The performance and longevity of any high-performance vehicle largely depend on understanding its internal and external elements. Each component works in harmony to ensure optimal functionality, and knowing how these elements fit together can help you better maintain and troubleshoot your model.

This section will explore the intricate details of the various elements that make up a robust, high-powered vehicle. By gaining insight into these essential components, you will not only be better equipped to maintain your model but also to enhance its overall performance.

Understanding the core components is crucial for anyone looking to get the most out of their model. Whether you’re focusing on the mechanical structure, electrical systems, or auxiliary elements, this guide will provide a clear overview of what each element contributes to the overall function.

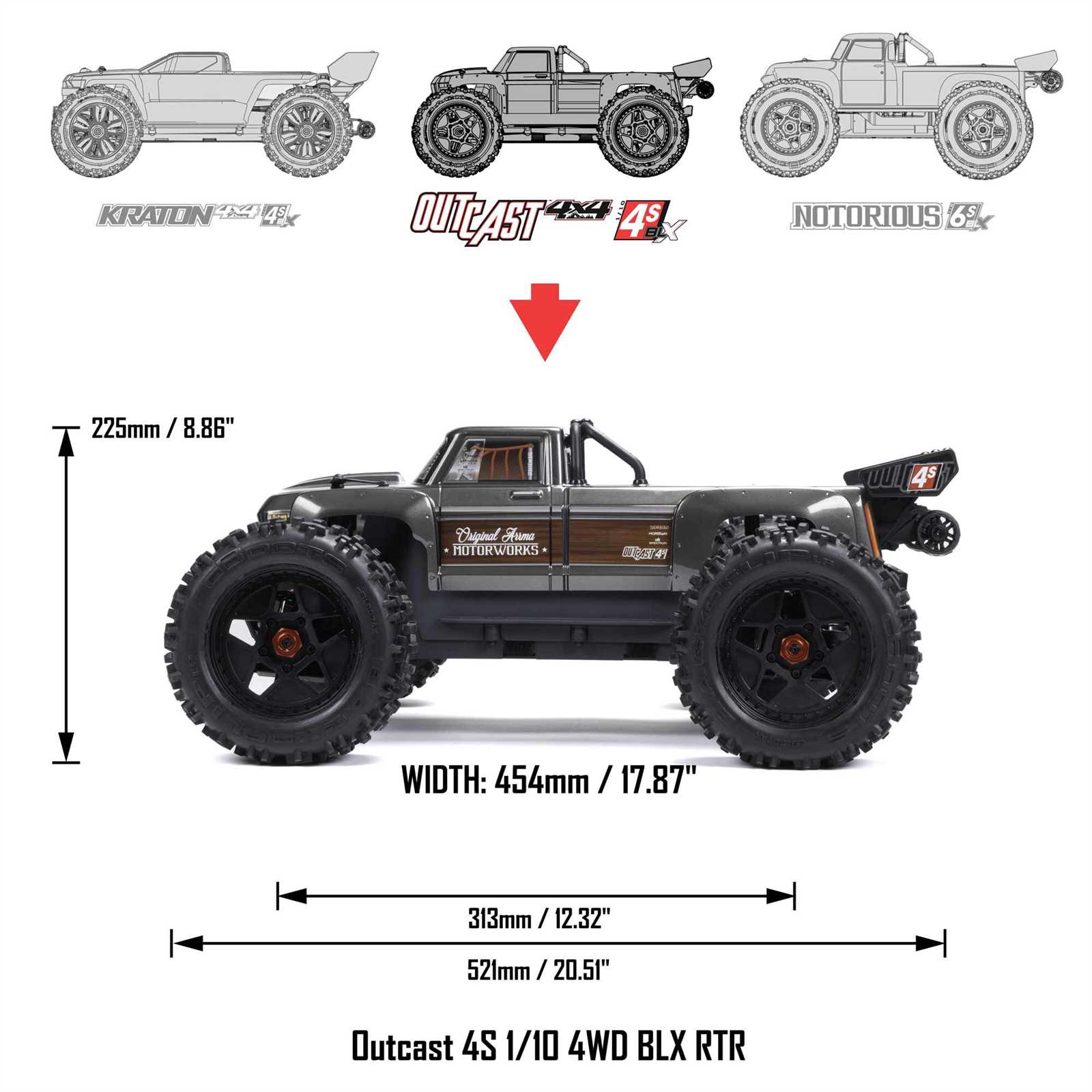

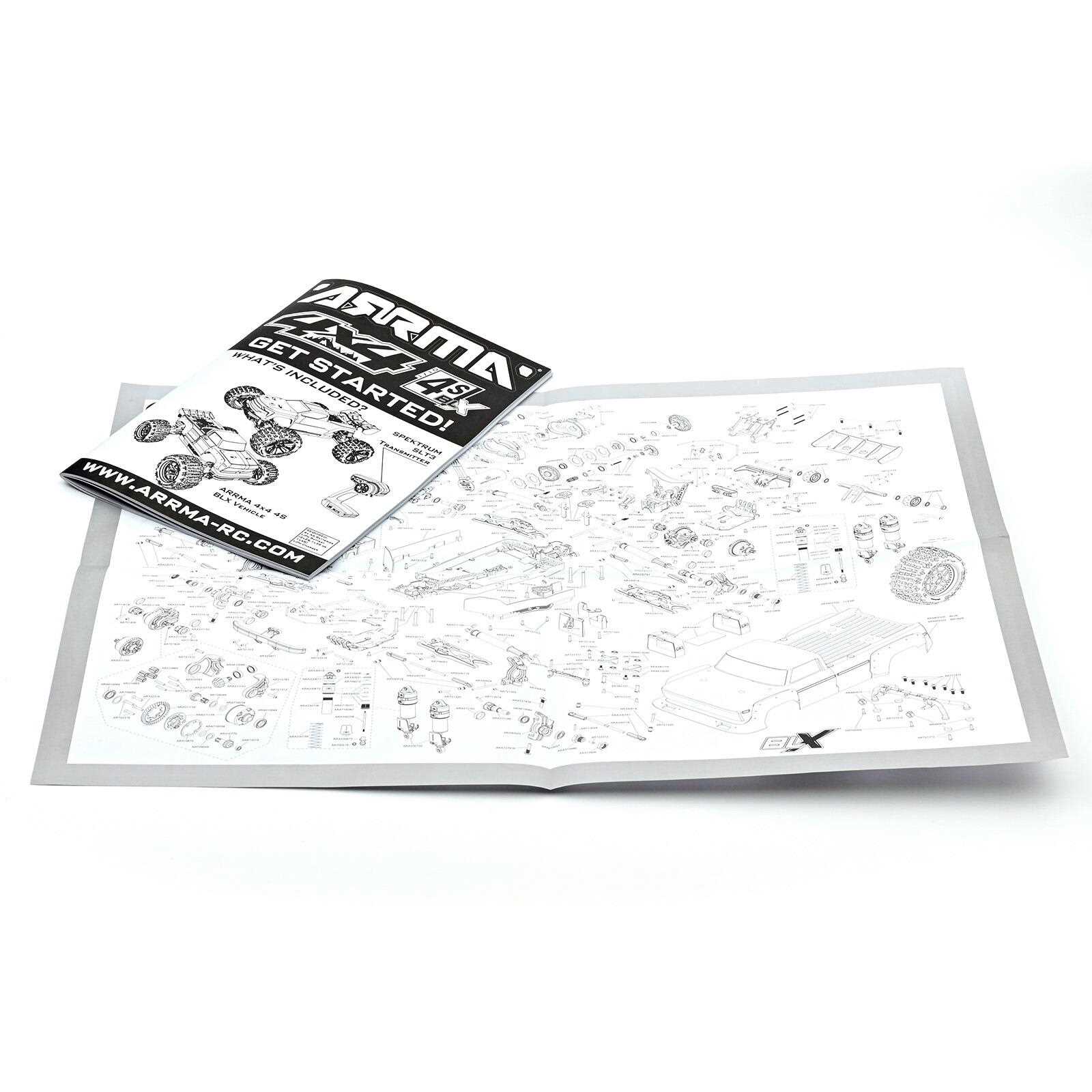

Arrma Outcast 6S: Key Component Breakdown

This section offers a detailed overview of the essential parts that make up the vehicle’s structure and performance. These components work in harmony to deliver both power and stability, allowing the model to handle various terrains and driving conditions with ease. Understanding each element helps in maintaining and optimizing the vehicle’s functionality.

