Understanding the structure and organization of machinery is essential for effective upkeep and smooth operation. When it comes to equipment used in landscaping and other outdoor tasks, having a clear overview of how different elements are interconnected can simplify repairs and replacements. This guide offers a detailed look at the internal setup, enabling users to keep their machinery in top condition.

The internal mechanisms are composed of various elements that work in harmony to deliver optimal performance. By familiarizing yourself with their arrangement, you can diagnose issues swiftly and carry out maintenance with confidence. This knowledge helps ensure long-term durability and enhances the efficiency of your machinery during operation.

Whether you’re dealing with mechanical failures or simply conducting routine checks, having a clear understanding of the layout is crucial. In this guide, we’ll break down the essential components, providing you with the insights needed to keep your equipment running smoothly.

Overview of the Walker MTGHS Parts Layout

Understanding the structure and components of this system is essential for ensuring its smooth operation. The layout includes several key elements that work together to provide optimal functionality. Each component is strategically positioned, making maintenance and repairs straightforward, provided you have a clear understanding of how everything is organized.

- The engine is placed centrally, allowing for easy access during service tasks.

- A well-organized deck arrangement ensures efficient grass collection and discharge.

- Drive mechanisms are positioned in such a way that ensures balanced performance and handling.

- The control panel is ergonomically designed for user-friendly operation and monitoring.

By familiarizing yourself with the arrangement, you can perform repairs more efficiently and extend the lifespan of the equipment. Each section plays a critical role, so

Key Components of the Walker Mower

The efficiency and longevity of any riding lawn machine depend on the proper functioning of its essential elements. This section provides an overview of the main mechanical structures that ensure smooth operation and high performance in daily use.

Engine and Power System

The power source is at the heart of every lawn machine. It drives the cutting deck, allows for forward movement, and supports other necessary functions. The engine’s capacity often dictates how efficiently the equipment can handle large areas of grass and challenging terrains.

- Fuel tank – stores the fuel that powers the engine.

- Air filter – prevents debris from entering the engine, ensuring smooth combustion.

- Cooling system – regulates the engine’s temperature to prevent overheating during long periods of use.

