Exploring the inner workings of a lawn vehicle reveals the intricacies behind its performance and reliability. Every mechanism is comprised of multiple elements working together to ensure smooth operation. Recognizing the layout and functionality of these elements helps in maintaining the vehicle and ensures longevity and efficiency.

Each section of the machinery plays a critical role, from driving mechanisms to cutting systems. By understanding the placement and interaction of various elements, it becomes easier to diagnose issues, perform maintenance, and enhance the performance of the machine.

Knowing the full composition of these elements not only aids in repairs but also empowers the user to customize and optimize performance. This insight offers practical benefits for both new and experienced users, ensuring the machinery continues to function at its best for years to come.

John Deere SRX95 Component Breakdown

Understanding the individual elements of this lawn care vehicle is essential for effective maintenance and troubleshooting. Each piece plays a crucial role in the operation, and a clear understanding of how these components fit together can simplify repairs and replacements.

The power source of the machine is connected to a system that drives the blades and wheels, ensuring efficient movement and cutting action. The seating area is mounted securely, providing the user with comfort during operation. Controls are conveniently placed, allowing the operator to easily manage the speed and cutting height. Additional features, such as safety mechanisms, ensure reliable function during use.

Various connections and fasteners hold the framework together, supporting the mechanical and hydraulic systems. Key structural elements offer both protection and ease of access for maintenance. By breaking down these critical systems, users can better understand how to maintain and repair their equipment for optimal performance.

Identifying Key Parts of the SRX95

Understanding the main components of your equipment is essential for maintaining its efficiency and extending its lifespan. In this section, we will explore the crucial elements that ensure optimal performance, helping you to easily recognize and address any maintenance needs.

| Component | Function | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | The powerhouse that drives the machine, providing the necessary energy for movement and operation. | ||||||||||||||||||||||||

| Steering System | Allows precise control and maneuverability, ensuring smooth direction changes and handling. | ||||||||||||||||||||||||

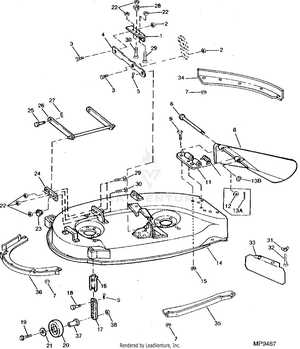

| Cutting Deck | Responsible for trimming grass, this element’s sharp blades and adjustable height settings offer tailored lawn care. | ||||||||||||||||||||||||

| Transmission | Regulates power distribution from the motor to the wheels, ensuring proper speed and torque. | ||||||||||||||||||||||||

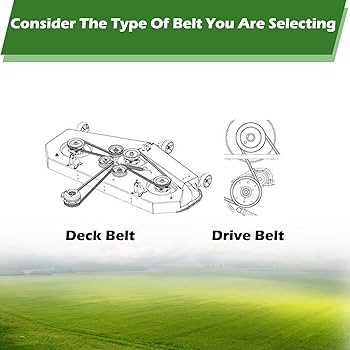

| Drive Belt | Connects key mechanisms, transmitting m

Understanding the Functionality of the Cutting Deck

The cutting deck plays a crucial role in maintaining the efficiency and precision of grass trimming. It ensures that vegetation is cut smoothly and evenly across the surface. By understanding how this mechanism operates, you can optimize its performance and prolong the lifespan of your equipment. Key Components of the DeckSeveral essential parts contribute to the deck’s overall function. Together, they enable seamless mowing, ensuring consistent results on various terrains.

