In the world of aquatic sports and boating, the need for reliable stabilization mechanisms is paramount. These systems provide essential support, ensuring that vessels remain steady in various water conditions. A closer examination of these mechanisms reveals a range of interconnected elements, each playing a crucial role in enhancing performance and usability.

Effective deployment and retraction of stabilization units rely on a well-engineered assembly. Understanding how each component functions allows users to optimize their setup for specific conditions. This exploration not only aids in proper maintenance but also empowers enthusiasts to troubleshoot issues efficiently.

By delving into the intricate design of these systems, users can appreciate the thoughtful engineering behind them. This insight fosters a deeper connection with the equipment, enhancing the overall experience on the water.

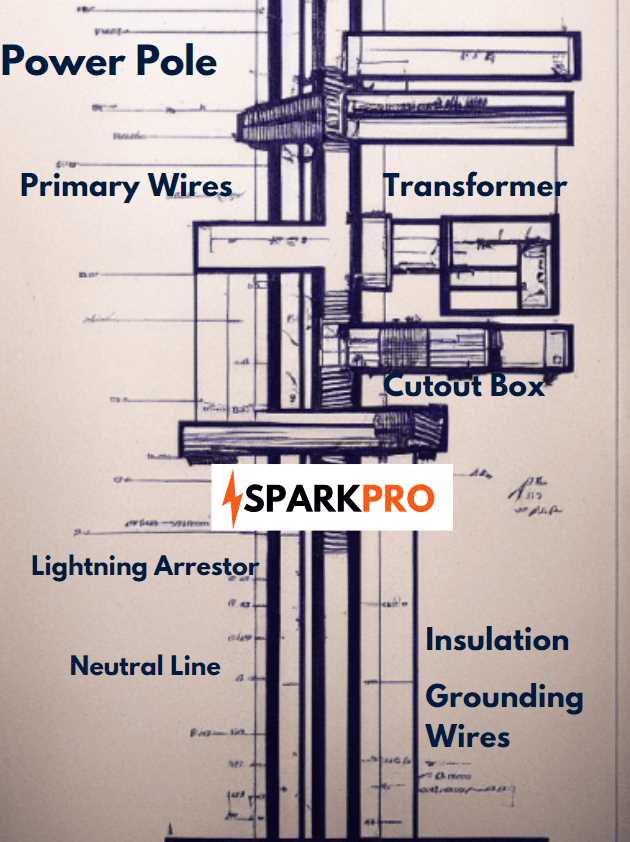

Understanding Power-Pole Anchor Components

In the realm of aquatic activities, having the right equipment is essential for stability and ease of use. This section explores the key elements that contribute to the functionality and reliability of a specific anchoring system, highlighting their roles and interconnections.

The various elements work together seamlessly to ensure that vessels remain securely positioned in the water. Each component plays a unique role, contributing to the overall effectiveness and efficiency of the system. Understanding these components helps users make informed choices for their boating needs.

| Component | Description |

|---|---|

| Base Unit | The foundation that supports the entire system, providing stability and strength. |

| Retractable Mechanism | Allows for easy deployment and retraction, enhancing convenience during use. |

| Connection Rod | Links the base to the securing element, ensuring a secure hold. |

| Securing Element | The part that grips the substrate, keeping the system anchored in place. |

| Adjustment System | Facilitates fine-tuning of the system’s depth and position for optimal performance. |

By familiarizing yourself with these components, you can maximize the effectiveness of your anchoring system, ensuring a smoother and more enjoyable experience on the water.

Key Parts of a Power-Pole System

Understanding the essential components of a positioning system enhances both functionality and efficiency on the water. Each element plays a crucial role in ensuring stability and ease of use, ultimately improving the overall experience for the user.

Essential Components

Key elements include the deployment mechanism, control interface, and stabilization features, which work together to facilitate seamless operation. Knowing how these components interact can significantly enhance performance.

Component Overview

| Component | Description |

|---|---|

| Deployment Mechanism | Responsible for lowering and raising the device into the water. |

| Control Interface | Allows the user to operate the system easily, often via a remote or panel. |

| Stabilization Features | Ensures that the system remains securely in place during use. |

Importance of Each Component

Understanding the significance of each element within a stabilization system is crucial for optimal performance and safety. Each component plays a unique role, contributing to the overall functionality and effectiveness of the mechanism. Recognizing these roles can enhance both the user experience and the longevity of the equipment.

- Base: Provides stability and support, ensuring that the system remains anchored securely in place.

- Vertical shaft: Facilitates the movement of the assembly, allowing for adjustments and positioning based on user needs.

- Control mechanism: Enables precise manipulation of the device, enhancing user control and operational efficiency.