Cutting Deck and Blades

The

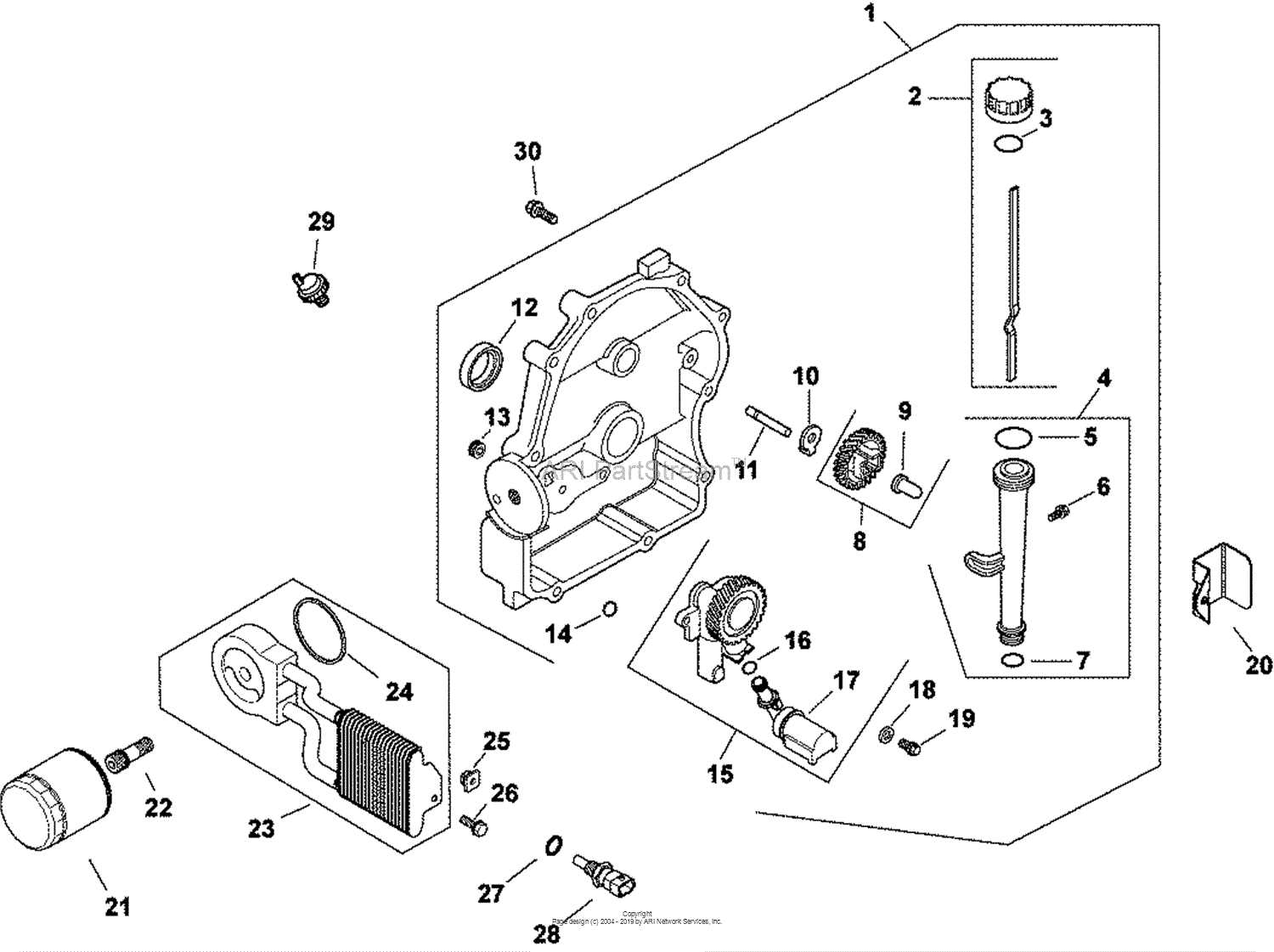

Understanding the Engine Structure

The engine serves as the core component responsible for powering the machine, converting energy into motion. Its overall configuration includes several interconnected elements that work in harmony to ensure efficient operation. By understanding the arrangement and role of each segment, we can gain a deeper insight into how the engine functions as a whole.

Core Components of the Engine

At the heart of the engine are key parts such as the cylinders, crankshaft, and pistons. These components interact to facilitate energy transfer, ensuring the machine runs smoothly. The cylinders house the pistons, which move in a precise rhythm, driven by the combustion of fuel. This motion is then transferred to the crankshaft, which converts the linear motion into rotational force.

Supporting Systems

In addition to the main elements, various systems contribute to the engine’s efficiency. The cooling system regulates

