Understanding the structure and elements of traditional black powder firearms can offer valuable insights into their design and functionality. These types of firearms have a long history, and examining their key components helps enthusiasts and professionals alike in maintaining and modifying them. Knowing how each piece interacts is crucial for both performance and safety.

In this guide, we delve into the essential elements of these firearms, breaking down each section to provide a clear view of how the entire mechanism works. Whether you’re looking to repair, upgrade, or simply learn more about these weapons, a detailed understanding of their anatomy is the first step.

Each segment is crafted with precision, and recognizing how they fit together allows for smoother operation and easier troubleshooting. From the ignition system to the barrel and trigger mechanisms, we will explore every crucial detail.

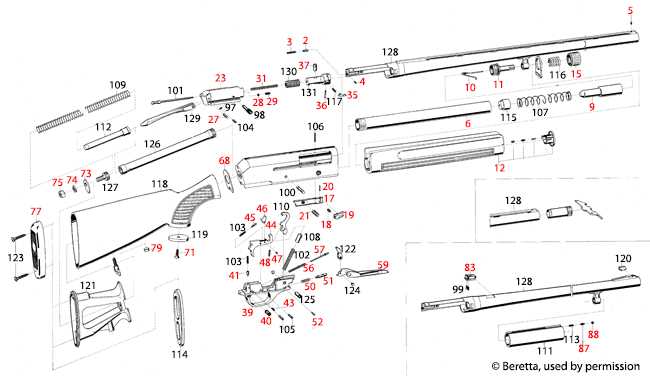

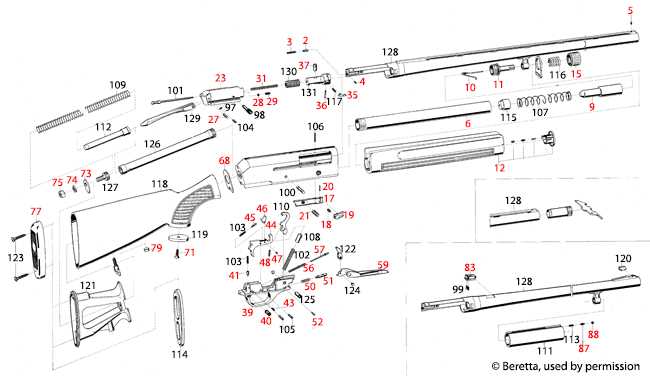

The internal and external structure of a modern inline black powder firearm consists of various crucial elements that ensure its performance, accuracy, and reliability. Understanding how these components work together is essential for maintaining and upgrading the firearm.

The primary components are meticulously designed to optimize efficiency during loading, firing, and cleaning. Each part plays a vital role in the overall operation, from the ignition system to the barrel and stock. Below is a detailed breakdown of the most significant elements found in this type of firearm.

| Component |

Function |

Internal Mechanism Structure of the Muzzleloader

The inner workings of this firearm are a complex yet efficient system designed to ensure smooth operation. The various components work together to achieve precise control over ignition, loading, and discharge. Each part plays a crucial role in maintaining performance and reliability, making the understanding of its construction vital for proper maintenance and usage.

At the core of the system lies a series of interconnected mechanisms responsible for igniting the charge. The firing process begins with the striker, which impacts the ignition source, transferring energy through the channels to initiate combustion. These elements are crafted to function seamlessly, ensuring safety and effectiveness during use.

Additionally, the loading and trigger systems are integral to the structure. The loading mechanism ensures that the ammunition is seated correctly, while the trigger assembly precisely releases the striker at the desired moment. Both systems are engineered to provide control and accuracy, contributing to the overall precision of the firearm.

Breakdown of Firing Pin Assembly

The firing pin assembly is a crucial component of any firearm, responsible for initiating the firing sequence. This mechanism operates by transferring the force of the hammer or striker to the primer, which ignites the propellant. Understanding the detailed construction and functionality of this assembly can aid in both maintenance and troubleshooting, ensuring optimal performance.

Main Components

The firing pin assembly consists of several key elements that work together to perform its function efficiently. Below is a simplified breakdown of its primary components

Trigger System Parts and Functions

The trigger system plays a crucial role in the firing mechanism, ensuring safe and precise performance. Understanding its components and how they interact is key to maintaining and enhancing the overall function of the firearm. Below, we will explore the main elements of the trigger mechanism and their specific roles.

Main Components of the Trigger Assembly

- Trigger Lever: This is the part that the shooter pulls to initiate the firing process. It transmits force to other internal components, leading to the release of the firing mechanism.