- Locking system: Ensures that the device remains in the desired position, preventing unintended shifts or movements.

- Connection fittings: Allow for easy attachment and detachment, making the device versatile for different applications.

Each part not only serves its individual purpose but also contributes to the synergy of the entire system. Proper maintenance and understanding of each element’s function can significantly impact the overall effectiveness and reliability of the setup.

How to Read the Diagram

Understanding a schematic representation can significantly enhance your grasp of its components and their functions. Familiarity with symbols, lines, and notations is essential for interpreting how each element interacts within the overall system.

Start by identifying the symbols: Each icon typically corresponds to a specific piece of equipment or mechanism. Familiarize yourself with the legend, as it provides crucial information about what each symbol signifies.

Next, follow the connections: Arrows and lines illustrate relationships and pathways between elements. Pay attention to how these connections flow, as they often indicate the sequence of operations or the transfer of forces.

Look for labels: Descriptive tags next to each symbol clarify their roles. These annotations can include specifications, which help in understanding the requirements and capabilities of each part.

Lastly, review the entire layout: The arrangement of components can reveal functional hierarchies or priorities, aiding in your overall comprehension of the system’s design and operation.

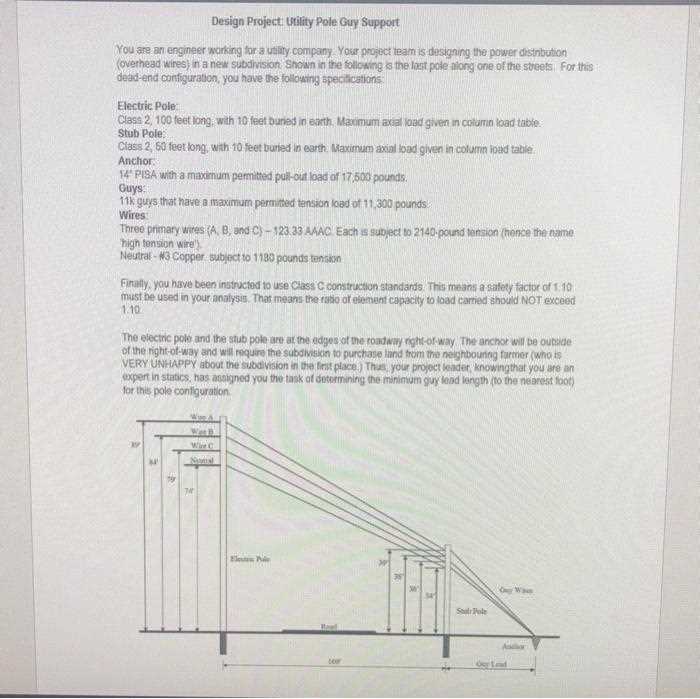

Common Materials Used in Construction

In the realm of construction, the choice of materials plays a crucial role in determining the durability, safety, and aesthetic appeal of structures. Various substances, each with unique properties, are utilized to meet specific needs in building projects. Understanding these materials helps in making informed decisions that can significantly impact the outcome of any construction endeavor.

Concrete is one of the most prevalent materials due to its strength and versatility. It can be molded into various shapes, making it ideal for foundations, walls, and pavements. The addition of aggregates enhances its properties, contributing to its widespread use.

Steel is another essential component, known for its high tensile strength and durability. It is commonly employed in frameworks and reinforcements, providing structural integrity. The adaptability of steel allows for innovative designs while maintaining safety standards.

Wood, a traditional building material, offers natural beauty and excellent insulation properties. It is often used in residential construction, providing warmth and a sense of comfort. Different types of wood, such as hardwood and softwood, serve various purposes based on their characteristics.

Brick is recognized for its thermal mass and aesthetic appeal. It is commonly used in walls and facades, offering a classic look while ensuring energy efficiency. The durability of brick also makes it a favored choice for many architectural styles.

Glass has gained popularity for its ability to enhance natural lighting and create open spaces. It is frequently used in modern designs to provide a sense of transparency and connection to the surroundings. Innovations in glass technology have also improved its strength and insulation capabilities.

By understanding the common materials employed in construction, one can appreciate the complexities of building design and the importance of selecting the right components for any project.

Installation Tips for Beginners

Setting up your new equipment can be an exciting yet daunting task. To ensure a smooth installation process, it’s important to familiarize yourself with the necessary steps and techniques. This guide provides essential tips to help novices navigate the setup with confidence and ease.

Preparation is Key

Before you begin, gather all the tools and materials you’ll need. Read the instructions thoroughly to understand the components involved. This will help you visualize the assembly and prevent any confusion during the process. Additionally, clearing your workspace can significantly enhance your efficiency, making it easier to handle and organize each piece.

