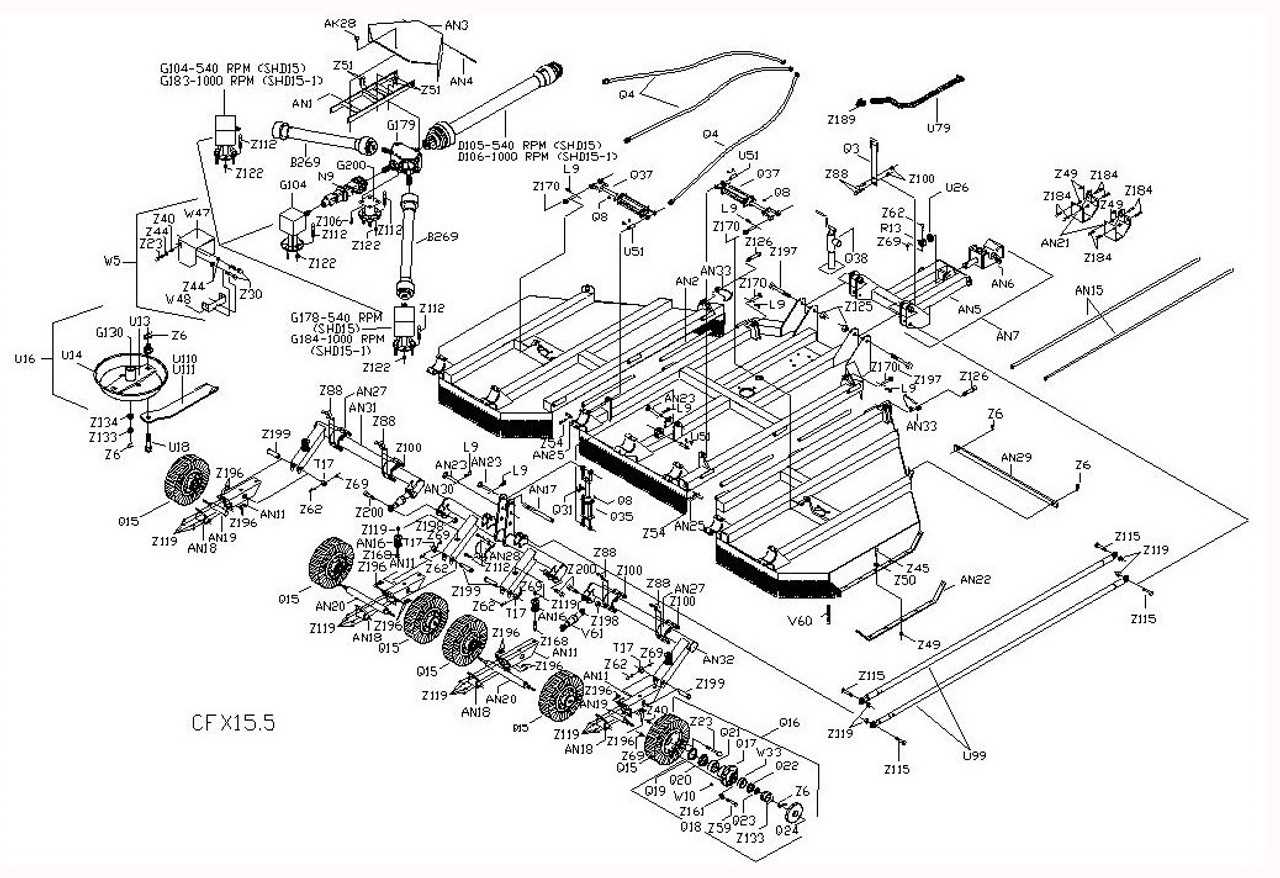

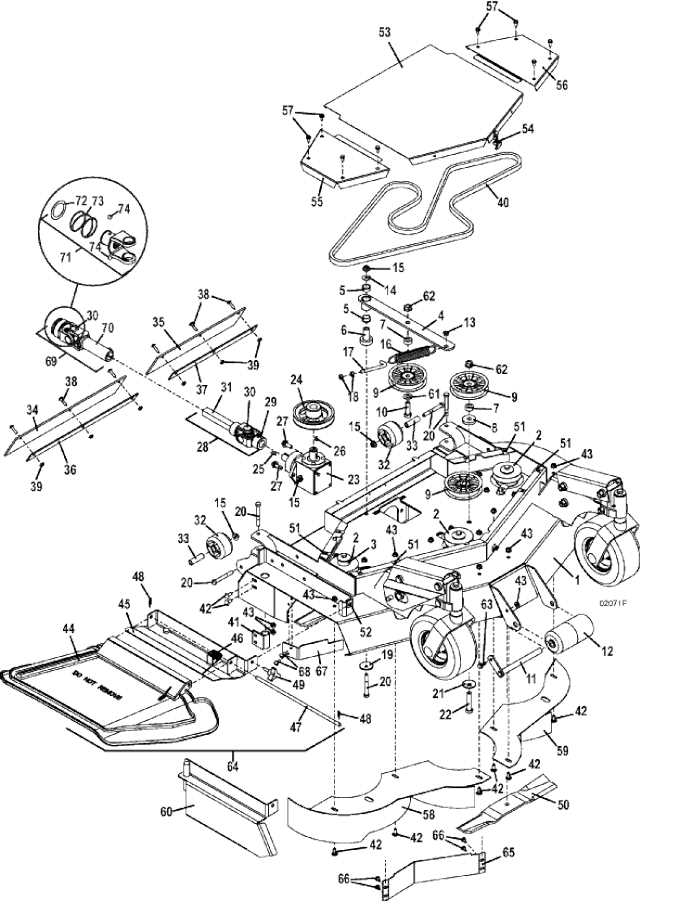

When it comes to maintaining a well-functioning grass trimming device, it is crucial to familiarize yourself with the essential mechanical elements that ensure smooth operation. The mechanism responsible for cutting vegetation requires several interconnected elements to work harmoniously, allowing efficient and effective trimming. Knowing how these elements fit together will help in both regular maintenance and troubleshooting potential issues.

Each individual component plays a vital role in the overall performance of the machine. From the rotating blades to the supportive frame, every part is designed to contribute to precise cutting and long-lasting durability. By understanding the purpose and location of these elements, you can make informed decisions when it comes to replacing or repairing specific sections of the device.

Whether you’re performing routine upkeep or addressing a malfunction, having a clear understanding of the system’s layout will save you time and effort. In this guide, we’ll explore the different elements, their functions, and how they interact to create a reliable cutting system for your outdoor needs.

