Maintaining a well-groomed outdoor space often relies on the efficiency of various gardening tools. Each device consists of multiple elements that work in harmony to achieve the desired results. A comprehensive exploration of these components not only enhances the functionality of your equipment but also extends its lifespan.

Gaining insight into the specific elements that make up your gardening machinery is essential for effective maintenance and repairs. By familiarizing yourself with each component, you can quickly identify issues and make informed decisions when replacements are needed. This understanding ultimately contributes to a more efficient and reliable gardening experience.

In this section, we will delve into the intricacies of the individual elements found within your equipment. By breaking down their functions and relationships, you will gain a clearer perspective on how to optimize your gardening tools for peak performance.

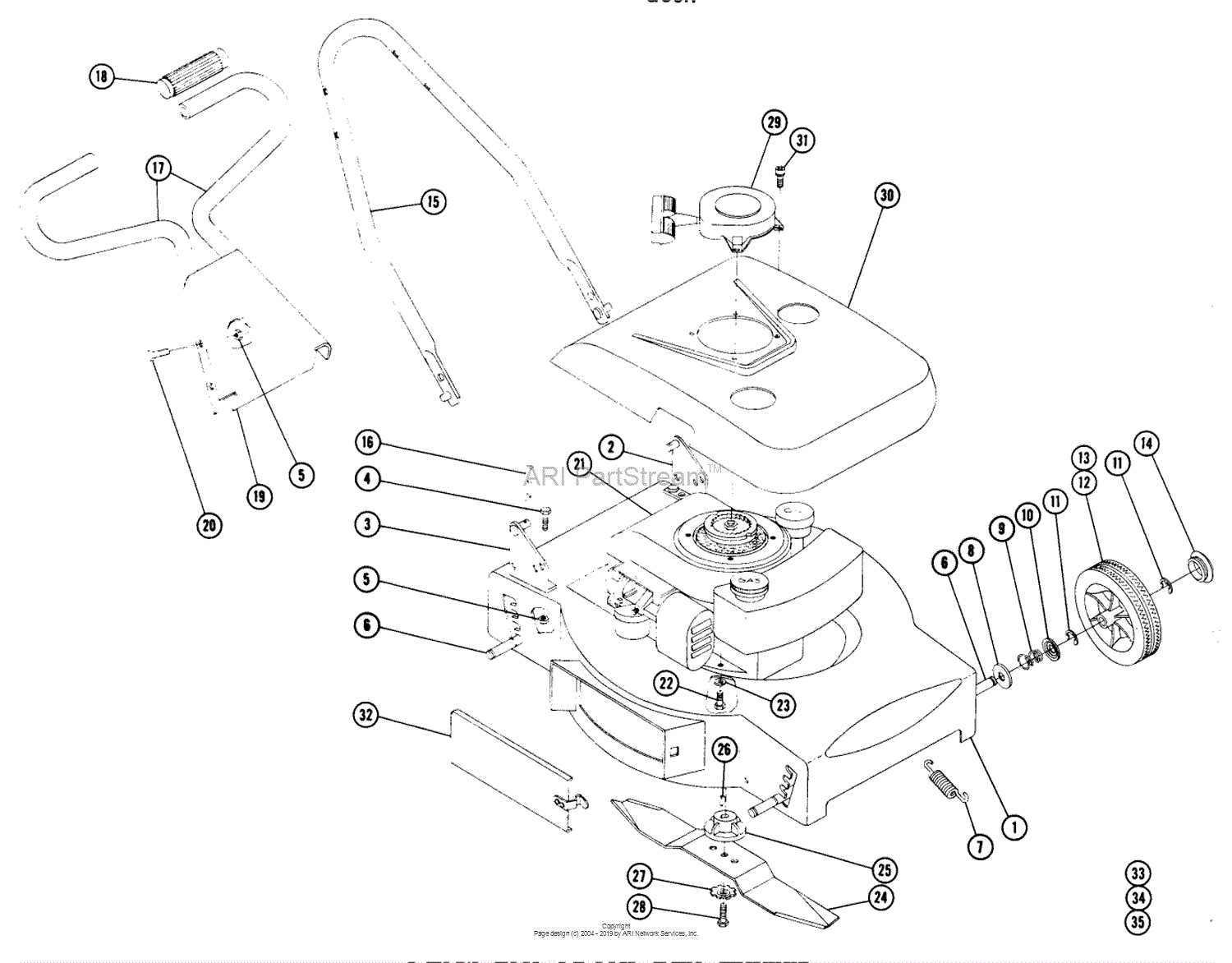

This section aims to provide a comprehensive overview of the various elements that constitute a specific type of grass cutting machine. By exploring these components, readers can gain insights into their functions, how they interact, and the importance of each part in ensuring efficient operation.