Step-by-Step Approach

Take your time and follow a methodical approach to the installation. Start with the base components, ensuring each is securely attached before moving on to the next. Double-check all connections to guarantee stability and safety. If you encounter any difficulties, don’t hesitate to refer back to the instructions or seek guidance from experienced individuals.

Maintenance Practices for Longevity

Ensuring the durability of your equipment requires regular care and attention. Adopting effective maintenance practices can significantly extend the life of your gear, preventing costly repairs and replacements. By implementing a routine that includes inspections, cleaning, and proper storage, you can keep your equipment functioning optimally.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Weekly | Check for signs of wear, rust, or damage. |

| Cleaning | After Each Use | Remove dirt and debris to prevent corrosion. |

| Lubrication | Monthly | Apply lubricant to moving parts to ensure smooth operation. |

| Storage | Seasonally | Store in a dry place, away from extreme temperatures. |

By following these practices, you can delve deeper into the maintenance process and achieve the ultimate longevity of your equipment, ensuring it remains reliable for years to come.

Safety Considerations When Using Anchors

Ensuring safety during the deployment and use of mooring devices is paramount for both users and the surrounding environment. Proper handling and awareness of potential hazards can significantly reduce the risk of accidents and enhance overall operational efficiency. It is essential to adhere to best practices and guidelines to maintain a secure setting while using these tools.

Understanding Environmental Conditions

Before engaging in any anchoring activities, it’s crucial to assess the surrounding environment. Factors such as wind speed, water currents, and weather conditions can greatly influence stability. Inadequate preparation for these elements can lead to unpredictable situations, potentially jeopardizing safety. Always check forecasts and be mindful of changing conditions during use.

Proper Equipment Inspection

Regular inspection of the equipment is vital to ensure functionality and reliability. Look for signs of wear, corrosion, or damage that could compromise performance. Maintaining your gear in optimal condition not only enhances safety but also prolongs its lifespan. Always replace worn or damaged components promptly to avoid any failures during critical moments.

Troubleshooting Common Issues

Addressing challenges in equipment functionality is essential for ensuring optimal performance. Identifying the source of problems can prevent further complications and enhance efficiency.

Inconsistent Deployment: If the system does not extend or retract smoothly, check for any blockages or debris that may hinder movement. Regular cleaning and maintenance can mitigate these issues.

Power Failure: If the device is unresponsive, examine the power source and connections. Ensure that all cables are securely attached and the battery is charged.

Unusual Noises: Unwanted sounds during operation often indicate wear or misalignment. Inspect all moving components and replace any damaged parts promptly to maintain proper function.

Remote Control Issues: If the remote does not work, verify that the batteries are functional and correctly installed. Also, check for signal obstructions that may interfere with communication.

By systematically analyzing these common challenges, users can efficiently restore functionality and enjoy a smoother experience.

Upgrades for Enhanced Performance

Improving the functionality of your equipment can significantly elevate your experience on the water. By integrating advanced features and high-quality components, you can achieve better stability, responsiveness, and ease of use. This section explores various enhancements that can transform your setup into a more efficient and reliable tool for your aquatic adventures.

Material Improvements

Choosing the right materials can greatly impact durability and performance. Opting for lightweight yet robust options ensures that your system can withstand challenging conditions while remaining easy to maneuver. Consider corrosion-resistant alloys and high-strength polymers for long-lasting use.

Technological Advancements

Incorporating modern technology can also provide significant advantages. Features like remote control functionality or smartphone integration can enhance convenience and precision. Additionally, sensors that provide real-time feedback can help in making informed adjustments during your activities.

