| Drive Shaft |

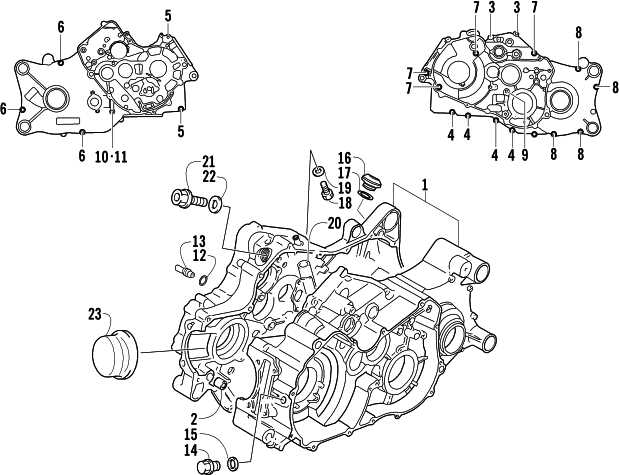

Detailed Look at the Transmission Assembly

The transmission assembly is a crucial component of any all-terrain vehicle, playing a vital role in delivering power from the engine to the wheels. Understanding its structure and function can greatly enhance maintenance efforts and performance tuning.

This assembly typically consists of various key elements, each contributing to the overall efficiency and functionality of the vehicle:

- Gearbox: The gearbox facilitates the selection of different speed ratios, enabling the vehicle to adapt to varying terrain conditions.

- Clutch Mechanism: This component allows for smooth engagement and disengagement of the engine from the transmission, providing seamless transitions during acceleration and deceleration.

- Drive Shafts: These shafts transfer torque from the gearbox to the wheels, ensuring effective power delivery to all four corners of the vehicle.

- Oil Pump: The oil pump circulates lubricant throughout the assembly, minimizing friction and heat buildup, thus prolonging the lifespan of internal components.

- Seals and Gaskets: These parts prevent fluid leaks, maintaining optimal pressure and performance within the assembly.

Regular inspection and maintenance of the transmission assembly can help identify wear and tear, ensuring reliable operation. It’s advisable to refer to the vehicle’s service manual for specific guidelines regarding fluid changes and component replacements.

Front Suspension Components

The front suspension system plays a crucial role in maintaining stability and control in all-terrain vehicles. This assembly is designed to absorb shocks, enhance steering precision, and provide a comfortable ride over uneven surfaces. Understanding its components is essential for proper maintenance and performance optimization.

Key elements of the front suspension include upper and lower control arms, which facilitate wheel movement while keeping the alignment intact. The struts or shocks absorb impacts from rough terrains, ensuring a smoother driving experience. Additionally, the steering knuckle connects the wheel hub to the control arms, allowing for directional changes. Bushings and ball joints are vital for flexibility and articulation, reducing wear and tear on the system.

Regular inspection and maintenance of these components are vital for the longevity and reliability of the suspension system. By ensuring each part is in optimal condition, drivers can enjoy better handling and a safer riding experience.

Exploring the Parts Involved in Front Suspension

The front suspension system plays a crucial role in providing stability, comfort, and control while navigating various terrains. Understanding the components that comprise this system is essential for effective maintenance and repair. Each element contributes to the overall performance and responsiveness of the vehicle, ensuring a smooth ride and optimal handling.

Main Components of Front Suspension

Several key elements make up the front suspension, each serving a distinct purpose in enhancing the vehicle’s performance. These components work in harmony to absorb shocks, maintain tire contact with the ground, and ensure precise steering control.

| Component |

Description |

| Control Arms |

These parts connect the suspension to the chassis, allowing for vertical movement while keeping the wheels aligned. |

| Shocks/Struts |

These components absorb bumps and road imperfections, providing a smoother ride and reducing body roll during cornering. |

| Coil Springs |

These are responsible for supporting the vehicle’s weight and absorbing shock, returning to their original shape after compression. |

| Sway Bar |

This component helps reduce body roll during turns, enhancing stability and handling. |

| Ball Joints |

These allow for smooth rotation and movement between the control arms and the steering knuckles, crucial for steering and suspension movement. |

Importance of Maintenance

Regular inspection and maintenance of the front suspension components are vital to ensure optimal performance and safety. Worn or damaged elements can lead to decreased handling and stability, posing a risk during operation. By keeping these parts in good condition, vehicle owners can enhance their driving experience and extend the lifespan of their vehicle.

