In the realm of small engine mechanics, grasping the configuration of various elements is essential for effective maintenance and troubleshooting. Each segment of the engine plays a pivotal role in its overall functionality, influencing performance and reliability. By delving into the intricate relationships between these components, one can better appreciate the design and operation of the machinery.

Visual representations of engine structures serve as invaluable resources for both novice enthusiasts and seasoned technicians. They provide a clear overview of how different pieces interconnect, facilitating a deeper understanding of the system. This knowledge empowers users to perform repairs, replacements, and optimizations with greater confidence.

As we explore the specifics of these configurations, we will highlight key features and functions of various elements, enhancing your familiarity with their operational significance. This exploration will guide you through the essential parts that contribute to the engine’s efficiency, ensuring a smoother experience in your maintenance endeavors.

This section aims to provide a comprehensive overview of the essential elements that make up a specific small engine model. By breaking down the various components, users can better understand their functions and how they contribute to the overall performance of the engine.

Key Elements of the Engine

Understanding the key components of this engine model can significantly enhance your ability to maintain and troubleshoot it. The following are the main parts that play a crucial role:

- Cylinder Head

- Piston Assembly

- Crankshaft

- Valves and Springs

- Fuel System

- Ignition Components

Functionality of Each Component

Each of these parts serves a unique purpose, ensuring the engine operates smoothly and efficiently:

- Cylinder Head: Houses the combustion chamber and contains vital components for airflow.

- Piston Assembly: Moves within the cylinder to create the power stroke.

- Crankshaft: Converts linear motion into rotational force.

- Valves and Springs: Control the intake and exhaust of air and fuel.

- Fuel System: Delivers the right mixture of fuel and air for combustion.

- Ignition Components: Initiate the combustion process to power the engine.

Key Parts and Their Functions

The overall performance and durability of an engine depend on the proper functioning of its main components. Each element within the system works together to ensure optimal operation, from ignition to fuel delivery, and contributes to the smooth running of the machine.

Crankshaft: This vital element converts linear energy from the piston into rotational motion. It is responsible for transmitting power to other mechanical parts, enabling the engine to generate movement.

Piston: The piston plays a crucial role in the combustion process by compressing the air-fuel mixture and transferring the energy generated by combustion to the crankshaft.

Valves: Intake and exhaust valves regulate the flow of air and fuel into the chamber and the release of exhaust gases. Proper timing ensures efficient engine cycles