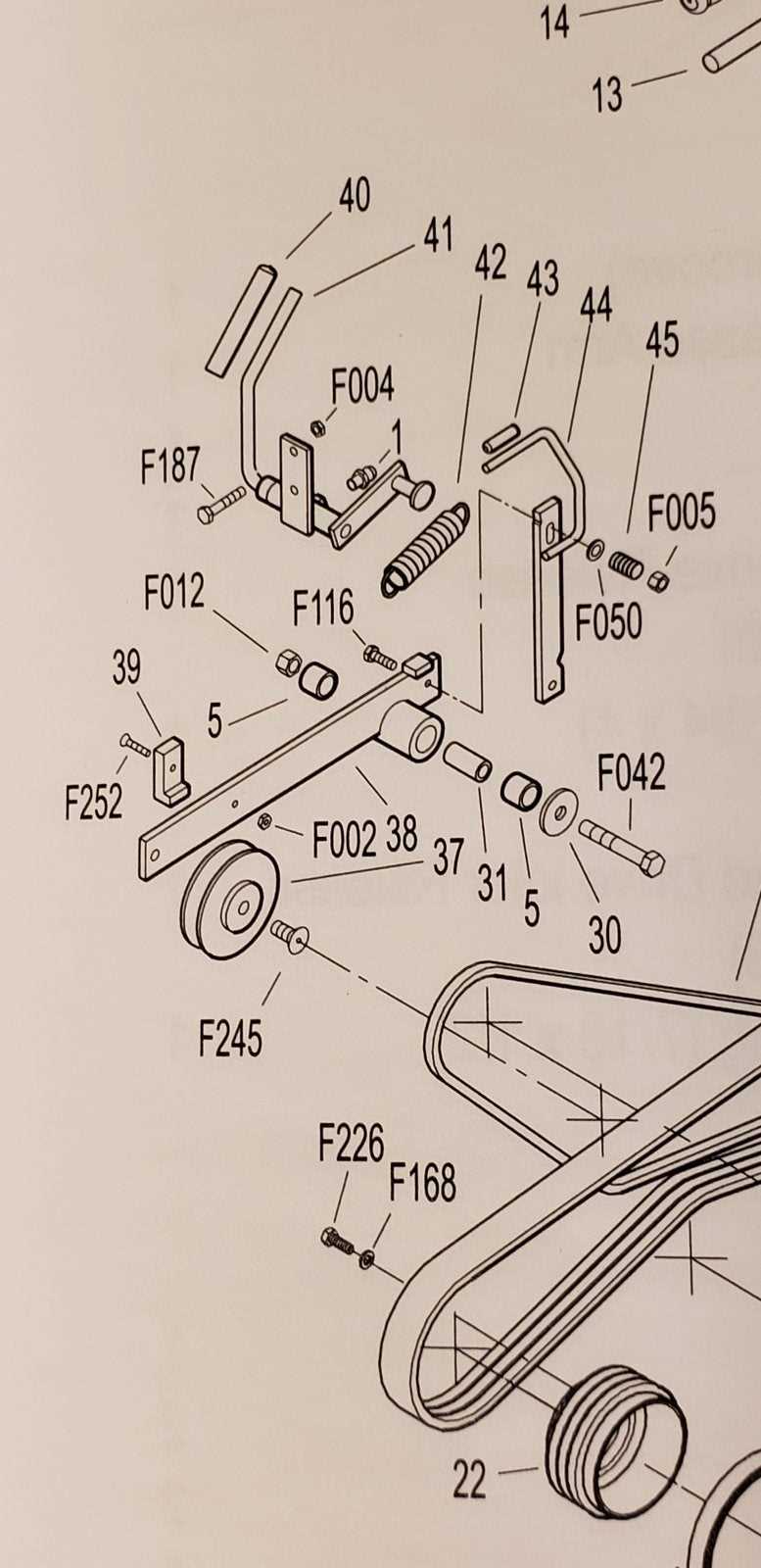

Blade Assembly and Functionality

The blade assembly plays a crucial role in the operation of the cutting system, providing efficient grass trimming and maintaining the overall performance of the equipment. Proper installation and maintenance of the cutting components ensure that the machine operates smoothly and delivers precise results in different conditions.

- Blade Structure: The blade is designed to create a consistent and even cut by rotating at high speeds. It is essential to check for wear and tear, as a dull blade can significantly affect performance.

- Installation: Securing the blade in the proper position ensures stable operation. It is recommended to use the correct fasteners and follow the manufacturer’s torque specifications to avoid potential damage or imbalance.

- Sharpening and Replacement: Regular sharpening of the blade is necessary to maintain cutting precision. If the blade shows signs of severe wear, such as nicks or bending, replacing it with a new one is advised for optimal functionality.

- Pump: The pump is responsible for converting mechanical energy into hydraulic energy, ensuring fluid movement throughout the system.

- Hydraulic Fluid: This fluid transmits power within the system and also helps with lubrication, cooling, and contamination control.

- Actuators: These convert hydraulic energy back

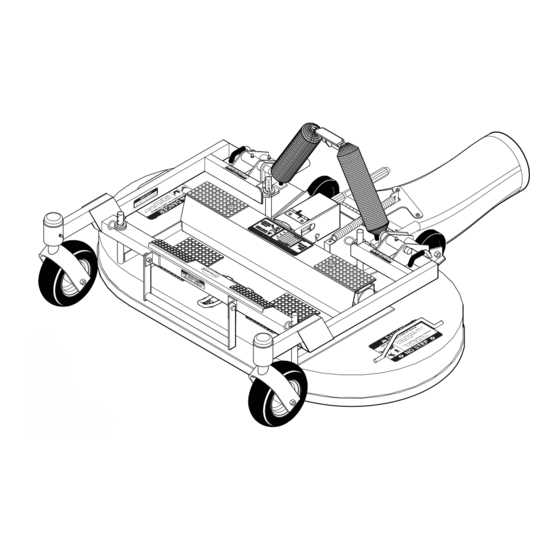

Deck and Frame Design

The construction of the platform and structure is fundamental to ensuring stability and functionality in outdoor machinery. This design plays a crucial role in providing a solid base that can withstand various conditions while supporting the overall system. An effective layout not only enhances performance but also contributes to user safety and ease of operation.

Structural Integrity

A robust framework is essential for maintaining the durability and longevity of the equipment. It involves selecting high-quality materials that can resist wear and tear over time. The arrangement of components should allow for optimal weight distribution, minimizing the risk of damage during operation. Furthermore, reinforcing joints and connections is vital for enhancing structural strength.

Ergonomic Considerations

Designing the platform with user comfort in mind can significantly improve the overall experience. The height and angle of the deck should facilitate easy access and maneuverability. Integrating features such as non-slip surfaces and strategically placed handholds can enhance safety and operational efficiency. Ultimately, thoughtful design choices can lead to a more intuitive and enjoyable user interaction.

