The operation of a marine engine is dependent on various interconnected elements that work in harmony. Recognizing the individual components and their functions is essential for maintaining optimal performance and ensuring longevity. This section delves into the intricate arrangement of these components, providing insights into their specific roles within the overall system.

To effectively manage and repair a marine engine, it is crucial to familiarize oneself with its structure. Each element plays a significant part in the engine’s efficiency, from the combustion chamber to the cooling system. A thorough understanding of these components allows for more informed decision-making during maintenance and troubleshooting processes.

In this exploration, we will highlight key features and functionalities of each section, equipping readers with the knowledge needed to navigate the complexities of marine engine mechanics. By grasping the interrelations among various components, one can better appreciate the importance of each in the overall operation of the system.

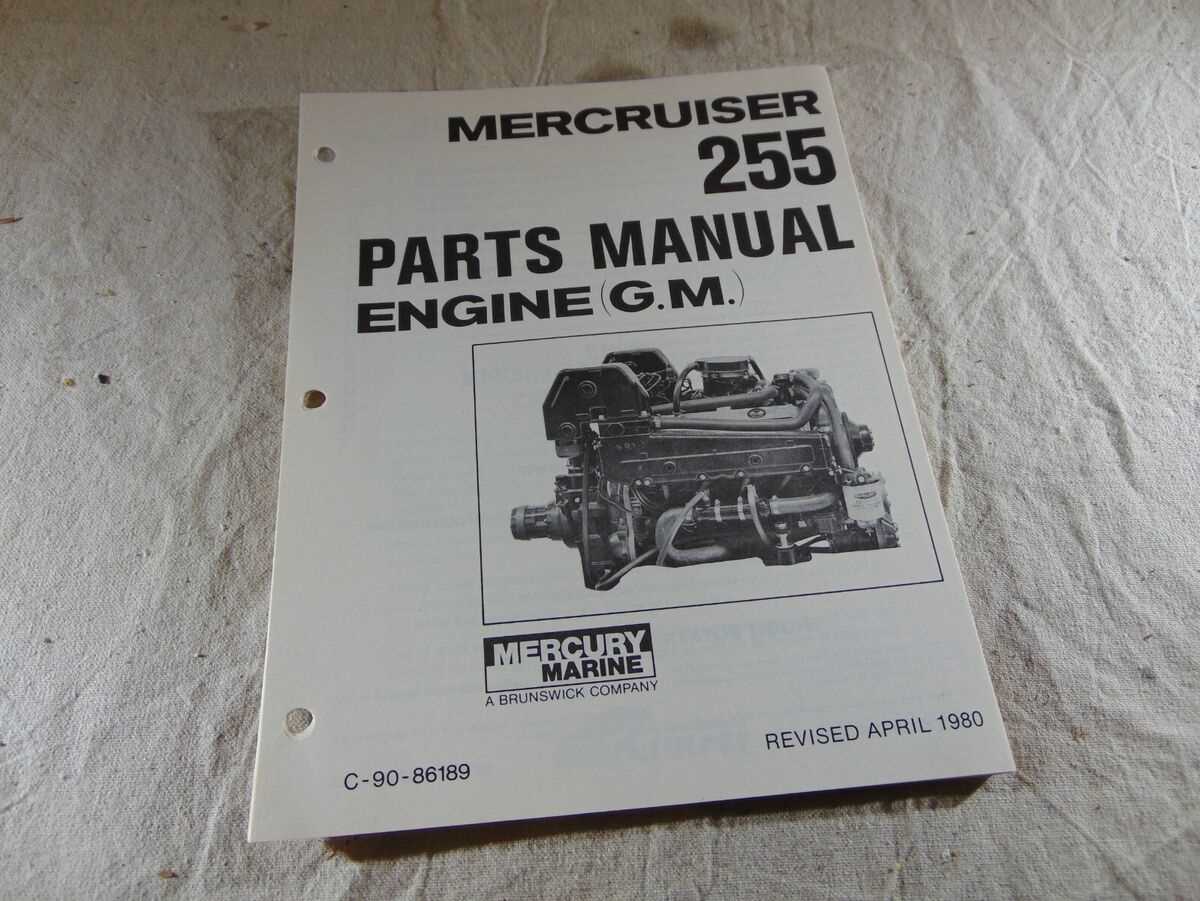

Understanding the Mercruiser 260 Engine

The engine in question is a critical component for marine applications, providing the necessary power and performance for various watercraft. Designed with precision engineering, it combines efficiency and reliability, making it a popular choice among boating enthusiasts.

