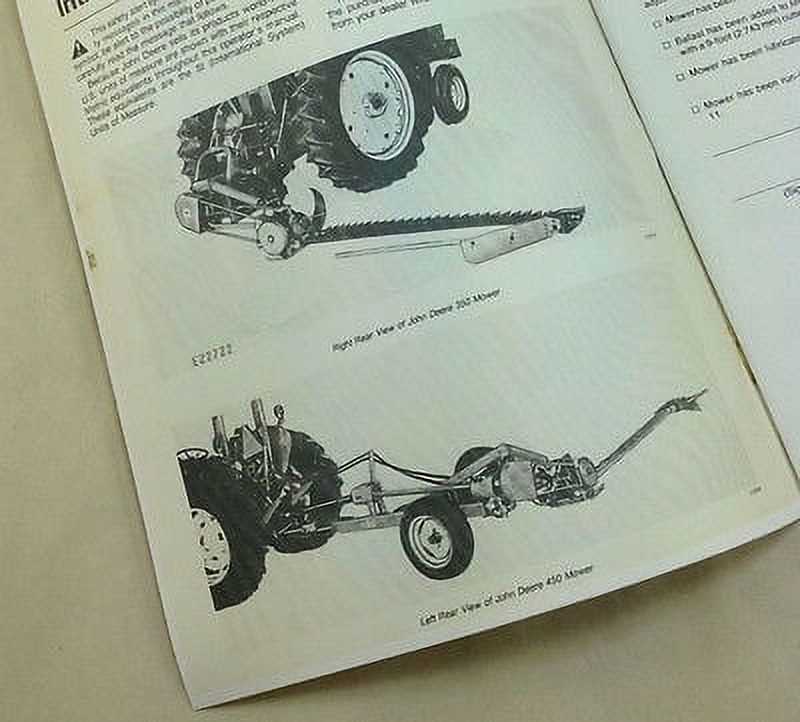

The efficiency and longevity of agricultural machinery depend largely on the proper understanding of its individual elements. Knowing how each component functions within the system ensures smoother operation and helps to prevent unexpected breakdowns. Maintaining these mechanisms not only extends their lifespan but also improves productivity in the field.

When dealing with equipment for cutting crops, it’s essential to recognize the various pieces that come together to form a cohesive unit. Understanding the structure and functionality of these elements allows for timely maintenance and the replacement of worn-out components, ensuring the machinery operates at peak efficiency.

