Understanding the various elements and structure of complex machinery is essential for efficient maintenance and troubleshooting. This guide aims to provide a clear view of how different mechanical components are organized and function together.

By examining the layout and connections between these elements, users can better identify key areas that require attention. Whether it’s routine servicing or addressing specific issues, having a detailed understanding of the internal workings ensures smoother operations.

In the following sections, you will find a detailed breakdown of the equipment’s primary units and how they interrelate, offering valuable insights for both professionals and those new to handling such systems.

Understanding the Key Components of This Pressure System

In this section, we will explore the essential elements that make up this pressure equipment. Each component plays a critical role in ensuring optimal performance and reliability. By understanding the functions of these parts, you can better maintain and troubleshoot your machine.

- Pump Mechanism – Responsible for generating the necessary pressure to drive the water through the system.

- Engine Unit – Powers the pump, ensuring the system operates efficiently under various conditions.

- Hose and Nozzle Assembly – Delivers the pressurized water to the desired location for effective cleaning.

- Frame and Chassis – Provides support and mobility, allowing easy transport of the machine.

- Control Valves – Regulate the flow and pressure, offering precise control over the system’s operation.

- Safety Features – Integrated to prevent overheating or overpressure, ensuring safe usage.

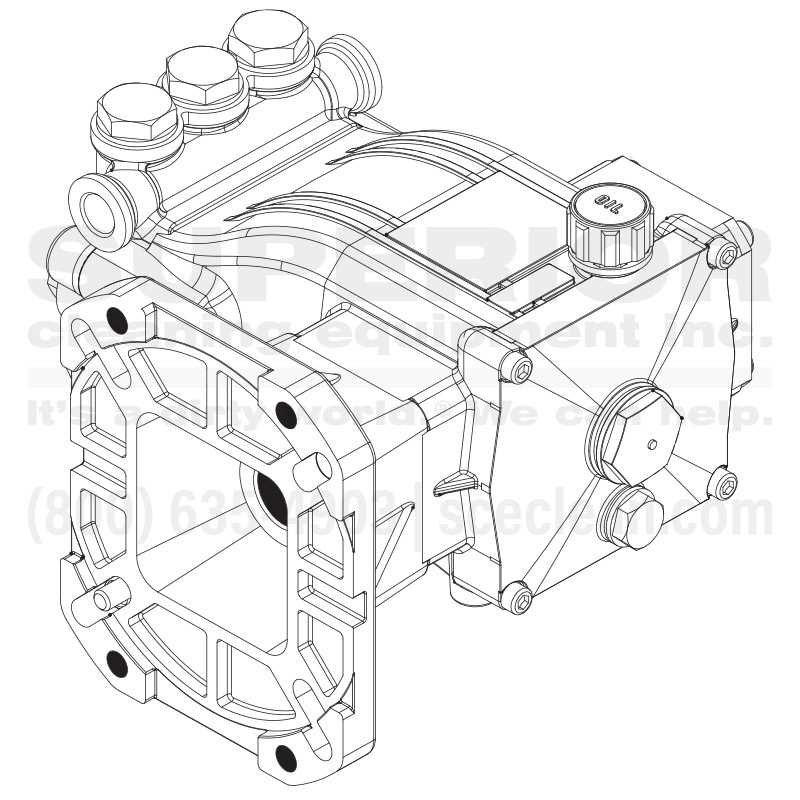

Breakdown of the Pump System

The pump mechanism is an essential component for delivering high-pressure water flow in various cleaning applications. Understanding the individual elements and how they interact within the system is crucial for effective operation and maintenance.

Main Components Overview

- Motor – Powers the system, converting electrical energy into mechanical force.

- Piston Assembly – Responsible for creating pressure by compressing and moving water through the system.

- Valves – Direct the flow of water, ensuring it moves through the correct channels.

Key Maintenance Tips

- Regularly check the pistons for wear and tear to avoid system inefficiencies.

- Ensure all valves are functioning properly to maintain optimal water pressure.