This particular engine showcases a variety of features that enhance its functionality and durability:

- Robust Design: Built to withstand the harsh marine environment, ensuring longevity and performance.

- Power Output: Capable of delivering significant horsepower, allowing for smooth navigation and quick acceleration.

- Fuel Efficiency: Engineered to optimize fuel consumption, which is crucial for extended trips on the water.

Understanding the key components and their roles is essential for effective maintenance:

- Cooling System: Maintains optimal operating temperatures, preventing overheating.

- Ignition System: Responsible for the timely combustion of fuel, ensuring efficient power delivery.

- Lubrication System: Reduces friction among moving parts, extending the life of the engine.

By familiarizing oneself with these aspects, boat owners can ensure that their engine operates smoothly and reliably, contributing to an enjoyable boating experience.

Essential Components of Mercruiser 260

The efficient operation of marine engines relies on a variety of key elements, each playing a crucial role in the overall performance and reliability of the system. Understanding these components is vital for maintenance and troubleshooting, ensuring a seamless experience on the water.

At the heart of the engine lies the power unit, which generates the necessary force for propulsion. This is supported by an intricate fuel system designed to deliver the right mixture of air and fuel, optimizing combustion for maximum efficiency. Additionally, cooling mechanisms are essential to regulate temperature, preventing overheating and ensuring consistent operation.

Electrical systems, including batteries and ignition components, provide the necessary energy to start the engine and maintain its functionality. Coupled with exhaust systems, these elements work together to manage emissions and enhance performance. Each component is engineered to contribute to the overall functionality, making their understanding crucial for effective upkeep.

Lastly, accessories such as gauges and control systems offer vital feedback to the operator, allowing for real-time monitoring of engine health. Knowledge of these essential parts not only aids in effective management but also enhances the longevity of the marine engine.

