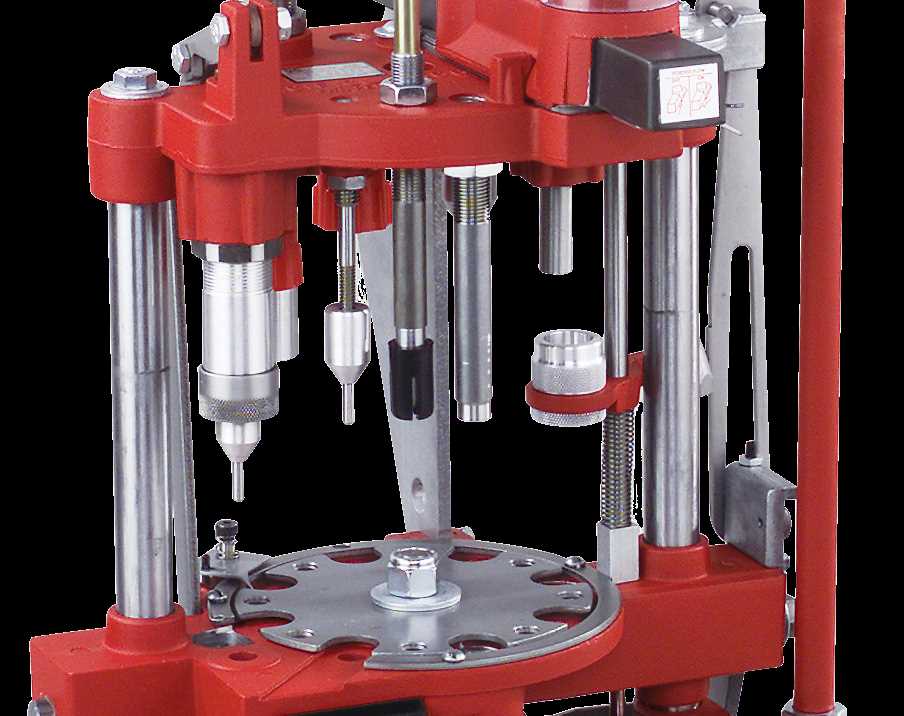

In the realm of ammunition reloading, having a clear visualization of the intricate assembly of your equipment can greatly enhance both efficiency and accuracy. A comprehensive overview of the individual elements involved allows users to familiarize themselves with their tools, ensuring that each component functions optimally within the larger system.

The interplay of various mechanisms is essential for achieving seamless operation. By exploring a detailed representation of these units, enthusiasts can identify potential wear and tear, facilitating timely maintenance and repairs. This not only prolongs the lifespan of the equipment but also contributes to improved performance during reloading sessions.

Additionally, grasping the layout and relationship between different components empowers users to make informed decisions when upgrading or replacing parts. Whether you are a novice or a seasoned reloader, having this knowledge at your fingertips can significantly enhance your overall experience and outcomes.

Understanding Hornady 366 Parts Diagram

Gaining insight into the components of a specific reloading device is essential for both novice and experienced users. This knowledge allows for better maintenance, efficient troubleshooting, and a deeper appreciation of how each element contributes to overall functionality. A comprehensive look at the internal structure enhances operational understanding and can ultimately improve reloading performance.

| Component | Description |

|---|---|

| Frame | The main body providing support and housing for various elements. |

| Ram | Responsible for the movement of shells through different stages. |

| Dies | Specialized tools used for shaping and resizing cartridges. |

| Feed Mechanism | Facilitates the smooth loading of components into the press. |

| Shell Holder | Secures the cartridge during the resizing process. |

Overview of Hornady 366 Press

This innovative reloading tool is designed for precision and efficiency, offering users a seamless experience in crafting ammunition. Its robust construction and user-friendly interface make it an ideal choice for both novice and experienced reloaders alike.

Key Features

- Durable design ensures longevity and reliability.

- Automatic indexing streamlines the reloading process.

- Customizable settings for various calibers enhance versatility.