| Component Name | Description | Function |

|---|---|---|

| Engine | The power unit responsible for driving the machine. | Generates the necessary force for movement and cutting. |

| Cutting Blade | A sharp metal blade that trims the grass. | Provides the primary cutting action for achieving an even lawn. |

| Deck | The housing that contains the cutting mechanism. | Protects the internal components and helps guide grass clippings. |

| Wheels | Round components that allow the machine to move. | Facilitate maneuverability and control over different terrains. |

| Handlebar | The grip area for operator control. | Provides stability and guidance during operation. |

| Grass Bag | A collection unit for clippings. | Holds cut grass, minimizing debris on the lawn. |

Essential Parts of Your Mower

Understanding the key components of your lawn equipment is crucial for maintaining its efficiency and longevity. Each element plays a vital role in ensuring smooth operation, allowing for effective grass cutting and overall performance. Familiarizing yourself with these essential elements will enable you to make informed decisions regarding maintenance and repairs.

Cutting Mechanism

The cutting mechanism is the heart of the machine, responsible for achieving a precise and even trim. This component typically includes sharp blades that rotate at high speeds, allowing them to slice through grass effortlessly. Regular inspection and sharpening of these blades are necessary to maintain optimal performance and achieve the desired results.

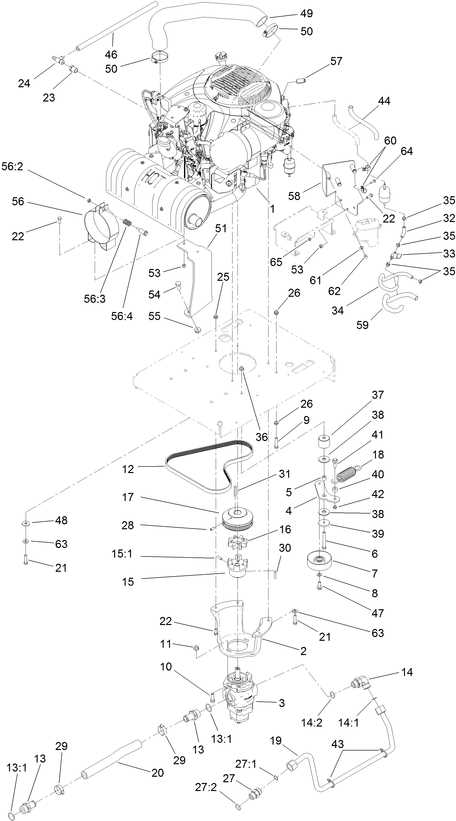

Engine and Drive System

The engine powers the entire unit, converting fuel into mechanical energy to facilitate movement and operation. Alongside the engine, the drive system transmits this energy to the wheels, enabling the device to navigate across various terrains. Ensuring both the engine and drive system are in good condition is essential for reliable performance.