- Hammer: Responsible for striking the primer, the hammer is activated by the trigger and plays a vital role in setting off the firing sequence.

Barrel Components and Their Roles

The barrel plays a crucial role in the overall function of the firearm, ensuring both accuracy and safety during use. Understanding the various elements of the barrel and how they contribute to the firing process is essential for maintaining the device and improving performance.

Muzzle

The muzzle is located at the end of the barrel, where the projectile exits. It is engineered to provide a clean exit for the bullet, reducing any disturbances that could affect the accuracy. The design of the muzzle can also influence the amount of recoil experienced during firing.

Breech Area

Stock Assembly and Its Elements

The stock assembly is a fundamental component of a firearm, serving as the primary structure that houses various mechanisms and ensures stability during use. This assembly not only contributes to the overall aesthetics but also plays a crucial role in enhancing accuracy and control when handling the weapon.

Key elements of the stock assembly include the buttstock, which provides support against the shoulder, and the forearm, which aids in gripping and maneuvering. These parts are typically constructed from durable materials to withstand the stresses of repeated use. Additionally, components such as the recoil pad and sling swivels can be incorporated to improve comfort and versatility during operation.

Understanding the various elements of the stock assembly is essential for maintenance and customization. By familiarizing oneself with these components, users can ensure optimal performance and longevity of the firearm. Regular inspection and care can also prevent wear and enhance the shooting experience.

Ignition System Breakdown

The ignition mechanism plays a crucial role in the functionality of firearm systems, serving as the catalyst for propelling projectiles. This intricate assembly is designed to convert a small amount of energy into a powerful ignition source, ensuring reliability and efficiency in operation. Understanding the various components and their interactions can significantly enhance the user experience and maintenance practices.

Key Components

The ignition assembly typically consists of several essential elements. These include a firing mechanism, ignition source, and housing. Each component must work in harmony to ensure optimal performance. The firing mechanism, often spring-loaded, activates the ignition source upon trigger pull. This results in a rapid expansion of gases, which propels the projectile down the barrel.

Maintenance and Troubleshooting

Regular inspection and maintenance of the ignition system are vital for ensuring consistent performance. Users should check for signs of wear, corrosion, or damage. Cleaning the ignition components can prevent misfires and enhance reliability. Should issues arise, identifying the specific component that is malfunctioning can streamline repairs and reduce downtime.

Hammer Assembly and Key Features

The hammer assembly is a crucial component in the operation of various firearms, playing a vital role in initiating the firing sequence. Understanding its structure and functionality can enhance the overall performance and reliability of the weapon.

Key features of the hammer assembly include:

- Material Quality: High-grade materials are essential for durability and resistance to wear.

- Design Precision: Accurate manufacturing ensures a smooth operation and minimizes the risk of malfunctions.

- Weight Distribution: Proper balance aids in consistent trigger control and enhances shooting accuracy.

- Spring Mechanism: A robust spring system allows for efficient energy transfer, ensuring a reliable strike on the firing pin.

Regular maintenance and inspection of the hammer assembly are recommended to ensure optimal functioning. Any signs of wear or damage should be addressed promptly to maintain the integrity and safety of the firearm.

Maintenance of the Breech Plug

Proper upkeep of the breech plug is essential for ensuring optimal performance and safety. Regular maintenance helps prevent issues such as corrosion, debris buildup, and malfunctions, ultimately extending the lifespan of your firearm.

To maintain the breech plug effectively, follow these key steps:

- Inspection: Regularly check the breech plug for any signs of wear or damage. Look for cracks, rust, or unusual wear patterns that may indicate a need for replacement.

- Cleaning: Clean the breech plug after each use. Use a suitable solvent and a brush to remove fouling and residue. Ensure all nooks and crannies are thoroughly cleaned.

- Lubrication: Apply a light coating of high-quality lubricant to the threads of the breech plug. This prevents galling and ensures smooth operation during installation and removal.

- Testing: After maintenance, test the breech plug to ensure it fits correctly and functions properly. Perform this check before each use to guarantee safety.

By adhering to these maintenance practices, you can ensure the reliability and efficiency of your firearm’s breech mechanism.

Scope Mounting Hardware Explained

Understanding the components used for securing optical sights is crucial for achieving optimal accuracy and performance in shooting sports. Proper mounting hardware ensures that the scope remains stable and aligned, facilitating precise aiming and target acquisition. This section delves into the essential elements of scope mounting, outlining their functions and significance.