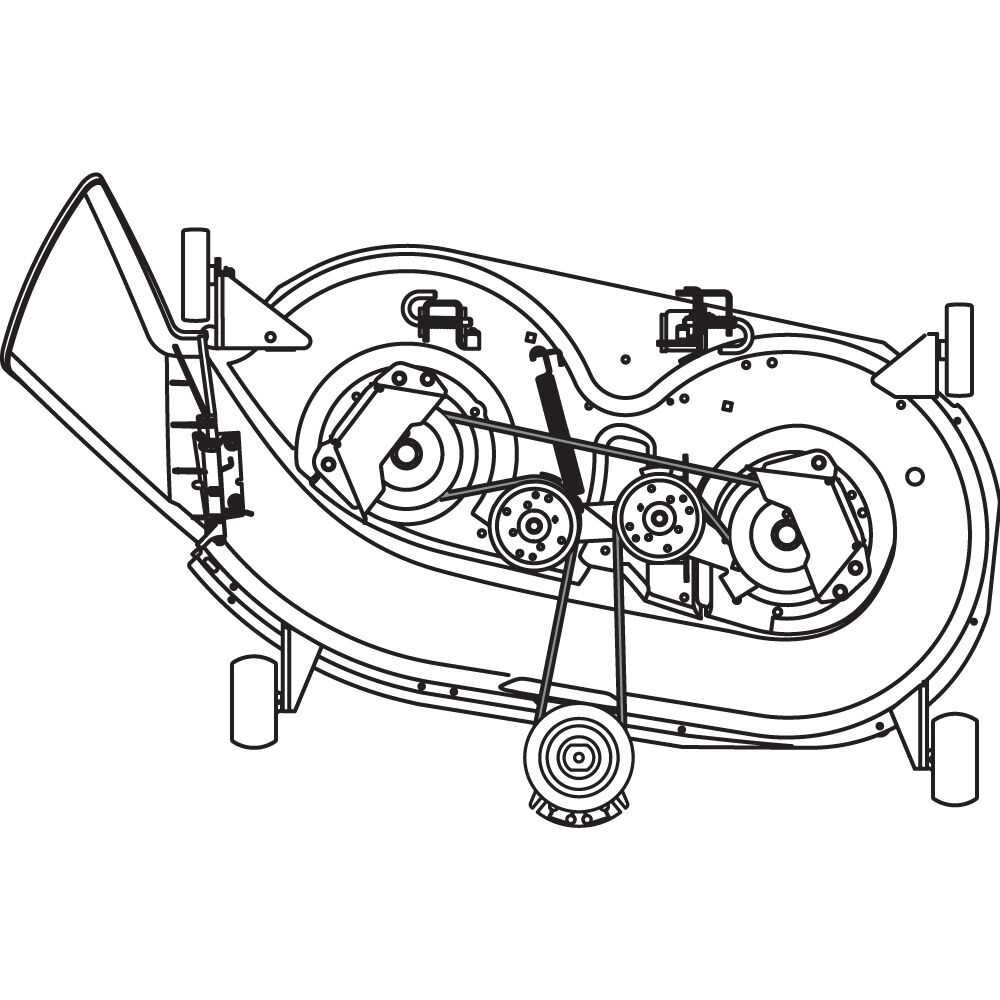

Understanding Lawn Mower Deck Components

Maintaining and repairing garden equipment requires a basic understanding of the essential elements involved in its cutting mechanism. The structure beneath the cutting tool is designed to house various moving parts that work together to ensure smooth operation and an even trim.

The primary elements include the rotating blade, which performs the actual cutting, and the framework that supports the entire system. Each piece plays a crucial role in stabilizing the device and optimizing its performance. Proper alignment and function of these components are essential for achieving desired results and extending the lifespan of your equipment.

Key features of this assembly include adjustment levers, which control cutting height, and fasteners that keep everything securely in place. Regular inspection of these parts can prevent potential issues and improve overall efficiency during operation. By understanding how each element works together, you can effectively troubleshoot common problems and maintain your equipment with ease.