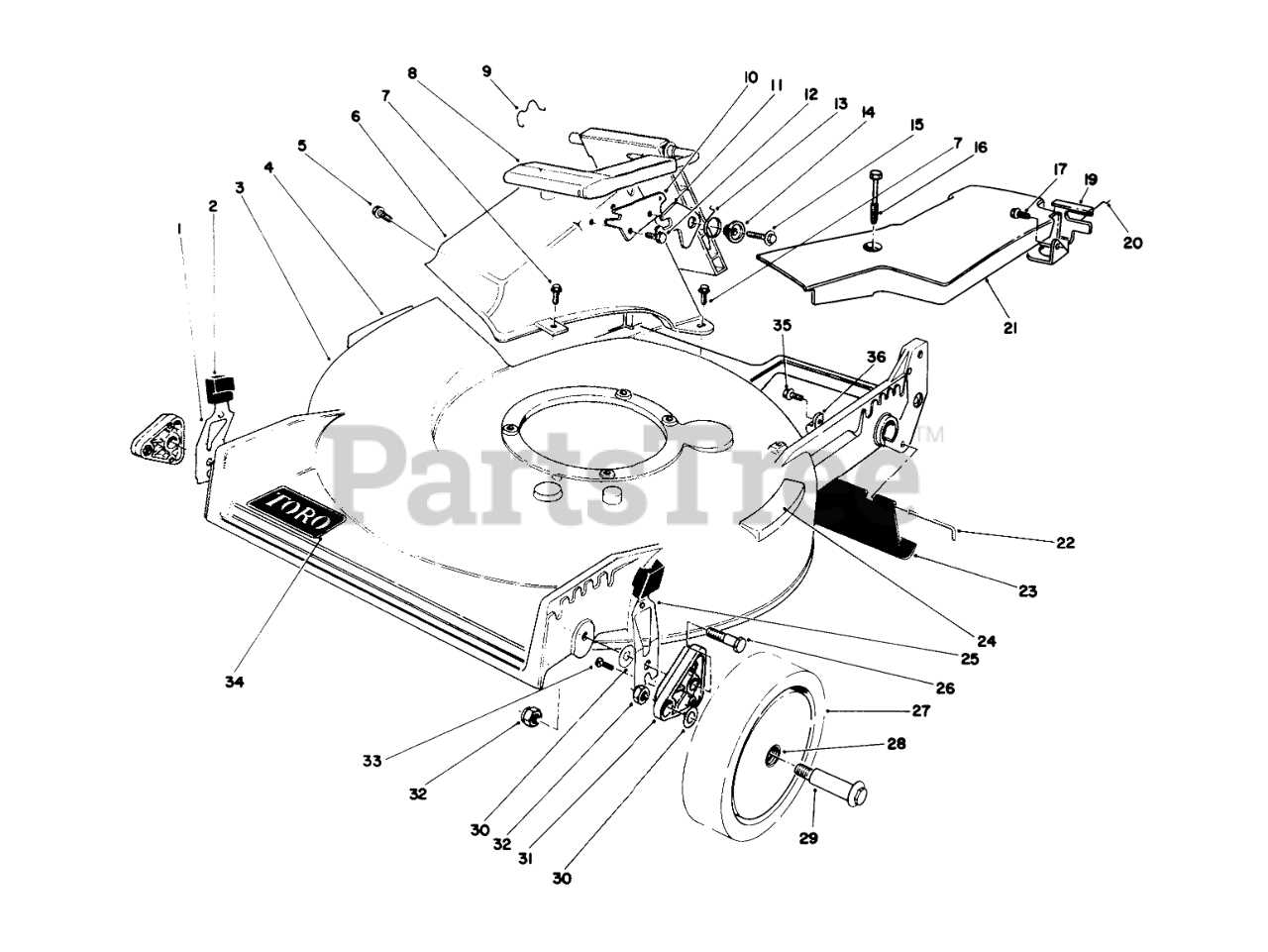

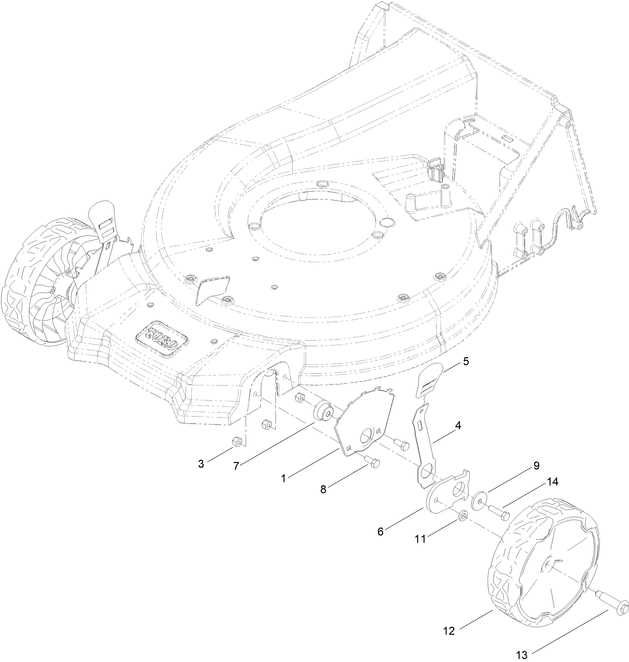

Identifying Key Features in Diagrams

Understanding the essential elements in visual representations is crucial for effective comprehension and analysis. These illustrations often convey significant information through various components, enabling users to interpret and utilize the information efficiently.

