In any mechanical system, grasping the relationship between various components is essential for effective operation and maintenance. This section delves into the intricate relationships and functions of different elements that work together to ensure seamless functionality. A comprehensive overview of these components can enhance one’s understanding of the entire mechanism.

Analyzing how each segment interacts can provide valuable insights into troubleshooting and optimizing performance. Familiarity with the configuration and roles of these essential elements equips individuals with the knowledge needed to address common issues and implement improvements. By exploring the structural layout and functions of these interconnected parts, users can gain a deeper appreciation for the complexity of the system.

Furthermore, recognizing the significance of each component fosters a proactive approach to maintenance and repairs. Understanding how to identify and replace specific elements can lead to enhanced efficiency and longevity of the overall system. This exploration aims to empower readers with the knowledge necessary to navigate the intricacies of these mechanical arrangements effectively.

Understanding Elevator Components

Within modern transportation systems, various essential elements work together to facilitate smooth and efficient vertical movement. Each component plays a vital role, contributing to the overall functionality and safety of the mechanism. A comprehensive understanding of these elements can enhance the appreciation of the sophisticated engineering behind such systems.

Main Functional Elements

The primary functional elements include mechanisms for movement, control, and safety. These critical components ensure that users experience a reliable and secure ascent or descent. Their design is meticulously crafted to handle significant weight and stress while maintaining performance and safety standards.

Support structures and safety mechanisms are crucial for the stability and protection of passengers. These systems are engineered to respond effectively in emergencies, providing peace of mind during use. Understanding their operation is essential for recognizing the importance of safety features in any vertical transport system.

Types of Elevator Systems

This section explores various mechanisms designed to facilitate vertical transportation in buildings. Different systems cater to specific requirements, balancing efficiency, speed, and capacity, thus enhancing user experience and safety.

Hydraulic Systems

Hydraulic mechanisms utilize fluid pressure to lift and lower the carriage. This system is typically employed in low to mid-rise structures, offering a smooth ride and reliable operation. Advantages include less noise and the ability to lift heavier loads, while disadvantages encompass slower speeds and the need for a machine room.

Traction Systems

Traction mechanisms operate using ropes and pulleys, driven by an electric motor. These systems are common in high-rise buildings due to their efficiency and speed. Key benefits include energy efficiency and the ability to achieve higher speeds, while drawbacks involve more complex installation and maintenance requirements.

Key Functions of Elevator Parts

The functionality of a vertical transport system relies on various components that work together to ensure smooth and safe operation. Each element plays a vital role, contributing to the overall performance, reliability, and safety of the entire mechanism. Understanding these roles helps in recognizing the importance of maintenance and timely inspections.

Essential Elements and Their Roles

The following table outlines the primary components and their key functions within the vertical transport system:

| Component | Function |

|---|---|

| Motor | Drives the movement of the system, enabling it to ascend and descend as needed. |

| Control System | Manages operations, ensuring that the system responds accurately to user commands and safety protocols. |

| Cable | Transmits the force from the motor to facilitate movement, supporting the weight of the cabin. |

| Safety Mechanism | Prevents free fall and enhances user safety during operation, engaging in emergencies. |

| Cabin | Provides the enclosed space for passengers, designed for comfort and accessibility. |

Importance of Regular Maintenance

Consistent upkeep of each element is crucial for optimal functionality. Neglecting any component can lead to performance issues or safety hazards. Routine inspections and timely repairs contribute significantly to the longevity and reliability of the vertical transport system.

Safety Mechanisms in Elevators

Ensuring the secure operation of vertical transportation systems is crucial for user confidence and overall functionality. Various protective features are integrated to prevent accidents and enhance passenger safety. These mechanisms work collectively to address potential risks and maintain the reliability of the lifting systems.

Key Safety Features

One of the primary components designed to enhance security is the emergency braking system. This feature activates during unexpected scenarios, halting movement and preventing falls. Another important aspect is the door locking mechanism, which ensures that entryways are securely closed before movement begins, mitigating the risk of accidents during transit.

Regular Maintenance and Testing

To guarantee the effectiveness of these safety features, routine inspections and maintenance are essential. Regular checks help identify wear and tear, ensuring all mechanisms function as intended. This proactive approach is vital in sustaining the reliability of the system and safeguarding all users.

How Elevators are Powered

The operation of vertical transportation systems relies on various energy sources and mechanisms to ensure smooth and efficient movement between different levels. Understanding how these systems are energized provides insight into their functionality and reliability in modern architecture.

