In the realm of agricultural machinery, the 9N model stands out for its efficiency and reliability. This section delves into the essential elements that contribute to its functionality, offering a detailed overview of each crucial component.

Recognizing the intricate relationships between various mechanical elements is vital for maintaining optimal performance. By exploring the distinct sections and their roles, operators can gain valuable insights into how the machine operates, ultimately leading to better management and upkeep.

Whether you’re a seasoned expert or new to the field, having a clear visualization of these essential components can significantly enhance your understanding. This exploration aims to equip you with the knowledge needed to navigate the complexities of this iconic model.

This section delves into the essential elements that contribute to the functionality of the machine. Understanding these critical components helps in grasping how they work together to ensure optimal performance and reliability. Each part plays a vital role, influencing the overall efficiency and capability of the equipment.

Primary Mechanisms

Among the various assemblies, certain mechanisms stand out due to their importance. These include the engine, transmission, and hydraulic systems, which collectively facilitate movement and operational tasks. An insight into their operation reveals how they enhance productivity and support diverse agricultural applications.

Supporting Elements

In addition to the main assemblies, various supporting elements are crucial for seamless operation. These include systems that handle fuel, electrical functions, and control interfaces, ensuring that everything operates in harmony. Each supporting part is engineered to withstand demanding conditions, thereby extending the lifespan of the overall setup.

| Component | Function |

|---|---|

| Engine | Generates power for operation |

| Transmission | Transfers power to the wheels |

| Hydraulic System | Facilitates lifting and movement |

| Fuel System | Stores and delivers fuel to the engine |

| Electrical System | Provides power for controls and ignition |

Historical Significance of the 9N

The 9N model represents a pivotal moment in agricultural machinery, marking a transition towards more efficient farming practices. Its introduction revolutionized the way work was performed on the fields, offering farmers greater power and versatility compared to previous designs. This innovation contributed significantly to increased productivity and laid the groundwork for modern agricultural equipment.

Impact on Farming Practices

This model’s design incorporated user-friendly features that appealed to a broad audience, enabling smaller operations to utilize machinery effectively. The versatility allowed for various attachments, making it suitable for diverse tasks ranging from plowing to harvesting. As a result, it not only enhanced efficiency but also encouraged the mechanization of agriculture, a trend that shaped the industry for decades.

Cultural Legacy

The influence of this machine extends beyond its functional capabilities; it became a symbol of progress in rural America. The 9N fostered a sense of community among farmers, who shared knowledge and experiences regarding its use. Its enduring presence in vintage shows and collector circles today highlights its lasting impact on the agricultural landscape.

Major Systems Explained

The functionality of agricultural machinery relies on a variety of interconnected systems, each playing a crucial role in the overall operation. Understanding these essential components enhances maintenance efforts and contributes to effective usage.

Engine: The heart of the equipment, this assembly transforms fuel into mechanical energy, driving the vehicle’s movement. It comprises various elements, such as cylinders, pistons, and a crankshaft, which work harmoniously to generate power.

Transmission: This system is responsible for transferring the engine’s power to the wheels. It allows for speed adjustment and torque delivery, enabling efficient operation across different terrains. Key components include gears, shafts, and clutches.

Hydraulic System: Utilizing fluid power, this system operates implements and attachments. By converting mechanical energy into hydraulic energy, it facilitates various functions, such as lifting and pushing. Important parts include pumps, cylinders, and hoses.

Electrical System: Vital for ignition, lighting, and starting, this network powers various electronic components. It includes the battery, alternator, and wiring harnesses, ensuring reliable functionality and safety features.

Chassis: Serving as the framework, this structure supports all other components, providing stability and strength. It also plays a crucial role in weight distribution and overall durability, ensuring the machinery can withstand rigorous use.

Common Issues and Solutions

Maintaining machinery can be challenging, often leading to various complications. Understanding frequent problems and their remedies can enhance operational efficiency and prolong the lifespan of the equipment.

Frequent Complications

- Engine performance issues

- Hydraulic system malfunctions

- Electrical failures

- Worn-out components

Solutions and Recommendations

- For engine performance concerns, regularly check fuel quality and replace filters as needed.

- If the hydraulic system is unresponsive, inspect fluid levels and ensure there are no leaks in hoses or connections.

- For electrical issues, examine wiring for frays and ensure all connections are secure.

- Replace any worn components promptly to prevent further damage and ensure smooth operation.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your machinery requires regular upkeep and attention to detail. Implementing a systematic maintenance routine can significantly enhance the lifespan and reliability of your equipment. Here are some essential practices to consider.

- Regular Inspection: Frequently check for any signs of wear, leaks, or damage. Identifying issues early can prevent costly repairs down the line.