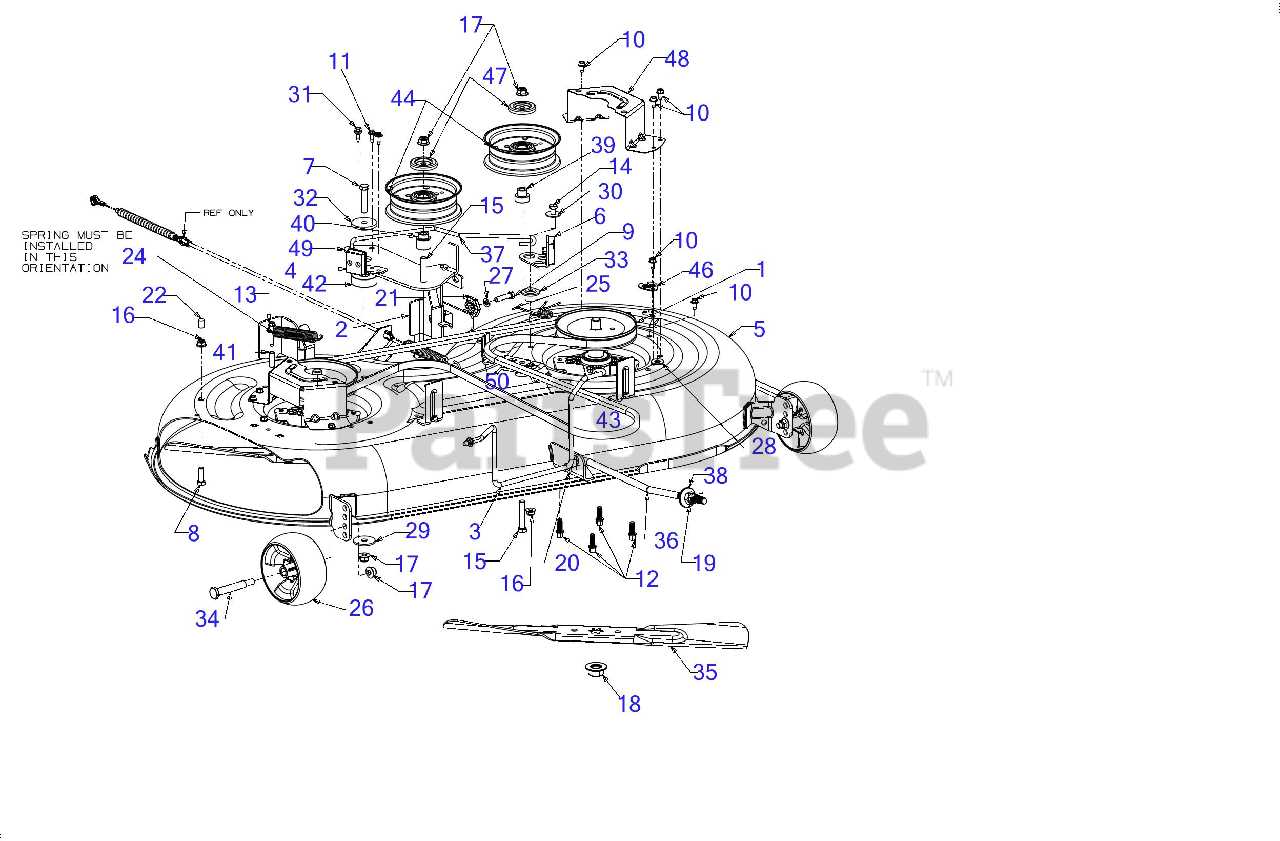

Key Functions of a Mower Deck

The cutting platform of a grass-cutting machine plays an essential role in ensuring efficient and precise trimming. It is designed to house and protect the blades while facilitating the smooth flow of grass beneath the machine, which is crucial for achieving an even cut.

Blade Housing and Protection

One of the primary functions of this platform is to safely enclose the rotating blades. This not only protects the user from potential hazards but also prevents debris from causing damage to the components during operation.

Grass Discharge Management

The system helps to control how grass is discharged after being trimmed. Some platforms are designed to allow the clippings to be mulched, while others may direct the grass to the side or rear, depending on the model’s capabilities.

| Function | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blade Protection | Enc