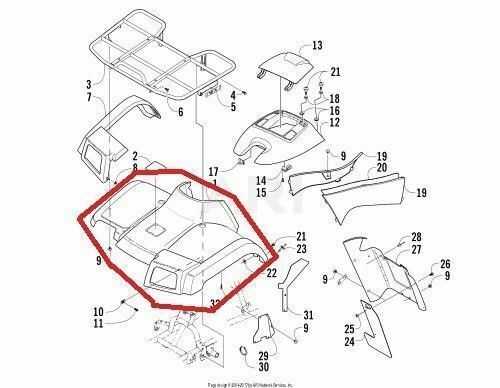

Rear Axle Diagram and Parts

The rear axle assembly plays a crucial role in the overall functionality of an all-terrain vehicle, ensuring stability and power delivery to the rear wheels. Understanding the various components involved in this assembly can enhance maintenance and repair efforts, leading to improved performance and longevity of the vehicle.

Key Components of the Rear Axle Assembly

- Axle Shaft

- Differential Housing

- Bearings

- Hub Assembly

- Brake Rotor

- U-Joint

Functions of Each Component

- Axle Shaft: Transmits power from the differential to the wheels.

- Differential Housing: Houses the gears that allow for wheel speed variation during turns.

- Bearings: Support the axle and allow smooth rotation.

- Hub Assembly: Connects the wheel to the axle and facilitates braking.

- Brake Rotor: Works with the brake caliper to stop the vehicle.

- U-Joint: Connects the drive shaft to the axle and allows for flexibility in movement.

Essential Components of the Rear Axle System

The rear axle system plays a crucial role in providing stability and traction for off-road vehicles. This assembly not only supports the weight of the vehicle but also transfers power from the engine to the wheels, ensuring optimal performance on various terrains. Understanding its essential components is vital for maintenance and repair, enhancing the longevity and functionality of the vehicle.

- Axle Shaft: The primary component responsible for transmitting power from the differential to the wheels, ensuring they rotate together.

- Differential: This device allows the wheels to rotate at different speeds, crucial for turning and maneuvering without skidding.

- Wheel Hub: Connects the axle shaft to the wheel, providing a secure attachment point while allowing for smooth rotation.

- Bearings: These components reduce friction between the axle and the hub, ensuring smooth rotation and longevity of the system.

- Brake Assembly: Essential for stopping the vehicle, this includes components such as brake pads, rotors, and calipers.

- Suspension Linkages: These parts connect the axle to the vehicle’s frame, allowing for controlled movement over rough terrain.

- Seals and Gaskets: Prevent leakage of lubricants, protecting the internal components from dirt and moisture, which can cause damage.

Each of these components works in unison to ensure the rear axle system operates effectively, enhancing the overall performance of the vehicle. Regular inspection and maintenance of these parts are essential to prevent failures and ensure a safe driving experience.