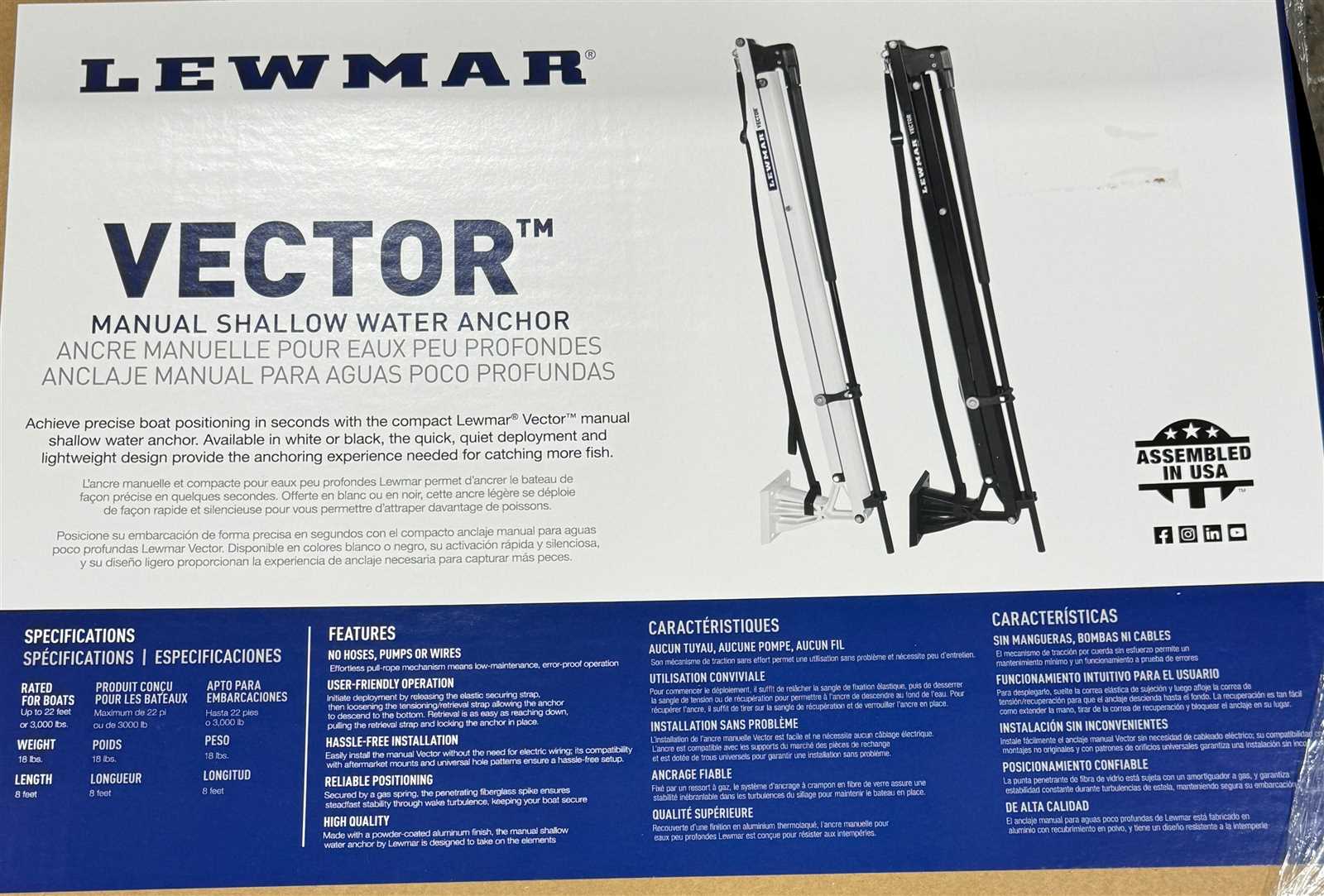

Comparing Power-Pole to Other Anchors

When assessing different solutions for securing vessels in place, it’s essential to examine the unique features and benefits each option provides. Various systems offer distinct mechanisms, materials, and ease of use, influencing their effectiveness based on specific conditions and preferences.

| Feature | Device A | Device B | Device C |

|---|---|---|---|

| Deployment Speed | Fast | Moderate | Slow |

| Weight | Light | Medium | Heavy |

| Durability | High | Medium | Low |

| Price Range | Affordable | Moderate | Expensive |

Ultimately, the choice between these alternatives will depend on the user’s specific needs, including frequency of use and environmental conditions. Understanding the strengths and weaknesses of each option allows for a more informed decision in securing your craft effectively.

FAQs About Power-Pole Systems

This section aims to address common inquiries related to the advanced anchoring systems used in various watercraft applications. These systems enhance stability and convenience, allowing users to better manage their vessels in different environments.

Common Questions

- What are the main benefits of these anchoring systems?

These systems offer several advantages:

- Quick deployment and retrieval.

- Enhanced stability in challenging conditions.

- Improved control over positioning.

- How do I maintain my anchoring equipment?

Regular maintenance is essential for optimal performance:

- Inspect for wear and tear after each use.

- Clean components to prevent corrosion.

- Lubricate moving parts as needed.

Technical Specifications

- What type of materials are used?

These systems typically incorporate:

- Marine-grade aluminum for durability.

- High-strength plastics to reduce weight.

- Corrosion-resistant finishes for longevity.

- Are there weight limits?

Yes, weight capacities vary by model:

- Check the manufacturer’s specifications for details.

- Exceeding the limit may compromise safety and effectiveness.