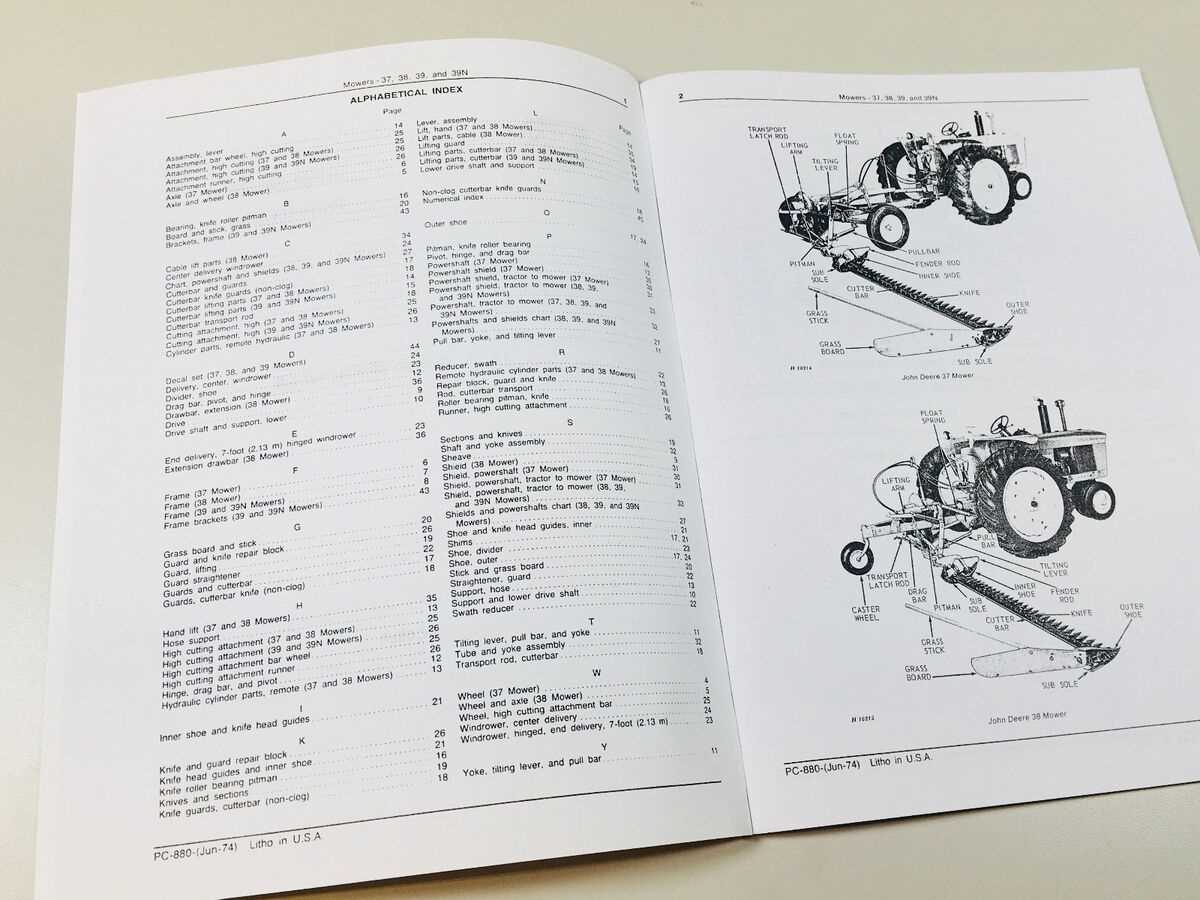

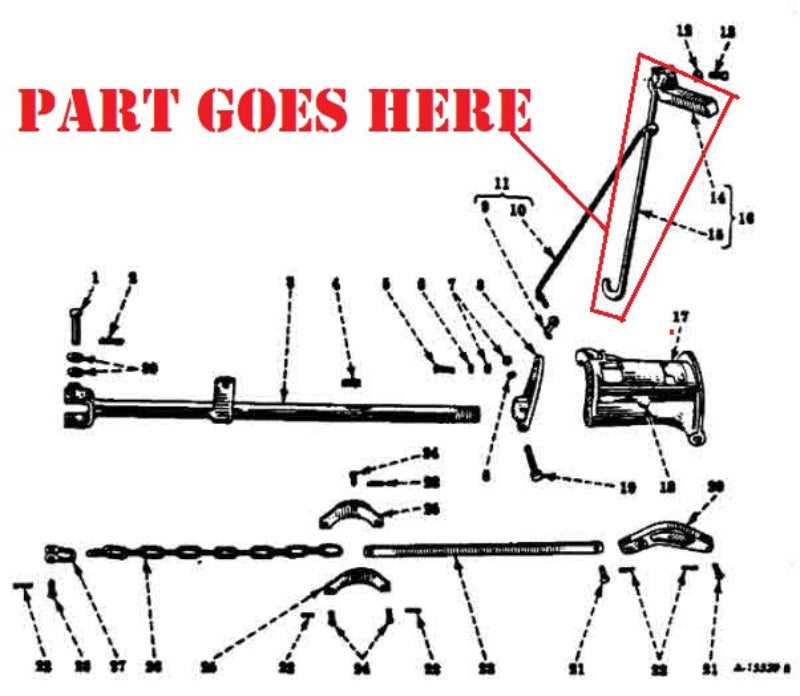

By familiarizing yourself with the arrangement and purpose of different elements in the cutting mechanism, you can better address potential issues. This knowledge aids in quicker identification of any malfunctions, making it easier to keep the equipment in optimal working condition.