Optimizing Performance

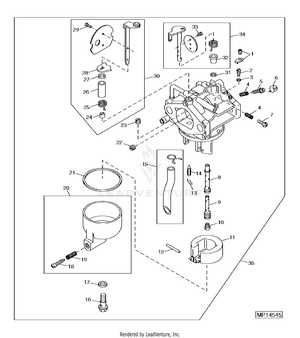

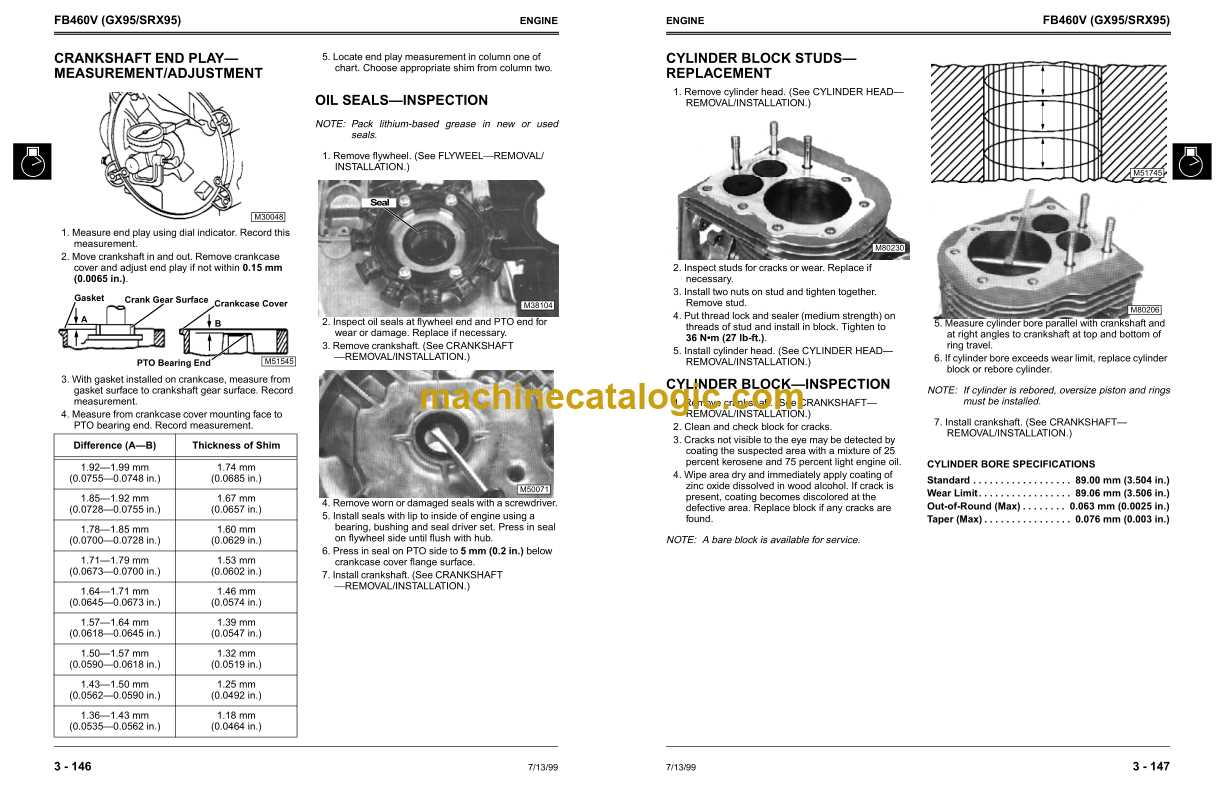

To keep the deck in optimal Exploring the Engine Layout and Details

The structure of the power unit plays a crucial role in ensuring optimal performance and reliability. Understanding the arrangement of key components and how they interact provides valuable insight into the overall functionality of the machine. This section will break down the essential elements and explain their connections, helping to visualize the complete system. Core Components Overview

The engine is made up of several critical parts that work together harmoniously to generate power. Each component has a specific purpose, contributing to the overall efficiency of the system.

Mechanical Interactions

The interact The Drive System and How It OperatesThe driving mechanism in this type of machine is designed to ensure smooth and efficient movement across various terrains. Its functionality is based on a complex combination of components that work together to transfer energy from the engine to the wheels, allowing the vehicle to move with precision and control. Understanding this system is crucial for maintaining optimal performance, as each element plays a vital role in delivering power and managing speed effectively. Power transmission is a key aspect of the mechanism, relying on a network of gears and belts to transfer energy efficiently. The engine’s output is directed through these elements, which regulate the speed and force applied to the wheels. This ensures that the vehicle can adjust to different conditions, whether moving on flat surfaces or inclines. Additionally, the system includes clutches and brakes to control the flow of power and manage stopping. The clutch mechanism allows for smooth transitions between gear changes, while the braking system ensures safe operation by reducing speed or bringing the machine to a halt when necessary. Proper maintenance of these components Electrical System Overview for the SRX95

The electrical framework of this model plays a crucial role in ensuring optimal performance and efficiency. This system is designed to provide power and facilitate communication between various components, allowing the machine to operate smoothly under different conditions. Understanding the intricacies of this network can aid in troubleshooting and maintenance, ensuring longevity and reliability. Key Components

Several critical elements contribute to the overall functionality of the electrical setup. Each component serves a specific purpose, and together they create a cohesive system that enhances performance.

