The complexity of modern machinery requires a detailed understanding of its various components and their arrangements. Each machine is a collection of interconnected parts, each serving a specific function that contributes to the overall performance. Grasping how these elements fit together is essential for maintenance and troubleshooting.

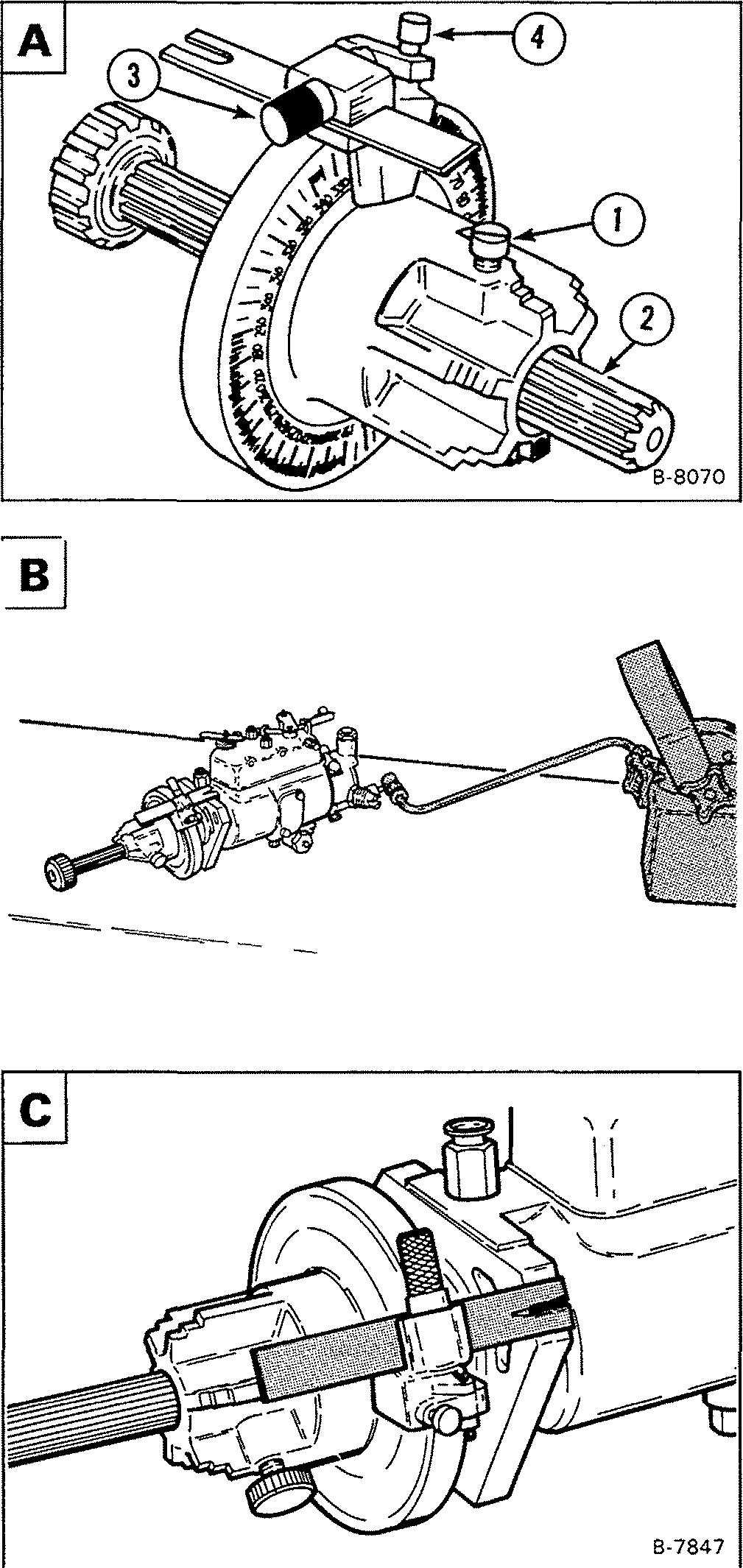