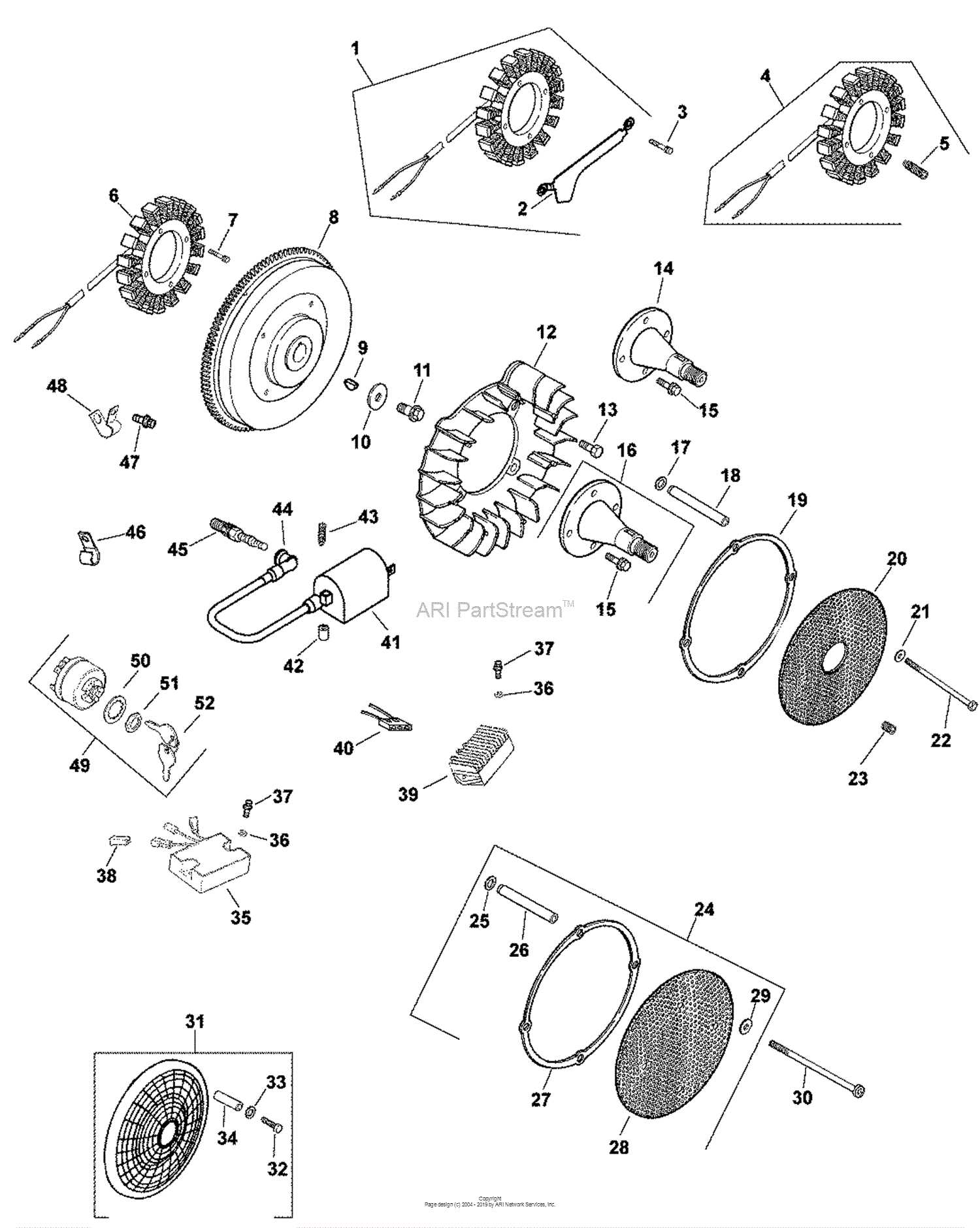

Electrical Wiring and Connections

The significance of proper electrical wiring and connections cannot be overstated, as they play a crucial role in ensuring the functionality and safety of any system. Understanding the layout and interconnections of electrical components is essential for maintaining optimal performance. This section delves into the various aspects of electrical connections, highlighting the best practices for achieving reliable and efficient configurations.

Key Considerations for Wiring

When establishing electrical connections, several factors must be taken into account to guarantee effectiveness and safety. The quality of materials, the arrangement of wires, and the choice of connectors are vital elements that contribute to a seamless operation. Here are some important considerations:

Factor Description Material Quality Utilizing high-quality wires and connectors can significantly reduce resistance and enhance durability. Wire Gauge Selecting the appropriate gauge for the application is crucial to prevent overheating and ensure sufficient current flow. Connection Type Employing the correct type of connector, such as soldered, crimped, or screw terminals, ensures secure and reliable connections. Insulation Proper insulation prevents short circuits and protects against environmental factors, prolonging the lifespan of the wiring. Common Wiring Practices

Adhering to standard wiring practices can lead to improved safety and efficiency. Some common methods include:

- Color Coding: Using standardized color codes for wires helps in easily identifying functions and preventing mistakes during connections.

- Labeling: Clearly labeling wires and connectors can aid in future maintenance and troubleshooting.

- Testing: Regular testing of connections ensures that any issues are identified and rectified promptly, minimizing potential hazards.

