In the realm of energy solutions, grasping the intricate workings of various machinery is crucial for efficient operation and maintenance. Each system comprises numerous elements that collaborate to deliver optimal performance. A comprehensive exploration of these components not only enhances functionality but also prolongs the lifespan of the equipment.

Visual aids serve as invaluable resources for technicians and enthusiasts alike, allowing them to delve deeper into the intricate relationships between individual elements. By studying these illustrations, one can uncover the ultimate configurations and connections that facilitate seamless energy generation.

Understanding how each piece fits into the larger framework enables informed decisions regarding repairs and upgrades. This knowledge empowers users to troubleshoot effectively and ensures that their machinery operates at peak efficiency.

Understanding Onan 3600 LP Generator

The exploration of a specific model of power-producing equipment reveals a wealth of intricate components that work in harmony to deliver reliable energy. This particular unit, designed for efficiency and durability, serves as an ideal solution for various power needs, making it a staple for both recreational and emergency uses.

To fully appreciate its functionality, one must delve into the assembly of its vital elements. Each component plays a crucial role, from the fuel system to the electrical outputs, ensuring optimal performance and longevity. Understanding these parts can lead to more informed maintenance and troubleshooting.

Ultimately, a grasp of how these pieces interconnect enhances the user experience, allowing for more effective utilization of the equipment and fostering confidence in its operational reliability.

Key Components of the Generator

Understanding the essential elements of a power-producing machine is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring optimal performance and reliability.

- Engine: The heart of the system, responsible for converting fuel into mechanical energy.

- Alternator: This part transforms mechanical energy into electrical energy through electromagnetic induction.

- Fuel System: Supplies the necessary fuel to the engine, consisting of tanks, pumps, and filters.

- Cooling System: Maintains an appropriate operating temperature to prevent overheating, including radiators and fans.

- Control Panel: Allows users to monitor and manage the operation, featuring gauges and switches.

- Exhaust System: Directs harmful gases away from the unit, ensuring safe operation and compliance with regulations.

Each of these elements collaborates to deliver reliable energy, making them integral to the overall functionality of the machine.

Importance of Regular Maintenance

Routine upkeep is essential for ensuring the longevity and efficiency of machinery. By conducting regular inspections and servicing, potential issues can be identified and addressed before they escalate, thereby safeguarding the overall performance and reliability of the equipment.

Benefits of Consistent Upkeep

Engaging in systematic maintenance practices not only enhances operational efficiency but also reduces the likelihood of unexpected breakdowns. This proactive approach minimizes downtime and associated costs, ultimately leading to a more productive environment.

Long-Term Cost Savings

Investing time and resources into regular maintenance can lead to significant financial savings over time. Proper care helps to avoid costly repairs and extends the lifespan of components, making it a crucial element of responsible ownership.

Common Issues and Troubleshooting Tips

Operating machinery can sometimes lead to unexpected challenges. Understanding common problems and their solutions can significantly enhance performance and prolong the lifespan of the equipment. This section outlines frequent complications that users might encounter, along with practical advice for resolving them.

Frequent Complications

Many users face similar issues during operation, often stemming from mechanical wear, electrical faults, or improper usage. Identifying these challenges early can prevent more severe damage and costly repairs.

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Failure to Start | Weak battery, faulty ignition system, or fuel issues | Check battery charge, inspect ignition components, and ensure fuel flow. |

| Overheating | Insufficient coolant, blocked air intake, or worn parts | Examine coolant levels, clean air filters, and check for worn components. |

| Inconsistent Output | Load imbalance, fuel quality, or electrical connections | Assess load distribution, use high-quality fuel, and tighten electrical connections. |

Maintenance Recommendations

Regular maintenance is crucial for preventing complications. Following a scheduled upkeep routine can help maintain optimal performance and reliability. Simple tasks such as changing filters, checking fluid levels, and inspecting for wear can go a long way in ensuring smooth operation.

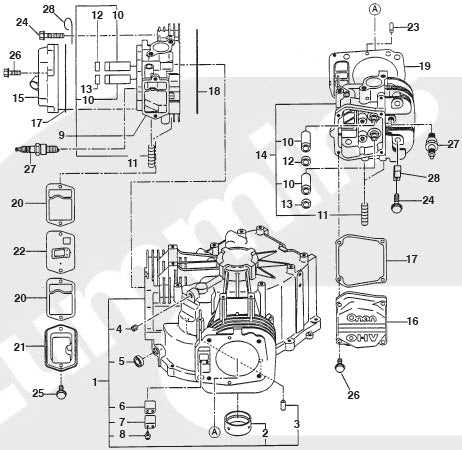

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of equipment. These visual aids offer a clear representation of components and their relationships, enabling users to identify and troubleshoot issues efficiently.

To navigate these illustrations successfully, consider the following steps:

- Familiarize Yourself with Symbols: Each component has a specific symbol. Knowing what they represent is crucial.

- Identify Key Sections: Diagrams often have labeled sections. Pay attention to these to locate the relevant parts quickly.

- Follow Connections: Arrows and lines indicate how components interact. Tracing these helps in understanding the system’s functionality.

- Refer to the Legend: Most illustrations include a legend or key. This provides definitions for symbols and abbreviations used.

- Take Notes: Jot down any important information or references as you study the illustration for easier access later.

By applying these strategies, you’ll enhance your ability to interpret technical visuals, leading to more informed decision-making during repairs and upgrades.

