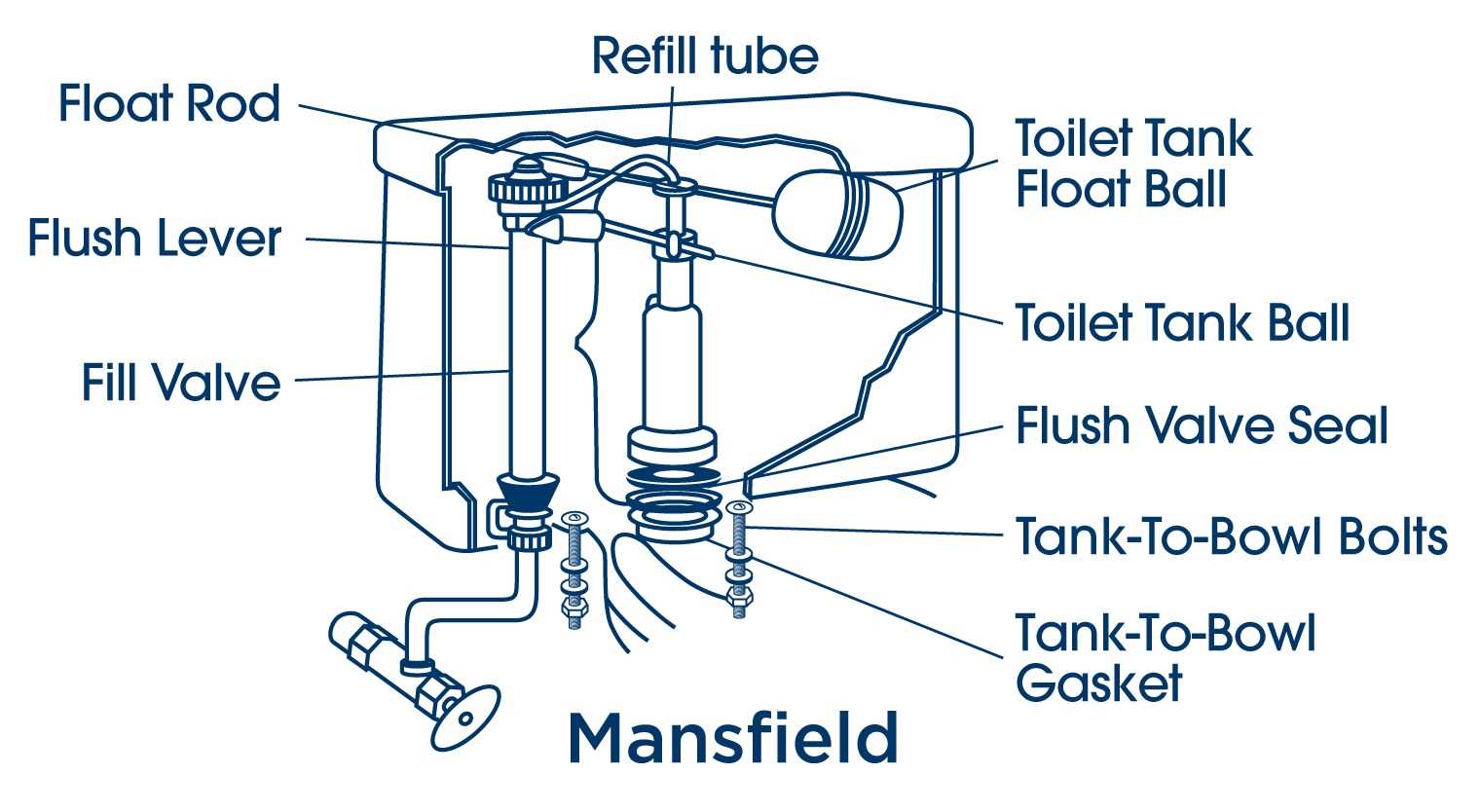

The inner workings of modern water containers can seem intricate at first glance. However, by focusing on the individual components that ensure smooth operation, you can gain a clear understanding of how these systems function. The layout of these mechanisms is designed to maintain efficiency, control water flow, and provide durability over time.