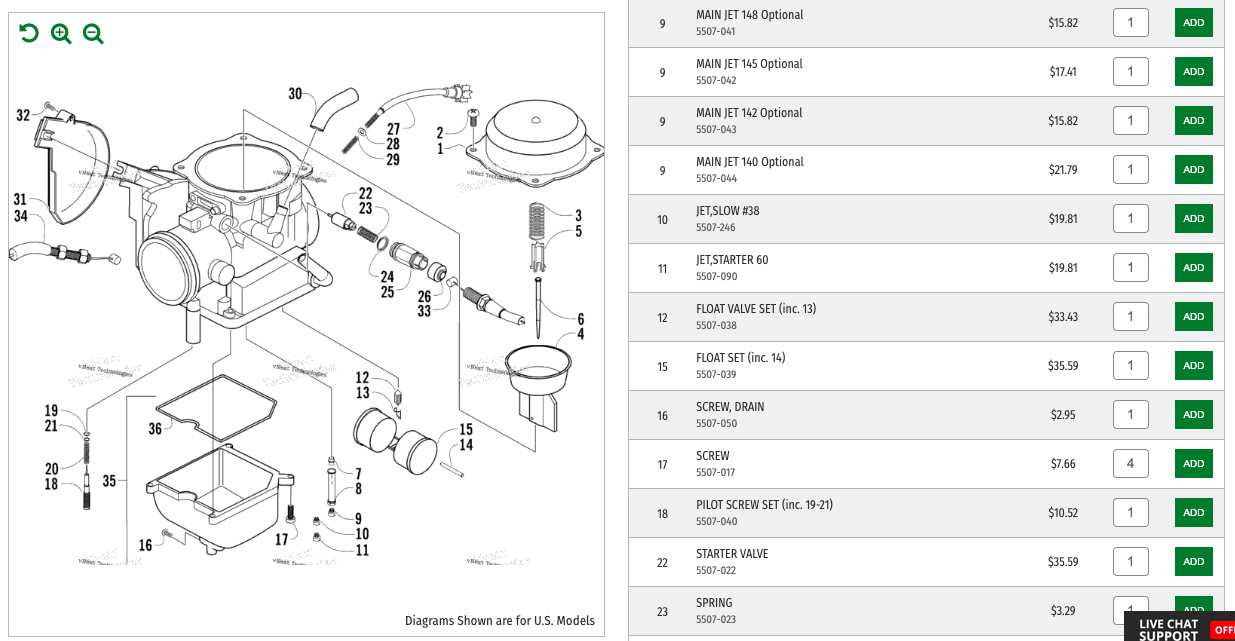

Fuel System Parts and Layout

The fuel delivery mechanism is crucial for optimal engine performance and efficiency. This section delves into the components involved in this system, outlining their functions and positioning within the overall structure. Understanding the layout helps in diagnosing issues and performing maintenance effectively.

Key Components of the Fuel Delivery Mechanism

- Fuel Tank: The reservoir that holds the fuel before it is pumped to the engine.

- Fuel Pump: A device that moves fuel from the tank to the engine, ensuring a steady supply under pressure.

- Fuel Filter: This component removes impurities from the fuel, protecting the engine from potential damage.

- Fuel Lines: Tubing that transports fuel from the tank to the engine, designed to withstand pressure and prevent leaks.

- Fuel Injector: Responsible for delivering the precise amount of fuel into the combustion chamber for efficient combustion.

Layout Considerations

When examining the configuration of the fuel delivery system, several aspects are important:

- Placement of the fuel tank is critical for balance and accessibility during refueling.

- Positioning of the fuel pump affects the efficiency of fuel transfer; it should be near the tank to reduce strain.

- Accessibility of the fuel filter is vital for regular maintenance and replacement.

- Routing of the fuel lines must minimize bends and avoid sharp turns to ensure smooth fuel flow.

- The injector placement should optimize the mixing of fuel and air within the combustion chamber.

Proper understanding and maintenance of the fuel delivery mechanism are essential for ensuring reliability and performance. Familiarity with these components and their arrangement can aid in troubleshooting and enhance overall functionality.

How the Fuel Delivery System is Organized

The fuel delivery system plays a crucial role in ensuring optimal engine performance by efficiently supplying fuel from the tank to the combustion chamber. This intricate arrangement involves various components working together seamlessly to maintain a steady flow of fuel, allowing for smooth operation and effective energy generation.

Key Components of the Fuel Delivery System

- Fuel Tank: The reservoir that holds the fuel until needed.

- Fuel Pump: Responsible for transporting the fuel from the tank to the engine under pressure.

- Fuel Filter: Removes impurities and contaminants from the fuel to protect engine components.

- Fuel Lines: The conduits through which the fuel travels from the tank to the engine.

- Fuel Injectors: Precise devices that spray fuel into the combustion chamber in a controlled manner.

Operation Process

- The fuel is drawn from the tank by the fuel pump.

- The fuel passes through the filter to eliminate any dirt or debris.

- The clean fuel moves through the lines towards the engine.

- The injectors then deliver the fuel into the combustion chamber at the right time and in the correct amount.

Understanding the organization of this system is vital for diagnosing issues and ensuring proper maintenance. Regular checks and timely replacements of components can significantly enhance performance and longevity.

Electrical System Components

The electrical framework of an all-terrain vehicle plays a pivotal role in ensuring its functionality and performance. This system encompasses various elements that work in harmony to power essential features, control mechanisms, and safety functions. Understanding these components is crucial for effective maintenance and troubleshooting.

Key Components

Central to the electrical system are the battery, which stores and supplies energy, and the alternator, responsible for recharging the battery while the vehicle is in operation. Additional parts, such as fuses and relays, safeguard the circuitry from overloads and facilitate the control of electrical currents. Furthermore, wiring harnesses connect these elements, allowing for seamless communication and operation.

Control and Lighting Systems

The control system comprises various switches and sensors that enable the driver to operate the vehicle’s features effortlessly. This includes lights, indicators, and gauges that provide vital information about the vehicle’s status. Effective lighting systems enhance visibility and safety, making them indispensable for off-road travel.