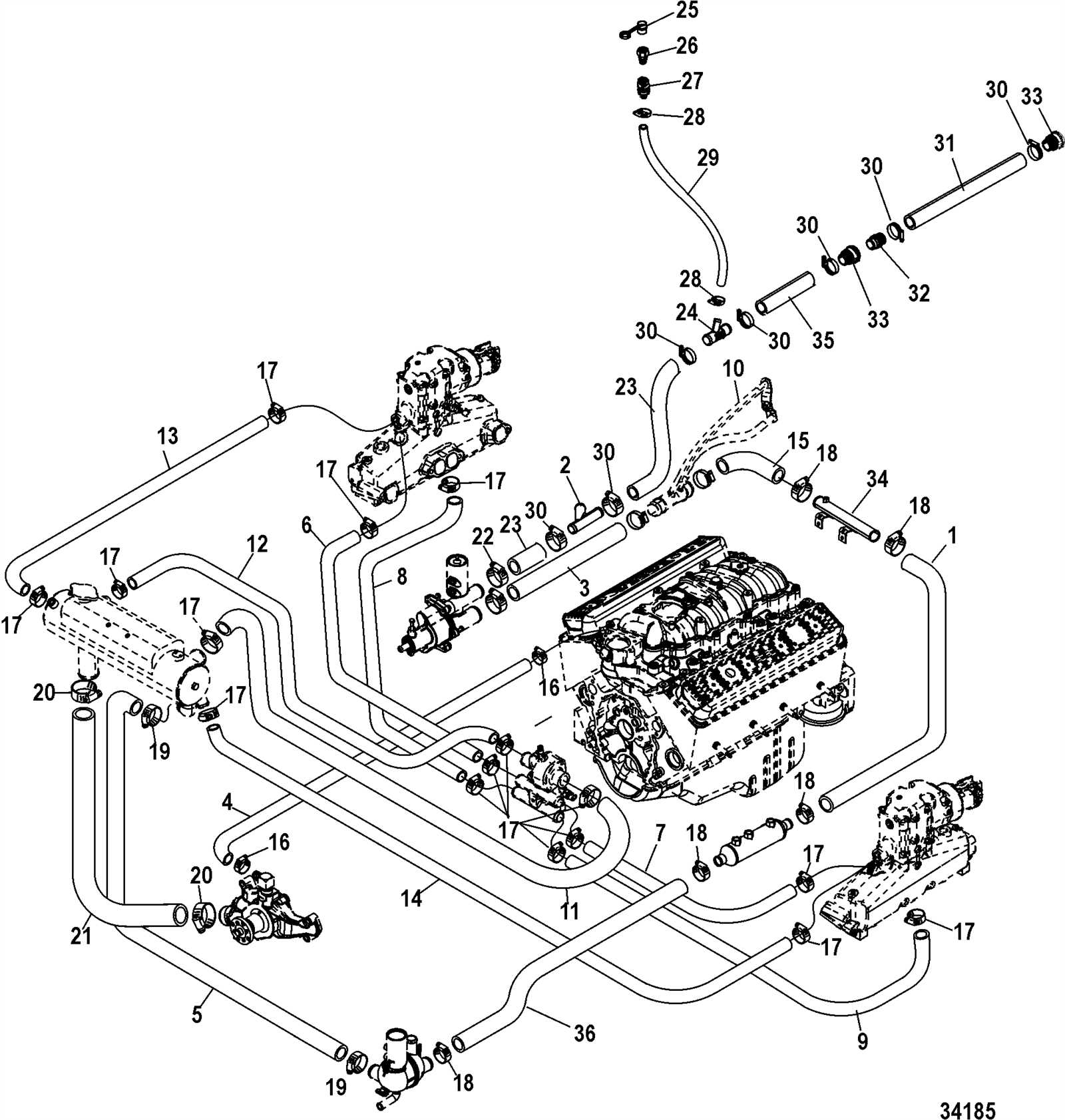

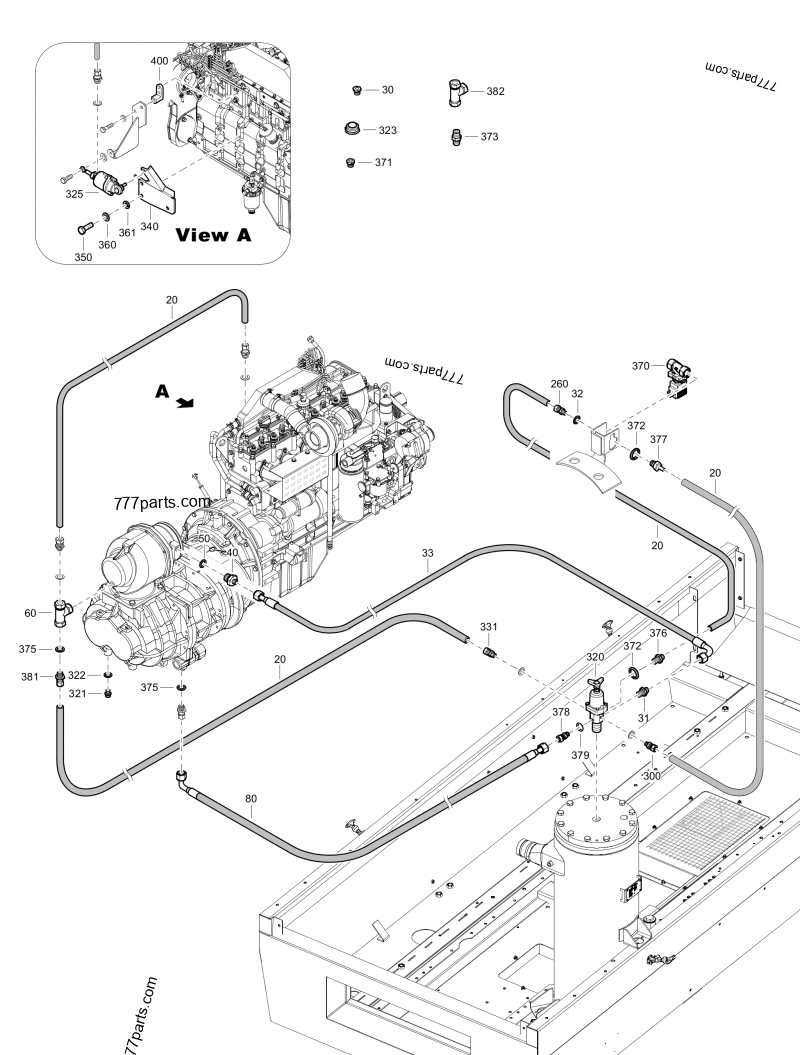

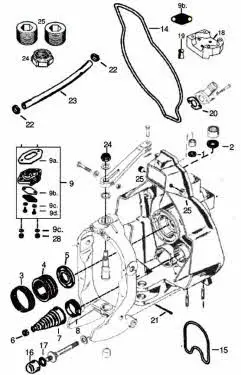

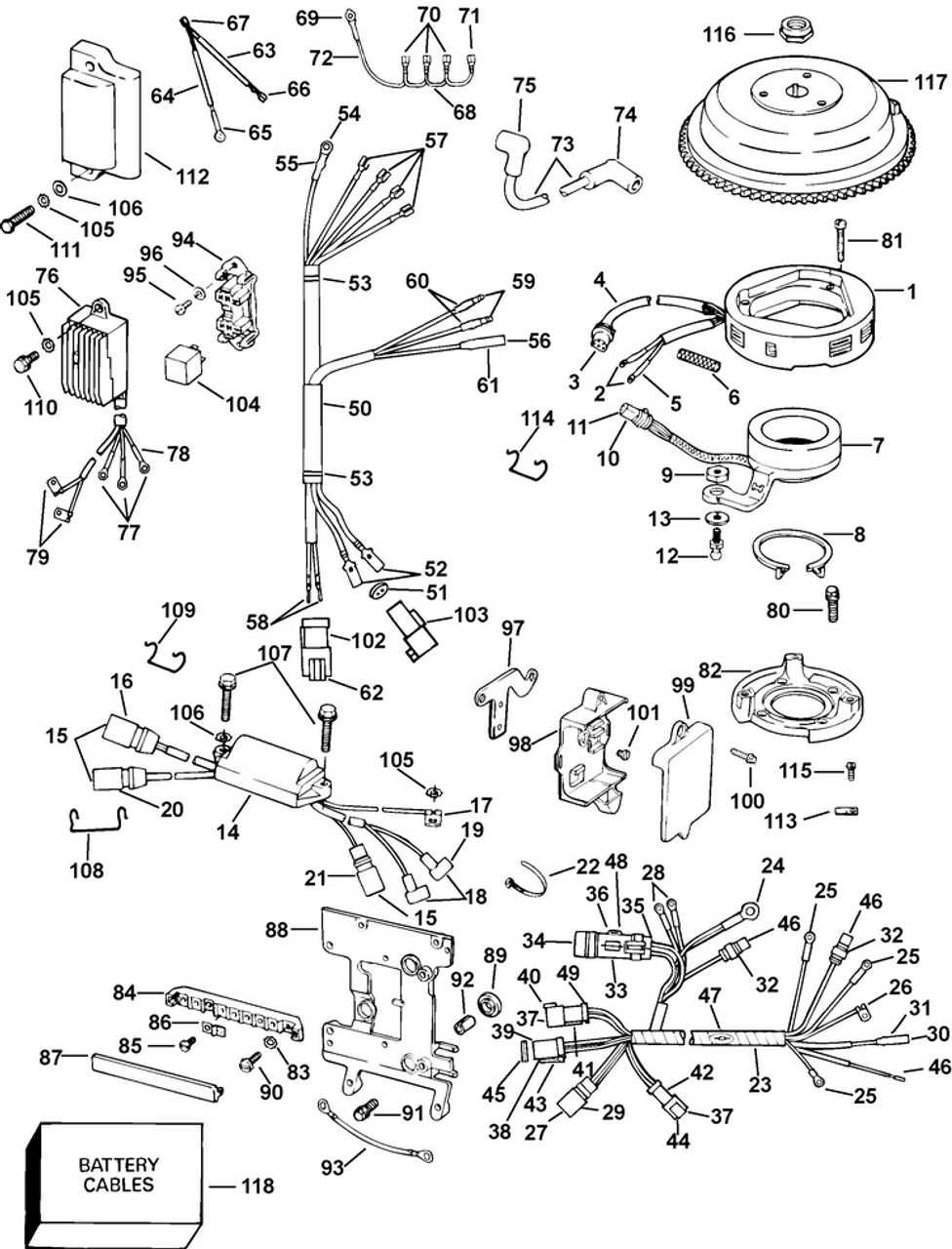

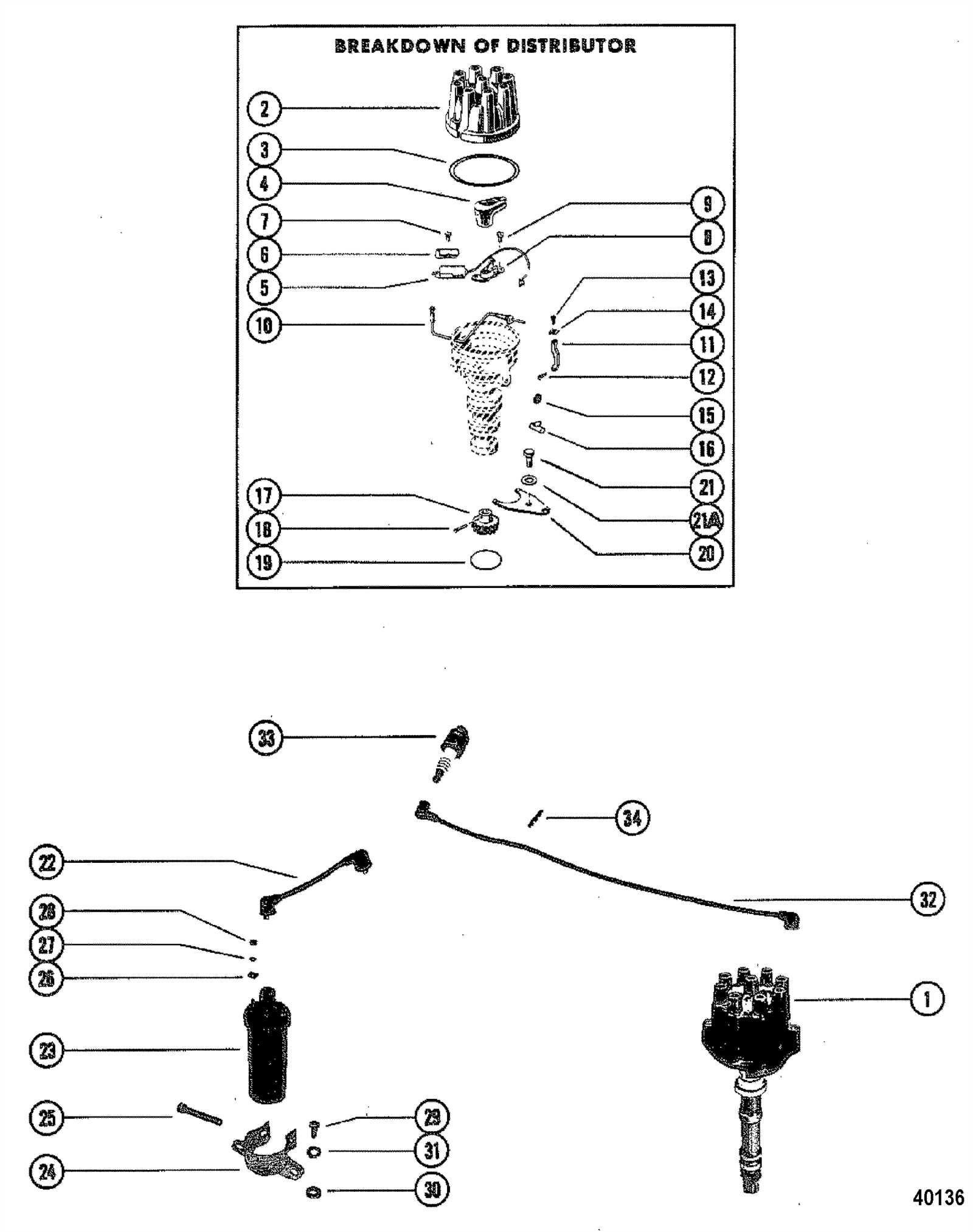

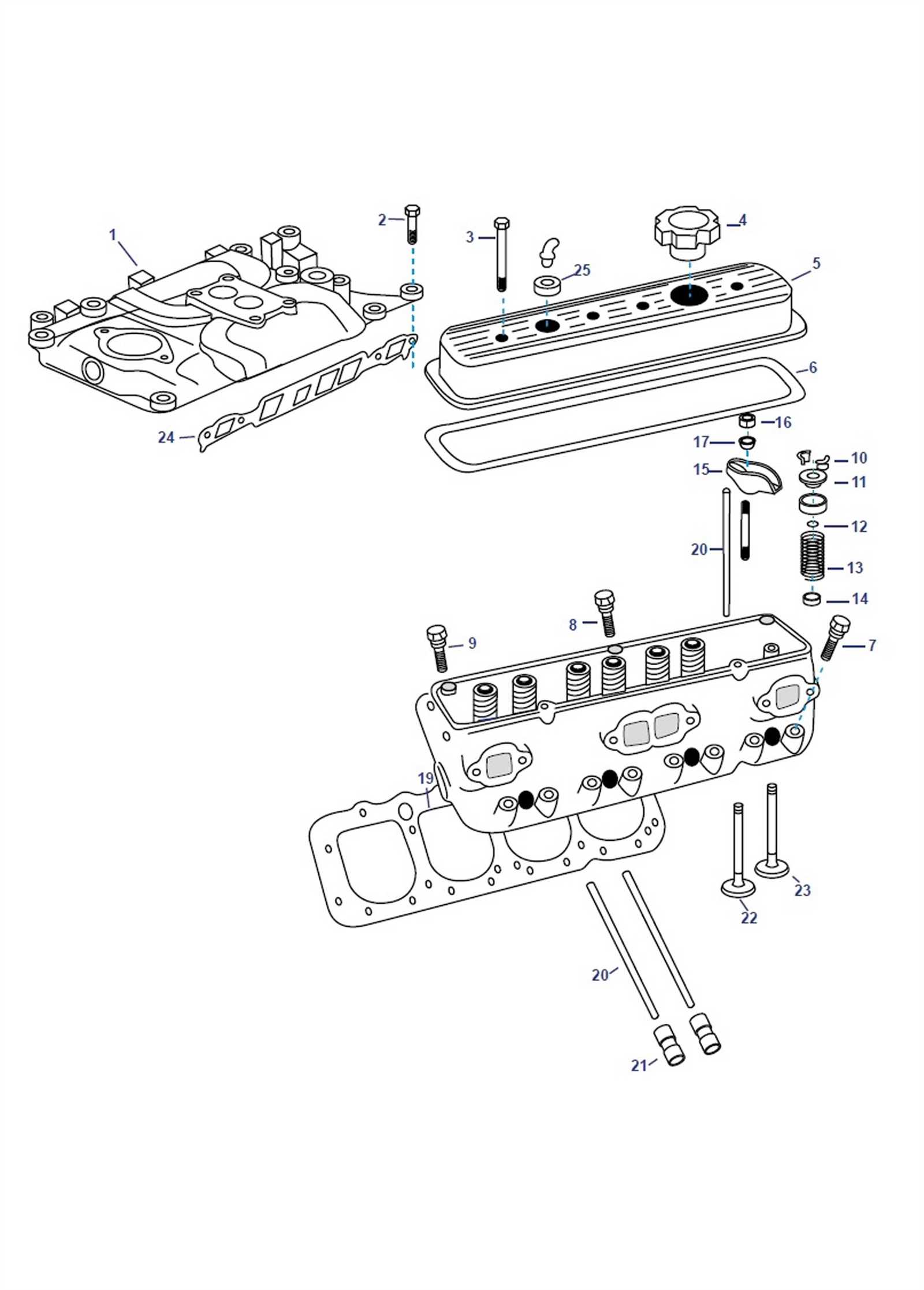

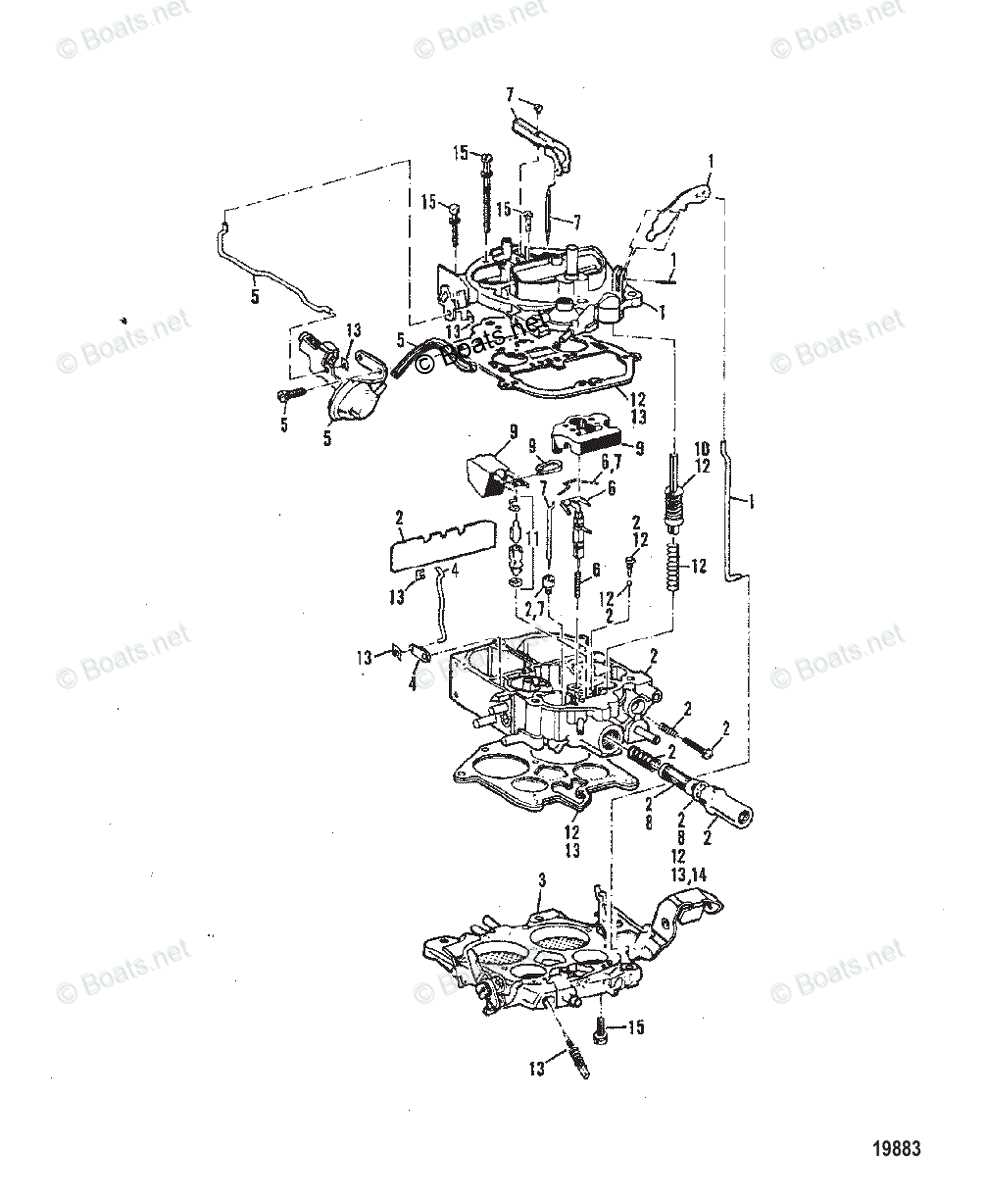

Detailed Parts Breakdown Diagram

This section provides a comprehensive overview of the various components and assemblies that make up the marine engine system. Understanding each element’s function and arrangement is crucial for effective