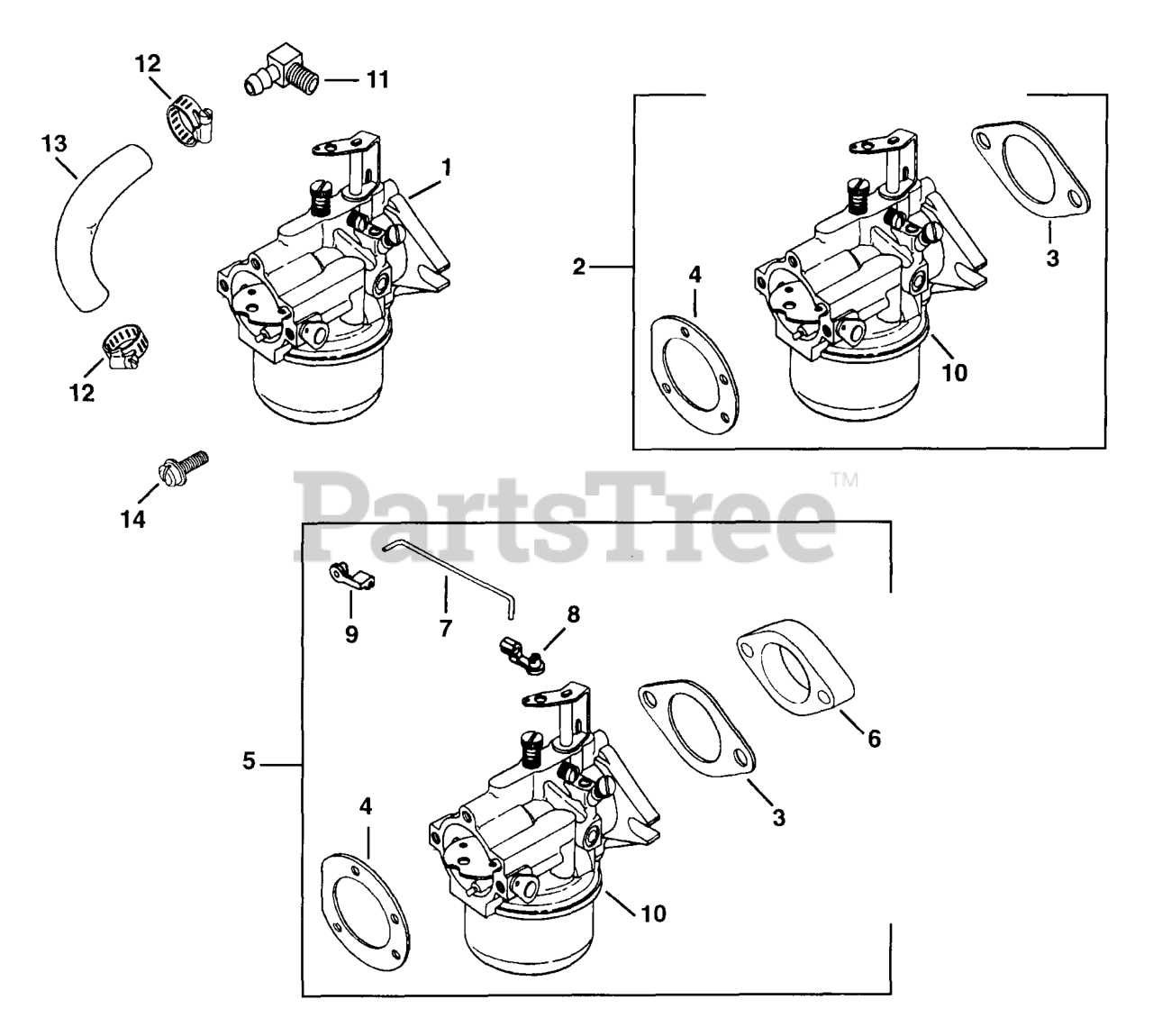

Fuel System Parts Breakdown

The fuel system is a vital component in ensuring efficient engine performance. It comprises various elements that work together to deliver the right amount of fuel to the engine, optimizing combustion and enhancing overall functionality. Understanding each component’s role can aid in maintenance and troubleshooting, leading to improved reliability and longevity.

- Fuel Tank: The storage unit for gasoline, designed to prevent leaks and ensure safety.

- Fuel Pump: A device that moves fuel from the tank to the engine, generating the necessary pressure for delivery.

- Fuel Filter: This component removes impurities and debris from the fuel before it reaches the engine, protecting critical parts.

- Fuel Injector: Responsible for atomizing fuel and injecting it into the combustion chamber at the right time for optimal performance.

- Fuel Rail: A conduit that delivers fuel to the injectors, ensuring even distribution across all cylinders.

- Pressure Regulator: Maintains the correct fuel pressure within the system, adjusting flow based on engine demands.