Exploring Engine Assembly Details

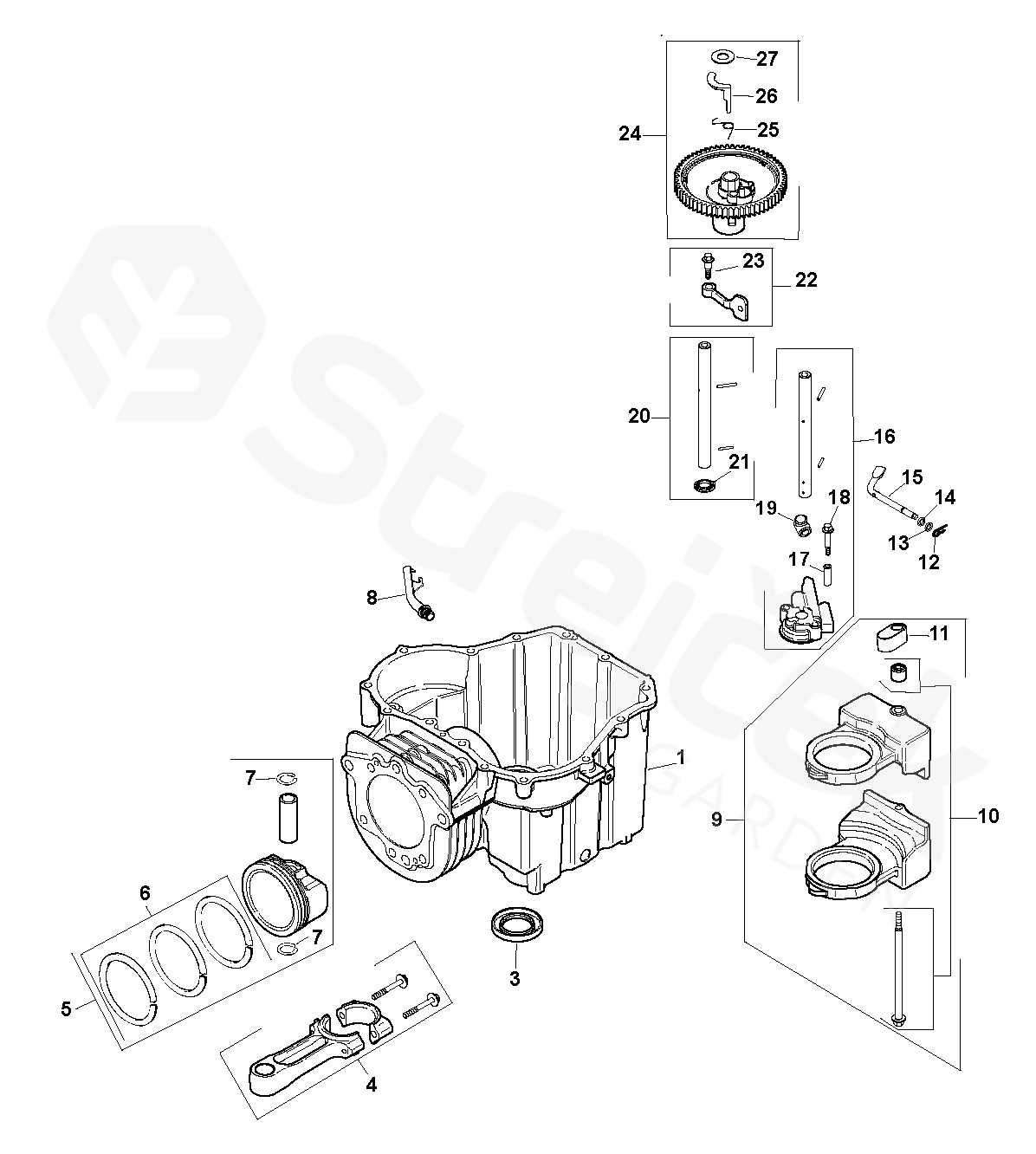

The engine assembly is a complex combination of components that work together to ensure smooth performance and efficient power delivery. Understanding the construction and interaction between different elements is essential for those who maintain or repair the machine. This section delves into the various parts of the engine, emphasizing how they fit and operate as a unified system.

Main Components of the Engine

- Cylinder Block: This is the foundation, housing the moving parts and providing structural support.

- Pistons: Vital for converting fuel energy into mechanical power, the pistons move within the cylinder block.

- Crankshaft: The crankshaft transforms the linear motion of the pistons into rotational energy, driving the engine.

- Camshaft: Responsible for timing the opening and closing of valves, it

Identifying Common Replacement Parts

Maintaining the longevity and performance of a small engine requires awareness of frequently replaced components. These elements endure wear and tear through regular use, making it crucial to recognize when a substitution is needed to ensure continuous operation.

One of the most regularly swapped components is the air filter, responsible for keeping debris out of the internal system. Over time, it becomes clogged, reducing efficiency. Another critical element is the spark plug, which can degrade and affect ignition performance. Regular inspection helps to determine its condition and prevent failures.

The fuel filter also plays a vital role by preventing impurities from entering the fuel system, and it should be changed periodically. Additionally, the oil filter ensures the engine’s lubricant remains clean, prolonging its lifespan and reducing internal friction.

By identifying and replacing these key elements, users can maintain optimal engine functionality, avoid downtime, and extend the lifespan of

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the smooth performance and long life of your equipment. By following a few practical steps, you can keep your machine running efficiently and avoid potential issues that arise from neglect.

- Oil Changes: Make it a habit to replace the engine oil at recommended intervals. Fresh oil helps maintain lubrication, reducing friction and wear on internal components.

- Air Filter Inspection: Routinely check the air filter for debris and dirt. A clean filter allows for better airflow, which is vital for optimal engine function.

- Cooling System Care: Ensure the cooling system remains clear of blockages. Keeping airways open prevents overheating, which can cause long-term damage to the engine.

- Spark Plug Maintenance:

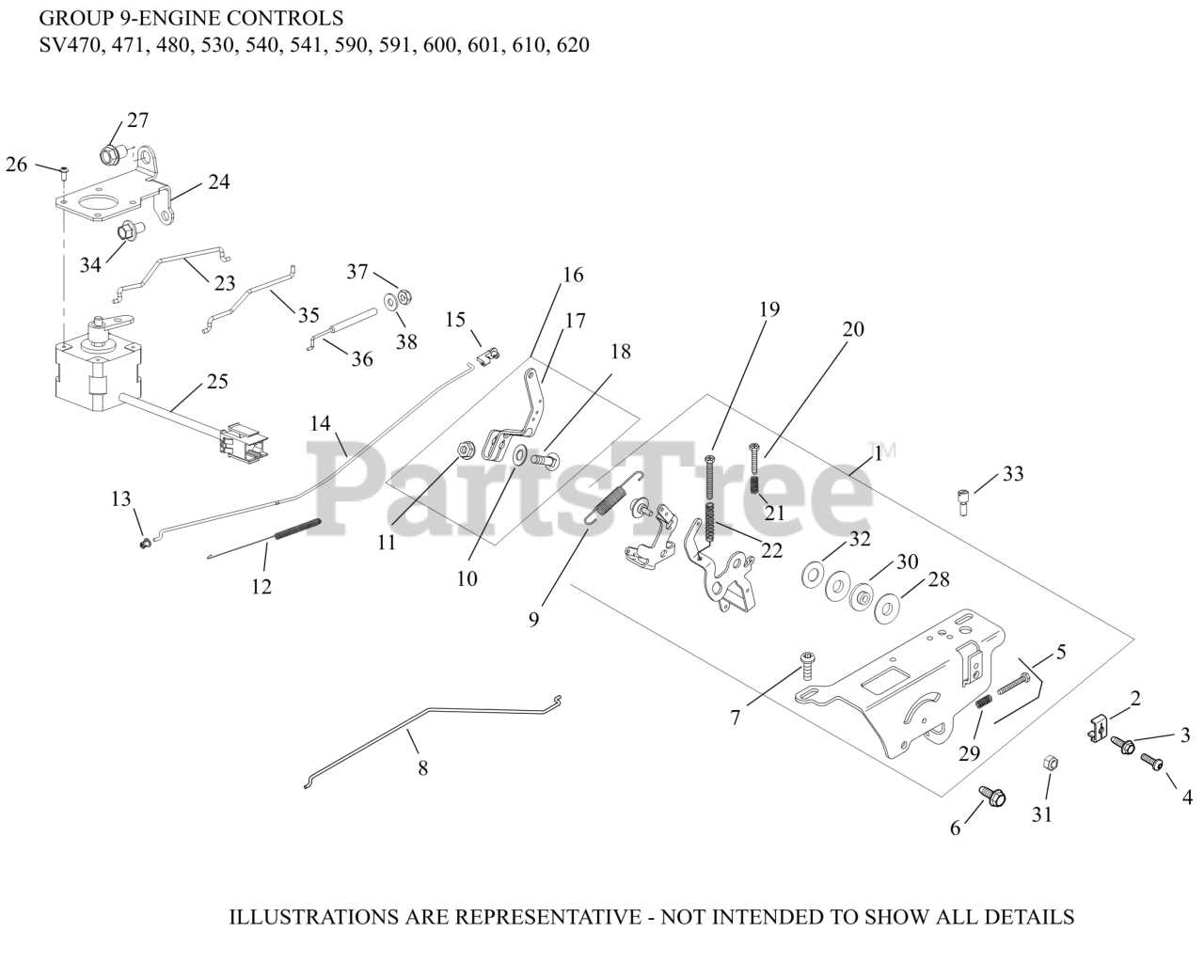

How to Read a Parts Diagram

Understanding how to interpret visual representations of mechanical systems is essential for proper maintenance and repairs. These drawings offer a detailed breakdown of components, helping identify individual elements and their positions within the system.

Identify Component Labels: The first step is to examine the labels associated with each element in the diagram. These tags typically include numbers or letters that correspond to a reference list, providing clarity on each item’s function.

Follow the Structure: Diagrams are usually arranged in a logical sequence, displaying how each element connects to the next. By tracing the flow from one piece to another, you can easily determine how the system functions as a whole.

Use the Legend: Some diagrams

Tools Required for Repairs

Proper maintenance and restoration of mechanical systems demand a set of essential tools that ensure efficient and safe work. Depending on the type of task, having the right equipment on hand can significantly reduce downtime and improve precision during the repair process.

Basic repair tasks often require wrenches, screwdrivers, and pliers. These versatile tools help with loosening or tightening bolts, removing fasteners, and adjusting components. For more intricate work, specialized instruments such as torque wrenches, socket sets, and precision measuring devices may be necessary to ensure exact alignment and secure fitting.

Safety gear, including gloves and protective eyewear, should always be part of the toolkit to prevent injuries while handling sharp or heavy objects. Having a complete, organized toolset at your disposal will contribute to a smoother repair experience and minimize potential risks.

Comparing Similar Engine Models

When evaluating different power units, it’s essential to consider various factors that distinguish one model from another. These differences can include design, functionality, fuel efficiency, and overall performance. By carefully comparing these aspects, it becomes easier to select the best option for specific needs, whether for small-scale operations or more demanding tasks.