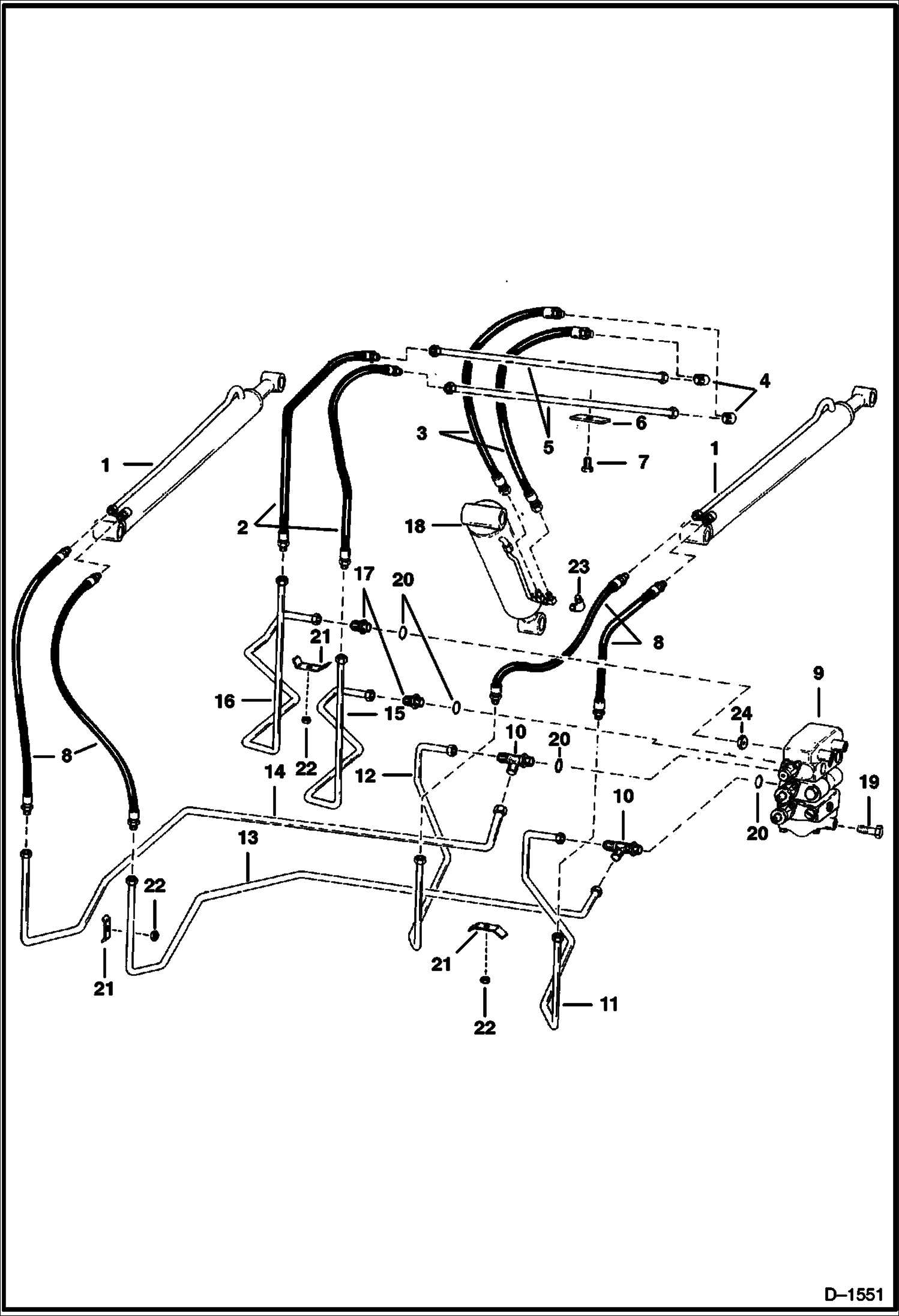

In this section, we will explore a visual representation that highlights the organization of components within a specific model. By analyzing this illustration, users can gain insights into the relationships between different parts, facilitating better understanding and easier repairs. Knowledge of the layout can significantly enhance operational efficiency and reduce downtime.