- Lubricate moving parts as required to reduce friction and extend

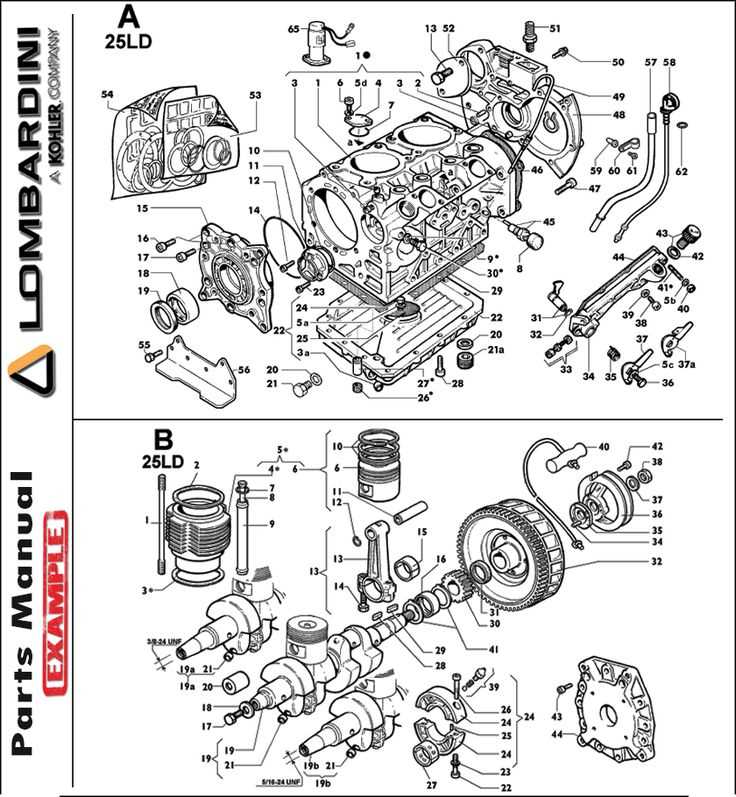

Exploring the Engine Assembly of This Pressure Washer

The heart of this power equipment lies in its meticulously designed motor system. Understanding the internal workings of this unit’s drive mechanism is essential for both maintenance and repair. The engine is built for durability and efficiency, providing the necessary power to handle heavy-duty cleaning tasks.

Key Components of the motor assembly include various parts responsible for delivering a consistent and strong performance. Each element is carefully crafted to withstand high-pressure operations, ensuring the machine runs smoothly under demanding conditions.

Maintenance Tips include regular inspections to check for wear or damage in essential sections, such as the cooling and ignition systems. This proactive care ensures the longevity and reliability of the engine’s function over time.

Detailed View of the Frame Structure

The framework of this high-performance machine is designed to provide stability and support during operation. Its construction ensures durability and long-term reliability, making it suitable for various demanding environments. The frame is engineered with precision to accommodate all components effectively.

Key Features of the Frame

The framework is made of reinforced materials, which guarantees both strength and resilience. Its layout is optimized for easy access to internal parts, facilitating maintenance and repairs. The structure is resistant to wear and tear, even under continuous use.

Frame Components

Component Guide to Nozzle Configurations

Understanding the various nozzle setups is essential for optimizing the performance of any pressure cleaning system. The correct combination of size and type ensures efficient water flow, pressure control, and coverage, all of which are key factors in achieving effective cleaning results.

Nozzle Type Best Use 0-Degree High-pressure, concentrated stream for tough stains 15-Degree General cleaning of surfaces like driveways and patios 25-Degree Wider coverage for medium-duty tasks, such as cleaning vehicles Identifying High-Pressure Hoses and Connectors

Understanding the various components of high-pressure systems is essential for ensuring optimal performance and safety. Among these components, hoses and connectors play a crucial role in maintaining the integrity of the fluid delivery system. Proper identification and maintenance of these elements can prevent leaks and enhance overall efficiency.

High-pressure hoses are designed to withstand extreme conditions and are often constructed from durable materials. It is important to recognize the specific characteristics that distinguish these hoses from standard ones:

- Material: Common materials include reinforced rubber or thermoplastic to handle elevated pressure.

- Diameter: Hoses typically come in various diameters to accommodate different flow rates.

- Pressure Rating: Each hose should have a clearly marked pressure rating, indicating the maximum safe operating pressure.