Regular inspection and maintenance of these components can prevent fuel-related issues, ensuring smooth operation and enhanced efficiency. Proper knowledge of each element’s function allows for timely repairs and replacements, contributing to the overall health of the vehicle.

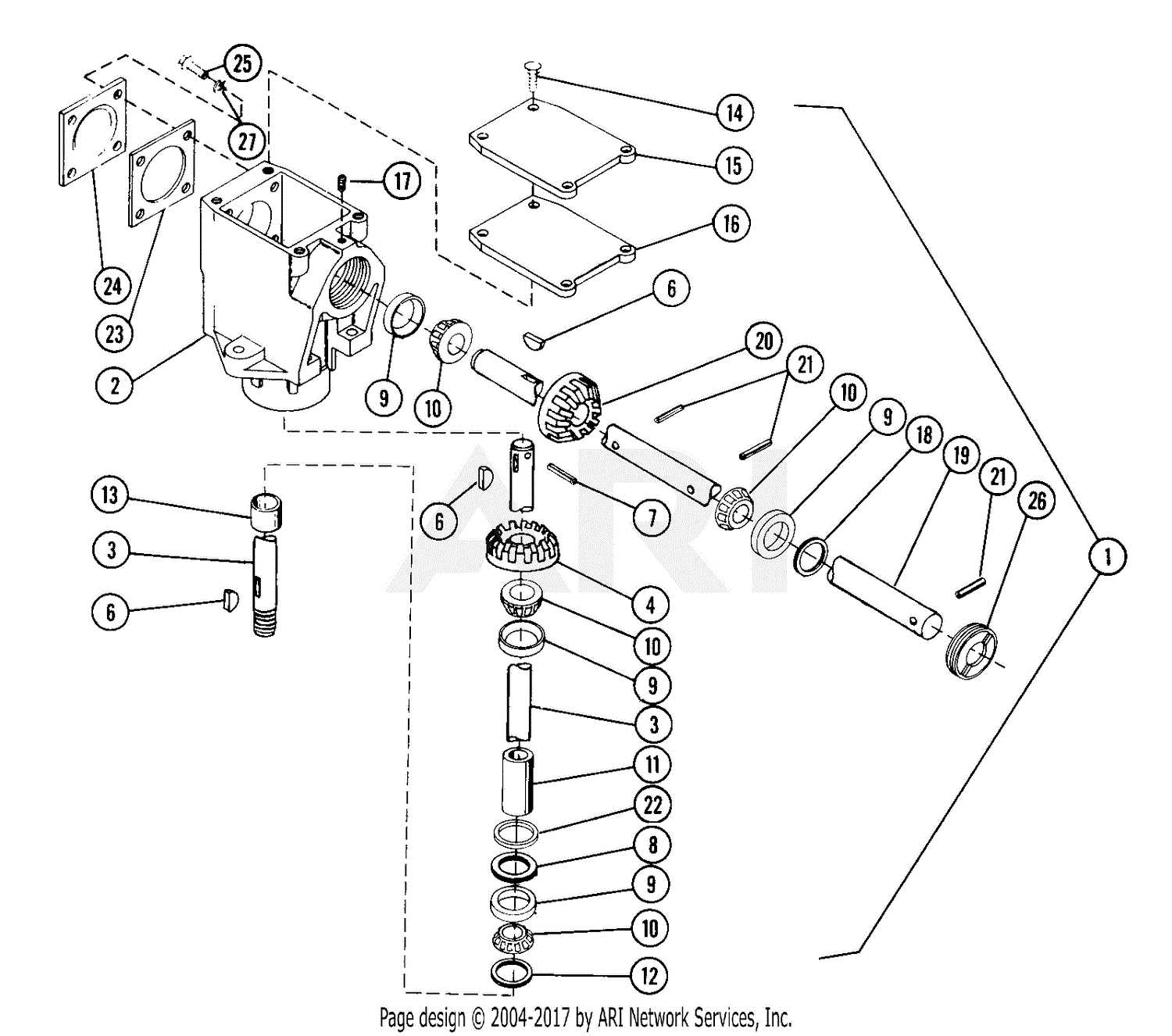

Transmission Mechanism Explained

The transmission mechanism plays a vital role in the effective operation of various machinery and vehicles. It serves as the conduit through which power is transferred from one component to another, ensuring that movement is achieved efficiently. Understanding this mechanism is essential for comprehending how different systems function and interact.

At its core, the transmission mechanism consists of several key elements that work together seamlessly. These components include gears, belts, pulleys, and shafts, each designed to facilitate the transfer of energy in a specific manner. Below are some fundamental aspects of this mechanism:

- Gears: These are toothed wheels that mesh with one another to change the direction and speed of motion.

- Belt Drives: Flexible loops of material that transmit power between shafts, often found in various machines.