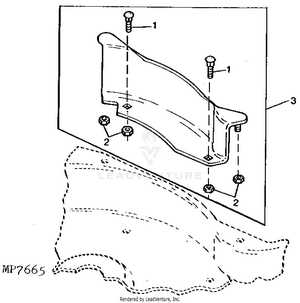

System FunctionalityThis network operates seamlessly to ensure that all electrical components function as intended. Regular checks and maintenance of the electrical elements can prevent potential issues, leading to enhanced performance and reliability. Understanding this framework is vital for effective troubleshooting and servicing. Steering Mechanism and Related ComponentsThe steering system is a vital aspect of any vehicle, playing a crucial role in ensuring precise maneuverability and control. This mechanism is designed to facilitate smooth navigation and responsiveness while operating the machine. Understanding its components and their functions can enhance maintenance efforts and optimize performance. Components of the steering system typically include the steering wheel, linkage, and actuator. The steering wheel is the primary control interface for the operator, allowing for easy adjustments to the vehicle’s direction. The linkage connects the wheel to the steering actuator, translating the driver’s input into movement. The actuator, often a hydraulic or mechanical unit, amplifies the steering force to ensure effortless handling. Regular inspection of these components is essential for identifying wear and tear, which can lead to decreased functionality. Proper lubrication and alignment of the steering linkage are also critical for maintaining optimal performance. By understanding the intricacies of the steering system, operators can ensure safe and efficient operation. Transmission System and Its ComponentsThe transmission system is a vital aspect of any machinery, responsible for transferring power from the engine to the wheels. It consists of various components that work together to ensure efficient movement and control of the equipment. Understanding these elements is crucial for proper maintenance and optimal performance. The key components of the transmission system include:

Each of these components plays a significant role in the overall functionality of the transmission system, making it essential to maintain them properly for optimal performance and longevity of the equipment. Maintaining the Mower Blades for EfficiencyProper upkeep of cutting tools is essential for achieving optimal performance and extending the lifespan of lawn care equipment. Regular maintenance not only enhances the efficiency of the machinery but also ensures a clean and precise cut, promoting healthier grass growth. By following a few simple practices, users can ensure that their cutting implements operate at peak effectiveness. Regular Inspection and Sharpening

Frequent examination of cutting implements is crucial. Dull blades can cause uneven cuts and lead to stress on the grass, making it more susceptible to disease. It is recommended to inspect the blades at least once a month during the mowing season. Sharpening should occur whenever signs of dullness appear, which may include frayed grass edges. Using a sharpening tool designed for the specific blade type can make this task easier and more effective. Cleaning and LubricationAfter each use, it is important to clean the cutting components to remove grass clippings, dirt, and debris. This helps prevent rust and corrosion, which can degrade the quality of the blades over time. Additionally, applying lubricant to moving parts reduces friction and wear, contributing to smoother operation. Following these maintenance steps will not only enhance performance but also extend the lifespan of the equipment. Fuel System Layout and Parts Identification

The layout of the fuel delivery system is crucial for the efficient operation of machinery. Understanding the configuration and components involved ensures optimal performance and maintenance. This section provides an overview of the essential elements within this system, facilitating effective troubleshooting and servicing. Key Components

Layout Overview

The arrangement of these components typically follows a streamlined path from the fuel tank to the engine. The flow begins at the tank, where the fuel pump draws the liquid and pushes it through the filter to eliminate impurities. Subsequently, the fuel travels through the lines to reach the injector, which delivers it directly into the combustion chamber. This process highlights the interconnectivity of the components, each contributing to the overall efficiency of the system. Essential Maintenance Tips for LongevityEnsuring the extended lifespan of your equipment requires regular attention and care. Adopting a systematic maintenance approach can help prevent breakdowns and enhance performance. Here are some fundamental practices to consider for optimal upkeep.

By implementing these maintenance strategies, you can significantly improve the reliability and efficiency of your machinery, ensuring it remains in excellent working condition for years to come. |