Furthermore, this exploration will emphasize the importance of familiarity with machine configurations. Recognizing where each element is located and how they interact can empower operators and technicians alike, leading to more informed decisions during servicing and usage. A clear visual guide serves as an invaluable tool in any maintenance toolkit.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools for users, providing clear insights into the intricate relationships between various elements.

Enhanced Clarity: These visual aids simplify complex systems, allowing technicians to quickly identify parts and their respective functions. This clarity minimizes errors during assembly and disassembly, ensuring smoother operations.

Efficient Troubleshooting: When issues arise, these illustrations facilitate faster diagnosis by highlighting potential problem areas. Technicians can refer to specific sections, leading to more accurate repairs and less downtime.

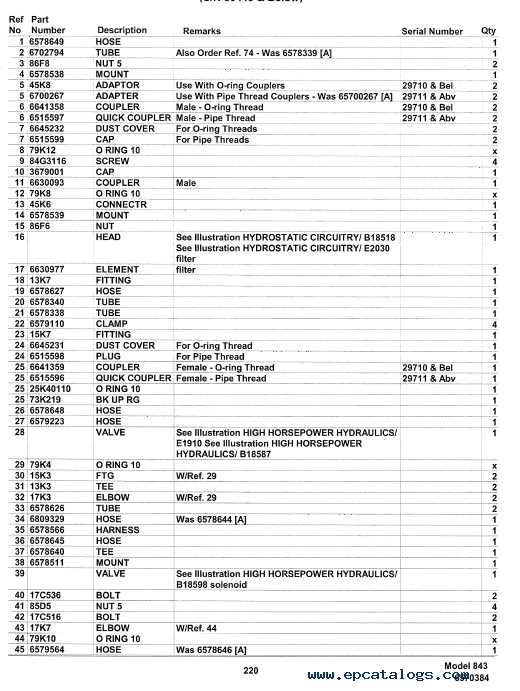

Streamlined Ordering: Knowing the exact components needed for replacements becomes easier with visual guides. Users can refer to these references when ordering new items, reducing the likelihood of mistakes and ensuring the right parts are obtained.

Knowledge Transfer: For new technicians, these resources act as educational tools, helping them learn about machinery structure and function. This knowledge transfer contributes to a more skilled workforce, enhancing overall operational efficiency.

Key Features of Bobcat 843

This section highlights the essential characteristics and components of a popular compact loader model. Understanding these features is crucial for operators and technicians looking to optimize performance and maintain efficiency.

| Feature | Description |

|---|---|

| Engine Power | A robust power unit ensures reliable performance under various load conditions. |

| Hydraulic System | An efficient hydraulic system allows for swift and effective operation of attachments. |

| Operator Comfort | An ergonomic cabin design enhances comfort, reducing fatigue during extended use. |

| Versatility | Compatibility with numerous attachments expands the machine’s functionality for diverse tasks. |