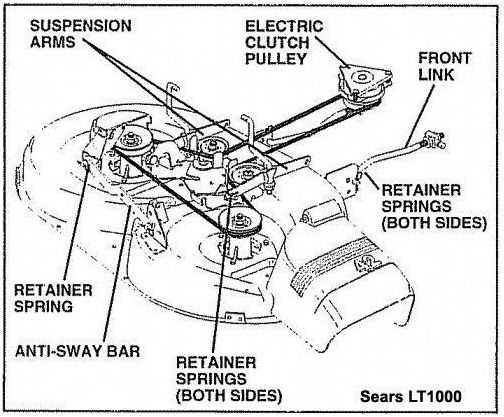

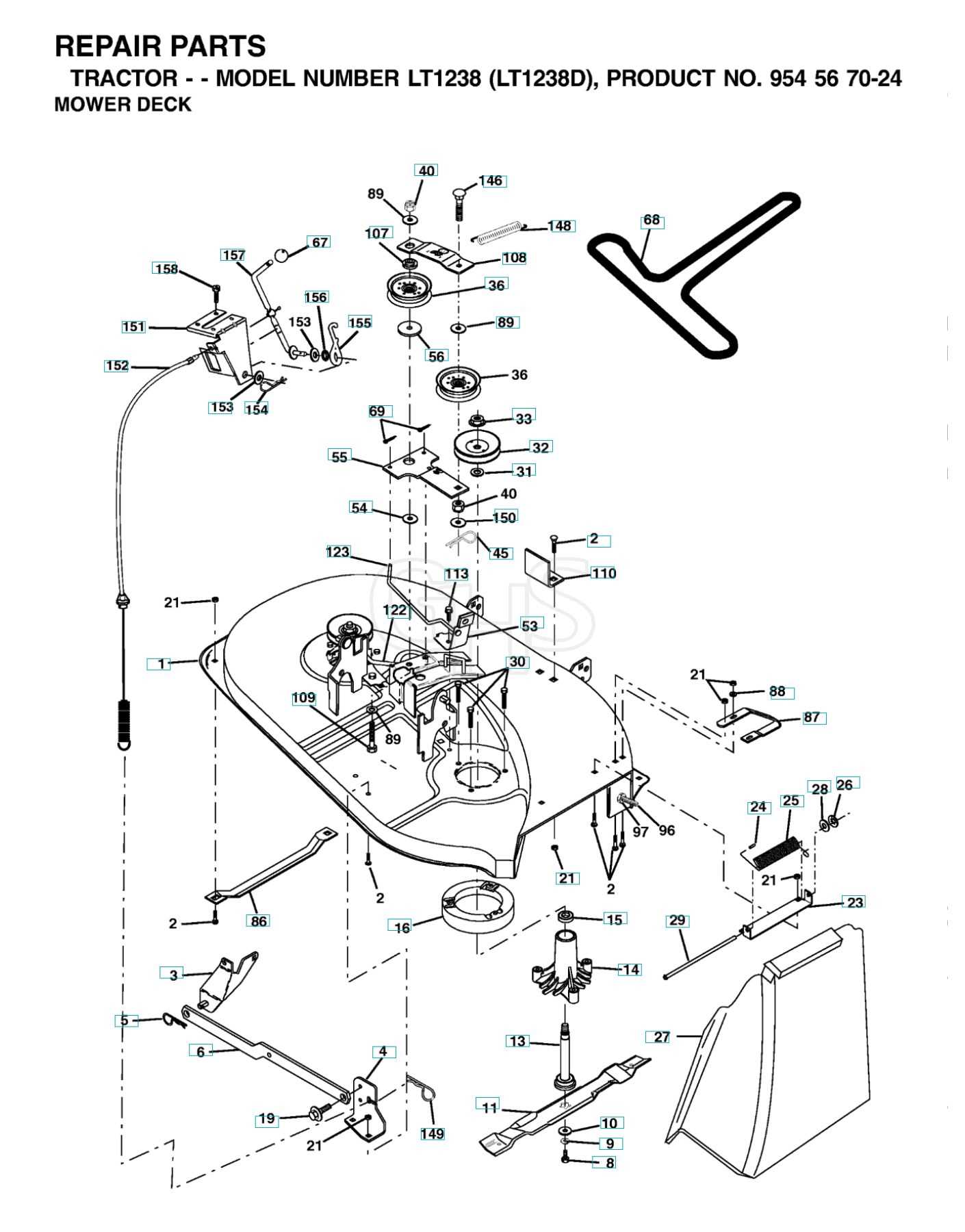

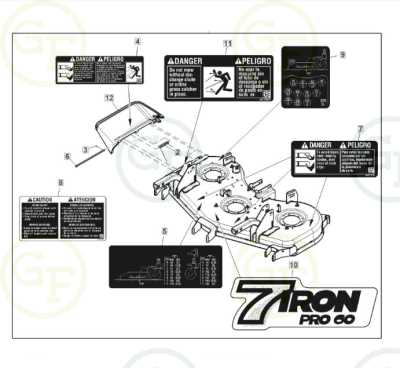

How to Identify Deck Parts

Understanding the various components of your cutting machine is essential for maintenance and repair. Each element plays a unique role in ensuring optimal performance, and knowing how to spot them can save time and effort during routine checks. Recognizing the individual pieces requires familiarity with their shapes, sizes, and positions within the system. To begin, observe the primary framework. This section supports multiple moving mechanisms, including those responsible for cutting and propulsion. Next, identify the attachments connected to this structure. These include fasteners, bearings, and tensioning systems, all critical for ensuring smooth operation. With careful examination, the relationships between different elements become clearer, allowing you to pinpoint potential wear or misalignment. Common Issues with Deck Assemblies

