In the realm of cold-weather machinery, understanding the intricate elements that comprise these powerful devices is essential for effective maintenance and operation. Each component plays a crucial role in ensuring optimal performance during challenging winter conditions.

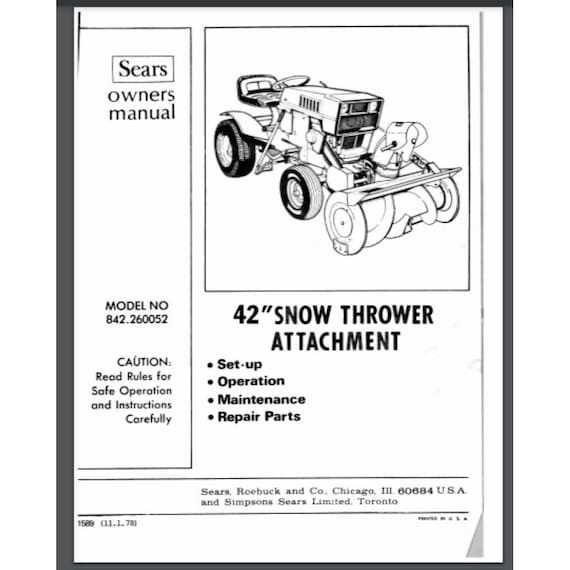

Illustrations of these components provide valuable insights into their arrangement and functionality, enabling users to identify and address potential issues efficiently. This knowledge not only enhances the longevity of the machinery but also ensures safety and reliability in usage.

Whether you’re a seasoned user or a newcomer, familiarizing yourself with the various elements involved will empower you to make informed decisions regarding repairs and upgrades. Embracing this understanding can significantly improve your experience with winter equipment.

Understanding Snow Thrower Components

When it comes to efficient winter machinery, comprehending the various elements involved is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring that the device operates smoothly and effectively, helping to clear pathways and driveways during heavy snowfall.

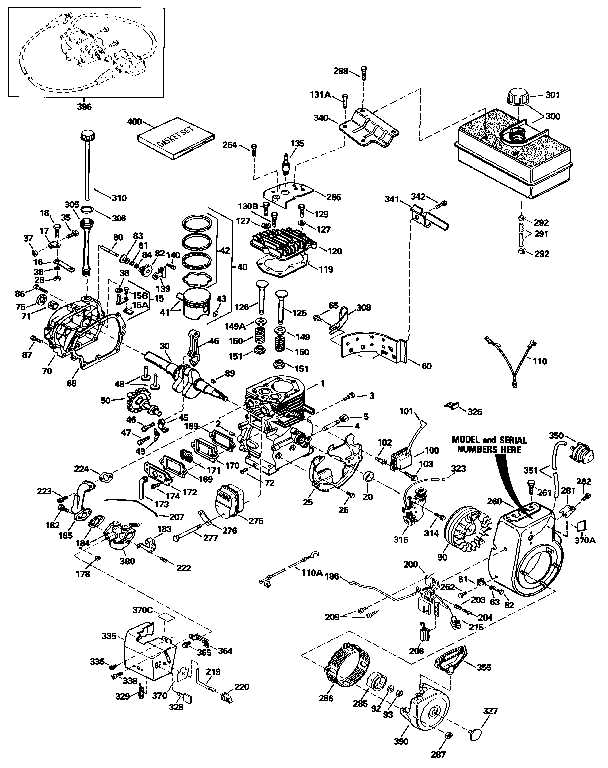

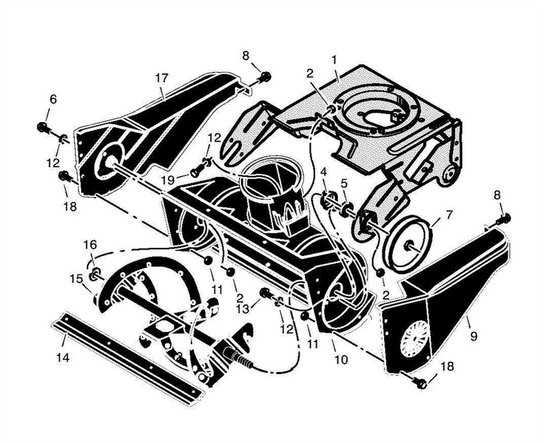

Key elements of these machines include the engine, which provides the necessary power, and the auger, which facilitates the movement of accumulated material. Additionally, the discharge chute directs the flow of cleared debris, making it essential for maneuverability. Understanding how these parts interact can lead to improved functionality and longevity of the equipment.