Essential Elements to Consider

- Labels: Clear identification of each section or component allows for quick reference and understanding.

- Symbols: Specific icons or shapes that represent various functionalities can enhance clarity and convey meaning effectively.

- Color Coding: Utilizing different colors can help distinguish between various types of elements, making it easier to follow and understand.

- Legends: A key or legend provides essential explanations for symbols and colors, aiding in the overall interpretation of the representation.

Tips for Effective Interpretation

- Start by familiarizing yourself with the overall layout and flow of the illustration.

- Pay attention to the labels and symbols, ensuring you understand their meanings.

- Use the legend to clarify any uncertainties regarding the color coding or symbols.

- Cross-reference with any accompanying documentation for additional context and information.

Common Issues with Mower Parts

Understanding the frequent problems that can arise with various components of a grass-cutting machine is essential for maintaining optimal performance. Regular maintenance and awareness of potential issues can help prevent breakdowns and prolong the lifespan of the equipment.

Frequent Mechanical Failures

- Worn-out blades: Dull or damaged cutting edges can lead to inefficient grass trimming, requiring more power and time.

- Engine troubles: Problems such as hard starting, stalling, or lack of power may stem from fuel issues, air blockages, or spark plug malfunctions.

- Transmission issues: Difficulty in changing speeds or erratic movement can indicate wear in the drive components or cable problems.

Maintenance Challenges

- Clogged air filters: Reduced airflow can lead to performance issues and engine overheating.

- Fuel system problems: Contaminated fuel or old gasoline can cause starting difficulties and operational inconsistencies.

- Corroded battery terminals: Poor connections can result in electrical failures, making starting and operation unreliable.

Maintenance Tips for Toro Mowers

Proper upkeep is essential for ensuring the longevity and efficiency of your lawn equipment. Regular attention to various components can significantly enhance performance and reduce the likelihood of issues. By following a few straightforward practices, you can keep your machinery in optimal condition.

Regular Cleaning

Cleaning the exterior and interior of the equipment is vital. Grass clippings and debris can accumulate and affect performance. After each use, take a moment to remove any buildup from the blades and undercarriage. This not only keeps the device functioning well but also prevents rust and deterioration.

Inspection and Lubrication

Perform routine inspections to identify any wear and tear on essential components. Pay close attention to belts, cables, and the engine. Additionally, applying the appropriate lubricant to moving parts can minimize friction and enhance efficiency. Regular maintenance checks can help catch potential problems early and save on costly repairs.

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repairs. These visual representations provide a clear overview of components, their arrangement, and how they interact within the overall structure. Mastering the art of interpreting these graphics can enhance your ability to identify issues and streamline replacement processes.

Familiarize Yourself with Symbols

Each illustration uses specific symbols to represent different elements. Familiarizing yourself with these icons will help you quickly locate components and comprehend their functions. Look for a legend or key that explains the symbols used in the illustration, as this can provide valuable insights into the layout.

Follow the Flow of Assembly

When analyzing an illustration, it is important to follow the assembly sequence. Components are often arranged in a manner that reflects the order in which they are assembled. By tracing this flow, you can gain a better understanding of how each piece fits into the overall mechanism and identify potential areas of concern.

Ordering Replacement Components

When it comes to maintaining your equipment, acquiring the right components is essential for ensuring optimal performance. Understanding the process of obtaining these necessary items can help you keep your machinery running smoothly.

To successfully order replacement components, consider the following steps:

- Identify the Required Components: Start by determining which specific items you need. Referencing a schematic or a list of components can be beneficial.

- Check Availability: Look for reliable suppliers, both online and local, to see if they have the needed items in stock.

- Verify Compatibility: Ensure that the components you intend to purchase are compatible with your specific model.

- Compare Prices: Before making a purchase, compare prices from different suppliers to get the best deal.