Where to Find Replacement Parts

Locating suitable components for your equipment is crucial for maintaining its performance and longevity. Various avenues can be explored to ensure you acquire the right elements without unnecessary delays or complications.

Here are some effective sources to consider:

- Manufacturer’s Website: Many companies provide an online catalog of their offerings, which can be a reliable resource for original components.

- Authorized Dealers: Local distributors often stock genuine items and can assist with specific inquiries regarding compatibility.

- Online Marketplaces: Websites such as eBay and Amazon offer a wide range of options, including new and refurbished items.

- Specialty Stores: Retailers focused on machinery or equipment frequently carry essential components and can provide expert advice.

- Forums and Community Groups: Online communities dedicated to enthusiasts can be valuable for recommendations and second-hand options.

Before purchasing, it is advisable to verify the specifications and ensure compatibility with your model to avoid any issues. Thorough research will lead to successful repairs and uninterrupted use of your machinery.

Benefits of Using Genuine Parts

Opting for authentic components ensures optimal performance and longevity for your equipment. When maintaining machinery, the choice between original and aftermarket options can significantly influence functionality, safety, and overall efficiency. Genuine elements are designed specifically to fit seamlessly, minimizing the risk of malfunctions and ensuring the best possible operation.

Quality Assurance

One of the primary advantages of selecting original components is the guarantee of superior quality. These parts are manufactured to strict standards, which helps maintain the integrity of the machine. With genuine options, users can be confident that they are investing in durability and reliability.

Enhanced Compatibility

Authentic components are engineered to work harmoniously with existing systems. This compatibility reduces the likelihood of installation issues and subsequent repairs. Utilizing original items also preserves any warranties, providing additional peace of mind for the user.

| Benefit | Description |

|---|---|

| Reliability | Ensures consistent performance and reduces the risk of breakdowns. |

| Longevity | Designed for prolonged use, decreasing the need for frequent replacements. |

| Safety | Manufactured with safety standards in mind, protecting both the equipment and its users. |

| Value | Investing in quality components can lead to cost savings in the long run due to fewer repairs. |

DIY Repairs: What You Need to Know

Engaging in self-repairs can be both satisfying and cost-effective. Understanding the essentials of maintenance and troubleshooting will empower you to address common issues with confidence. Whether it’s a minor fix or a more complex problem, having the right knowledge can save you time and money.

Before starting any repairs, consider the following key points:

| Tip | Description |

|---|---|

| Safety First | Always prioritize safety by disconnecting power sources and using appropriate protective gear. |

| Research | Look for reliable resources, such as manuals or online forums, to gather insights about your specific situation. |

| Tools | Ensure you have the necessary tools and replacement components ready before starting your repair. |

| Step-by-Step Approach | Follow a methodical process to diagnose and fix the issue, documenting each step to avoid confusion. |

By equipping yourself with these fundamentals, you can delve into repairs with greater assurance, leading to ultimate satisfaction in your DIY endeavors.

Safety Precautions When Repairing

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Adhering to specific guidelines and protocols can significantly reduce risks associated with working on machinery and equipment.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves, safety goggles, and sturdy footwear to shield against potential hazards during repairs.

Proper Ventilation and Environment

Ensure that the workspace is well-ventilated and free from clutter. Working in a clean environment minimizes distractions and promotes focus, thereby enhancing safety during the repair process. Remember to always disconnect power sources before commencing any work.

Upgrading Components for Better Performance

Enhancing key elements of your machinery can lead to significant improvements in efficiency and reliability. By selecting superior materials and advanced technology, users can achieve optimal functionality, reducing downtime and extending the lifespan of their equipment.

Key Areas for Upgrades

Focus on the following components for impactful enhancements:

| Component | Benefits of Upgrade |

|---|---|

| Fuel System | Improved combustion efficiency and reduced emissions. |

| Cooling System | Enhanced heat dissipation, preventing overheating. |

| Electrical Components | Better energy output and reduced risk of failure. |

Choosing the Right Upgrades

When selecting components, prioritize compatibility and quality. Research reputable brands and consider the specific requirements of your system to ensure that each upgrade contributes to overall performance and reliability.

Comparing Onan with Other Brands

This section explores the strengths and weaknesses of one popular brand in relation to its competitors in the power supply sector. Understanding the nuances between different manufacturers can guide consumers in making informed choices based on performance, reliability, and overall value.

Performance and Reliability

When assessing power solutions, performance is paramount. Some brands may offer higher wattage output, while others excel in fuel efficiency. Reliability is also a crucial factor, with some manufacturers consistently ranking higher in customer satisfaction and durability.

Cost and Value

Pricing strategies can vary significantly across brands. While some may provide lower upfront costs, others justify their pricing with superior technology and longevity. Consumers must evaluate the ultimate cost of ownership, considering both purchase price and long-term operational expenses.

Customer Reviews and Experiences

This section explores user feedback and personal narratives related to a specific type of power supply equipment. Customers often share insights about performance, reliability, and overall satisfaction, providing valuable information for potential buyers.

Common Themes in Feedback

Many users appreciate the efficiency and durability of the equipment, noting that it consistently meets their energy needs. Several reviews highlight ease of maintenance and availability of replacement components as significant advantages.

Rating Summary

| Rating | Number of Reviews |

|---|---|

| 5 Stars | 120 |

| 4 Stars | 75 |

| 3 Stars | 30 |

| 2 Stars | 10 |

| 1 Star | 5 |