Each element within this structure plays a crucial role, working together to regulate the release and refill processes. Whether it’s the control mechanism for adjusting water levels or the refill system that ensures proper flow, these components are vital for maintaining overall functionality. Knowing the role of each part will help you identify potential issues and ensure a long-lasting performance of the entire unit.

In this guide, we’ll explore the main elements, their functions, and how they contribute to the effective operation of water containers. This will provide you with a clearer perspective on what keeps the system running efficiently and how to approach any necessary adjustments

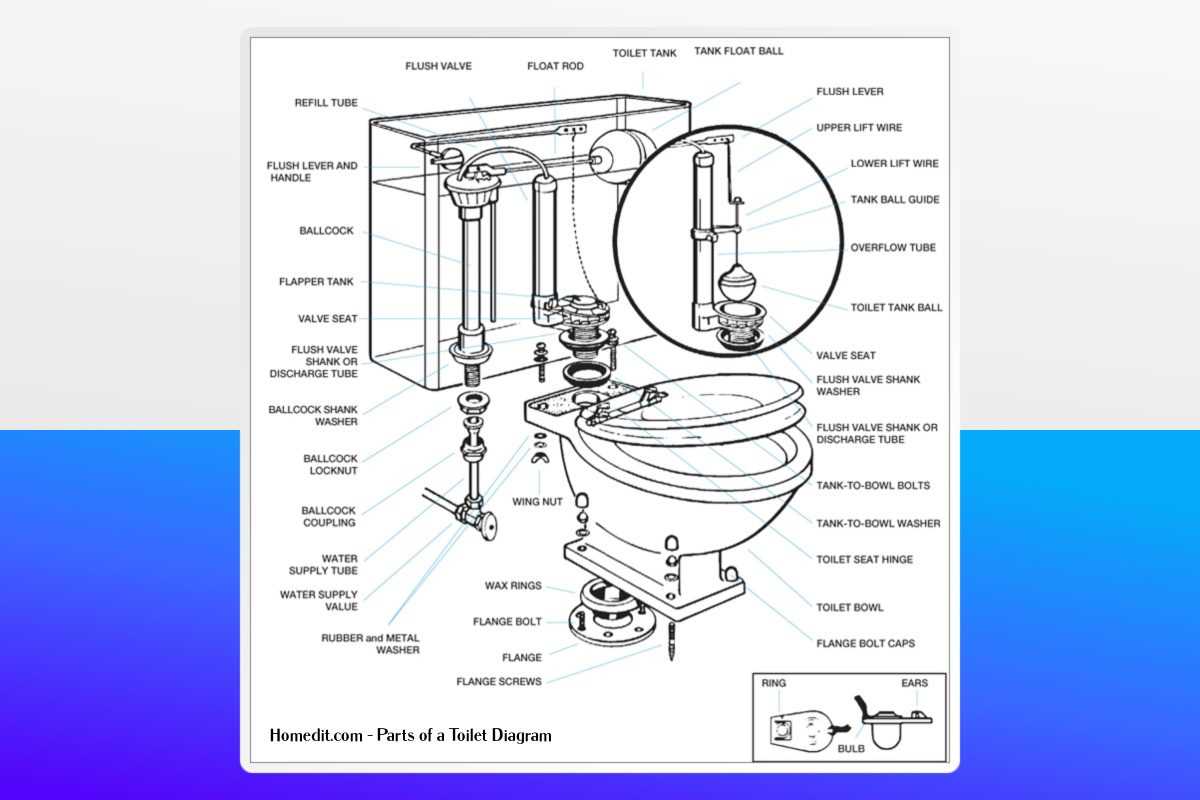

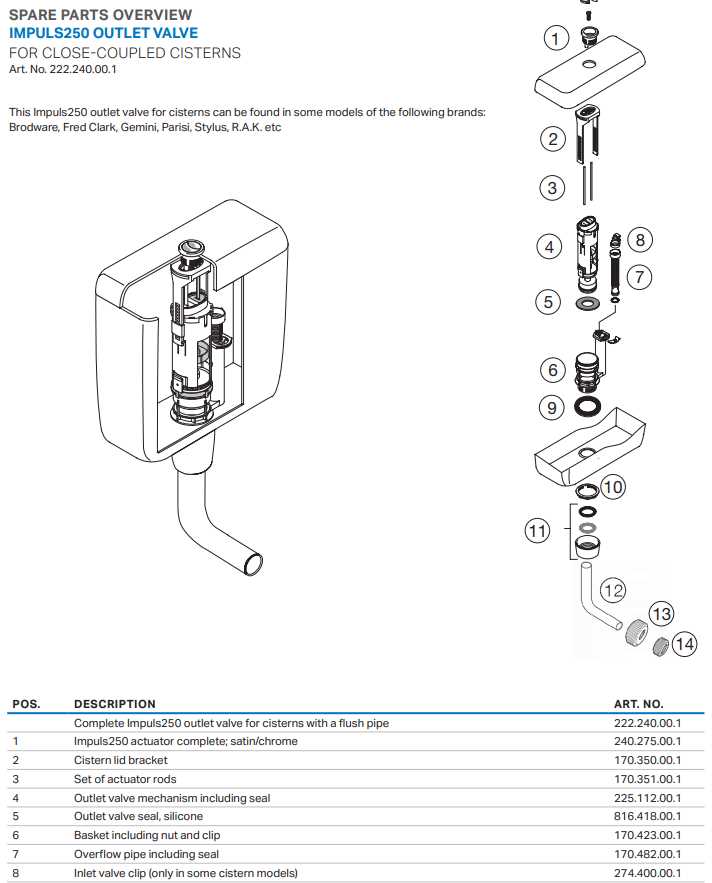

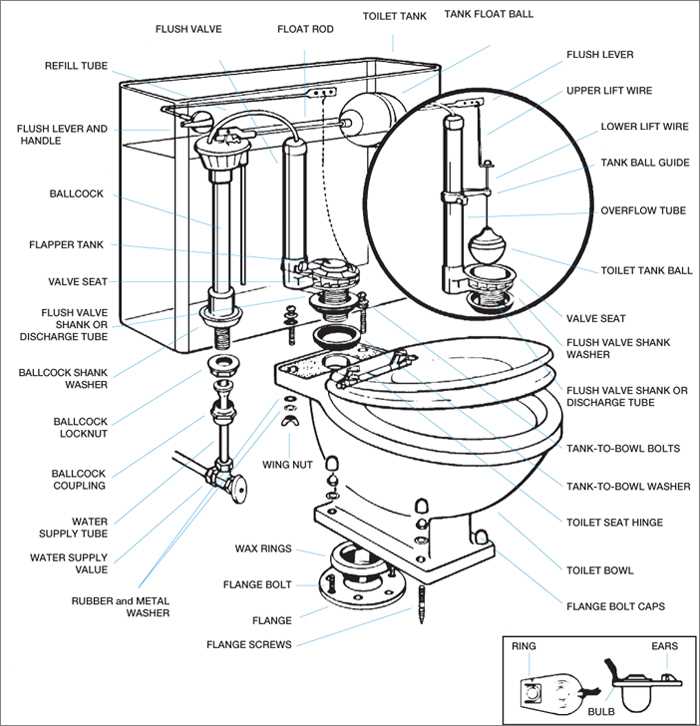

Understanding Key Components of a Toilet Cistern

Every water-based system used for flushing has several integral elements that work together to ensure proper function. These mechanisms regulate water flow, control the release, and enable refilling after each use. A solid understanding of these individual parts helps in recognizing potential issues and maintaining the system efficiently.