Power Sources

Various energy sources are employed to facilitate vertical movement. The most common include:

- Electric Motors: The primary source of energy, these motors convert electrical energy into mechanical motion.

- Hydraulic Systems: Utilizing fluid pressure, these systems lift and lower the carriage by controlling hydraulic fluid flow.

- Counterweights: Balancing the load, counterweights reduce the energy required by motors to move the carriage.

Control Mechanisms

In addition to power sources, various control systems ensure safe and efficient operation:

- Microcontrollers: These electronic devices manage the motor’s operation, ensuring precise movements.

- Sensors: Safety and positioning sensors detect the system’s status, preventing accidents and ensuring smooth operation.

- Safety Brakes: In case of malfunction, these mechanisms activate to halt movement and secure the carriage in place.

Common Elevator Malfunctions

In any vertical transportation system, various issues can arise that impede functionality and user safety. Understanding these common problems can help in diagnosing faults and ensuring efficient operation. This section explores frequent challenges encountered in such systems.

Unexpected Stops: One of the most prevalent issues is sudden halting. This can occur due to sensor malfunctions, wiring issues, or software glitches. When a carriage stops unexpectedly between floors, it can cause panic among passengers and delay transit.

Door Malfunctions: Another frequent complication involves the entry and exit mechanisms. Problems such as doors failing to open or close properly can result from mechanical wear, misalignment, or electrical failures. Ensuring smooth operation is crucial for passenger convenience and safety.

Noise and Vibration: Unusual sounds or excessive movement can indicate underlying mechanical problems. Grinding or rattling noises may signal issues with the motor, pulley system, or other components. Regular maintenance is essential to prevent these disturbances from escalating.

Overheating: Overheating can occur if the motor operates beyond its capacity, often due to prolonged use or inadequate ventilation. This not only affects performance but can also lead to system shutdowns to prevent damage.

Power Failures: Power interruptions can cause disruptions in functionality, leading to emergency protocols being activated. This situation necessitates backup systems to ensure user safety and efficient operations during outages.

Recognizing these typical issues and understanding their implications can facilitate timely repairs and enhance the reliability of vertical transportation systems.

Maintenance Tips for Elevators

Regular upkeep is essential for ensuring the smooth operation and longevity of vertical transport systems. By following a structured maintenance routine, you can significantly reduce the risk of unexpected breakdowns and enhance overall safety for users. This section outlines crucial practices that should be implemented to maintain optimal functionality.

Routine Inspections

Conducting periodic assessments is vital to identify potential issues before they escalate. Focus on checking components such as the control mechanisms, cables, and safety systems. Early detection of wear or malfunctions can prevent costly repairs and enhance operational reliability.

Professional Servicing

Engaging qualified technicians for in-depth maintenance is crucial. These experts possess the knowledge to perform intricate diagnostics and repairs. Regular professional servicing ensures that all elements function correctly and comply with safety regulations, giving peace of mind to both operators and users.

Key practices include:

- Keeping a log of maintenance activities.

- Replacing worn components promptly.

- Staying informed about regulatory requirements.

Modern Innovations in Elevator Design

Recent advancements in vertical transportation systems have transformed the way we experience mobility within buildings. These innovations enhance efficiency, safety, and user convenience, leading to a redefined approach to moving people and goods. The integration of cutting-edge technologies has opened new avenues for design and functionality, making these systems smarter and more adaptable to diverse environments.

Smart Technologies and Connectivity

The incorporation of smart technologies is revolutionizing the operation of vertical transport systems. Features such as real-time monitoring and predictive maintenance leverage data analytics to optimize performance and reduce downtime. Enhanced connectivity allows users to call for a ride through mobile applications, streamlining the user experience and minimizing wait times. This level of integration fosters greater control and personalization for individuals.

Sustainable and Energy-Efficient Solutions

In response to growing environmental concerns, the latest advancements focus on sustainability. The use of regenerative drives and energy-efficient motors significantly reduces energy consumption. Additionally, innovative materials and designs contribute to minimizing the overall carbon footprint. These eco-friendly approaches not only benefit the environment but also lead to long-term cost savings for building owners.

Importance of Proper Installation

Ensuring the correct setup of mechanical systems is crucial for their optimal performance and longevity. Accurate installation contributes significantly to safety, functionality, and reliability, impacting not only the equipment itself but also the users and the surrounding environment.

Safety Considerations

- Inadequate assembly can lead to malfunctions, posing risks to users.