- Integrated safety mechanisms promote user protection.

Benefits of Using This Reloading Tool

- Increased consistency in ammunition quality.

- Time-saving operations lead to higher productivity.

- Cost-effectiveness compared to purchasing factory-loaded rounds.

- Ability to tailor loads to specific shooting needs.

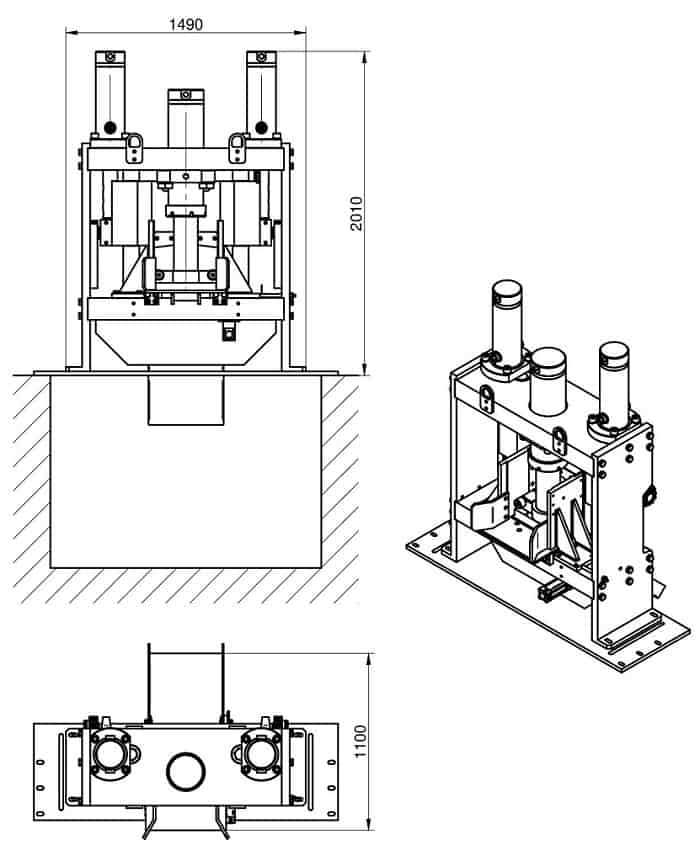

Importance of Accurate Parts Diagram

A precise representation of components is crucial in ensuring efficient maintenance and troubleshooting processes. It serves as a reference that aids users in identifying each element’s function and placement, ultimately enhancing the overall performance and longevity of the equipment. Without an accurate illustration, the risk of misassembly or part misplacement increases significantly, leading to potential operational issues.

Such a visual guide not only supports the user in understanding the intricacies of their device but also fosters a deeper appreciation for its engineering. Knowledge of individual components allows for informed decision-making during repairs and upgrades, contributing to optimal usage.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Clear visuals help users grasp the roles of various elements. |

| Efficient Repairs | Accurate layouts facilitate quicker troubleshooting and reassembly. |

| Reduced Errors | Minimizes the likelihood of mistakes during maintenance tasks. |

| Improved Longevity | Proper care and assembly lead to longer-lasting equipment performance. |

In summary, a well-crafted representation is indispensable for users aiming to maintain their equipment effectively, ensuring both safety and efficiency in its operation.

Key Components of Hornady 366

Understanding the essential elements of this reloading machine is crucial for both novice and experienced users. Each component plays a significant role in ensuring optimal performance and efficiency during the reloading process.

The primary elements include:

- Frame: The sturdy structure that supports all other components, providing stability during operation.

- Die Station: The area where the resizing and shaping of the cartridge takes place, allowing for precision adjustments.

- Shell Holder: This piece securely grips the case, ensuring it remains in place while being processed.

- Feed Mechanism: A crucial system that automates the insertion of cases into the working area, enhancing efficiency.

- Priming System: An integrated feature that simplifies the process of seating primers into the cases, reducing manual effort.