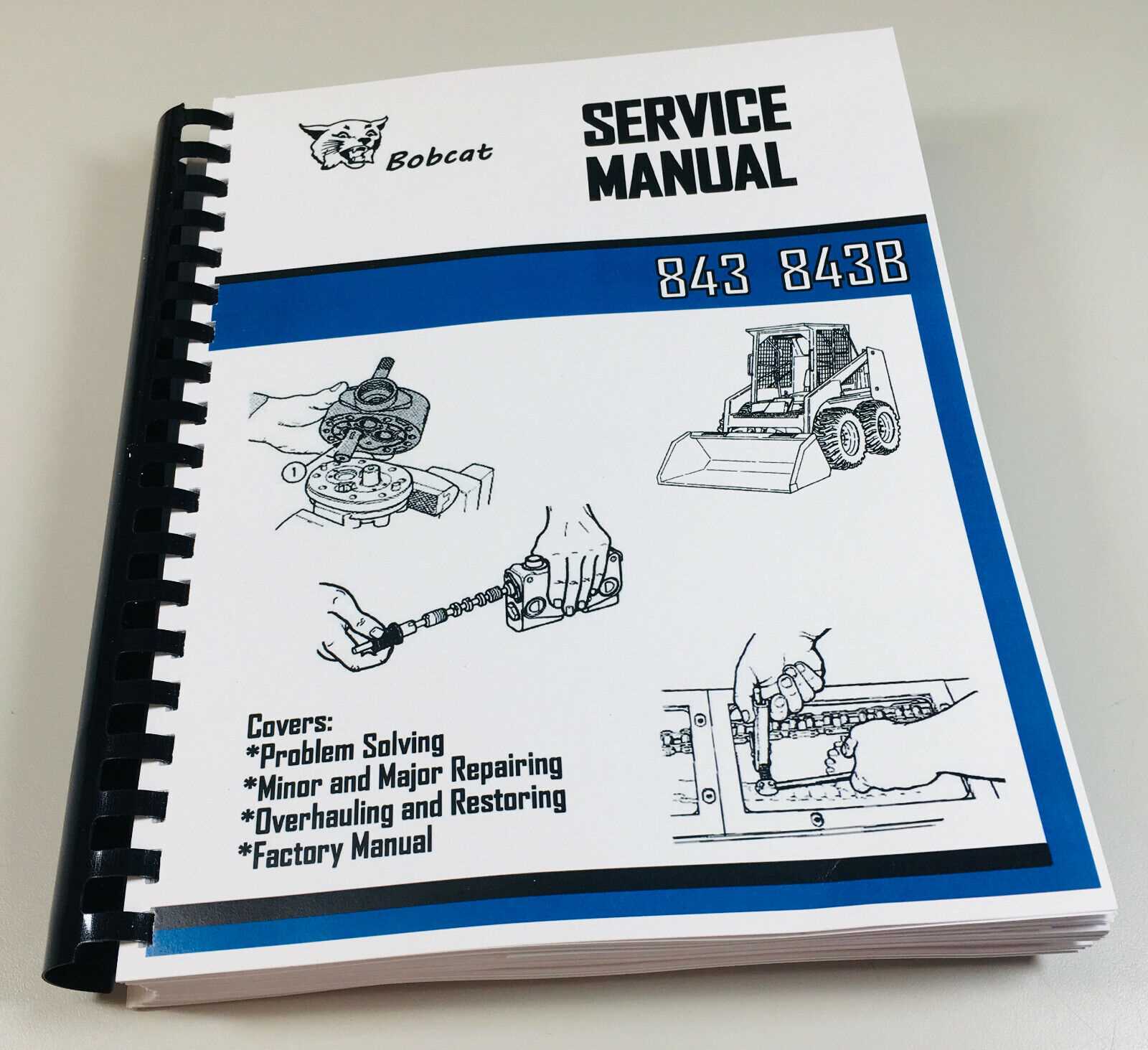

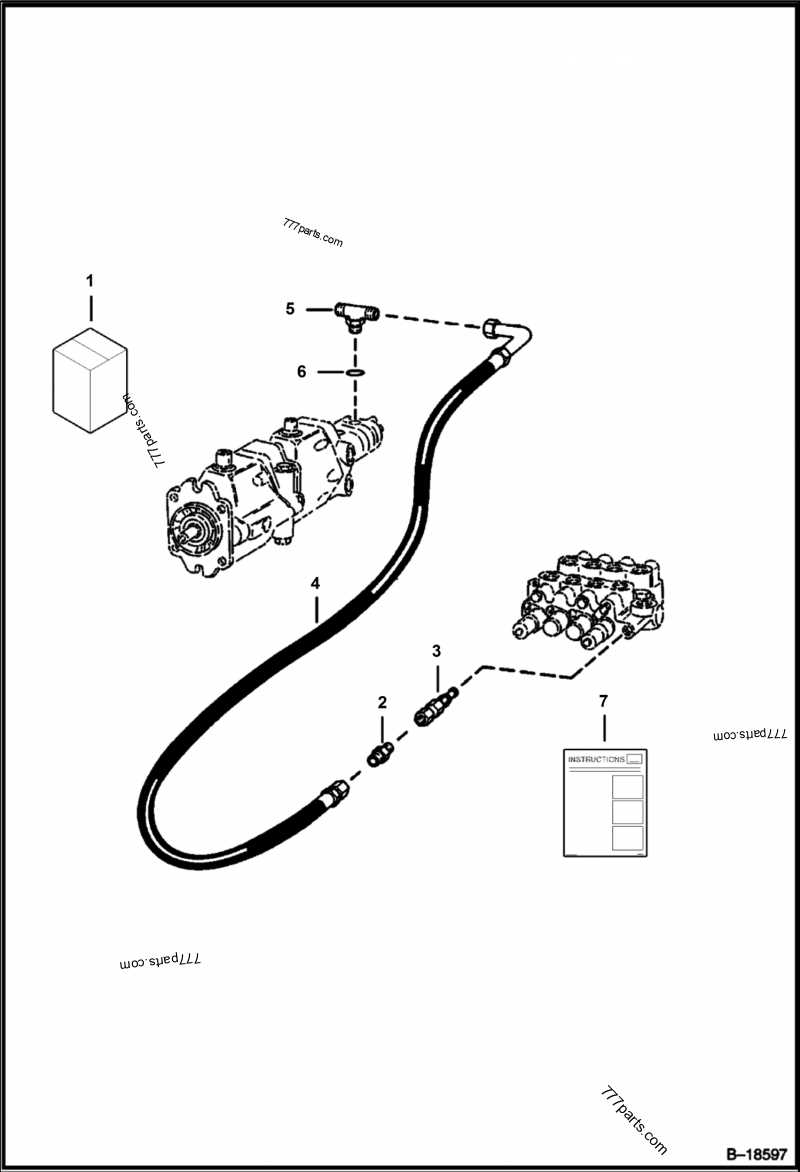

Understanding the Hydraulic System

The hydraulic system plays a crucial role in the operation of various machinery by utilizing fluid under pressure to transmit power. This technology allows for smooth and efficient movement of components, making it essential for tasks that require significant force.

In this section, we will explore the main components of the hydraulic system, their functions, and how they interact to ensure optimal performance.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates fluid flow and pressure needed for operation. |

| Hydraulic Cylinders | Convert hydraulic energy into linear motion. |

| Valves | Control the flow and direction of the hydraulic fluid. |

| Hoses and Fittings | Transport fluid between components and maintain system integrity. |

| Reservoir | Stores hydraulic fluid and allows for expansion and cooling. |

Understanding these elements and their interrelationships is vital for troubleshooting and maintaining the efficiency of hydraulic systems in heavy machinery.

Electrical System Breakdown

The electrical framework of a machinery unit is crucial for its overall functionality and performance. Understanding the components and their interconnections is essential for effective troubleshooting and maintenance.

Key Components

- Battery: Provides the necessary power to start the engine and operate electrical accessories.

- Alternator: Generates electrical energy to recharge the battery and power the machine’s systems.

- Starter Motor: Initiates the engine’s operation by converting electrical energy into mechanical energy.

- Wiring Harness: Connects various electrical parts, ensuring efficient transmission of power and signals.

- Fuses and Relays: Protect circuits from overloads and facilitate the control of electrical functions.

Troubleshooting Tips

- Check the battery voltage and connections for any signs of corrosion.

- Inspect the alternator for proper operation and output voltage.

- Examine the starter motor for any signs of wear or malfunction.

- Ensure the wiring harness is intact and free from damage.

- Test fuses and relays to confirm they are functioning correctly.