Regular maintenance and knowledge of replacement options enhance reliability, ensuring that the device remains a valuable tool throughout the winter season. Familiarizing oneself with the operational mechanics and potential issues can empower users to tackle challenges efficiently.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of any mechanical equipment. Proper maintenance not only enhances performance but also extends the lifespan of the machine, preventing costly repairs and replacements in the future.

Implementing a routine maintenance schedule can help identify potential issues before they escalate. Key actions include cleaning, lubricating moving parts, and checking for wear and tear. This proactive approach minimizes downtime and maximizes operational efficiency.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Cleaning | After each use | Prevents buildup and corrosion |

| Lubrication | Every season | Ensures smooth operation |

| Inspection | Monthly | Identifies potential issues early |

Common Issues and Troubleshooting Tips

Understanding typical challenges that arise during operation can significantly enhance performance and longevity of outdoor equipment. By identifying these common problems, users can implement effective solutions to ensure smooth functionality.

1. Engine Won’t Start: This is a frequent issue that may stem from various factors, such as fuel blockage or battery failure. Ensure that the fuel is fresh and the battery is charged. Additionally, check for any loose connections or damaged components.

2. Poor Performance: If the machine struggles to operate efficiently, inspect the blades for wear or damage. Dull blades can lead to ineffective operation, so regular sharpening or replacement is recommended.

3. Unusual Noises: Strange sounds during use could indicate mechanical issues. Check for foreign objects lodged in the machinery and ensure all bolts and screws are securely fastened.

4. Excessive Vibration: Vibration may result from imbalanced components or wear. Regular maintenance and inspection of the base and attached parts can prevent this problem.

Addressing these issues promptly will enhance reliability and extend the lifespan of your equipment.

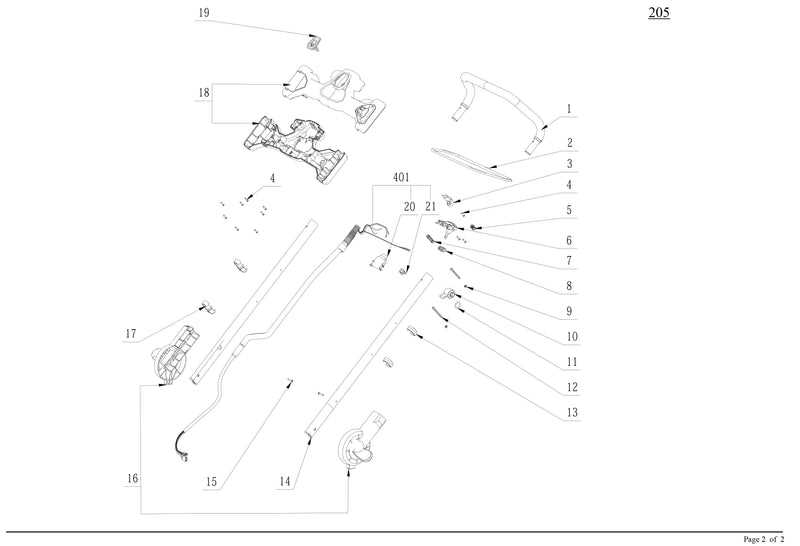

How to Identify Replacement Parts

Identifying suitable components for your equipment is crucial for ensuring optimal performance. Start by reviewing the manufacturer’s specifications and recommendations. Understanding the model and serial numbers can help streamline the process of finding the right items.

Next, consult online resources or repair manuals that provide detailed information about various components and their functions. Comparing visuals can be beneficial; diagrams or images can assist in recognizing parts more easily.

Additionally, consider reaching out to local suppliers or forums where enthusiasts discuss their experiences. Engaging with the community can provide insights into where to locate hard-to-find elements and the best options for replacements.

Step-by-Step Assembly Instructions

This section provides detailed guidance for assembling your equipment efficiently. Following these instructions will ensure that each component is correctly fitted, promoting optimal functionality and longevity of the machine.

Begin by organizing all components in a clean workspace. Verify that you have all necessary elements before starting the assembly process. Refer to the provided list to ensure nothing is overlooked.