In addition to these core components, various accessories and enhancements can be added to further improve functionality and tailor the machine to specific needs:

- Conversion Kits: Allowing users to switch between different calibers effortlessly.

- Powder Measures: Ensuring accurate and consistent powder charges for each reload.

- Case Trimmers: Providing the ability to maintain optimal case length for better performance.

By familiarizing oneself with these integral parts, users can maximize the potential of their reloading equipment, leading to enhanced precision and overall satisfaction in the reloading experience.

Common Issues with Hornady 366 Parts

When operating a reloading machine, several frequent complications may arise that can hinder performance. Understanding these common problems is essential for maintaining efficiency and ensuring high-quality ammunition production.

- Improper alignment of components

- Frequent jams or misfeeds

- Wear and tear on critical elements

- Difficulty in adjusting settings

- Inconsistent powder charges

To effectively address these issues, users should regularly inspect the equipment, ensure proper lubrication, and replace any worn-out components promptly.

Identifying Parts in the Diagram

Understanding the components of a mechanical system is essential for efficient operation and maintenance. A clear visual representation helps users recognize each element and its function within the assembly. This familiarity not only enhances the overall user experience but also aids in troubleshooting and repairs.

Common Components

Typically, the illustration showcases various integral sections such as the frame, operational mechanisms, and control features. Each part is labeled for easy identification, allowing users to locate and comprehend the role of every individual piece in the structure. Recognizing these components is the first step toward effective handling.

Assembly and Maintenance Tips

When examining the visual guide, it is advisable to cross-reference the labeled sections with a maintenance manual. This practice ensures that users are well-informed about assembly procedures and can confidently perform routine upkeep. Additionally, understanding the layout assists in identifying potential wear or damage, promoting timely interventions.

Step-by-Step Assembly Guide

Assembling your reloading equipment can be a rewarding experience, providing you with the satisfaction of crafting your own ammunition. This guide will walk you through the process in a clear and concise manner, ensuring you understand each stage. Following these steps carefully will help you achieve a well-functioning setup.

Preparation and Gathering Tools

Before you start, make sure to collect all necessary components and tools. This may include screws, washers, and other essential items specific to your equipment. Having everything on hand will streamline the assembly process and prevent unnecessary interruptions.

Assembly Steps

Begin by consulting the provided instructions, ensuring you have a clear understanding of the sequence. Start with the base, attaching it securely to provide a stable foundation. Progressively add components, checking each connection for tightness. Take your time with each step to avoid mistakes. Once fully assembled, conduct a thorough inspection to ensure everything is in place before use. Happy reloading!

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent attention and care. Regular maintenance not only prolongs the lifespan of components but also enhances performance and safety. Implementing a few key practices can significantly impact reliability and usability.

Regular Cleaning: Keeping your machinery free from dust and debris is essential. Regularly wipe down surfaces and ensure that moving parts are clear of obstructions.

Lubrication: Apply appropriate lubricants to moving components to minimize friction and wear. This helps maintain smooth operation and reduces the likelihood of breakdowns.

Inspection: Frequently inspect all elements for signs of wear or damage. Addressing issues promptly can prevent more serious problems from developing.

Storage: Store your equipment in a dry, controlled environment to prevent rust and corrosion. Proper storage conditions help maintain overall functionality.

Documentation: Keep a maintenance log to track inspections and repairs. This can assist in identifying patterns and predicting future needs.

Replacing Worn-Out Components

Regular maintenance is crucial for ensuring optimal performance of machinery. Over time, certain elements may deteriorate, affecting overall efficiency and reliability. Identifying and substituting these aged parts can significantly enhance functionality and extend the life of your equipment.

Signs of Wear

Recognizing the indicators of degradation is essential for timely intervention. Common symptoms include unusual noises, reduced effectiveness, and visible damage. Monitoring these signs helps prevent further complications.