Understanding the Components of a Sickle Mower

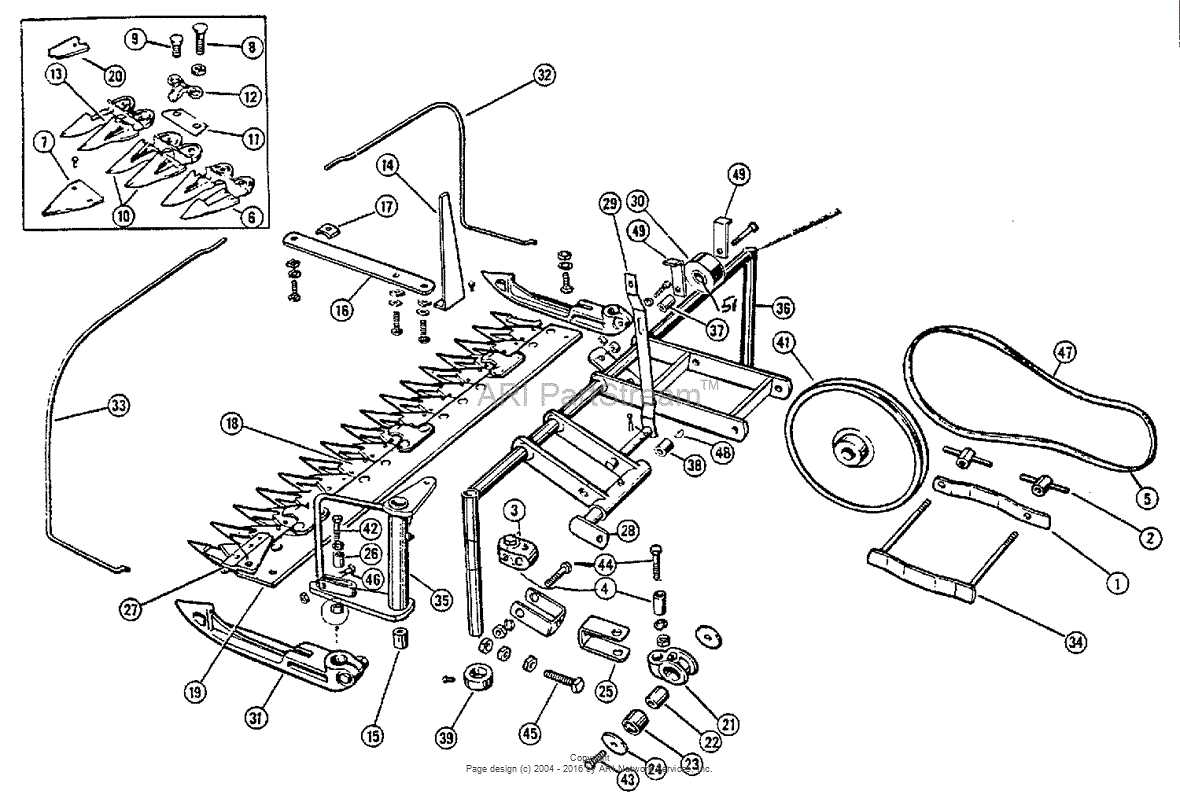

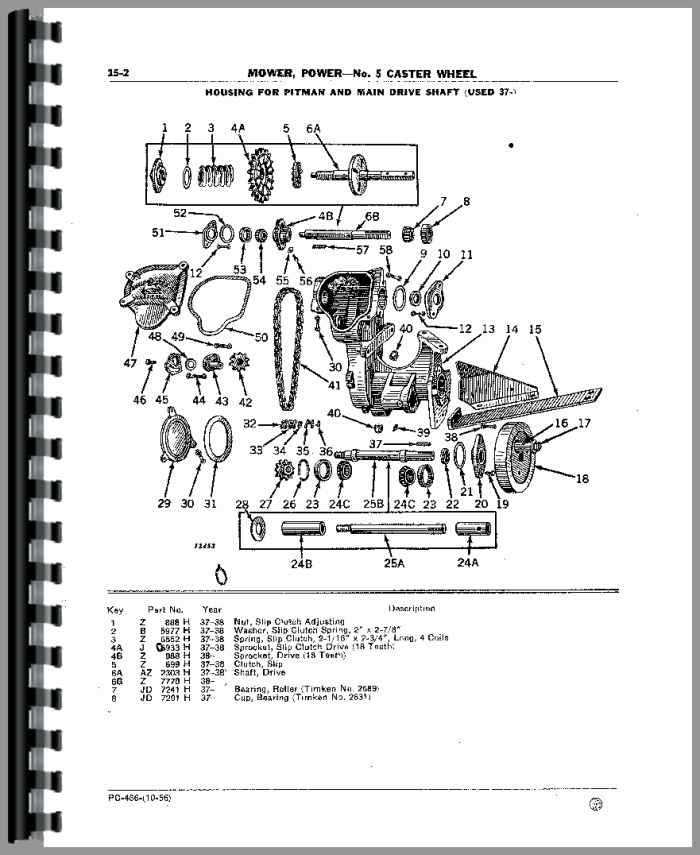

Comprehending the various elements that make up an agricultural cutting machine is essential for efficient operation and maintenance. Each section plays a crucial role in ensuring smooth functionality, whether it’s for trimming vegetation or handling larger crops. To ensure optimal performance, it’s important to familiarize yourself with how these individual mechanisms work together.

| Component | Function | |||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

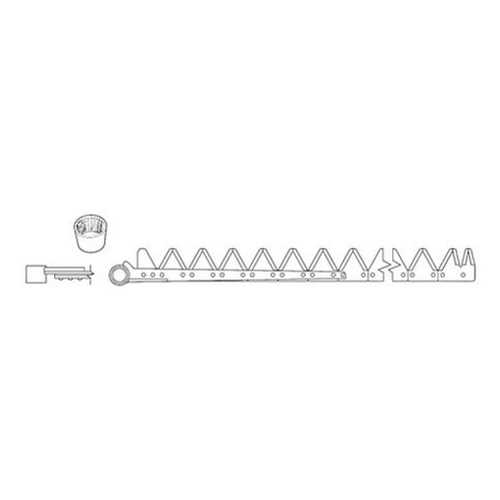

| Cutting Blades | Responsible for clean and precise cutting of the plants. | |||||||||||||||||||||||||||||||||||||||||||||||

| Drive Mechanism | Transfers power to the cutting mechanism, ensuring motion and efficiency. | |||||||||||||||||||||||||||||||||||||||||||||||

| Symptom | Possible Cause | Recommended Action | ||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uneven cutting | Dull or damaged blades | Sharpen or replace blades | ||||||||||||||||||||||||||||||||||||||||

| Frequent stalling | Clogged discharge area | Clear obstructions, clean discharge