- Place Your Order: Once you have confirmed compatibility and found the right price, proceed with placing your order.

Following these steps can streamline the process of acquiring replacement components, leading to more efficient upkeep of your machinery.

Assembly Instructions for Mower Parts

Proper assembly of the components is crucial for optimal performance and longevity of your equipment. Each section should be carefully fitted to ensure stability and functionality. Following a systematic approach can simplify the process and prevent errors.

Begin by organizing all necessary elements, ensuring that you have everything at hand. Identify each component and refer to the included instructions for guidance. It’s essential to match each piece with its corresponding location, checking for any discrepancies before proceeding.

Step 1: Start by attaching the main body. Ensure it is aligned correctly to avoid any misfits. Use the provided fasteners to secure it in place, tightening them adequately without over-torquing.

Step 2: Next, focus on the blade assembly. Carefully position the cutting element, ensuring it fits snugly within the designated area. Utilize the locking mechanism to hold it securely, preventing any accidental disengagement during operation.

Step 3: Proceed to attach the handle. Adjust its height for comfort and ensure it locks into place firmly. A properly positioned handle enhances maneuverability and user experience.

Step 4: Finally, double-check all connections. Ensure there are no loose fittings, and confirm that everything is assembled according to the specifications. This final inspection is vital for safe and efficient use.

By following these straightforward instructions, you can effectively assemble your equipment and enjoy a smooth operation for all your outdoor tasks.

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right tools is essential for efficient and effective work. Proper instruments not only expedite the repair process but also ensure that tasks are completed with accuracy and safety. Below is a list of essential tools that will aid in the repair and upkeep of your machinery.

Basic Tools

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing and tightening screws.

- Wrenches: A set of adjustable and socket wrenches will help with various nuts and bolts.

- Pliers: Needle-nose and regular pliers are useful for gripping and bending wires.

- Hex Keys: These are vital for assembling and disassembling components with hexagonal sockets.

Specialized Tools

- Torque Wrench: Ensures that nuts and bolts are tightened to the correct specifications.

- Oil Filter Wrench: Simplifies the removal and installation of oil filters.

- Diagnostic Tools: Such as multimeters, can help troubleshoot electrical issues.

- Cleaning Brushes: Essential for removing dirt and debris from engine parts.

Having these tools on hand will make any repair task more manageable and help maintain the longevity of your equipment.

Safety Precautions During Maintenance

When performing maintenance tasks on outdoor equipment, ensuring safety is of utmost importance. Proper precautions help prevent accidents and injuries, creating a secure environment for both the individual working on the machinery and those nearby. Understanding and implementing these measures can significantly reduce risks associated with maintenance activities.

Preparation Before Maintenance

Prior to starting any maintenance work, it is essential to prepare adequately. Always read the manufacturer’s instructions to familiarize yourself with the specific safety guidelines for the equipment. Ensure the machine is turned off and has cooled down completely. Disconnecting the power source is crucial to avoid any accidental activation while servicing.

Using Protective Gear

Wearing appropriate protective gear can mitigate potential hazards. Utilize gloves to protect your hands from sharp edges or moving parts, and safety goggles to shield your eyes from debris. Additionally, sturdy footwear is recommended to provide support and protect against heavy items that may fall during the maintenance process.

Benefits of Regular Parts Inspection

Conducting frequent evaluations of machine components is essential for maintaining optimal performance and extending the lifespan of equipment. Regular checks help identify potential issues before they escalate, ensuring reliable operation and reducing the likelihood of unexpected breakdowns.

One of the primary advantages of systematic inspections is the enhancement of safety. By ensuring that all elements are functioning correctly, operators can minimize the risk of accidents and injuries. Furthermore, addressing wear and tear promptly can lead to significant cost savings by preventing extensive repairs or replacements.

In addition, regular evaluations contribute to improved efficiency. Well-maintained machinery operates more smoothly and effectively, resulting in better fuel consumption and overall productivity. This not only benefits the operator but also positively impacts the environment by reducing emissions associated with poorly functioning equipment.

In summary, prioritizing routine assessments of equipment components is a proactive approach that yields multiple benefits. From ensuring safety and efficiency to prolonging the lifespan of machinery, the importance of regular inspections cannot be overstated.