In any machinery designed for precise functions, comprehending the layout and interaction of its elements is crucial for optimal performance. This section focuses on a specific model known for its efficiency, providing insight into its structural configuration. By exploring the various components and their placements, users can gain a deeper appreciation of how each part contributes to the overall functionality.

Having a clear visual representation of the individual elements and their connections allows for better maintenance and troubleshooting. Understanding how these pieces fit together can simplify the process of assembly and disassembly, enhancing user experience. Furthermore, this knowledge empowers operators to identify potential issues swiftly and accurately, ensuring the equipment remains in top condition.

By delving into the arrangement of the various parts, one can also appreciate the engineering behind the design. Each component plays a vital role, and recognizing these roles aids in maximizing efficiency and extending the lifespan of the device. In this exploration, users will find a comprehensive overview that emphasizes the importance of familiarity with the machinery’s structure.

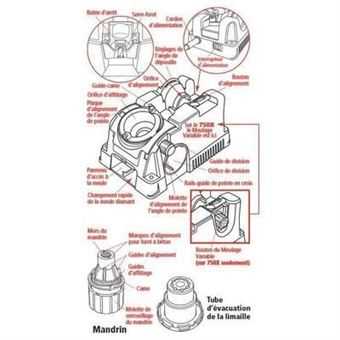

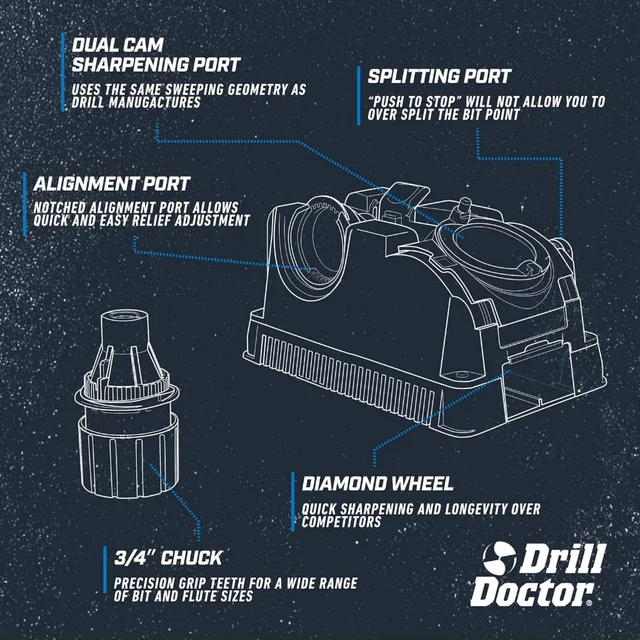

Understanding Drill Doctor 750X Components

When it comes to sharpening tools effectively, it’s essential to have a clear grasp of the various elements involved in the process. Each component plays a significant role in ensuring optimal performance and efficiency. By familiarizing oneself with these individual parts, users can enhance their understanding of how to maintain and operate the equipment successfully.

The primary structure consists of a robust frame that supports the other elements, ensuring stability during operation. Within this framework lies the motor, which powers the sharpening mechanism, providing the necessary speed and precision. Additionally, a versatile sharpening system is integrated, allowing for adjustments according to the specific requirements of different tools.

Furthermore, the adjustment features are critical for achieving the desired sharpening angles, which contribute to the overall effectiveness of the tool maintenance process. Understanding the layout and functionality of these components can significantly improve the user’s experience, making the entire operation smoother and more efficient.

Key Parts of the 750X Model

This section highlights the essential components of a specific sharpening unit designed for enhancing tool performance. Understanding these elements is crucial for effective operation and maintenance, ensuring optimal functionality for various cutting instruments.

- Motor Assembly: This is the driving force behind the unit, providing the necessary power to rotate the sharpening wheel.

- Sharpening Wheel: A vital component that grinds the cutting edges of tools to restore their sharpness.

- Angle Adjuster: Allows users to set the precise sharpening angle, accommodating different tool types.

- Base Plate: The sturdy foundation that supports the entire system, ensuring stability during operation.

- Tool Holder: Secures the instrument in place while it is being sharpened, providing accuracy and safety.

- Dust Collector: Helps maintain a clean workspace by capturing debris generated during the sharpening process.

Familiarizing oneself with these key components enhances user experience and promotes efficient maintenance practices.

Functionality of Each Component

This section provides a comprehensive overview of the various elements within the sharpening tool, highlighting their individual roles and contributions to the overall performance of the device. Each component is meticulously designed to enhance the efficiency and effectiveness of the sharpening process.