Replacement Process

When it’s time to replace components, follow these steps to ensure a smooth transition:

| Step | Description |

|---|---|

| 1 | Disconnect power and ensure safety measures are in place. |

| 2 | Remove the old component carefully to avoid damage. |

| 3 | Install the new part, ensuring proper alignment and fit. |

| 4 | Reconnect power and test the system for functionality. |

Customization Options for Hornady 366

When it comes to enhancing the functionality of reloading equipment, enthusiasts often seek ways to tailor their machines to better suit their needs. Various modifications and upgrades can significantly improve performance, streamline the reloading process, and provide greater versatility for different calibers and loads.

Accessory Upgrades

One of the most popular methods of personalizing your reloading setup is by incorporating accessories. Upgrading components such as the shell plate, powder measure, and resizing dies can greatly enhance accuracy and efficiency. Custom die sets allow users to achieve specific dimensions and tolerances, ensuring that each round is loaded to perfection.

Adjustable Features

Another effective way to customize your machine is by utilizing adjustable features. This includes modifications like height and tension settings, which can accommodate various shell types and sizes. By fine-tuning these elements, reloaders can achieve a more consistent operation, reducing the likelihood of errors during the reloading cycle.

Resources for Parts and Support

Finding reliable assistance and components for your equipment can be crucial for ensuring optimal performance and longevity. This section aims to provide valuable information and avenues for obtaining necessary items, as well as support services tailored to meet your needs. Whether you are looking for specific components or require guidance on maintenance, various resources are available to help you navigate your options effectively.

Manufacturer’s Website: The primary source of information is often the official website of the equipment maker. Here, you can access manuals, instructional materials, and product specifications that are vital for understanding your machinery’s requirements.

Authorized Dealers: Establishing contact with authorized retailers can provide you with high-quality components and knowledgeable support. These dealers are well-versed in the products and can offer expert advice on compatibility and installation.

Online Communities: Engaging with online forums and social media groups dedicated to your equipment can foster a sense of community. Enthusiasts and experts share their experiences, troubleshooting tips, and recommendations, which can be invaluable for both new and seasoned users.

Local Repair Shops: Many local service centers specialize in maintenance and repairs. Building a relationship with a trusted technician can ensure that your equipment receives proper care, and they may also have access to components not readily available elsewhere.

Technical Support Lines: Don’t hesitate to reach out to customer service for assistance. Many manufacturers offer dedicated support lines where you can ask questions, report issues, or seek advice on your machinery.

By exploring these various resources, you can enhance your understanding and management of your equipment, ensuring it remains in top working condition for years to come.

Comparing Hornady 366 with Other Models

When evaluating various reloading machines, it’s essential to examine their features and performance to determine which best suits the needs of enthusiasts and professionals alike. This section focuses on the distinct attributes of a particular model and how it stacks up against its competitors, highlighting efficiency, ease of use, and overall reliability.

| Feature | This Model | Competitor A | Competitor B |

|---|---|---|---|

| Speed | High | Moderate | High |

| Ease of Use | User-friendly | Complex | User-friendly |

| Durability | Excellent | Good | Fair |

| Versatility | High | Low | Moderate |

Ultimately, selecting the right device hinges on individual requirements and preferences, making thorough comparisons crucial for informed decisions.

User Reviews and Experiences

This section highlights the perspectives and insights shared by users regarding their encounters with the product. Testimonials provide valuable information about functionality, reliability, and overall satisfaction, helping potential buyers make informed decisions. Here, we delve into various experiences that illustrate the strengths and weaknesses reported by users.

Positive Feedback

Many users have expressed their satisfaction with the ease of use and efficiency. Common themes in positive reviews include:

- Intuitive design that simplifies operation.

- Consistent performance, even under heavy use.

- High-quality materials contributing to durability.

- Effective customer support and resources available.

Areas for Improvement

While the product has received commendations, some users pointed out areas where enhancements could be beneficial:

- Initial setup can be challenging for beginners.

- Occasional compatibility issues with certain accessories.

- Request for more detailed documentation.

Overall, the collection of experiences reveals a well-regarded item, with users appreciating its strengths while also recognizing opportunities for improvement. These insights are essential for anyone considering this product for their needs.