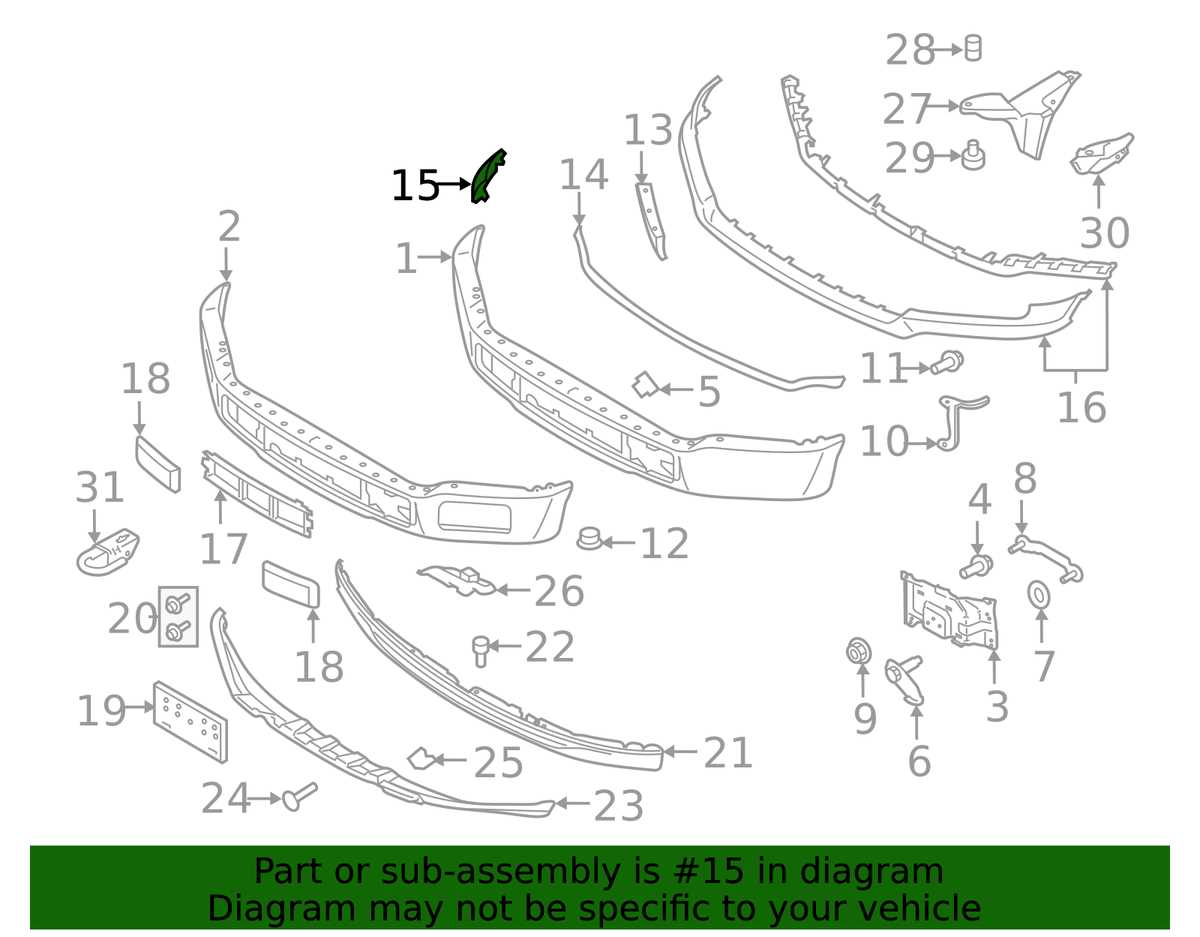

Diagram Analysis and Explanation

This section delves into the intricate representation of the vehicle’s assembly. By examining the various components, we can gain a deeper understanding of how each element interacts within the system. A thorough analysis not only highlights the significance of individual elements but also clarifies their roles in overall functionality.

Throughout the examination, it is crucial to focus on the relationships between different components. Each segment is interconnected, contributing to the efficiency and performance of the vehicle. Observing the layout allows for identification of potential wear areas, maintenance points, and opportunities for enhancement.