Key Elements and Their Roles

- Motor: This vital part powers the entire mechanism, ensuring smooth operation and consistent performance during use.

- Grinding Wheel: Essential for the actual sharpening process, this component grinds and shapes the cutting edge to achieve the desired sharpness.

- Angle Adjustment Mechanism: Allows users to set the optimal angle for sharpening, ensuring precision and accuracy for different tool types.

- Feed System: Facilitates the proper alignment and movement of the tool being sharpened, allowing for uniform results across the cutting edge.

- Guide Rod: Assists in stabilizing the tool during the sharpening process, promoting safety and reducing the risk of damage.

Additional Components

- Base: Provides stability and support, ensuring that the unit remains steady during operation.

- Dust Collector: Captures debris produced during sharpening, helping to maintain a clean workspace and improve visibility.

- Control Switch: Enables users to easily power the tool on and off, enhancing user convenience.

- Safety Guard: Protects the user from debris and potential injuries, promoting a safer sharpening experience.

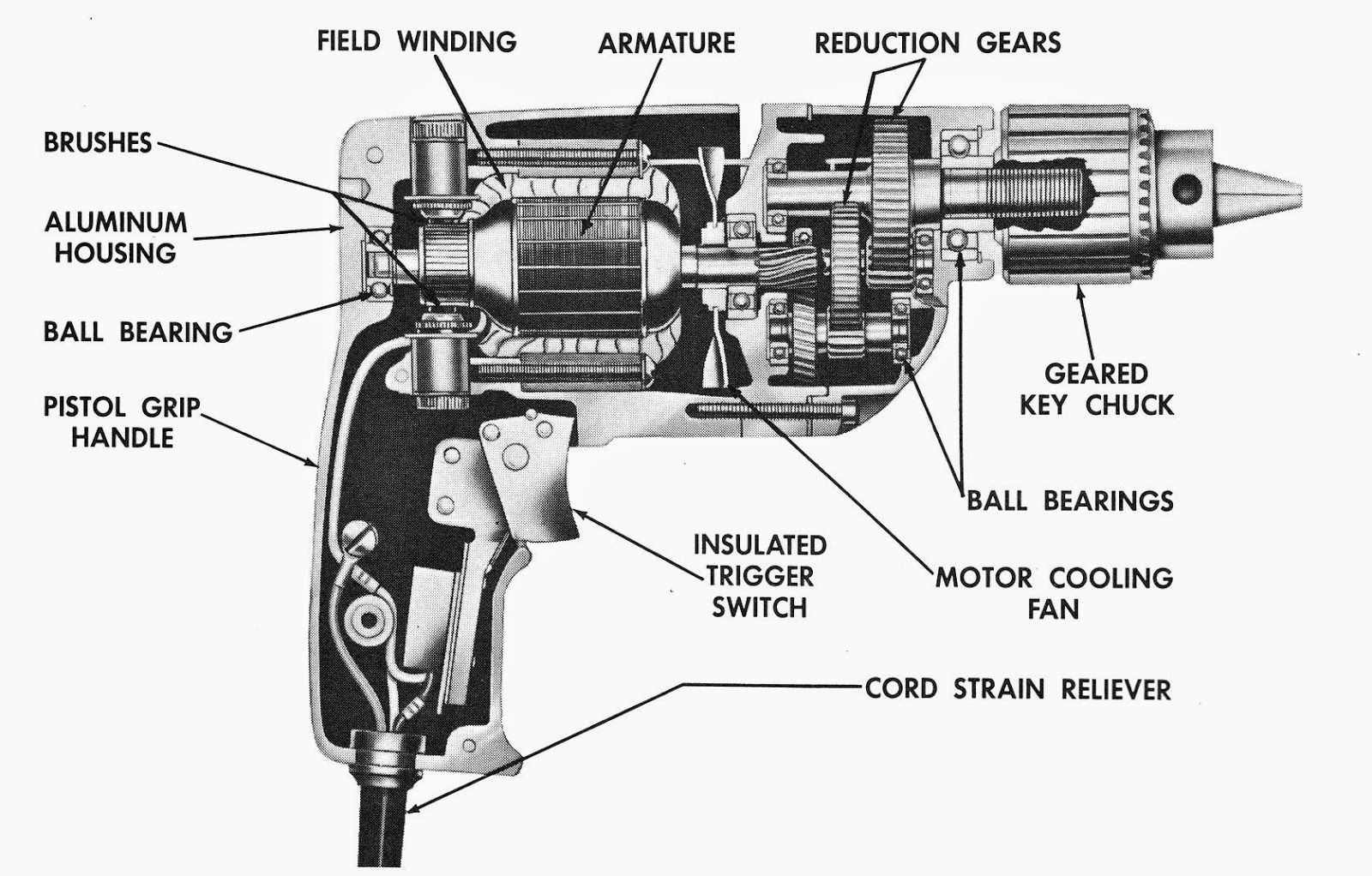

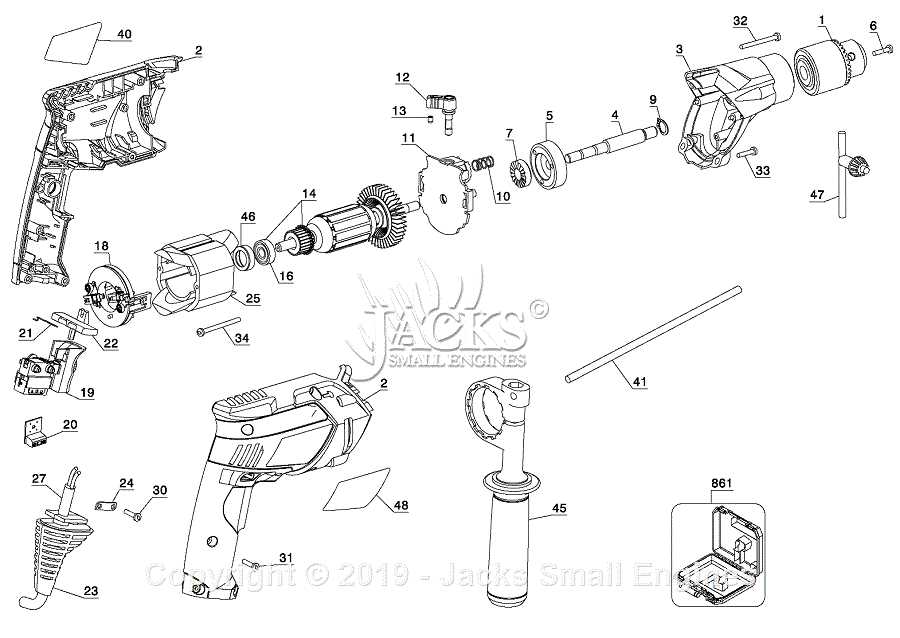

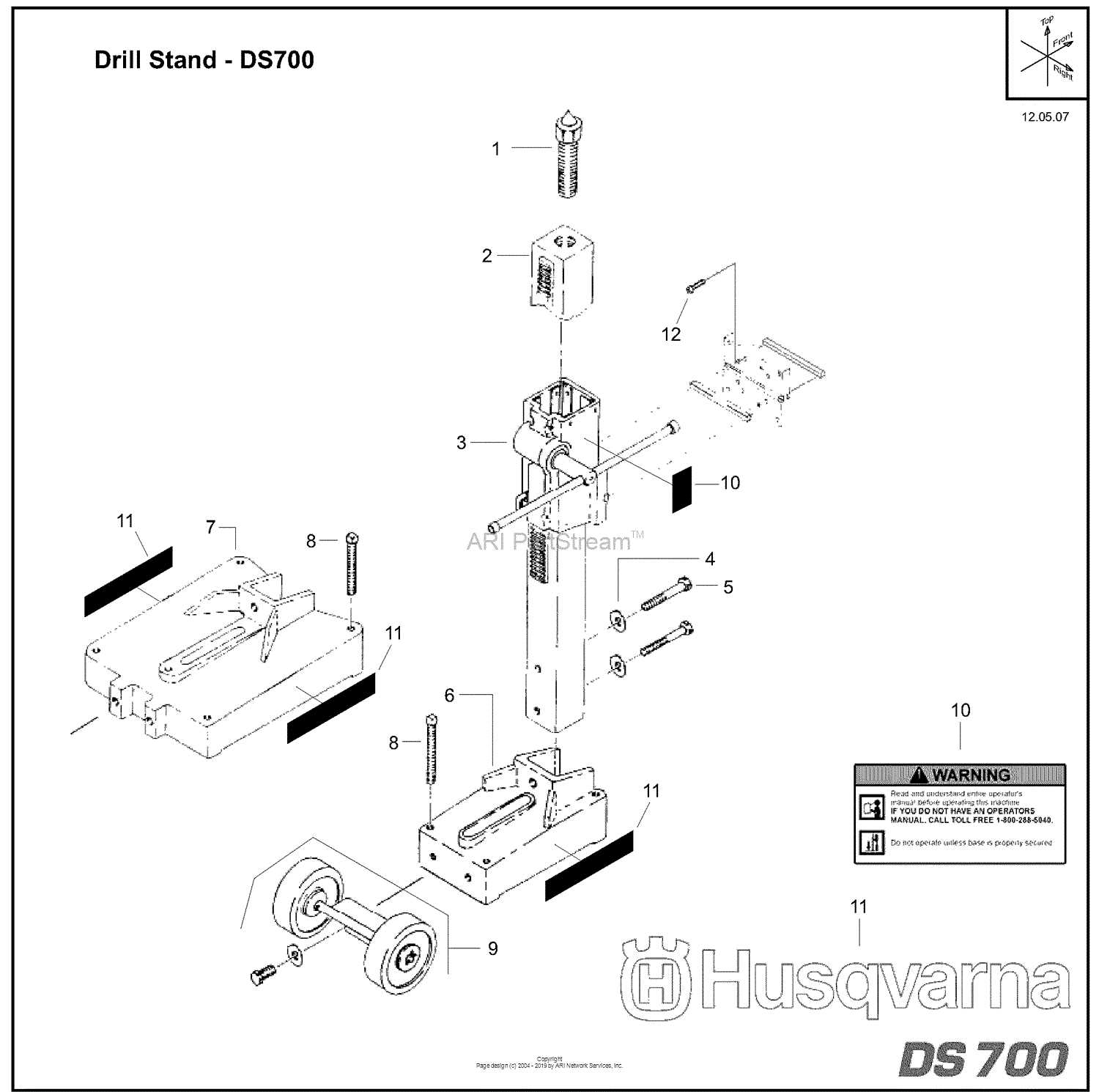

Assembly Diagram Overview

This section provides a comprehensive look at the assembly illustration, highlighting the components involved in the construction process. Understanding the arrangement and functionality of each element is essential for efficient operation and maintenance.

Key Components and Their Functions