Connectors are equally vital in linking hoses within the system. Their identification is essential for ensuring proper assembly and operation:

- Type: There are several types of connectors, including threaded, quick-connect, and clamp-style, each serving distinct functions.

- Size: Selecting the correct size ensures a secure fit and prevents leaks.

- Material: Connectors are often made from metal or high-grade plastics, which can resist corrosion and pressure.

Regular inspection and replacement of high-pressure hoses and connectors are vital for maintaining system performance and preventing failures. Always refer to the manufacturer’s specifications for guidance on selection and maintenance.

Water Supply System Components

The water supply system in pressure cleaning equipment plays a crucial role in ensuring efficient operation. This system is designed to deliver a consistent flow of water, enabling optimal performance during cleaning tasks. Understanding the various elements involved is essential for effective maintenance and troubleshooting.

Key Elements of the Water Supply System

Several components work together to facilitate water intake and distribution. The primary parts include:

- Pump: This component is responsible for moving water from the source to the cleaning unit, generating the necessary pressure.

- Hoses: Durable hoses transport water from the supply source to the equipment, ensuring a steady flow during operation.

- Filters: These elements prevent debris and contaminants from entering the system, protecting internal components from damage.

Maintenance and Troubleshooting Tips

Regular inspection and maintenance of the water supply system are vital for longevity and performance. Key practices include:

- Inspect hoses for wear and tear to prevent leaks.

- Clean filters regularly to ensure unobstructed water flow.

- Check the pump operation to guarantee consistent pressure and efficiency.

Exhaust and Ventilation Parts of Landa LP3035G

The efficiency of any pressure cleaning machine relies heavily on its exhaust and ventilation components. These elements are crucial for ensuring optimal airflow and preventing overheating, thus enhancing overall performance. Proper maintenance of these systems is vital for extending the lifespan of the equipment and achieving desired cleaning results.

Key Components

- Exhaust Fan: Facilitates the expulsion of hot air from the machine, ensuring a consistent temperature.

- Air Filter: Captures dust and debris, preventing them from entering the internal systems and causing damage.

- Ventilation Ducts: Guide airflow to and from various parts of the equipment, promoting efficient circulation.

- Noise Dampeners: Reduce sound levels generated during operation, enhancing user comfort.

Maintenance Tips

- Regularly inspect and clean the air filter to maintain optimal airflow.

- Check exhaust fans for any signs of wear or damage and replace as needed.

- Ensure ventilation ducts are free of obstructions for efficient airflow.

- Monitor noise levels and replace dampeners if noise exceeds acceptable limits.

Maintenance Tips for Landa LP3035G Belt Drive

Regular upkeep of the belt-driven machinery is essential for optimal performance and longevity. Proper maintenance not only enhances efficiency but also prevents potential breakdowns that could lead to costly repairs. Implementing a few key practices can ensure that your equipment remains in excellent working condition.

Routine Inspections

Conducting frequent checks on the components is vital. Look for any signs of wear or damage, particularly on belts and pulleys. Ensure that all connections are secure and that there are no unusual noises during operation. Addressing minor issues promptly can prevent them from escalating into major problems.

Proper Lubrication

Ensuring that all moving parts are adequately lubricated is crucial. Use the recommended lubricant to minimize friction and wear. Regularly lubricating the drive system not only extends the lifespan of the machinery but also improves overall efficiency. Follow the manufacturer’s guidelines for lubrication intervals to maintain optimal performance.

Replacement Parts for Landa LP3035G Accessories

In the realm of equipment maintenance, having access to suitable components is essential for ensuring optimal performance and longevity. This section focuses on the various alternatives available for enhancing the functionality of specific devices, providing users with insights into compatible options.

When it comes to replacing components, it is crucial to identify the key accessories that may require attention. Here are some commonly needed replacements:

- Hoses and fittings: Essential for maintaining fluid flow and pressure.

- Nozzles: Different types for varying spray patterns and pressure levels.

- Filters: Important for keeping the system free from contaminants.

- Pumps: Vital for ensuring efficient operation and performance.

- Seals and gaskets: Necessary for preventing leaks and maintaining pressure.

Choosing the right substitutes not only improves equipment efficiency but also contributes to a smoother operation. Make sure to consult your user manual or a professional for assistance in selecting the most suitable alternatives.