Replacing Worn-Out Parts on a Sickle Mower

Over time, various components of cutting equipment can wear down due to regular use, which may lead to reduced efficiency and performance. To ensure smooth operation, it’s crucial to inspect these elements periodically and replace any that show signs of excessive wear. By doing so, you can maintain the optimal functionality of your machine and avoid potential breakdowns during critical tasks. Identifying Damaged ComponentsThe first step in restoring performance is to carefully examine the mechanical system. Look for any visible cracks, bends, or broken sections that may be hindering the smooth operation. Pay close attention to the fasteners, blades, and other moving elements, as they are more prone to degradation over time. Re Maintaining Your Sickle MowerProper upkeep of your cutting equipment is essential for ensuring optimal performance and longevity. Regular maintenance tasks not only enhance efficiency but also minimize the likelihood of breakdowns. By following a structured maintenance routine, users can enjoy seamless operation and improved results. Here are some key maintenance activities to consider:

Adhering to these practices will help in maintaining the performance and durability of your equipment, allowing for a smoother and more efficient operation over time. Best Practices for Sickle Mower Use

Utilizing cutting equipment effectively requires understanding its operation and maintenance. Proper techniques can enhance performance, ensure safety, and prolong the life of the machine. This section outlines essential recommendations to maximize efficiency while minimizing wear and tear. Preparation and SetupBefore commencing any cutting tasks, it is crucial to inspect the equipment thoroughly. Ensure that all components are in optimal condition and properly adjusted. The following checklist can assist in preparing the machinery:

Operational TechniquesEmploying the right techniques during operation can significantly impact efficiency and safety. Here are some effective practices to follow:

Exploring the Mower’s Cutting MechanismThe efficiency of any cutting tool relies heavily on its operational design. Understanding the intricacies of the cutting mechanism is essential for optimal performance and maintenance. This section delves into how the assembly functions, ensuring precise trimming and a clean finish. At the heart of the mechanism lies a series of sharp, interlocking blades that move in a coordinated manner. This system is engineered to create a scissor-like action, effectively slicing through vegetation with minimal effort. Maintenance of these blades is crucial, as dull or misaligned components can lead to uneven cutting and increased wear. Furthermore, the configuration of the supporting frame plays a significant role in the stability and maneuverability of the cutting tool. A well-designed frame allows for better weight distribution and easier navigation across various terrains. Regular inspections of the frame and its attachments are advisable to ensure that all elements function harmoniously. In conclusion, a thorough understanding of the cutting mechanism not only enhances operational efficiency but also prolongs the lifespan of the entire assembly. Regular maintenance and careful handling are key to achieving superior results and maintaining the integrity of the tool. Common Causes of Sickle Mower WearUnderstanding the typical reasons behind the deterioration of cutting equipment can greatly enhance maintenance strategies and prolong the lifespan of these tools. Various factors contribute to wear and tear, impacting their efficiency and performance over time. Inadequate Lubrication: Insufficient lubrication can lead to increased friction between moving components. This often results in overheating and accelerated wear, necessitating more frequent repairs and replacements. Exposure to Harsh Conditions: Operating in extreme weather or rough terrains can accelerate degradation. Dust, moisture, and debris can significantly affect the functionality and longevity of the equipment. Improper Adjustments: Incorrect settings during operation can create undue stress on cutting edges, leading to premature wear. Regular checks and adjustments are essential for optimal performance. Low-Quality Materials: Using inferior materials for maintenance or replacement can compromise the integrity of the equipment. High-quality components are vital for maintaining performance and reducing wear. Lack of Regular Maintenance: Neglecting routine inspections and upkeep can result in undetected issues, which may worsen over time. Consistent maintenance is key to preventing significant damage and ensuring efficient operation. Essential Tools for Mower RepairsWhen it comes to maintaining and fixing lawn care equipment, having the right set of tools is crucial. A well-equipped toolbox can significantly ease the repair process, ensuring that tasks are completed efficiently and effectively. Understanding the necessary implements can help enthusiasts and professionals alike to keep their machinery in optimal condition.

Guide to Sickle Mower Blade CareMaintaining the sharpness and integrity of cutting implements is essential for achieving optimal performance in agricultural tasks. Proper upkeep not only enhances efficiency but also prolongs the lifespan of the equipment. This guide outlines essential practices for ensuring that your cutting blades remain in excellent condition.

|