Chassis: The core foundation, designed to withstand impacts and provide the structural integrity needed for high-speed performance. It serves as the base for mounting other critical systems.

Suspension System: A robust setup that includes shocks and arms, crucial for absorbing impacts and maintaining control. This system ensures smooth handling even on rough terrain, keeping the vehicle stable at all times.

Transmission: A powerful mechanism responsible for delivering torque to the wheels. It ensures efficient power transfer, enabling the vehicle to accelerate quickly and handle challenging off-road environments.

Understanding the Chassis Structure

The chassis forms the foundation of any high-performance vehicle, providing stability and housing key components that work together to ensure efficient movement and handling. Its design plays a crucial role in both the durability and functionality of the model, making it a vital element to consider for optimal performance.

Main Components of the Chassis

The framework typically consists of various interconnected elements, including the base, suspension mounts, and reinforcement plates. These are designed to support the vehicle’s weight while absorbing shocks and stresses during operation. The rigidity of the frame ensures that all other parts work in harmony without unnecessary strain.

Impact on Performance

The overall structure directly influences speed, agility, and durability. A well-designed framework allows for better control during high-speed maneuvers and minimizes the risk of damage from impacts. Flexibility and resilience are key factors, as they allow the vehicle to handle rough terrain and demanding

Suspension System Overview for Smooth Performance

The suspension system plays a crucial role in ensuring optimal handling and stability, particularly when navigating uneven terrains. By providing flexibility and support, it helps maintain balance and control, allowing for smooth and responsive movement during operation. A well-designed suspension minimizes the impact of bumps and rough surfaces, enhancing the overall driving experience.

Key Components of the Suspension Setup

The suspension assembly consists of several integral elements that work together to absorb shocks and provide a steady ride. These include shock absorbers, springs, and linkages. Shock absorbers are responsible for dampening the vibrations caused by uneven surfaces, while springs help return the vehicle to its natural position after compression. Linkages connect the suspension to other parts, ensuring coordinated movement.

Maintaining Suspension for Peak Performance

Battery Tray Placement and Compatibility

The positioning of the power cell holder plays a crucial role in optimizing performance and ensuring compatibility with various energy storage solutions. Proper installation not only influences balance and weight distribution but also affects the overall efficiency and safety of the system.

When selecting the appropriate energy pack, it’s important to consider both the dimensions of the holder and the type of connectors used. Compatibility depends on the space available in the compartment, as well as the ability to securely fasten the cell without compromising stability during operation.

Different models may require specific mounting solutions to accommodate various sizes and types of cells. Always check the specifications to ensure the correct fit, as improper installation can lead to issues such as dislodging or overheating.

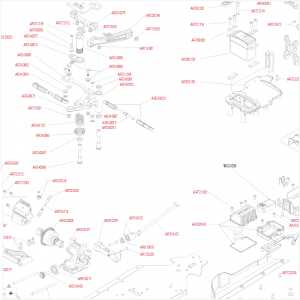

Motor Assembly and Mounting Details

The correct installation of the power unit is essential for ensuring the smooth and efficient operation of your vehicle. This section covers the fundamental steps needed to properly assemble and secure the motor, as well as important considerations for mounting to maintain optimal performance.

- Ensure the motor is aligned correctly with the mounting brackets before tightening any screws.

- Use the appropriate fasteners to secure the motor tightly in place, ensuring no movement during operation.