The assembly representation showcases various elements that contribute to the overall functionality of the device. Each part plays a crucial role in ensuring the equipment operates smoothly and effectively. Familiarity with these components can aid users in troubleshooting and repair, enhancing their overall experience.

Importance of Proper Assembly

Correct assembly is vital for optimal performance. Misalignment or improper installation of components can lead to decreased efficiency and potential damage. By consulting the assembly overview, users can ensure that each part is positioned accurately, which will ultimately extend the lifespan of the tool and improve its functionality.

Maintenance Tips for Your Machine

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Adopting a proactive approach to maintenance can prevent potential issues and enhance efficiency. Here are some key recommendations to keep your device running smoothly.

- Clean the Exterior: Regularly wipe down the machine’s surface to remove dust and debris, which can lead to overheating and mechanical issues.

- Inspect Moving Parts: Check all components for wear and tear. Lubricate moving parts as necessary to reduce friction and prevent damage.

- Replace Worn Out Components: Identify parts that show signs of deterioration. Timely replacement can prevent further complications and ensure continued effectiveness.

- Follow Usage Guidelines: Adhere to the manufacturer’s recommendations regarding usage to avoid overloading the machine, which can lead to premature failure.

By implementing these strategies, you can significantly extend the lifespan of your equipment and maintain its efficiency for years to come.

Common Issues and Solutions

When operating sharpening equipment, users may encounter various challenges that affect performance and efficiency. Understanding these common problems can help in troubleshooting and implementing effective solutions, ensuring optimal functionality and longevity of the machine.

One frequent issue is inconsistent sharpening results. This may be due to improper alignment of the tool within the device. Ensuring that the tool is securely positioned can significantly improve accuracy. Additionally, maintaining the right angle during the sharpening process is crucial for achieving the desired edge quality.

Another common concern involves wear and tear on the sharpening components. Over time, these elements can degrade, leading to subpar performance. Regular inspection and timely replacement of worn parts can prevent further complications and enhance the overall effectiveness of the equipment.

Lastly, insufficient power supply can hinder operation. Checking connections and ensuring the machine is plugged into a reliable source can resolve issues related to power. Maintaining the electrical system in good condition is vital for uninterrupted functionality.

Upgrading Your Drill Doctor Parts

Improving the functionality of your sharpening tool can significantly enhance its performance and extend its lifespan. By selecting high-quality replacements and enhancements, users can ensure optimal operation and maintain the effectiveness of their equipment.