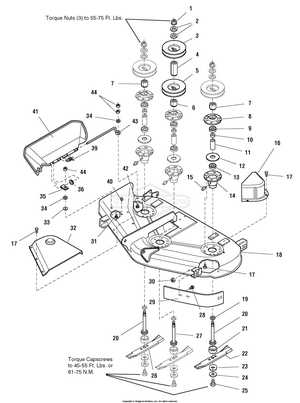

One of the most frequent challenges encountered with cutting equipment involves problems related to the overall assembly. These issues can lead to uneven cutting, excessive vibration, or even malfunctioning components. It’s essential to identify and address these concerns early to avoid further damage. Uneven Performance: If the cutting surface is not even, it may result in an inconsistent trim. This could be due to misaligned components or wear and tear in certain areas of the assembly. Vibration and Noise: Excessive shaking or strange noises often indicate loose or damaged parts. This can also put unnecessary strain on the entire structure, leading to more significant problems over time. Component Failure: Over time, moving parts may wear out or break. Regular maintenance can help detect early signs of failure, allowing for timely replacements Maintaining the Blades and SpindlesProper upkeep of cutting components is essential for ensuring smooth operation and long-term efficiency. Regular care will not only help preserve sharpness but also prevent wear on other connected parts, which can result in a more reliable performance over time. Sharpening and Inspecting the Blades

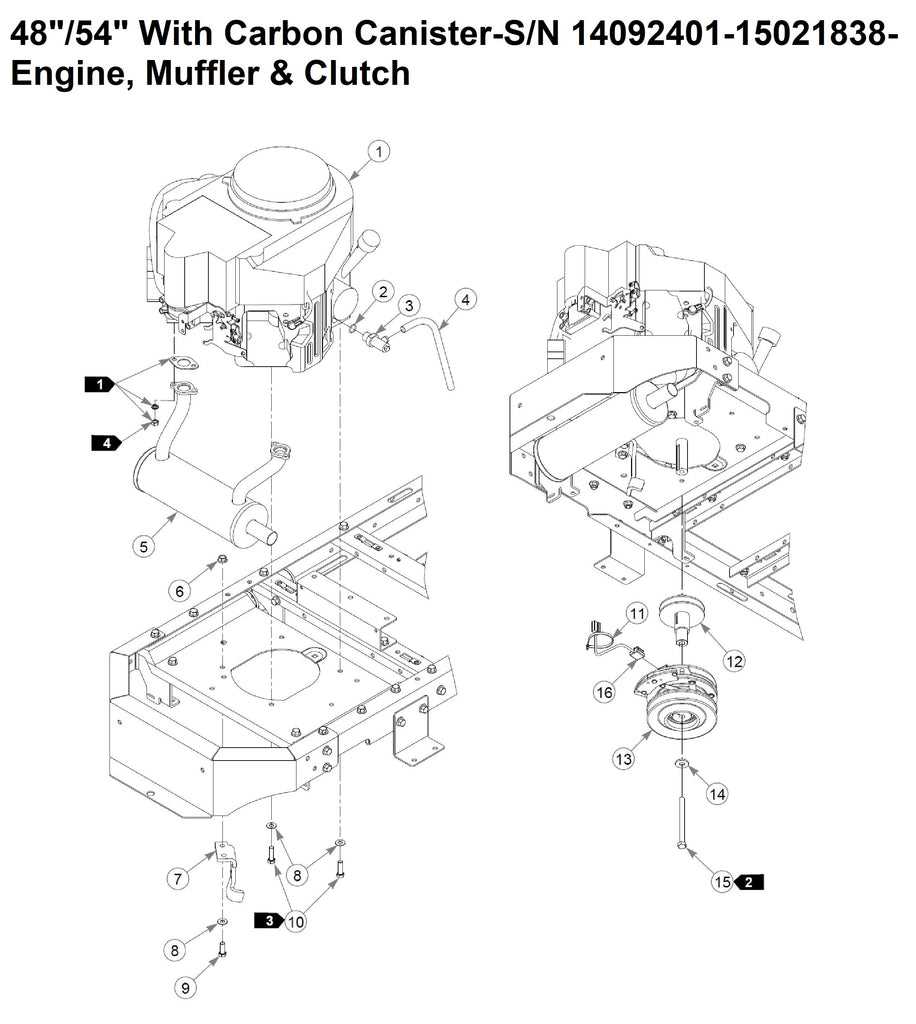

Blades should be sharpened periodically to maintain their cutting efficiency. Dull edges can cause strain on the engine and lead to uneven cuts. It is also important to inspect for any signs of damage, such as cracks or bends, which may affect functionality. If any significant damage is found, replacement is recommended. Spindle Maintenance