- Check that the motor’s connectors are properly attached to the power source, ensuring solid electrical contact.

- When mounting, verify that the motor has sufficient clearance from surrounding components to prevent overheating or interference.

- Inspect all mounting points and fasteners periodically to prevent loosening due to vibrations during use.

- Position the motor onto the designated mount and ensure alignment.

- Attach the screws loosely at first to allow adjustments.

- Adjust the motor’s position for optimal balance and secure fit.

- Tighten the screws evenly, ensuring the motor is firmly fixed.

- Double-check all connections and positioning before

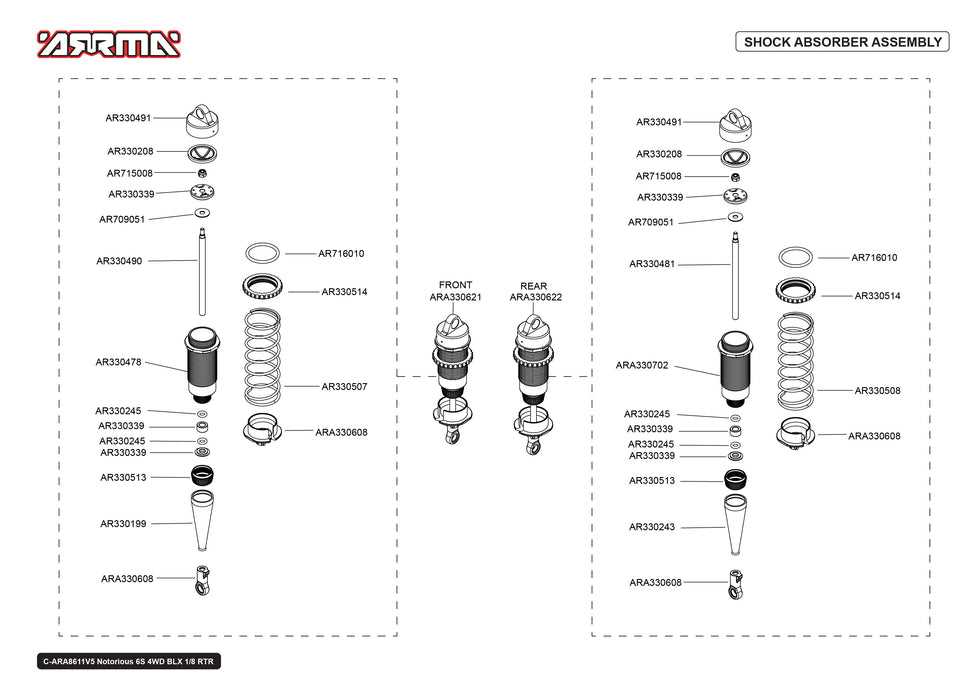

Shock Absorber Setup for Optimal Control

Properly adjusting shock absorbers is essential for achieving the best performance and handling in off-road vehicles. The goal is to enhance control during jumps, cornering, and rough terrain by fine-tuning the suspension system to suit different driving conditions.

To ensure optimal performance, it’s important to understand how various adjustments can impact stability and responsiveness. The settings can be tailored based on the vehicle’s weight, terrain, and driving style.

Steps to Adjust Shock Absorbers

- First, inspect the oil level in each shock to ensure consistent damping. Adjust if necessary.

- Next, set the spring preload to balance the ride height and vehicle weight distribution.

- Fine-tune the compression by adjusting the stiffness, which helps absorb impacts and control landing after jumps.

- Adjust rebound settings

Wheel Hub and Tire Connection

The relationship between the wheel hub and tire is essential for ensuring optimal performance and stability in any vehicle. This connection plays a crucial role in the overall functionality, influencing how well the vehicle handles various terrains and conditions. Understanding the components involved in this assembly can enhance maintenance practices and improve longevity.

The wheel hub serves as the central part that attaches to the axle, providing a sturdy base for the tire. The tire, in turn, is mounted onto the hub, allowing for the necessary grip and traction needed during operation. Proper alignment and secure fastening between these two components are vital to prevent premature wear and ensure efficient energy transfer from the engine to the wheels.