When considering upgrades, it’s essential to identify the components that may require attention. Focusing on durable materials and precision-engineered elements can lead to better outcomes. Below is a table outlining some potential enhancements and their benefits.

| Component | Benefit |

|---|---|

| Sharpening Wheel | Increased durability and improved sharpening efficiency. |

| Guide System | Enhanced precision in angle adjustments for better results. |

| Motor Upgrade | Higher power output for quicker and more efficient sharpening. |

| Replacement Housing | Improved resilience and protection against wear and tear. |

Investing in quality upgrades not only boosts the performance of your tool but also contributes to a smoother sharpening process. By making informed choices, users can ensure their equipment remains reliable and effective for years to come.

Compatibility with Other Models

This section explores the versatility of a specific sharpening tool and its ability to work seamlessly with various alternatives available on the market. Understanding compatibility is crucial for users who wish to maximize the efficiency and functionality of their equipment.

Many users seek devices that can accommodate multiple models, enabling them to switch between different types of bits or accessories without hassle. This adaptability not only enhances performance but also extends the lifespan of the tools by ensuring they are properly maintained.

When considering alternatives, it is essential to examine the specifications and features of each unit. By doing so, users can identify which models share similar attributes, thereby ensuring optimal compatibility and achieving the desired results during usage.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right tools is crucial for achieving efficient and effective results. A well-equipped toolkit can significantly simplify the process and enhance your ability to address any issues that may arise. Below are essential tools to consider for your repair endeavors.

- Screwdrivers: A set of various sizes and types, including flathead and Phillips, to accommodate different fasteners.

- Wrenches: Adjustable and socket wrenches are necessary for loosening and tightening nuts and bolts.

- Pliers: These tools are essential for gripping, twisting, and cutting wires or other materials.

- Hex keys: Also known as Allen wrenches, they are vital for accessing hexagonal socket screws.

- Measuring tools: A tape measure or caliper helps ensure accurate dimensions and alignments.

- Cleaning supplies: Brushes and cloths assist in maintaining a clean workspace and ensuring optimal performance.

- Safety gear: Protective eyewear and gloves are critical for safeguarding against potential hazards during repairs.

Having these tools readily available will empower you to tackle various maintenance challenges effectively. Always prioritize safety and ensure you have a clear understanding of the tasks at hand before commencing any repairs.

Where to Purchase Replacement Parts

Finding suitable components for your sharpening tool is essential for maintaining its performance and longevity. Whether you are looking to replace a worn item or upgrade your equipment, several avenues are available to obtain the necessary materials.

Authorized Retailers

One of the best ways to ensure you receive high-quality components is to shop at authorized retailers. These sellers often provide genuine items that meet the original manufacturer’s specifications.

- Visit local home improvement stores that specialize in tool accessories.

- Check online platforms that are recognized for selling genuine equipment materials.

- Consult the manufacturer’s website for a list of approved retailers.

Online Marketplaces

The internet offers a vast selection of components at competitive prices. Numerous online marketplaces cater to tool enthusiasts and professionals alike.

- Explore well-known e-commerce sites for various options.

- Consider specialized online shops that focus on sharpening equipment.

- Read customer reviews to gauge the quality and reliability of the products offered.

Frequently Asked Questions about 750X

This section addresses common inquiries related to the specific sharpening equipment. Here, we aim to provide clear answers to assist users in understanding functionality, maintenance, and best practices. These insights are essential for maximizing the efficiency and longevity of your device.

General Inquiries

Many users often seek clarification on the features and usage of their sharpening tool. Below are some frequently raised questions and their concise answers.

| Question | Answer |

|---|---|

| What is the recommended maintenance schedule? | Regular cleaning after each use and periodic inspection of components are advisable to ensure optimal performance. |

| Can I sharpen different types of blades? | Yes, this equipment is versatile and can effectively sharpen various blade styles, including standard and specialty designs. |

| Is it easy to operate? | The device is designed for user-friendliness, making it accessible for both novices and experienced users. |

| What safety precautions should I take? | Always wear appropriate protective gear and ensure that the device is unplugged during maintenance to avoid accidents. |

Troubleshooting Common Issues

Users occasionally encounter challenges while operating the sharpening machine. Below are some common problems and solutions to help resolve them.

| Issue | Solution |

|---|---|

| Equipment not starting | Check the power supply and ensure that the unit is properly plugged in and switched on. |

| Poor sharpening results | Examine the sharpening angle and ensure it is set correctly for the type of blade being sharpened. |

| Unusual noises during operation | Inspect for any loose components or debris inside the machine and clear any obstructions. |

| Blade overheating | Reduce the sharpening speed and allow the blade to cool down before resuming the process. |