Types of Mounting Hardware

There are several types of hardware used in the installation of optical sights. Each type serves a specific purpose and can vary based on the design of the firearm and the scope being used. Here are the primary types of mounting components:

| Component |

Description |

| Base |

A platform attached to the firearm, providing the foundation for the scope mounts. |

| Rings |

Circular brackets that secure the scope to the base, available in different heights and widths. |

| Mounting Screws |

Fasteners that hold the rings and base together, ensuring a secure fit. |

| Locking Mechanisms |

Additional features to prevent movement of the scope after installation, enhancing stability. |

Importance of Proper Installation

Correct installation of mounting hardware is vital for maintaining accuracy. Misalignment or instability can lead to poor performance and missed targets. By carefully selecting and installing the appropriate components, shooters can enhance their overall shooting experience and effectiveness.

Recoil Pad and Buttstock Parts

The components related to the rear section of a firearm play a crucial role in enhancing user comfort and stability during use. These elements are designed to absorb shock, provide a secure grip, and improve overall handling, ensuring an enjoyable shooting experience. Understanding the various aspects of these components can aid in selecting the right accessories for optimal performance.

Recoil Pad

A recoil pad is an essential feature that mitigates the impact felt when a shot is fired. It not only enhances comfort but also helps in maintaining better control of the firearm. Key characteristics of a recoil pad include:

- Material: Often made from rubber or synthetic materials for effective shock absorption.

- Design: Ergonomically shaped to fit snugly against the shoulder.

- Thickness: Varies to accommodate different levels of recoil based on the firearm’s caliber.

Buttstock Components

The buttstock serves as the primary interface between the shooter and the firearm, contributing to stability and aim. Important aspects of the buttstock include:

- Structure: Made from materials such as wood or polymer, influencing weight and durability.

- Adjustability: Some models offer adjustable lengths or cheek risers for personalized fit.

- Mounting Options: Many buttstocks provide attachments for slings or other accessories to enhance usability.

External Sight System Components

The external sighting mechanism plays a crucial role in enhancing accuracy and precision in shooting. This system comprises various components that work together to provide optimal alignment and target acquisition. Understanding these elements is essential for effective use and maintenance.

- Front Sight: The front sight serves as the primary reference point for aiming. It can come in various styles, including bead, post, or blade designs.

- Rear Sight: This component complements the front sight by providing a notch or aperture for alignment. Different types include open, peep, and ghost-ring sights.

- Windage Adjustments: These mechanisms allow the shooter to correct horizontal alignment, ensuring that shots hit their intended target.

- Elevation Adjustments: This feature enables vertical corrections, helping to adjust for distance and trajectory.

- Sighting Dials: Some systems include dials that facilitate quick adjustments to both windage and elevation, enhancing shooting efficiency.

- Mounting Base: The mounting base secures the sighting system to the firearm, providing stability during use.

- Lens and Filters: In some advanced systems, lenses may be included to improve visibility or reduce glare in various lighting conditions.

Each component of the external sighting system contributes to the overall functionality and effectiveness of the aiming process, allowing users to achieve higher levels of accuracy.

Ramrod and Loading Mechanism Parts

The ramrod and loading system are essential components in the operation of a firearm, facilitating the effective loading of ammunition. These elements work together to ensure that the projectile is properly positioned and secured within the barrel, enabling accurate shooting and optimal performance. Understanding the various components involved in this mechanism is crucial for maintaining and enhancing the functionality of the weapon.

Ramrod: The ramrod serves as a critical tool for seating the projectile and wadding firmly into the barrel. Typically made from durable materials, it is designed to withstand the forces exerted during loading. Proper maintenance of the ramrod is essential to prevent bending or breakage, which could impair loading efficiency.

Loading Tube: This cylindrical component holds the ammunition securely until it is ready to be loaded into the barrel. It is designed to facilitate quick and easy access to the projectiles, allowing for faster reloading during use. Ensuring that the loading tube is free from obstructions is vital for smooth operation.

Seating Tool: A seating tool is sometimes used in conjunction with the ramrod to apply the necessary pressure when positioning the projectile within the barrel. This tool enhances precision and helps avoid damage to the projectile, ensuring a better seal and improved shooting accuracy.

Cleaning Jag: This accessory is attached to the end of the ramrod for cleaning purposes. It aids in the removal of fouling and debris from the barrel, promoting better performance and longevity of the firearm. Regular cleaning with the jag helps maintain the integrity of the loading mechanism.

Each of these components plays a pivotal role in the loading process, contributing to the overall efficiency and reliability of the firearm. Regular inspection and maintenance of the ramrod and loading system can significantly enhance performance and shooting experience.