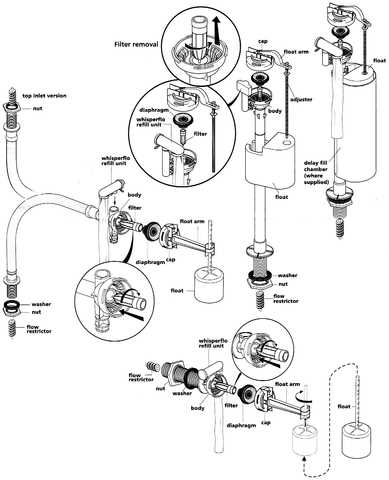

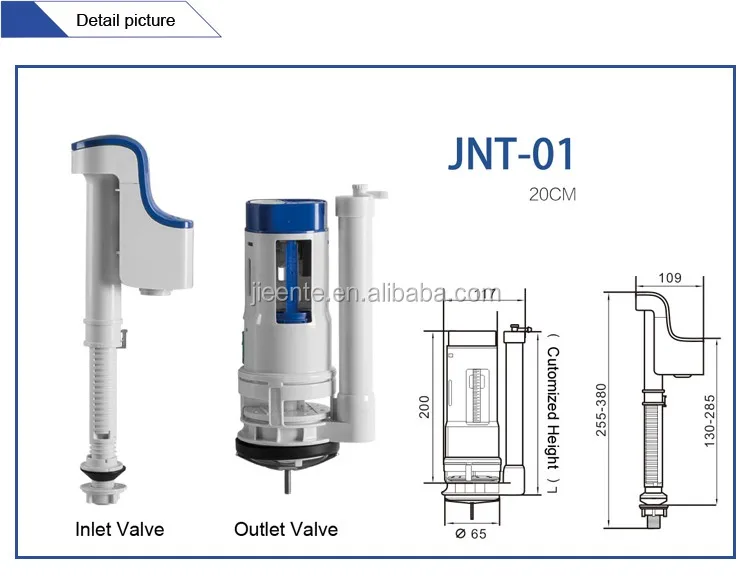

Water Inlet Mechanism is responsible for controlling how and when the water enters the container. It ensures a consistent flow and stops once the desired level is reached, preventing overflow and unnecessary wastage.