maintenance and repairs. A well-structured illustration can enhance comprehension and facilitate easier identification during service procedures.

Each segment in the representation highlights specific features and connections, ensuring that users can quickly locate and assess parts. The organization of this information allows for a clearer understanding of how these components interact within the system, ultimately contributing to optimal performance and longevity of the engine.

Essential components include various mechanical and electrical elements that work together seamlessly. By familiarizing oneself with the layout and function of each part, one can make informed decisions regarding upgrades, replacements, and troubleshooting. Detailed schematics serve as a valuable resource for both novice and experienced technicians alike.

Maintenance Tips for Mercruiser 260

Proper upkeep of marine engines is crucial for ensuring optimal performance and longevity. Regular attention to various components can prevent unexpected issues and enhance the overall reliability of the vessel. Below are some essential maintenance practices to keep in mind.

First, always check the oil levels and change the oil and filter at recommended intervals to maintain engine health. Clean fuel filters regularly to prevent clogs that can affect performance. Additionally, inspect and clean the cooling system to avoid overheating, which can lead to severe damage.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 100 hours or annually | Use recommended oil type for best results. |

| Fuel Filter Replacement | Every 100 hours | Ensure to use high-quality filters. |

| Cooling System Inspection | Annually | Flush and clean to prevent corrosion. |

| Battery Check | Monthly | Clean terminals and check connections. |

| Propeller Inspection | Every outing | Look for damage or debris that can affect performance. |

Finally, always refer to the manufacturer’s guidelines for specific maintenance procedures and recommendations. Keeping a detailed log of maintenance activities can also help track tasks and ensure nothing is overlooked.