Component Description Wheel Hub The main part that connects the wheel to the vehicle’s axle, providing support and stability. Tire The outer part that provides traction and absorbs shocks from the ground. Bolts Fasteners used to secure the tire to the wheel hub, ensuring a tight fit. Spacer A component that can be used to adjust the distance between the hub and tire for better clearance. Servo Mechanism and Its Role

The servo mechanism is an essential component in various applications, providing precise control over movement and position. This system utilizes feedback to adjust and maintain specific parameters, enabling accurate responses to input commands. In remote-controlled vehicles, such mechanisms play a critical role in steering, throttle control, and other functionalities, enhancing overall performance and user experience.

Components of a Servo Mechanism

A typical servo mechanism consists of a motor, a controller, and a feedback device. The motor generates the necessary motion, while the controller processes signals from the user or other systems. The feedback device, often a potentiometer or encoder, monitors the position of the output shaft and relays this information back to the controller. This closed-loop system allows for continuous adjustments, ensuring that the desired action is executed with precision.

Importance in Vehicle Operation

In the context of remote-controlled vehicles, the servo mechanism is vital for achieving accurate maneuverability. It translates the driver’s input into precise movements, allowing for smooth navigation and responsiveness. The integration of a reliable servo system can significantly enhance a vehicle’s handling characteristics, making it easier to control during various driving conditions.

ESC Wiring and Configuration Tips

When working with electronic speed controllers (ESCs), proper wiring and configuration are essential for optimal performance and reliability. This section provides guidance on how to connect and set up your ESC effectively, ensuring a seamless experience in your RC vehicle.

Wiring Connections

Correct wiring is crucial to avoid damage and ensure the ESC functions as intended. Follow these tips for successful connections:

- Power Leads: Connect the battery leads to the ESC, ensuring correct polarity. The red wire typically connects to the positive terminal, while the black wire goes to the negative terminal.

- Motor Connections: Connect the ESC to the motor using the designated wires. Many ESCs are designed with bullet connectors for easy plug-and-play functionality.

- Signal Wire: Ensure the signal wire from the ESC is connected to the throttle channel on your receiver. This connection allows for communication between the transmitter and the ESC.

Configuration Settings

Once the wiring is complete, it is important to configure the ESC settings for optimal performance:

- Throttle Calibration: Perform a throttle calibration by following the ESC manufacturer’s instructions. This process ensures that the ESC recognizes the full range of your transmitter’s throttle input.

- Brake Settings: Adjust the brake settings according to your preference. Some ESCs offer multiple braking modes that can be selected based on driving style.

- Timing Adjustments: If applicable, set the timing options on the ESC for improved efficiency and performance. Adjusting timing can help maximize motor output and responsiveness.

By paying attention to these wiring and configuration details, you can enhance the functionality of your ESC, resulting in a more enjoyable and reliable experience in your RC adventures.

Drive Shaft and Transmission Insights

The drive shaft and transmission system are crucial components of high-performance vehicles, impacting overall efficiency and handling. Understanding their functionality and interrelations can significantly enhance performance and durability. This section delves into the intricacies of these elements, providing insights for enthusiasts and hobbyists alike.

Drive Shaft Functionality

The drive shaft serves as the vital link between the engine and the wheels, transmitting power generated by the engine to the drivetrain. Here are some key aspects:

- Power Transfer: It effectively transfers torque from the motor to the wheels, facilitating smooth acceleration.

- Durability: Constructed from robust materials, the drive shaft is designed to withstand high rotational forces.

- Alignment: Proper alignment is essential to ensure efficient power delivery and minimize wear.

Transmission Mechanics

The transmission system plays a pivotal role in regulating the power flow from the engine to the wheels, allowing for varying speeds and torque. Consider the following elements:

- Types of Transmissions:

- Manual: Offers direct control over gear shifts, enhancing driver engagement.

- Automatic: Provides seamless gear changes, improving convenience.