Main Functions of a Flush Valve

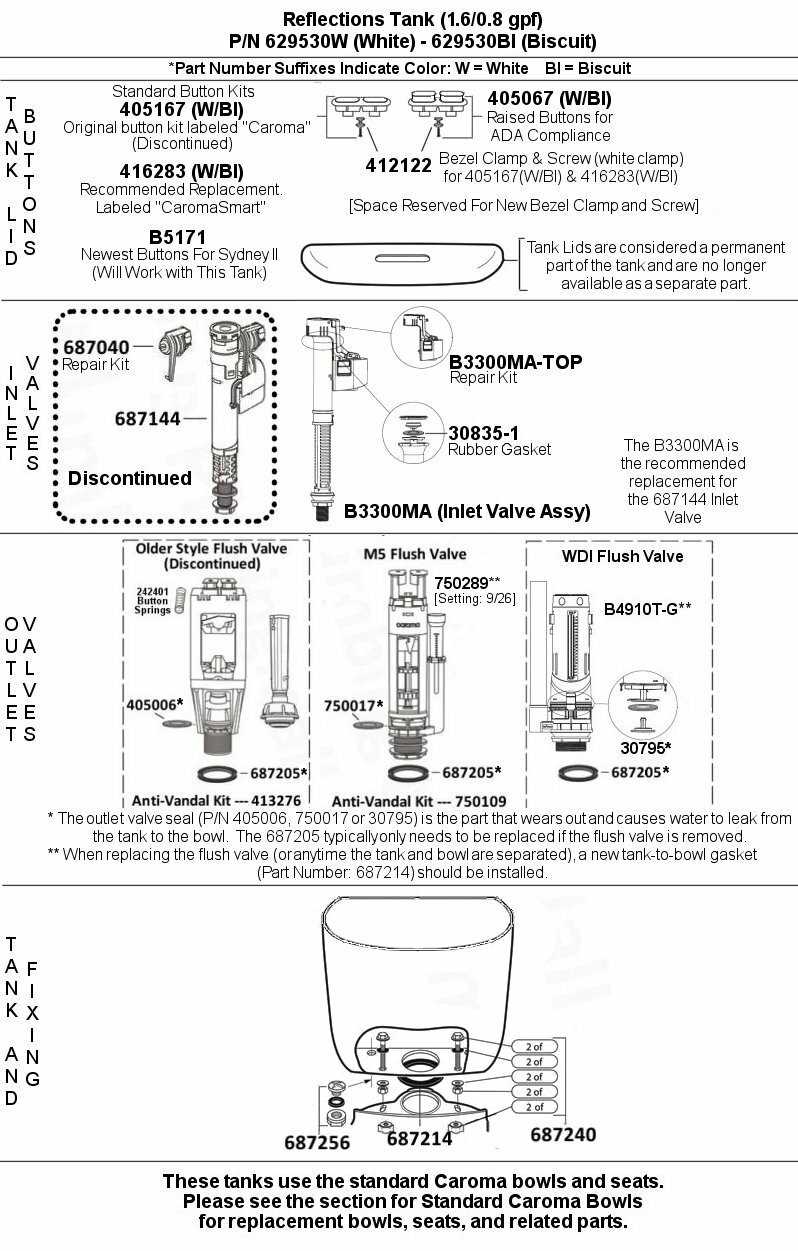

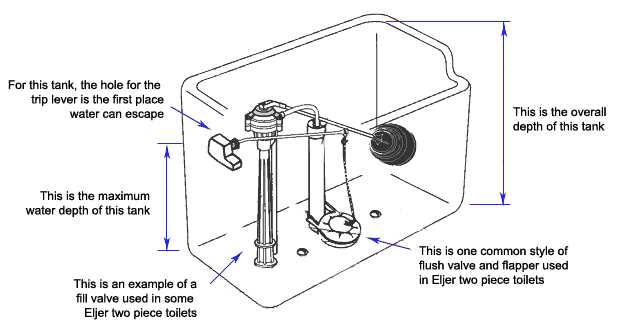

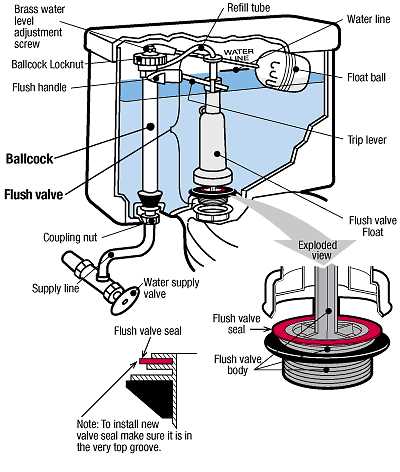

The operation of a flush valve is essential for managing the release of water within a fluid system. It ensures an efficient flow when activated and plays a key role in regulating the movement of liquid. Understanding how it works is important for maintaining effective performance and smooth functioning.

Water Flow Control

One of the primary tasks of the flush valve is to control the flow of water. When triggered, it allows a rapid release of liquid, creating a powerful and efficient cycle. This mechanism ensures that enough liquid is discharged in a short amount of time, enabling optimal fluid movement.