Understanding the layout helps enthusiasts and technicians alike to troubleshoot issues effectively. The visual representation serves as a roadmap, guiding users through the complexities of assembly and offering insights into best practices for upkeep. By engaging with this analysis, one can appreciate the thoughtful design and engineering that goes into creating a reliable vehicle.

In conclusion, a detailed exploration of the layout offers valuable knowledge for both current and prospective vehicle owners. It empowers them to make informed decisions regarding maintenance and upgrades, ensuring longevity and optimal performance.

Replacement Parts for F150 Front End

Maintaining the integrity of your vehicle’s exterior is essential for optimal performance and safety. Components located at the forefront of the vehicle play a crucial role in ensuring a smooth and secure driving experience. Over time, certain elements may wear out or sustain damage, necessitating timely replacements.

Among the most common components requiring attention are the suspension elements, which contribute significantly to ride quality and handling. This includes shock absorbers and sway bar links, which help stabilize the vehicle during turns and uneven terrain. Additionally, ball joints are vital for maintaining proper alignment and ensuring responsive steering.

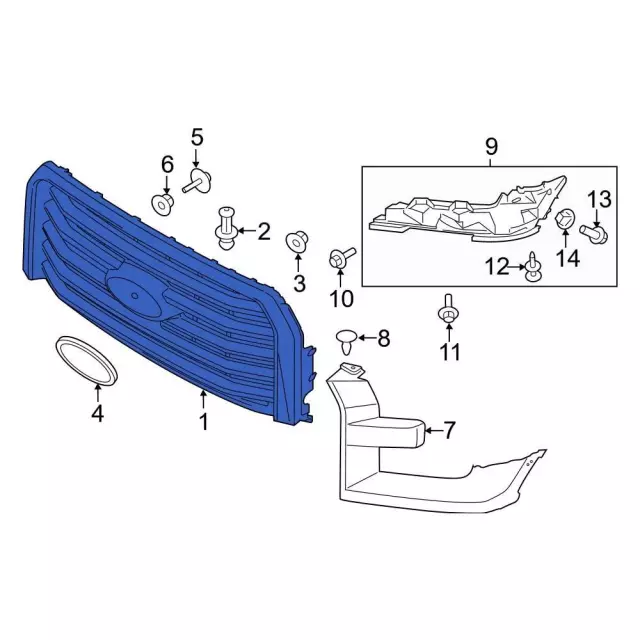

Another critical category consists of the protective covers and lighting systems. Bumpers and grilles not only enhance aesthetic appeal but also shield the internal mechanisms from debris and impact. Furthermore, headlights and turn signals are essential for visibility and signaling intentions to other road users.

Finally, various smaller accessories, such as fasteners and brackets, should not be overlooked, as they ensure that all components are securely attached and functioning correctly. Regular inspection and timely replacement of these elements can significantly extend the life of your vehicle and enhance overall driving safety.

Installation Guide for Front Components

This section provides a comprehensive overview of the installation process for essential components located at the vehicle’s forefront. Proper installation ensures optimal performance and longevity, contributing to a smooth driving experience.

Follow these steps for a successful installation:

- Gather all necessary tools and equipment.

- Ensure that the vehicle is parked on a flat surface and the engine is off.

- Raise the vehicle using a jack and secure it with jack stands for safety.

Next, you will need to remove the existing components:

- Carefully detach any coverings or shields protecting the area.

- Unscrew and remove the components that require replacement.

Once the old components are removed, prepare for the installation of the new ones:

- Align the new components with the designated mounting points.

- Secure each component with the appropriate fasteners, ensuring they are tightened to the manufacturer’s specifications.

- Reattach any protective coverings or shields as necessary.

Finally, lower the vehicle and perform a thorough inspection to confirm that all components are correctly installed and functioning properly.

Regular maintenance of these components is vital for maintaining vehicle performance and safety on the road.

Maintenance Tips for Front End

Regular upkeep of the vehicle’s front section is crucial for ensuring optimal performance and longevity. Proper attention to these components can enhance handling, improve safety, and prevent costly repairs down the line. This section will provide valuable insights into maintaining these essential elements effectively.

Routine Inspections

Conducting frequent examinations of the suspension and steering systems can help identify potential issues before they escalate. Look for signs of wear, such as unusual noises, vibrations, or uneven tire wear. Checking the alignment and adjusting it as necessary will also contribute to smoother handling and improved tire life.