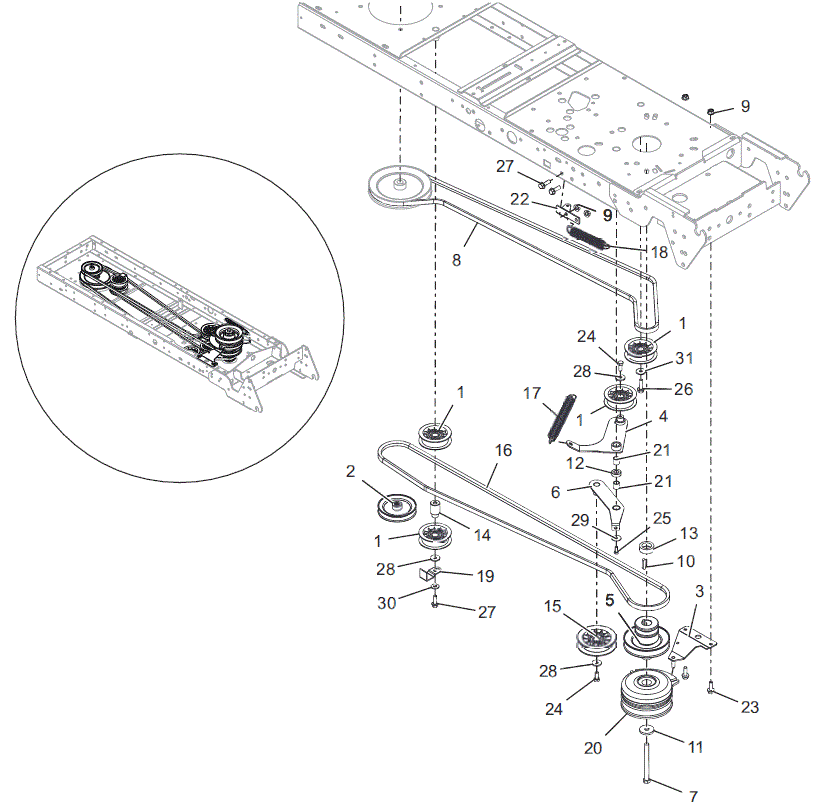

Spindles are a crucial part of the system as they support the rotation of the blades. Regular lubrication helps in preventing friction, which could lead to premature wear. Check the spindle assembly for any looseness or unusual noise during operation, as these can indicate underlying issues that require immediate attention. Belt Routing and Tensioning Tips

Proper routing and tensioning of belts are essential for the optimal performance of your equipment. Ensuring that belts are correctly aligned and appropriately tensioned can prevent premature wear and enhance the efficiency of the entire system. This section provides helpful insights and best practices for achieving the best results. Routing Guidelines

Tensioning Techniques

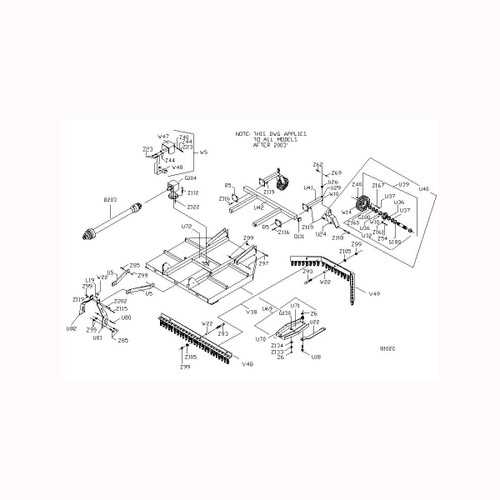

Replacing Pulleys and TensionersMaintaining the functionality of a grass cutting machine involves ensuring that the rotational components operate smoothly. Among these components, the wheels and tension mechanisms play a crucial role in the overall performance and efficiency of the equipment. Over time, these elements may wear out, necessitating replacement to restore optimal operation. When replacing these components, it is essential to follow a systematic approach:

After removing the worn components, installation of new wheels and tensioners should be conducted as follows:

Following these steps will help ensure that the rotational systems function effectively, leading to improved performance of the machine. Proper Alignment of the Deck Housing

Ensuring the correct positioning of the housing is essential for optimal performance and longevity of the equipment. Misalignment can lead to uneven wear, reduced efficiency, and potential damage over time. Proper setup involves meticulous adjustments to achieve a balanced configuration. To begin, it is crucial to verify that the housing is level and securely mounted. Use a level to check for any discrepancies, adjusting as necessary. This step lays the foundation for the entire setup process. After achieving a level position, inspect the attachment points to ensure they are tight and free of debris, which can hinder alignment. Next, adjust the height settings according to the manufacturer’s recommendations. This ensures that the housing operates within the designed parameters, promoting even cutting and effective operation. Regular maintenance and checks are vital to maintain alignment over time, preventing issues that could arise from wear or environmental factors. Finally, after making all necessary adjustments, take the time to perform a test run. Observing the equipment in action can reveal any lingering misalignments that may need further tweaking. Consistent attention to this detail will enhance performance and extend the lifespan of the unit. Cleaning and Preventing Rust on the Deck

Maintaining the surface of your outdoor equipment is essential to ensure its longevity and performance. Regular cleaning and protective measures can prevent corrosion and other forms of deterioration that arise from exposure to moisture and debris. This section outlines effective strategies for keeping your equipment in optimal condition. Effective Cleaning Techniques

Begin by removing any accumulated dirt and grass clippings using a stiff brush or a leaf blower. For deeper cleaning, utilize a mixture of mild detergent and water. Apply this solution with a sponge or cloth, scrubbing gently to avoid scratching the surface. Rinse thoroughly with clean water and allow the area to dry completely to prevent moisture from causing damage. Applying Protective CoatingsAfter cleaning, consider applying a rust-inhibiting spray or wax to create a protective barrier against moisture. Ensure the surface is dry before application for the best results. Regularly inspect the coating for signs of wear and reapply as necessary to maintain protection. Best Practices for Deck Height Adjustments

Adjusting the cutting height of your equipment is essential for achieving an optimal finish and promoting healthy growth. Understanding the appropriate methods and considerations for height modifications can enhance both the performance of the machine and the quality of the results. Here are some best practices to keep in mind:

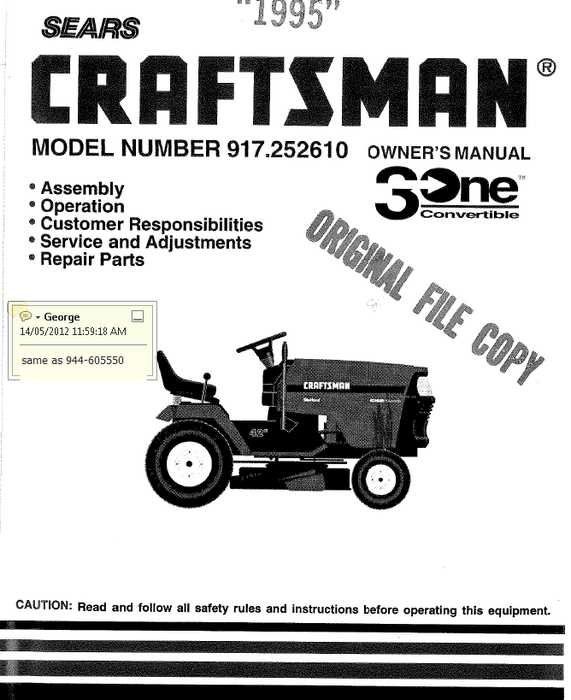

By following these guidelines, you can ensure that the cutting height adjustments contribute positively to your outdoor space’s aesthetics and health. Choosing the Right Replacement PartsSelecting appropriate components for your gardening equipment is crucial for maintaining optimal performance and longevity. Understanding the specific requirements of your machinery can help ensure you make informed decisions when sourcing these essential items. When seeking suitable alternatives, consider the following factors:

By taking these aspects into account, you can confidently select the most suitable alternatives for your equipment, ensuring its efficient operation and extending its lifespan. |