- Pulleys: These wheel-like devices work in conjunction with belts to alter the force and speed of motion.

- Shafts: Rods that transmit torque and rotation from one part of the system to another.

Each of these components contributes to the overall efficiency and performance of the transmission mechanism. The proper functioning of this system is crucial for maintaining the desired speed and power output in any mechanical application. By examining the interactions among these elements, one can appreciate the complexity and ingenuity behind modern machinery.

In summary, the transmission mechanism is a fundamental aspect of mechanical systems, ensuring that energy is conveyed efficiently. A thorough understanding of its components and their functions allows for better maintenance and innovation in various technological fields.

Cooling System Elements

The effectiveness of a cooling system is crucial for maintaining optimal operating temperatures in various machinery and vehicles. This system comprises several key components that work together to dissipate heat and ensure efficient performance. Understanding these elements is essential for effective maintenance and troubleshooting.

Radiator: The radiator serves as the primary heat exchanger, allowing coolant to release heat into the surrounding air. It consists of a series of tubes and fins that maximize surface area, enhancing heat dissipation.

Coolant: This fluid circulates through the system, absorbing heat from the engine and transferring it to the radiator. Proper coolant levels and composition are vital for preventing overheating and corrosion.

Water Pump: The water pump is responsible for circulating the coolant throughout the system. It ensures a continuous flow, allowing for effective heat exchange and maintaining appropriate temperature levels.

Thermostat: This component regulates the temperature of the coolant. It opens and closes based on the coolant temperature, allowing for efficient flow and preventing the engine from running too hot or too cold.

Cooling Fans: These fans assist in drawing air through the radiator, enhancing the cooling effect. They are typically activated when the engine temperature exceeds a certain threshold, ensuring optimal airflow when needed.

Hoses: Flexible hoses connect various components of the cooling system, facilitating the movement of coolant. Regular inspection and replacement of these hoses are essential to prevent leaks and ensure system integrity.

Each of these components plays a significant role in the overall functionality of the cooling system. Regular maintenance and awareness of how these elements interact can help prevent overheating and extend the lifespan of the machinery.

Safety Features and Their Components

Ensuring user safety is paramount in any mechanical equipment design. Various protective mechanisms are integrated into devices to mitigate risks and enhance operational security. Understanding these elements is crucial for effective maintenance and optimal performance.

Among the essential safety elements are emergency shut-off switches, stability supports, and anti-slip features. These components work collaboratively to provide a safe working environment and prevent accidents during operation.

Safety Feature Description Functionality Emergency Shut-off Switch A quick-access switch that halts operation in emergencies. Prevents accidents by allowing immediate cessation of function. Stability Supports Components designed to enhance the balance and stability of the device. Reduces the risk of tipping or instability during use. Anti-slip Features Surface treatments or materials that enhance grip. Minimizes the chance of slipping, ensuring safer handling. Regular inspection and maintenance of these safety features are essential to ensure their reliability and effectiveness. Users should familiarize themselves with each component to respond appropriately in various situations, thus promoting a safer operational environment.

Maintenance Tips for Walker Mower

Regular upkeep is essential for ensuring optimal performance and longevity of your mowing equipment. By following a systematic approach to maintenance, you can enhance the efficiency of your machine and reduce the likelihood of unexpected repairs. This section outlines some vital maintenance practices to keep your equipment in top shape.

Routine Checks and Cleaning

Start by inspecting the mower regularly for any signs of wear and tear. Check the blades for sharpness and damage; dull blades can lead to uneven cuts and strain the engine. Clean the mower after each use to remove grass clippings, dirt, and debris, which can accumulate and affect performance. Pay special attention to the air filter, as a clogged filter can hinder airflow and reduce efficiency.

Fluid Levels and Battery Care

Maintaining proper fluid levels is crucial for smooth operation. Regularly check the oil level and replace it as recommended in the owner’s manual. Additionally, monitor the fuel quality; using stale or contaminated fuel can cause starting issues. For battery-powered models, ensure that the battery is charged and free from corrosion to guarantee reliable performance.

