The intricate world of power equipment involves various essential elements that work harmoniously to ensure optimal performance. A comprehensive overview of these components is crucial for users who seek to maintain or enhance their machinery’s functionality. By examining the relationships and functions of each piece, one can gain valuable insights into effective operation and maintenance.

For individuals looking to delve deeper into their equipment, visual representations serve as a fundamental resource. These illustrations not only simplify complex assembly structures but also facilitate a clearer understanding of the specific roles each element plays. By utilizing such resources, operators can effectively troubleshoot issues and perform necessary repairs with confidence.

Moreover, recognizing the significance of each component can lead to informed decision-making when it comes to replacements and upgrades. A solid grasp of the equipment’s inner workings allows users to make choices that enhance both efficiency and longevity. Thus, exploring the layout of these integral parts is an essential step for anyone aiming to optimize their tool experience.

The assembly of this powerful tool consists of several critical components that work in unison to ensure optimal performance. Understanding these elements is essential for effective maintenance and operation.

The main sections of the assembly include:

- Power Unit

- Chassis and Housing

- Operational Controls

- Attachment Mechanism

- Safety Features

Each of these sections plays a vital role in the overall functionality of the equipment, contributing to its reliability and efficiency. Proper knowledge of these components aids users in troubleshooting and ensuring longevity.

Key Components and Their Functions

This section explores essential elements of a powerful tool, highlighting their roles and contributions to overall performance. Understanding these components can enhance the efficiency and effectiveness of operations.

- Motor: The driving force behind the tool, responsible for providing the necessary power to perform tasks.

- Gearbox: This component regulates the speed and torque, ensuring optimal operation under various conditions.

- Chisel: Designed for precision, this part facilitates effective material removal or alteration during use.

- Handle: Providing grip and control, this component ensures user comfort and safety while operating the tool.

- Switch: The mechanism that allows for easy activation and deactivation, enhancing user convenience.

Each of these elements works in harmony to deliver superior functionality, making the tool reliable for various applications.

Maintenance Tips for Longevity

Ensuring the durability of your tools requires regular attention and care. By implementing a few key practices, you can significantly extend the lifespan of your equipment and maintain optimal performance. Understanding the importance of maintenance will help you avoid unnecessary repairs and replacements.

Regular Cleaning

Keeping your tools clean is essential. Dust, debris, and moisture can accumulate, leading to potential malfunctions. Use a soft cloth and appropriate cleaning agents to remove any buildup, paying special attention to moving parts.

Scheduled Inspections

Conducting regular inspections helps identify wear and tear before it becomes a serious issue. Check for signs of damage or loose components and address any concerns promptly. This proactive approach will enhance reliability and performance over time.

Common Issues with TE 905 Parts

When working with power tools, certain components may experience wear and tear, leading to operational challenges. Understanding these common issues can help users maintain performance and extend the lifespan of their equipment.

Wear and Tear of Internal Mechanisms

Over time, internal mechanisms can become less efficient due to prolonged usage. This may manifest as reduced power output or inconsistent operation. Regular inspections and timely replacements of worn components are essential to ensure optimal functionality.

Connection Failures

Another frequent issue arises from connections between various elements. Loose or damaged connections can lead to disruptions in power delivery or even complete failure to operate. Ensuring that all connections are secure and in good condition can mitigate these problems.

Replacement Parts: Where to Find Them

Finding the right components for your tools is essential for maintaining their functionality and longevity. Whether you need to replace worn-out items or upgrade certain features, knowing where to source these essential elements can make a significant difference in your equipment’s performance.

Authorized Dealers

One of the most reliable options for acquiring components is through authorized dealers. These retailers not only guarantee authenticity but also provide expert advice and support. They often have a comprehensive inventory of items specific to your tool model, ensuring you receive the correct fit and quality.

Online Marketplaces

For convenience and often competitive pricing, online marketplaces are a great alternative. Websites dedicated to industrial supplies or large e-commerce platforms offer a wide range of components, often with customer reviews that can help guide your choices. However, it’s important to verify the seller’s reputation and return policies before making a purchase.