- Fluid Maintenance: Keep all fluids at appropriate levels, including oils and coolants. Change them according to the manufacturer’s recommendations to ensure efficient operation.

- Cleaning: Maintain cleanliness by removing dirt, dust, and debris from all surfaces. This helps prevent rust and corrosion, which can deteriorate components over time.

- Lubrication: Ensure that all moving parts are properly lubricated to reduce friction and wear. Regularly apply grease to joints and pivot points.

- Battery Care: Check the battery regularly for corrosion and ensure it is charged adequately. Clean the terminals and connections to maintain electrical performance.

By adhering to these maintenance practices, you can greatly extend the lifespan of your machinery and ensure it continues to operate efficiently for many years to come.

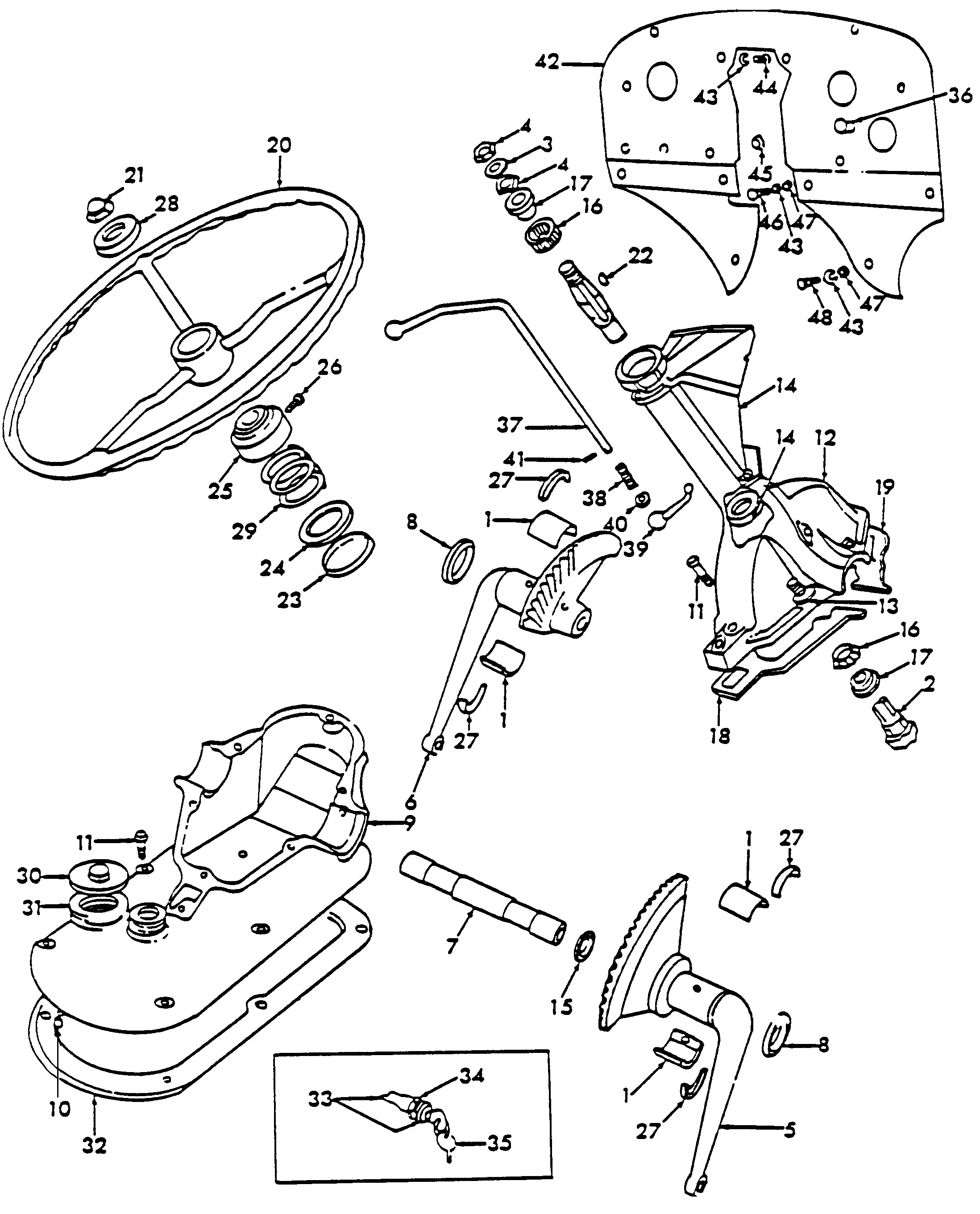

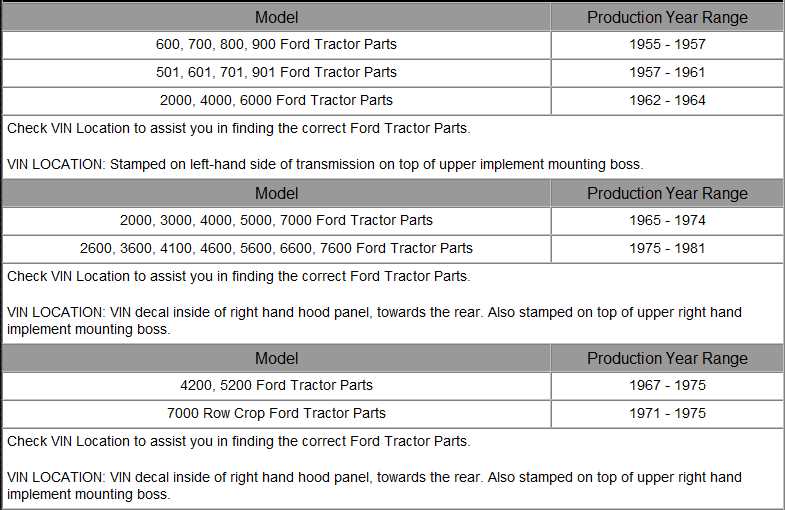

Parts Replacement Guide

This section provides essential information for effectively replacing components in your machinery. Understanding the various elements and their functions can enhance performance and extend the lifespan of your equipment. Proper replacement practices ensure that each unit operates at optimal efficiency.

Identifying Components

Before commencing any replacement procedure, it is crucial to identify the specific components that require attention. Here are steps to assist in this process:

- Consult the equipment manual to understand the layout and functionality of each element.

- Visually inspect the units for signs of wear or damage.

- Make a list of items that need to be replaced, noting their specifications.

Replacement Process

Once you have identified the components for replacement, follow these guidelines to ensure a smooth process:

- Gather the necessary tools and replacement components before starting.

- Follow the manual instructions for each specific unit to prevent mishaps.

- Ensure all connections are secure after replacement.

- Test the equipment post-replacement to confirm proper functionality.

Where to Source Authentic Parts

Finding reliable components for vintage machinery can be a challenge, but it is essential for maintaining optimal performance and longevity. Authentic pieces not only ensure compatibility but also contribute to the overall value of the equipment. Here are some effective ways to locate genuine replacements for your machinery.

1. Authorized Dealers

Visiting authorized dealers is one of the best ways to obtain genuine components. These establishments typically offer a wide selection of high-quality items that meet the original specifications. In addition, staff members are often knowledgeable about the specific requirements of various models, which can help you make informed decisions.

2. Online Marketplaces