- Gear Ratios: Different ratios optimize performance for various driving conditions, balancing speed and torque.

- Maintenance: Regular checks and fluid changes are crucial for maintaining optimal transmission performance.

Understanding these components and their interactions is essential for maximizing the potential of any high-performance vehicle. Proper maintenance and awareness of upgrades can significantly enhance both reliability and performance.

Differential Gear System Explained

The differential gear system plays a crucial role in the performance and handling of vehicles, particularly those designed for off-road and high-speed applications. This mechanism allows for the independent rotation of wheels, enabling smoother navigation through turns and uneven terrain. By distributing torque and allowing variations in wheel speed, it enhances stability and control, contributing significantly to the overall driving experience.

In essence, the differential consists of a series of gears that facilitate the transfer of power from the drive shaft to the wheels. When a vehicle turns, the outer wheels travel a longer distance compared to the inner wheels. The differential compensates for this difference in distance, allowing each wheel to rotate at its own speed. This functionality is vital for maintaining traction and preventing skidding, particularly in challenging conditions.

There are various types of differential systems, including open, limited-slip, and locking differentials. Each type serves distinct purposes and offers unique benefits depending on the application. Open differentials are common in standard vehicles, providing basic performance, while limited-slip differentials enhance grip by transferring power to the wheel with more traction. Locking differentials offer maximum traction by forcing both wheels to turn at the same speed, making them ideal for extreme off-road situations.

Understanding the differential gear system’s design and functionality is essential for anyone looking to optimize vehicle performance. Whether for racing or recreational use, knowledge of how these components interact can aid in making informed choices regarding upgrades and modifications, ultimately leading to an improved driving experience.

Wing Mount Installation for Stability

Properly attaching the wing mount is crucial for enhancing the overall performance and balance of your vehicle. A secure and stable wing not only improves aerodynamics but also helps maintain control during high-speed maneuvers. This section will guide you through the installation process to ensure maximum stability and efficiency.

Step 1: Begin by gathering all necessary tools and components. Having everything at hand will streamline the installation process and reduce the risk of errors. Ensure that the mounting brackets and screws are compatible with your specific model.

Step 2: Align the wing mount with the designated mounting points on the chassis. Make sure to position it evenly to distribute weight properly. This balance is essential for achieving optimal performance.

Step 3: Secure the mount using the screws provided. It’s important to tighten them gradually and evenly to avoid any misalignment. A secure fit will prevent any movement of the wing during operation, enhancing stability.

Step 4: After securing the mount, attach the wing. Ensure it is positioned at the correct angle for aerodynamic efficiency. Adjustments may be necessary to find the perfect balance between lift and drag.

Following these steps will significantly improve your vehicle’s handling and stability, allowing for a more enjoyable and controlled driving experience.

Protective Bumper and Skid Plate Design

The design of protective components plays a crucial role in enhancing the durability and resilience of vehicles. Effective bumpers and skid plates are essential in safeguarding the structure from impacts and abrasions that can occur during operation in challenging environments. By understanding the key features and benefits of these protective elements, enthusiasts can make informed choices to optimize performance and longevity.

Protective bumpers serve multiple functions, including:

- Impact Resistance: They absorb shock from collisions, minimizing damage to the vehicle.

- Structural Support: Bumpers provide stability and reinforce the overall integrity of the vehicle’s frame.

- Aesthetic Appeal: Custom designs can enhance the visual appeal while maintaining functionality.

On the other hand, skid plates are designed to protect the undercarriage, offering benefits such as:

- Obstacle Navigation: They help the vehicle glide over rough terrain, preventing damage to vital components.

- Durability: Made from robust materials, skid plates resist wear and tear, extending their lifespan.

- Weight Distribution: Properly designed skid plates contribute to balanced weight distribution, improving handling and stability.

In summary, well-engineered bumpers and skid plates are indispensable for ensuring the protection and performance of off-road vehicles. Their thoughtful design enhances both functionality and durability, allowing users to enjoy their driving experience with peace of mind.