Sealing Mechanism

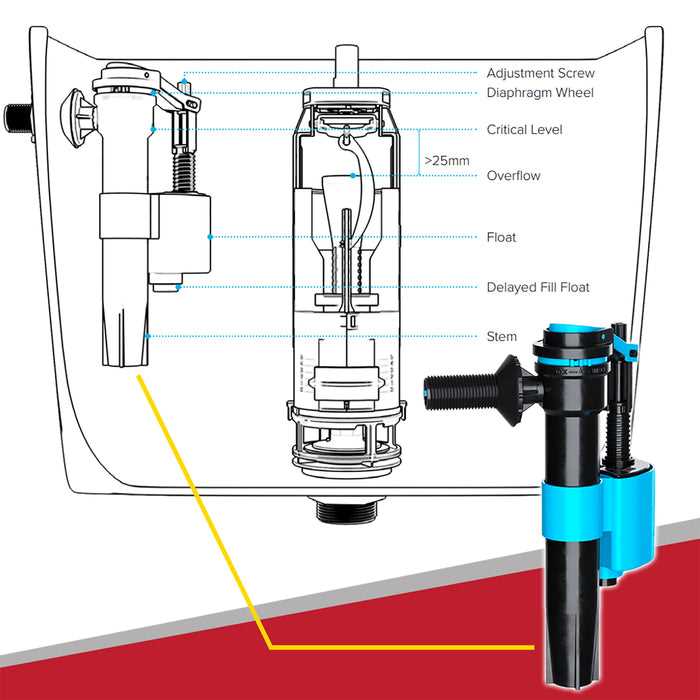

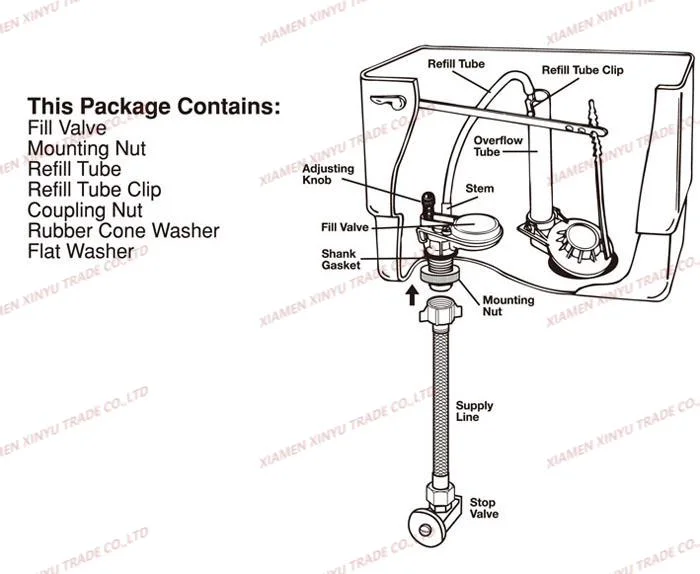

Role of the Fill Valve in Water Control

The fill valve is a crucial mechanism responsible for managing the flow of water, ensuring the proper balance between intake and output. It plays an essential role in maintaining efficient operation by regulating how much liquid enters and leaves the container.

Understanding the function of this component helps to appreciate its impact on overall performance. Below are key aspects of the fill valve’s role:

- Monitors the water level to avoid overflow.

- Ensures a consistent and controlled flow for optimal operation.

- Automatically adjusts the amount of liquid, ensuring the balance between efficiency and conservation.

This mechanism is designed for long-term performance and can significantly affect the smooth functioning of the system it controls.

How the Overflow Pipe Prevents Flooding

The overflow pipe serves as a crucial safety feature in many fluid systems, designed to avert water from rising to dangerous levels. When the liquid reaches a certain height, this mechanism redirects excess water, preventing any potential spillover. This ensures that the surrounding area remains dry and unharmed, even when the water supply continues to flow.

By channeling surplus water away from the main container, the overflow pipe effectively safeguards against flooding. It functions as a reliable barrier, allowing water to escape through a designated route before it causes damage. This simple yet efficient process helps maintain the balance within the system, ensuring smooth operation without any unexpected overflows.

The Importance of a Toilet Flapper

A flapper plays a crucial role in ensuring the proper operation of the water flow mechanism. This simple component acts as a valve that regulates the release and retention of liquid, contributing to both efficiency and overall system functionality. Without it, the entire setup may experience leaks, wasted resources, and operational inconsistencies.