Another convenient option is to explore online marketplaces specializing in vintage machinery components. Websites dedicated to classic equipment often feature sections for authentic replacements. When shopping online, look for sellers with positive reviews and verified authenticity guarantees to ensure you are purchasing quality items.

Upgrading Your 9N Tractor

Enhancing the performance and functionality of your vintage machinery can significantly improve its efficiency and usability. Whether you are looking to boost power, enhance comfort, or increase versatility, there are numerous options available to modernize your classic machine while maintaining its charm. By carefully selecting modifications, you can create a more enjoyable experience while working on your land or during various projects.

Performance Enhancements

One effective way to improve efficiency is by upgrading the engine components. Consider installing a higher-capacity air filter or an improved exhaust system to increase airflow and enhance combustion. Additionally, upgrading the ignition system can lead to better fuel efficiency and a more reliable start. These changes not only improve performance but also contribute to a smoother operation overall.

Comfort and Usability Upgrades

Modernizing the operator’s area can significantly enhance the user experience. Installing a more comfortable seat with better ergonomics can reduce fatigue during long working hours. Additionally, adding improved lighting systems can enhance visibility, allowing for safer operation during early morning or evening tasks. These upgrades contribute to a more enjoyable and productive experience, making your vintage machine feel more contemporary.

Community Resources and Forums

Engaging with a community can greatly enhance your understanding and access to various components and maintenance techniques. Numerous platforms exist where enthusiasts share knowledge, experiences, and resources related to machinery. These online spaces often serve as valuable hubs for advice, troubleshooting tips, and information on sourcing specific elements.

Forums dedicated to agricultural equipment frequently host discussions that cover a wide range of topics, from repair techniques to modifications. Participants often share detailed guides, photos, and even step-by-step instructions that can assist newcomers and seasoned users alike. Moreover, these communities provide an excellent opportunity to connect with others who share similar interests, fostering a sense of camaraderie and support.

Additionally, social media groups and online marketplaces can also be effective in connecting individuals looking for specific resources. By participating in these networks, users can stay updated on the latest trends, find compatible accessories, and discuss innovations in maintenance practices. Engaging with these platforms enhances both knowledge and access, making it easier to navigate the complexities of machinery care.