Performance and Efficiency

Power output and fuel consumption are two key elements that play a significant role in the choice of a motor. Some engines are designed with better fuel efficiency in mind, ideal for long-term use without compromising on output. Meanwhile, other models may focus on delivering maximum power, which is useful in heavy-duty applications. Understanding the balance between power and efficiency is crucial in making an informed decision.

Common Issues and Solutions

When dealing with engine systems, mechanical problems may arise due to regular wear or improper use. Identifying these challenges early and applying the correct fixes can extend the lifespan of the equipment and ensure optimal performance.

- Starting Problems: A common issue is difficulty starting the engine. This could be due to a faulty ignition switch, drained battery, or clogged fuel lines. Ensuring proper electrical connections and checking fuel flow can resolve this.

- Overheating: Engines can overheat when airflow is obstructed or when there’s insufficient lubrication. Regular cleaning of cooling fins and checking oil levels can prevent this from happening.

- Power Loss: A noticeable reduction in power output may stem from a dirty air filter, improper fuel mix, or issues with the carb

Ordering Genuine Replacement Parts

When it comes to maintaining the efficiency and performance of your equipment, using authentic spare components is essential. Genuine replacements are designed to fit perfectly and ensure long-term durability, reducing the risk of breakdowns and ensuring smooth operation.

To make sure you get the correct replacements, follow these steps:

- Check the model and serial number of your equipment for compatibility.

- Consult the official manual or reference guide for detailed information about the required components.

- Order from authorized distributors or the manufacturer’s official website to guarantee authenticity.

- Keep

Wiring Diagrams for Troubleshooting

Electrical systems can be complex, and when issues arise, detailed circuit layouts are essential for identifying the root cause of malfunctions. By analyzing these layouts, one can pinpoint broken connections, short circuits, or improper wiring. Understanding how to read and interpret these visuals is crucial for efficient problem-solving.

Key Components and Connections

Each component in an electrical system relies on proper connections to function correctly. The most common elements include switches, power sources, grounding points, and relays. The diagram will typically illustrate these components using standardized symbols, allowing for easy recognition of each part and its corresponding wiring path.

Exploring Upgrades and Modifications

Enhancing the performance and efficiency of small engines can lead to significant improvements in their functionality and longevity. By incorporating various upgrades and modifications, users can achieve better power output, fuel efficiency, and overall operational reliability. This section discusses the potential enhancements available for these engines, focusing on practical solutions that can be easily implemented.

When considering upgrades, it’s essential to evaluate several components that can be modified or replaced. Common areas for improvement include the ignition system, air intake, and exhaust. Below is a table summarizing popular modifications and their benefits:

Modification Description Benefits High-Performance Air Filter Replaces the standard filter with a less restrictive option. Increases airflow, enhancing combustion efficiency. Upgraded Ignition Coil Installs a coil that provides a stronger spark. Improves ignition timing and fuel burn, boosting power. Custom Exhaust System Replaces the factory exhaust with a free-flowing design. Reduces back pressure, leading to increased horsepower. Tuning Chip Adjusts engine parameters for optimized performance. Enhances fuel management and responsiveness. Implementing these modifications can transform an ordinary engine into a more powerful and efficient machine. It’s crucial to approach these upgrades thoughtfully, considering compatibility and the intended use of the equipment to maximize the benefits.

FAQs About Kohler Engines

This section aims to address common inquiries regarding small power units, providing clarity on various aspects of their operation, maintenance, and troubleshooting. Whether you’re a seasoned user or new to these machines, understanding the intricacies can enhance performance and longevity.

What are the common issues faced with small power units?

Users often encounter challenges such as difficulty starting, irregular performance, or unexpected shutdowns. Regular maintenance and proper fuel management can mitigate many of these problems.

How often should maintenance be performed?

It is advisable to conduct routine inspections and servicing every 50 to 100 hours of operation, or at least once a season. This includes oil changes, air filter replacements, and spark plug inspections.

What type of fuel should be used?

Most engines operate efficiently on standard unleaded gasoline, although it’s crucial to avoid fuel with a high ethanol content, as it can cause damage over time.

Can I perform repairs myself?

Basic maintenance tasks can be handled by users with mechanical skills. However, for more complex repairs, consulting a professional is recommended to ensure safety and proper functioning.

Where can I find replacement components?

Replacement parts are typically available at authorized dealers, online retailers, or local repair shops specializing in power equipment.