Step-by-Step Disassembly Guide

This section aims to provide a clear and structured approach to disassembling the tool efficiently and safely. Following these steps will help ensure that each component is removed correctly, minimizing the risk of damage.

Preparation Before Disassembly

Before starting the disassembly process, gather the necessary tools and equipment. Make sure to work in a well-lit area and wear appropriate safety gear. Organizing the workspace will streamline the process and help keep track of the components as they are removed.

Disassembly Steps

Begin by removing the outer casing, followed by unscrewing any internal fasteners. Carefully lift out each part, taking care to note their positions for reassembly. Documenting the process can be helpful for future reference. Always handle the internal mechanisms with care to avoid damaging delicate components.

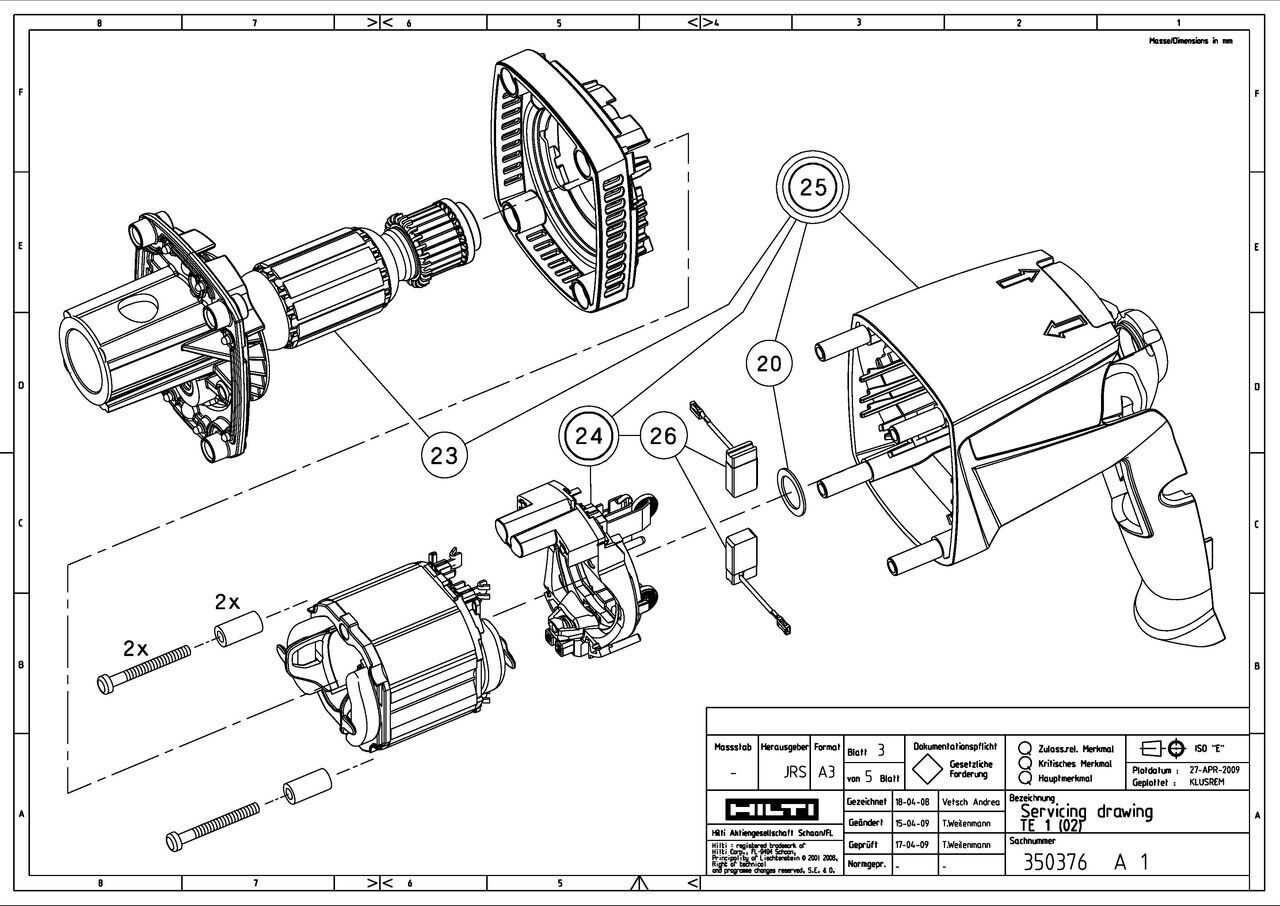

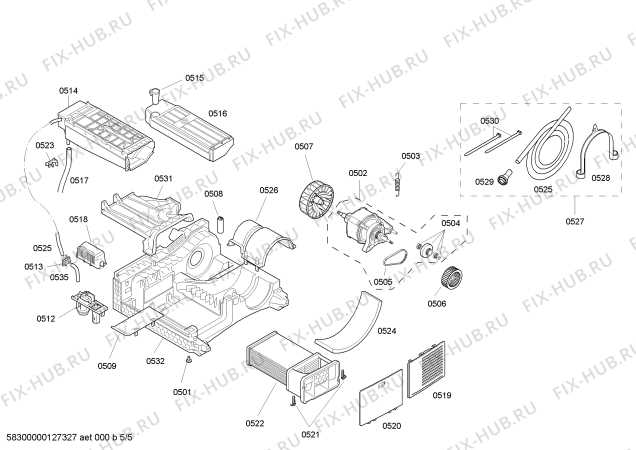

Illustrating the Parts Diagram

This section aims to provide a clear visual representation of various components found in power tools. Understanding how each element interacts is crucial for effective maintenance and repairs. A well-organized illustration can serve as a valuable reference for technicians and enthusiasts alike.

Understanding Component Relationships

By showcasing the relationships between different elements, users can better grasp the assembly and functionality of the equipment. Recognizing how parts fit together enhances troubleshooting skills and promotes more efficient repairs.

Benefits of Visual Guides

Visual aids simplify complex information, making it easier to understand the structure and function of each element. Such guides are indispensable for both novice users and experienced professionals, facilitating quicker decision-making and effective problem-solving.

How to Interpret the Diagram

Understanding technical illustrations can enhance your ability to service and maintain equipment effectively. These visual representations provide crucial information regarding various components and their interrelations, helping users identify parts and functions with ease.