How the Flapper Ensures Proper Operation

The flapper’s ability to open and close at the right moment is essential for maintaining the correct liquid levels. It creates a seal that prevents unnecessary leakage when not in use, and it opens only when the release of water is necessary. This controlled action helps optimize the system’s efficiency and prevents the frequent need for adjustments or repairs.

Common Issues with the Inlet Valve

The inlet valve is a crucial component responsible for regulating water flow into a reservoir. Understanding the frequent problems associated with this mechanism can help in maintaining its functionality and ensuring efficient operation.

One common issue is leakage, which can lead to water wastage and increased utility bills. This may occur due to worn-out seals or misalignment within the valve assembly. Regular inspection can help identify potential leaks before they become significant problems.

Another frequent concern is clogging, caused by debris or mineral buildup. This can hinder the valve’s ability to fill the reservoir effectively, resulting in inadequate water levels. Cleaning the inlet valve periodically can mitigate this issue and enhance overall performance.

Additionally, the valve may experience malfunctions due to pressure fluctuations. Such irregularities can cause the mechanism to stick or fail to close properly, leading to overflow or inefficient filling. Ensuring proper pressure levels is essential for optimal operation.

Sealing Mechanism of the Cistern Gasket

The sealing mechanism of a water storage unit plays a crucial role in maintaining optimal functionality. This essential component ensures a watertight closure, preventing leaks and maintaining pressure within the system. Understanding its operation can help in identifying potential issues and enhancing overall performance.

A well-functioning sealing mechanism is vital for effective water retention. The following elements contribute to its efficiency:

- Material Quality: The choice of materials affects durability and resilience against wear and tear.

- Design Precision: Accurate dimensions and shapes ensure a snug fit, which is critical for preventing leaks.

- Installation Method: Proper installation techniques can significantly impact the sealing capability.

- Maintenance Practices: Regular inspections and timely replacements can prolong the lifespan of the sealing system.

In summary, the sealing mechanism is integral to the effective operation of a water storage unit. Attention to detail in its design, material selection, and maintenance is essential for optimal performance.

Function of the Float Arm in Water Levels

The float arm plays a crucial role in maintaining appropriate fluid levels within a storage unit. This component is designed to respond to changes in the liquid volume, ensuring that the desired height is achieved for optimal performance. By adjusting its position based on the water’s level, the float arm activates or deactivates the filling mechanism, effectively managing the flow of water.

When the liquid level drops, the float arm descends, triggering a valve to allow fresh water to enter the chamber. Conversely, as the liquid rises to the set threshold, the float arm rises, closing the valve and halting further inflow. This mechanism not only conserves water but also prevents overflow, making the float arm an essential feature in the overall system’s efficiency.

Adjusting the Ballcock for Optimal Performance

Ensuring proper functioning of the water supply mechanism is crucial for efficient operation. Fine-tuning this component can lead to significant improvements in water management and prevent unnecessary wastage. This guide outlines the steps to achieve the best performance from your water control system.

Understanding the Mechanism

The water supply system utilizes a float-controlled valve to regulate the inflow of liquid. Familiarizing yourself with its components will aid in effective adjustments:

- Float: Rises and falls with water level changes.

- Valve: Controls the flow based on float position.

- Arm: Connects the float to the valve, allowing for movement.

Adjustment Steps

Follow these steps to calibrate the water control unit properly:

- Check the current water level in the chamber. It should be about an inch below the overflow tube.

- Locate the adjustment screw on the top of the ballcock. This may be a screw or a sliding mechanism.

- Turn the screw clockwise to raise the water level or counterclockwise to lower it. Adjust gradually and check the level after each adjustment.

- Observe the float’s movement. Ensure it moves freely and isn’t obstructed by any components.

- Test the system by flushing and observing the refill process. The water should stop flowing at the correct level without continuous running.