- Correct positioning minimizes the chances of accidents, enhancing overall safety standards.

- Following guidelines reduces liability issues for operators and technicians.

Efficiency and Performance

- Proper configuration ensures smooth operation, reducing wear and tear on components.

- Well-installed systems maximize energy efficiency, leading to cost savings over time.

- Regular maintenance becomes easier when systems are installed correctly, facilitating troubleshooting and repairs.

In conclusion, meticulous attention to installation practices is vital. It not only ensures safety and efficiency but also contributes to the longevity and reliability of the mechanical systems in question.

Regulatory Standards for Elevators

The guidelines governing vertical transport systems play a crucial role in ensuring safety, reliability, and efficiency. These standards are established to protect users, maintenance personnel, and the general public. Compliance with these regulations is essential for manufacturers, installers, and operators to maintain operational integrity and public trust.

Various organizations contribute to the development and enforcement of these standards, often addressing aspects such as design, construction, inspection, and maintenance. Adhering to these regulations not only minimizes risks but also enhances the overall performance of these systems.

| Standard | Description | Issuing Organization |

|---|---|---|

| ASME A17.1 | Safety Code for Elevators and Escalators | American Society of Mechanical Engineers |

| EN 81 | Safety Rules for the Construction and Installation of Lifts | European Committee for Standardization |

| ISO 25745 | Energy Performance of Lifts | International Organization for Standardization |