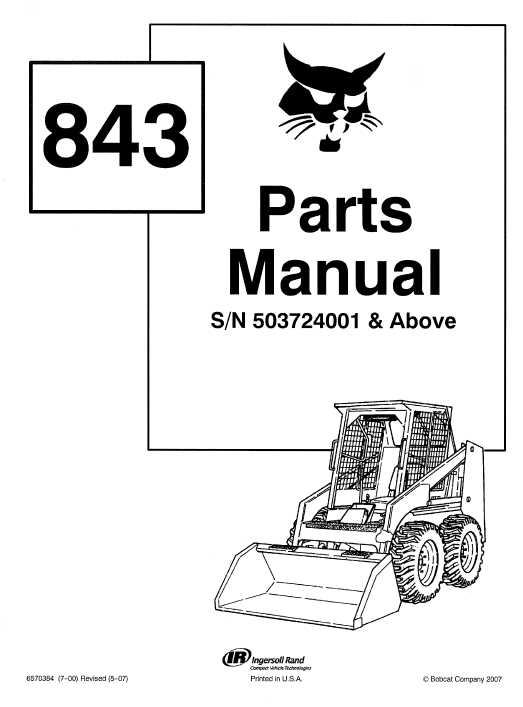

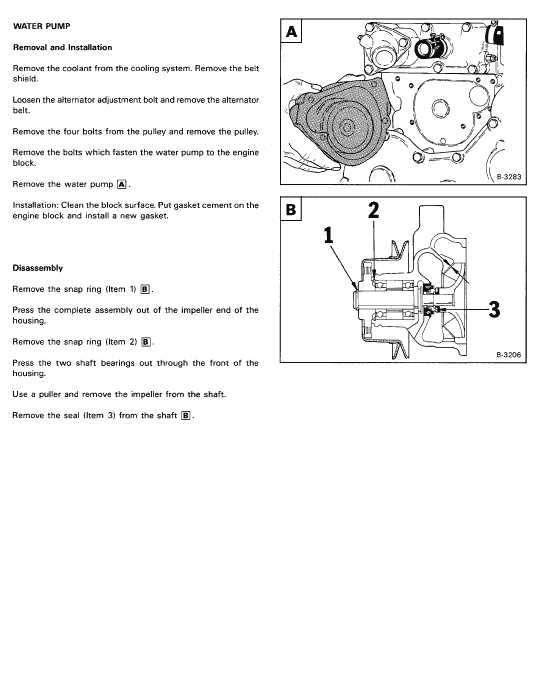

Engine and Transmission Details

This section provides an overview of the core components responsible for the machine’s movement and performance. Understanding these elements is crucial for maintenance and troubleshooting.

The power unit is designed for optimal efficiency, delivering the necessary horsepower for various tasks. It features a robust construction that ensures durability and reliability under challenging conditions.

The transmission system is engineered to provide smooth gear shifts, enhancing the overall driving experience. It allows for effective power transfer from the engine to the wheels, ensuring excellent traction and maneuverability on different terrains.

Regular inspection and maintenance of both the engine and transmission are essential for sustaining performance and prolonging the lifespan of the equipment. Keeping these systems in top condition will help prevent costly repairs and downtime.

Common Wear Parts to Monitor

In any machinery, certain components are subject to regular wear due to their frequent use. Monitoring these elements is essential to ensure optimal performance and longevity of the equipment. Awareness of the common wear items can prevent unexpected failures and costly downtime.

Key Components to Watch

- Hydraulic Hoses

- Filters

- Seals and Gaskets

- Belts

- Bearings

Signs of Wear

Regular inspection of these components can reveal signs of deterioration. Look for:

- Cracks or bulges on hoses

- Clogging in filters

- Leaks around seals

- Fraying or cracks on belts

- Unusual noises from bearings

Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of your machinery and ensuring optimal performance. By following a few key practices, you can significantly reduce the risk of breakdowns and enhance efficiency.

First, consistently check fluid levels and replace them according to the manufacturer’s recommendations. Clean fluids facilitate smooth operation and protect internal components from wear and tear. Additionally, make sure to inspect filters regularly, as clogged filters can hinder performance and lead to overheating.

Next, pay attention to the overall cleanliness of the equipment. Accumulated dirt and debris can cause components to function improperly. Implement a routine cleaning schedule to remove dust and grime, particularly in areas prone to buildup.

Moreover, keep an eye on wear items such as belts, hoses, and seals. Timely replacement of these components can prevent unexpected failures and costly repairs. It’s also wise to follow a scheduled maintenance plan that includes periodic checks and servicing.

Lastly, consider investing in quality parts when replacements are necessary. Using high-quality materials ensures durability and reliability, ultimately leading to a longer service life for your machinery.

How to Use Parts Diagrams

Understanding the visual representations of components is essential for effective maintenance and repairs. These illustrations provide a clear overview of the various elements involved in machinery, making it easier to identify and locate specific items.