Lubrication and Cleaning

Keeping the moving parts well-lubricated is vital for reducing friction and preventing premature wear. Regularly clean components to remove dirt and debris that can cause damage. Utilize high-quality lubricants suited for automotive use to ensure longevity and efficiency of the mechanisms involved.

Performance Upgrades for Front Parts

Enhancing the efficiency and responsiveness of a vehicle’s frontal assembly can significantly improve overall performance. Upgrades can encompass a variety of components, including suspension systems, steering mechanisms, and braking systems. By selecting high-quality aftermarket options, enthusiasts can experience improved handling, increased stability, and enhanced aesthetics.

Suspension Enhancements

Upgrading the suspension is crucial for better road contact and handling dynamics. Options such as adjustable shock absorbers and performance springs allow for fine-tuning the ride height and stiffness, catering to both on-road comfort and off-road capabilities. Lowering kits can enhance cornering stability, while coilovers provide a customizable solution for various driving conditions.

Braking System Improvements

Another vital area for performance enhancement is the braking system. Upgrading to larger rotors and high-performance calipers can greatly increase stopping power, while performance brake pads ensure consistent performance under various conditions. Stainless steel brake lines can improve pedal feel and responsiveness, making the driving experience safer and more engaging.

Tools Needed for Front End Work

When undertaking repairs or modifications to the vehicle’s exterior assembly, having the right tools is essential for ensuring a smooth and efficient process. Proper equipment not only enhances productivity but also contributes to the overall quality of the work performed. This section outlines the essential instruments required to tackle various tasks related to the vehicle’s structure.

A comprehensive toolkit should include basic hand tools such as wrenches, ratchets, and screwdrivers, which are vital for loosening and tightening fasteners. Additionally, specialized tools like alignment kits and suspension compressors may be necessary for precise adjustments and replacements. Safety gear, including gloves and goggles, is also crucial to protect the technician during the procedure.

Investing in high-quality equipment can significantly improve the outcome of any project. Furthermore, having access to manuals or reference materials can aid in understanding the specific requirements for each task, ensuring that all procedures are carried out correctly and safely.

Professional Help vs. DIY Repairs

When it comes to vehicle maintenance and repairs, enthusiasts often face the choice between seeking professional assistance or tackling the task themselves. Each option presents its own set of advantages and challenges, making it essential to carefully consider the specifics of the situation.

Benefits of Professional Assistance

- Expertise: Professionals possess extensive knowledge and experience, ensuring high-quality work.

- Time-saving: Hiring an expert allows for quicker repairs, freeing up time for other important tasks.

- Warranty Protection: Many professionals offer warranties on their work, providing peace of mind for future issues.

Advantages of DIY Repairs

- Cost-effectiveness: Handling repairs personally can save money on labor costs.

- Learning Opportunity: Engaging in repairs enhances understanding of vehicle mechanics and systems.

- Flexibility: DIY repairs can be done at one’s own pace and on a convenient schedule.

Ultimately, the decision to seek professional help or undertake repairs independently depends on individual skill levels, the complexity of the task, and personal preferences. Balancing these factors will lead to a more informed and satisfying choice.

Cost Considerations for Parts Replacement

When it comes to maintaining or upgrading vehicle components, financial aspects play a crucial role. Understanding the expenses associated with the acquisition and installation of new elements is essential for any vehicle owner. Various factors influence the overall cost, which can impact budgeting decisions.

Key considerations include:

- Quality of Components: Higher-quality replacements may come at a premium, but they often provide better durability and performance.

- Labor Costs: Hiring a professional for installation can add significant expenses, so it’s important to compare rates and options.

- OEM vs. Aftermarket: Original Equipment Manufacturer (OEM) components typically offer guaranteed compatibility but may be more expensive compared to aftermarket alternatives.

- Warranty Coverage: Parts with warranty protection can save money in the long run, as they may cover repairs or replacements if issues arise.

- Vehicle Age: Older models may require more specialized components that can be harder to find and potentially more costly.

By weighing these factors carefully, vehicle owners can make informed decisions that align with their financial plans while ensuring their vehicles remain reliable and efficient.