| NFPA 70 | National Electrical Code | National Fire Protection Association |

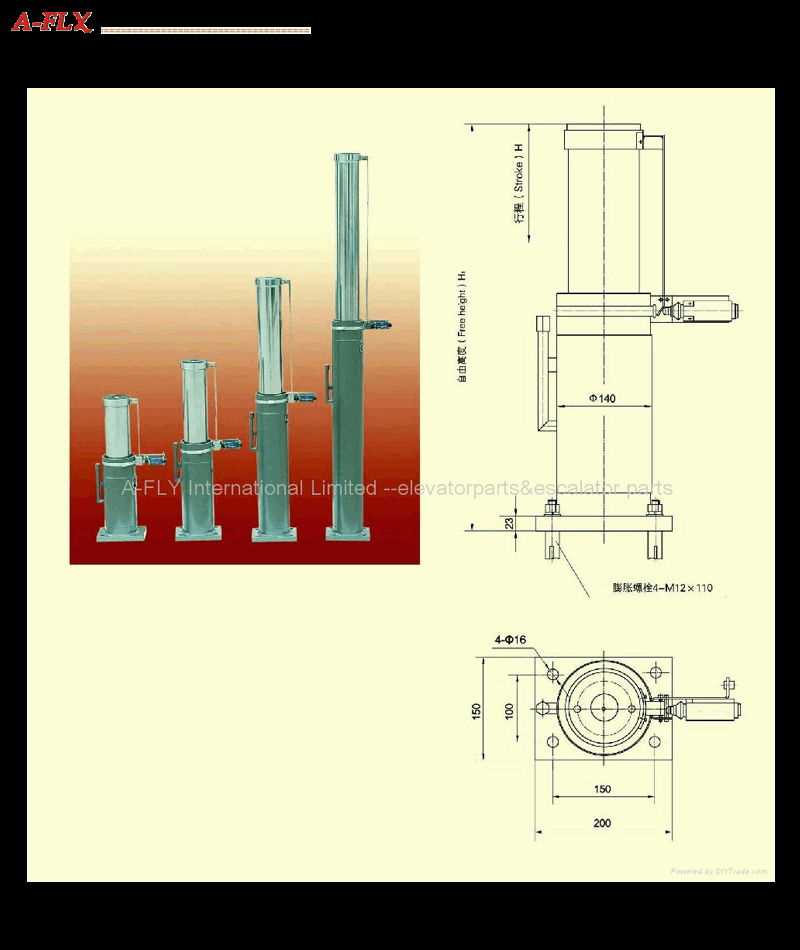

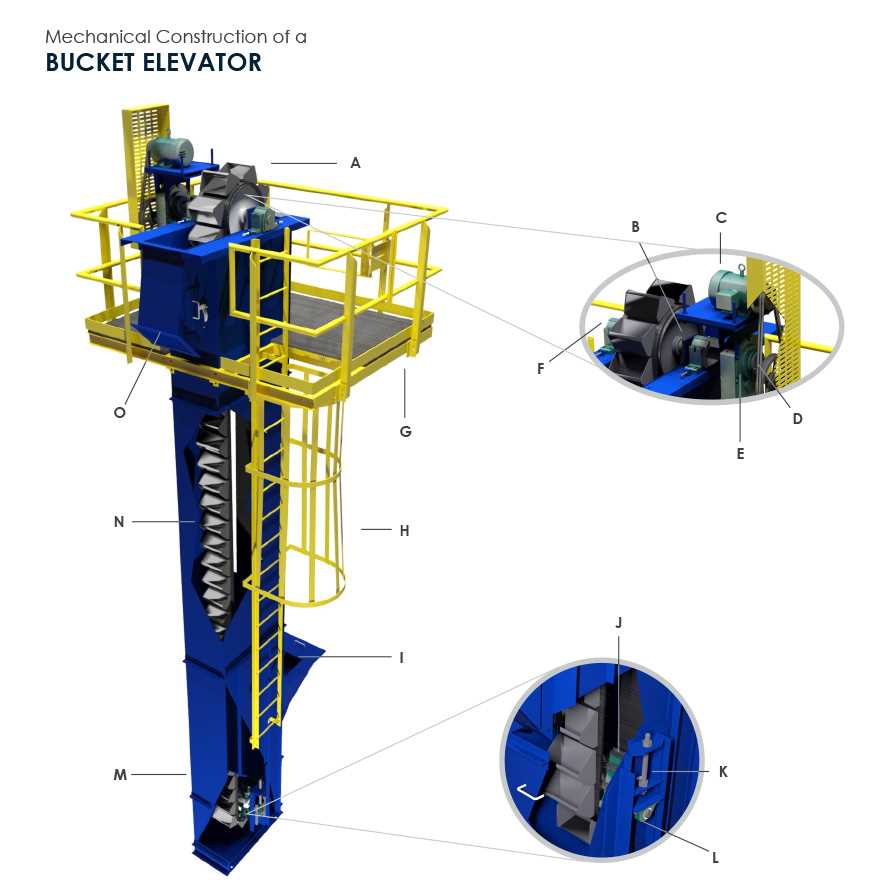

Diagram Interpretation for Technicians

Understanding visual representations of mechanical systems is crucial for professionals in the field. These illustrations serve as essential tools for identifying components and their relationships, facilitating efficient maintenance and troubleshooting. Technicians must develop skills to read and analyze these visuals to ensure optimal functionality and safety.

Key elements to consider when interpreting these visuals include:

- Symbols: Familiarize yourself with the various symbols used to represent different components. Each symbol conveys specific information that can aid in understanding the overall structure.

- Connections: Pay attention to how elements are interconnected. Recognizing these links is vital for diagnosing issues and implementing solutions.

- Annotations: Look for any accompanying notes or labels that provide additional context. These can clarify the function or specifications of each component.

- Scale: Assess the scale of the representation. A clear understanding of size relationships is necessary for effective installation or repair.

To enhance proficiency in this area, technicians can follow these guidelines:

- Study common representations used in the industry to build familiarity.

- Practice interpreting various illustrations to develop speed and accuracy.

- Collaborate with experienced colleagues to gain insights and tips.

- Utilize software tools that provide interactive features for better understanding.

By mastering the art of interpreting these visuals, technicians can significantly improve their effectiveness in maintaining and servicing mechanical systems, ultimately ensuring safety and reliability.

Future Trends in Elevator Technology

The evolution of vertical transportation systems is on the brink of significant advancements that promise to reshape the way we navigate multi-story structures. Emerging innovations are set to enhance efficiency, safety, and user experience in these mechanical transporters, catering to the demands of modern architecture and urban development.

Several key trends are anticipated to drive this transformation:

- Smart Systems: Integration of IoT technology will enable real-time monitoring and predictive maintenance, ensuring optimal performance and reducing downtime.

- Energy Efficiency: Development of regenerative drives and advanced materials will lead to systems that consume less energy, supporting sustainability efforts.

- Modular Design: Future designs will focus on modular components, allowing for easier upgrades and maintenance, as well as customization based on specific building needs.

- Autonomous Operation: The advent of autonomous navigation systems will facilitate seamless movement, reducing waiting times and improving overall convenience.

- Enhanced Safety Features: Innovations in safety protocols and emergency response systems will increase the security of users during operation.

As technology continues to advance, these trends will not only enhance the functionality of vertical transport systems but also contribute to the overall improvement of urban living spaces. The future holds exciting possibilities that will redefine our expectations of mobility within buildings.