Start by connecting the main frame to the engine unit. Secure it with the appropriate fasteners, ensuring a tight fit. Next, attach the control panel, making sure all wiring is properly connected to avoid any operational issues.

Proceed to install the wheels, ensuring they are aligned and securely fastened. After that, focus on attaching any additional accessories, following the specific order recommended in your reference material.

Finally, conduct a thorough inspection of all connections and components. Make any adjustments as needed to guarantee everything is securely in place. Once completed, your equipment should be ready for use.

Safety Precautions When Operating

Ensuring safety while handling outdoor equipment is crucial for both the operator and those nearby. Proper precautions can significantly reduce the risk of accidents and injuries during operation.

Always wear appropriate protective gear such as gloves, goggles, and sturdy footwear. This gear shields against potential hazards, including flying debris and sharp objects.

Before starting the equipment, familiarize yourself with its controls and functions. Read the manufacturer’s guidelines to understand how to operate it safely and effectively. Regular maintenance is also vital to ensure that all components are functioning correctly and safely.

Be aware of your surroundings. Clear the work area of obstacles and bystanders to create a safe operational zone. Avoid working in adverse weather conditions that can impair visibility or affect the performance of the equipment.

Finally, never operate under the influence of alcohol or drugs, as this can severely impair judgment and reaction time. By following these essential precautions, you can ensure a safer and more efficient working experience.

Upgrades to Enhance Performance

Improving the efficiency and functionality of your equipment can lead to significant benefits, especially during challenging weather conditions. By investing in the right enhancements, you can optimize performance and ensure greater reliability.

Engine Modifications

Upgrading the engine can provide a noticeable boost in power and speed. Consider options like enhanced air filters and performance exhaust systems to increase airflow and combustion efficiency, ultimately leading to improved overall output.

Enhanced Traction Solutions

Implementing better traction options such as specialized tires or chains can greatly improve handling and stability. This not only enhances maneuverability but also ensures safe operation on various surfaces, making your equipment more versatile.

Where to Find Genuine Parts

Finding authentic components for your equipment is essential for ensuring optimal performance and longevity. Numerous avenues are available to help you source the right items, allowing you to maintain your machinery effectively.

Authorized Retailers

- Visit local authorized dealers who specialize in equipment maintenance.

- Check online platforms of these retailers for a comprehensive catalog.

Manufacturer’s Website

- Explore the official website for direct access to a parts store.

- Utilize their search function to locate specific items easily.

Comparative Analysis of Models

This section delves into the evaluation of different units within a specific category, highlighting their unique features and functionalities. By examining various designs, one can identify strengths and weaknesses that cater to diverse user needs.

Each model presents a distinct combination of specifications and capabilities. Understanding these variations aids consumers in making informed decisions, as it directly impacts performance and usability. Factors such as size, engine power, and efficiency are crucial in determining the suitability of each unit for particular tasks.

Moreover, durability and maintenance requirements play significant roles in user experience. Some models may offer superior longevity and easier upkeep, which can be a decisive factor for potential buyers. Analyzing user feedback and expert reviews further enriches this comparative study, providing insights into real-world performance and reliability.

Cost-Effective Repair Solutions

When it comes to maintaining outdoor equipment, finding budget-friendly repair options can significantly extend the life of your machinery. By utilizing accessible resources and understanding basic maintenance practices, you can effectively address common issues without incurring high costs.

Utilizing Reusable Components

One of the most effective strategies is to assess and refurbish components that can be reused. Many users overlook the potential of existing parts that may only require minor adjustments or cleaning to function optimally. This approach not only saves money but also promotes sustainability.

DIY Repair Techniques

Engaging in do-it-yourself repairs can be a rewarding experience. There are numerous online tutorials and forums that provide step-by-step guidance on common fixes. By investing time in learning these techniques, you can tackle repairs confidently and reduce reliance on professional services.

FAQs About Snow Thrower Parts

This section addresses common inquiries related to components of winter equipment. Understanding these elements can enhance maintenance practices and overall performance, ensuring effective operation during cold months.

Common Questions

- What should I do if a component is damaged?

- How can I identify the right replacement for a specific piece?

- Are there any maintenance tips to prolong the lifespan of these items?

Replacement and Maintenance Tips

- Regularly inspect all components for wear and tear.

- Keep the machinery clean to prevent buildup that can cause damage.

- Follow the manufacturer’s guidelines for installation and upkeep.