Regular checks and adjustments of the water management system can prolong its lifespan and enhance performance.

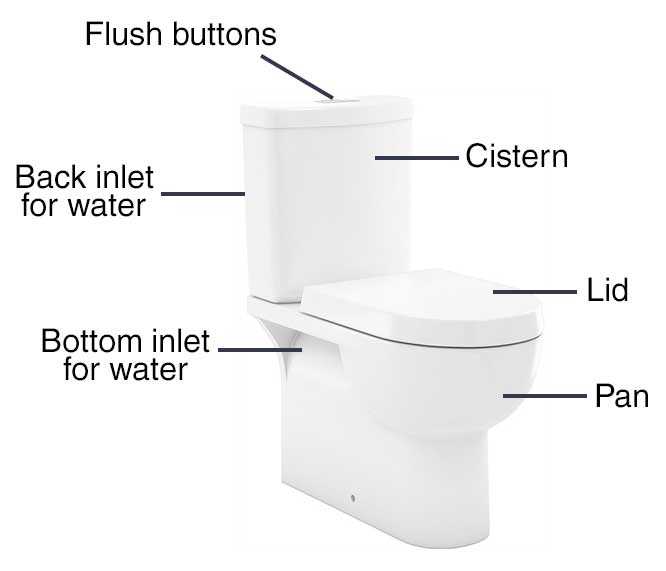

Exploring the Purpose of a Flush Handle

The mechanism responsible for initiating the water flow in a sanitation unit plays a crucial role in its operation. This component is designed to provide users with a convenient means to activate the flushing process, ensuring cleanliness and hygiene. Understanding its functionality is essential for maintaining a well-operating system.

How It Works

The activation mechanism typically involves a simple yet effective design. When the handle is engaged, it triggers a series of actions that result in water being released. Here’s a breakdown of the process:

- Engagement: The handle is pressed down or pulled, initiating the action.

- Linkage: This movement connects to a lever or chain, which facilitates the next step.

- Water Release: The mechanism opens a valve, allowing water to flow into the designated area.

Importance of Proper Functionality

Ensuring that this component operates efficiently is vital for several reasons:

- Hygiene: A well-functioning mechanism helps maintain cleanliness.

- Water Conservation: An efficient design minimizes wasteful usage.

- Ease of Use: A reliable handle ensures user satisfaction and comfort.

How to Replace a Broken Cistern Lever

Dealing with a malfunctioning mechanism can be frustrating, especially when it disrupts your daily routine. A broken lever can prevent the efficient operation of your flushing system, leading to unnecessary inconvenience. Fortunately, replacing this component is a straightforward process that can be accomplished with a few basic tools and a bit of guidance.

Step 1: Gather Your Tools

Before starting the replacement, ensure you have the necessary tools on hand. You will need a screwdriver, adjustable wrench, and possibly a pair of pliers. Having a replacement lever ready will streamline the process.

Step 2: Shut Off the Water Supply

To prevent any water leakage during the procedure, locate the shut-off valve, usually situated near the base of the fixture, and turn it clockwise. This action will stop the flow of water, allowing you to work without worry.

Step 3: Remove the Broken Lever

Carefully unscrew the broken lever from its mounting. Depending on the design, you may need to detach the linkage or any other connecting parts. Keep these components together to facilitate the installation of the new lever.

Step 4: Install the New Lever

Position the replacement lever in the same location as the old one and secure it using screws or clips. Ensure that the linkage is properly connected to guarantee smooth operation. Take a moment to double-check that everything is aligned correctly.

Step 5: Restore Water Supply

Once the new lever is securely in place, turn the water supply back on by rotating the shut-off valve counterclockwise. Allow the mechanism to fill and test the new lever to ensure it functions correctly.

Step 6: Final Checks

Observe for any leaks around the installation area and make sure the lever operates smoothly. If everything is working as it should, you have successfully replaced the broken mechanism!