To effectively utilize these visuals, begin by familiarizing yourself with the layout and symbols used in the representation. This foundational knowledge will help you navigate the illustration more efficiently. Next, refer to the key or legend often provided alongside the visuals to decode any unfamiliar markings.

As you assess the illustration, pay close attention to the arrangement of components. This will assist you in understanding how each piece fits into the larger system, enabling you to pinpoint the exact location of items when conducting repairs or replacements. Regular consultation of these visuals can greatly enhance your proficiency in handling machinery.

Replacing Damaged Components

Maintaining the functionality of your machinery requires timely replacement of any broken or worn-out elements. Regular inspections help identify issues before they escalate, ensuring smooth operation and preventing costly repairs. This section outlines the process of swapping out faulty parts to restore optimal performance.

Identifying Faulty Elements

Before proceeding with replacements, it’s essential to recognize which components require attention. Signs of wear can include unusual noises, reduced efficiency, or visible damage. Conducting a thorough assessment can help pinpoint the specific areas that need intervention.

Replacement Process

Once the damaged components have been identified, follow these general steps for replacement:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and replacement components. |

| 2 | Shut down the machinery and disconnect from power sources. |

| 3 | Carefully remove the damaged part, noting any connections or fasteners. |

| 4 | Install the new component, ensuring it is secure and properly connected. |

| 5 | Reconnect the power and conduct a test to verify functionality. |

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for maintaining optimal performance and longevity. Reliable sources ensure that you receive high-quality items tailored specifically for your equipment.

Consider the following avenues when searching for genuine components:

- Authorized Dealers: Start with authorized distributors who specialize in your equipment brand. They typically carry a wide range of original components and can offer expert advice.

- Manufacturer’s Website: Visit the official website of the manufacturer. Most brands provide a section for genuine components, including catalogs and ordering options.

- Industry Trade Shows: Attend industry-specific events and trade shows. These gatherings often feature manufacturers and suppliers showcasing their latest offerings.

- Online Marketplaces: Utilize reputable online platforms that focus on heavy machinery parts. Ensure that sellers are verified to avoid counterfeit items.

- Local Repair Shops: Consult with local repair shops that specialize in heavy equipment. They often have connections with suppliers and can assist in sourcing genuine items.

By exploring these options, you can ensure that your machinery remains in top condition with authentic components that meet the required specifications.

Aftermarket Parts Considerations

When it comes to replacing components for heavy machinery, exploring alternative options can often yield significant benefits. Choosing substitutes may provide cost savings, availability, and improved performance, but it’s essential to evaluate various factors to ensure compatibility and quality.

Key aspects to consider include:

| Factor | Description |

|---|---|

| Quality | Assess the durability and performance of alternative components, ensuring they meet or exceed original specifications. |

| Compatibility | Verify that the selected substitutes fit seamlessly within the machinery, preventing any operational issues. |

| Warranty | Check if the aftermarket items come with a guarantee, providing peace of mind regarding their reliability. |

| Supplier Reputation | Research the credibility of vendors to ensure that you are sourcing from reliable and experienced providers. |

By carefully evaluating these considerations, users can make informed decisions when opting for alternative components that enhance the functionality and longevity of their machinery.

Resources for Repair Manuals

Accessing comprehensive documentation is essential for effective maintenance and repair of machinery. Various resources are available that provide detailed guides and manuals to assist in troubleshooting and servicing equipment efficiently.

- Manufacturer Websites: Many manufacturers offer downloadable manuals and resources directly on their official websites.

- Online Forums: Dedicated communities often share insights, tips, and even documents related to specific models.

- Repair Shops: Local repair shops can provide valuable resources or recommend manuals that are effective for specific maintenance tasks.

- Library Resources: Local libraries or technical schools may have access to repair manuals and related materials for equipment.

- Online Retailers: Some online retailers specialize in selling hardcopy or digital repair manuals for various machinery.

Utilizing these resources ensures that users have the necessary information to perform repairs and maintenance effectively, leading to enhanced performance and longevity of the equipment.