Key Elements to Consider

Focus on the labels and symbols used within the illustration. Each part is typically represented with a unique identifier, often accompanied by a description. Pay attention to the orientation of the components, as it can indicate their arrangement and how they interact with one another.

Cross-Referencing with Manuals

Utilize accompanying documentation to clarify any uncertainties. Manuals often provide detailed explanations and troubleshooting tips, which can be invaluable when interpreting complex illustrations. Cross-referencing these resources can ensure a thorough understanding of the entire assembly.

Frequently Asked Questions about TE 905

This section addresses common inquiries related to the specific model, focusing on its features, maintenance, and troubleshooting. Whether you are a novice or an experienced user, these questions will provide valuable insights into the operation and care of this equipment.

General Information

Understanding the fundamental aspects of the device can enhance its usage and longevity. Here are some typical queries:

| Question | Answer |

|---|---|

| What is the recommended power supply for this model? | The equipment operates best with a standard voltage supply, typically around 230 volts. |

| How often should I perform maintenance? | Regular maintenance is advised every six months to ensure optimal performance. |

| What should I do if the machine overheats? | If overheating occurs, turn off the device and allow it to cool for at least 30 minutes before further use. |

Usage Tips

To maximize efficiency and effectiveness, consider the following recommendations:

| Tip | Description |

|---|---|

| Always use the correct accessories | Utilizing compatible accessories will enhance performance and prevent damage. |

| Keep the workspace clean | A tidy environment reduces hazards and improves efficiency. |

| Read the manual thoroughly | Familiarizing yourself with the manual ensures you understand all functionalities. |