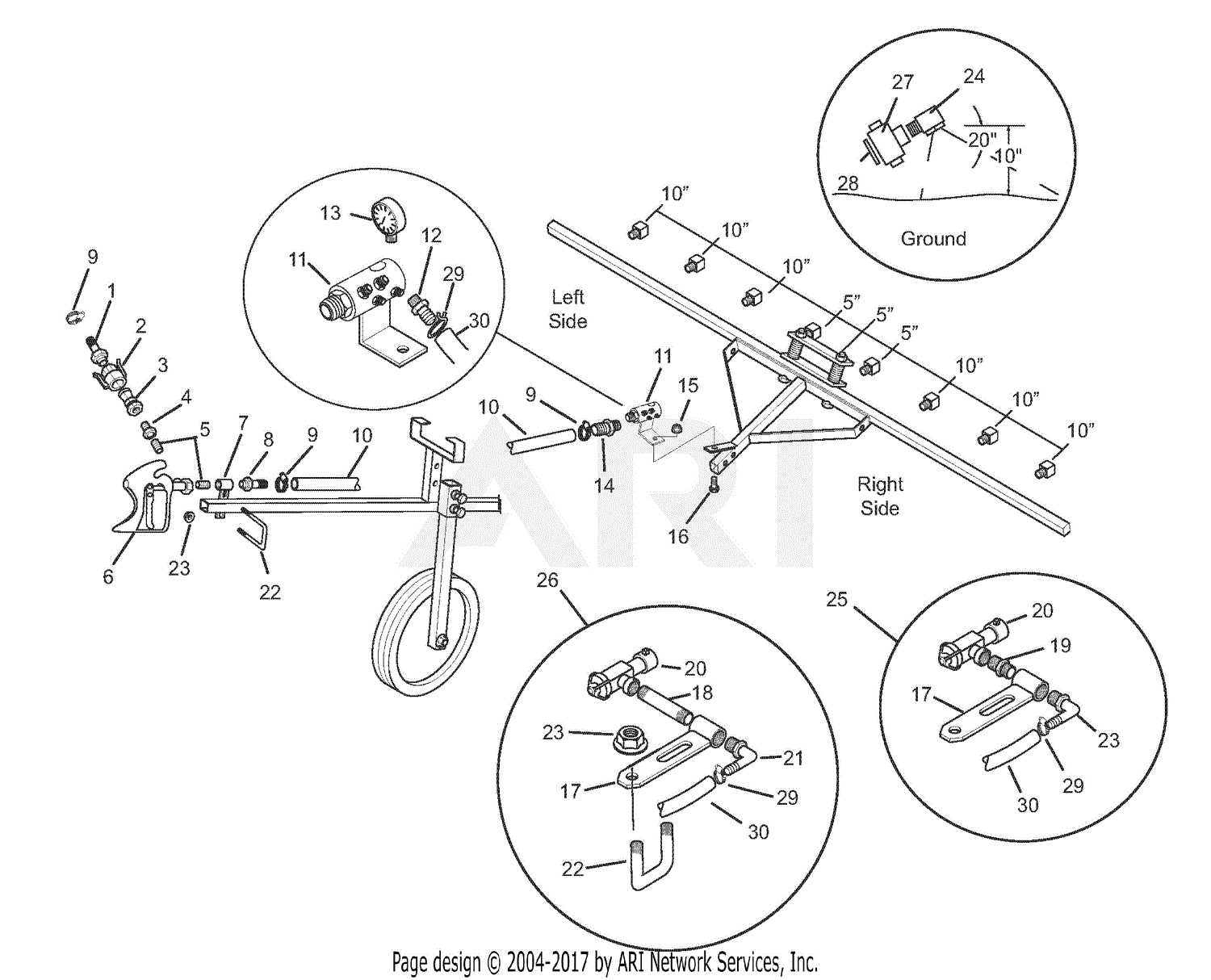

Ordering and Replacing Parts Efficiently

Efficiently obtaining and substituting components is crucial for maintaining equipment performance. By understanding the proper procedures and resources, users can ensure minimal downtime and optimal functionality. This section outlines key strategies for seamless procurement and installation of essential elements.

Research and Identify Components: Before initiating the ordering process, it is vital to accurately identify the required items. Utilize manuals, online resources, or community forums to gather information on specifications and compatibility. This knowledge will aid in avoiding errors during procurement.

Choose Reputable Suppliers: Selecting trustworthy vendors is essential for acquiring quality replacements. Look for suppliers that specialize in your equipment type and have positive reviews. Verify their credibility by checking customer feedback and return policies to ensure a satisfactory purchasing experience.

Utilize Online Tools: Many websites offer tools for cross-referencing and verifying part numbers. Take advantage of these resources to streamline the ordering process. Additionally, some platforms provide detailed descriptions, images, and installation instructions, further simplifying the task.

Plan for Installation: Once the items arrive, prepare for the replacement process. Gather necessary tools and review installation guidelines. Organizing your workspace and having all materials readily available can significantly reduce the time spent on the task.

Keep Records: Maintain a log of orders, including purchase dates, suppliers, and part numbers. This information can be invaluable for future replacements and helps to monitor component longevity and performance.

By following these steps, individuals can enhance their ability to efficiently order and replace necessary elements, ensuring their equipment remains in peak condition.

Hydraulic System Components

The hydraulic system is essential for ensuring the smooth and efficient operation of various machinery, providing power transmission and control. Understanding the main elements of this system helps maintain functionality and prevent malfunctions, enhancing performance and longevity.