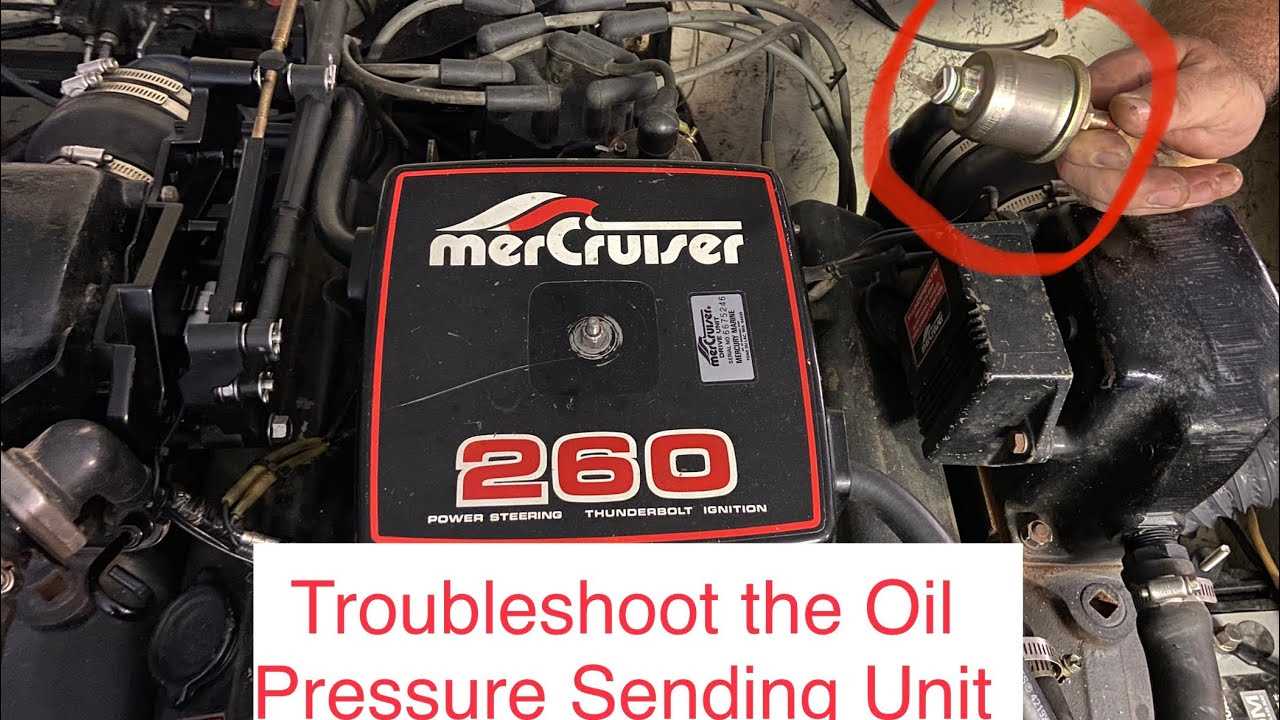

Common Issues with Mercruiser 260 Parts

When dealing with marine engines, several challenges can arise that impact performance and reliability. Understanding these issues can aid in effective maintenance and troubleshooting, ensuring optimal functionality. This section highlights frequent concerns encountered with various components of a popular engine model.

| Issue | Description |

|---|---|

| Overheating | Insufficient coolant flow due to clogged passages or malfunctioning thermostats can lead to elevated temperatures, risking engine damage. |

| Starting Problems | Faulty ignition components or a weak battery can prevent the engine from starting, causing frustration and delays in operation. |

| Fuel Leaks | Damaged fuel lines or faulty connectors may lead to leaks, posing safety hazards and reducing efficiency. |

| Vibration | Improper alignment of components can result in excessive vibration, affecting comfort and potentially causing further damage. |

| Oil Pressure Issues | Inconsistent oil pressure can indicate underlying problems, such as worn bearings or blockages in the oil passages, necessitating immediate attention. |

Finding Quality Replacement Parts

When maintaining or restoring marine engines, sourcing reliable components is crucial for optimal performance and longevity. Whether you’re a seasoned technician or a passionate enthusiast, knowing where to find high-quality substitutes can significantly affect your vessel’s efficiency. This section explores effective strategies and considerations for acquiring the best replacements available.

To ensure you are making informed decisions, consider the following factors when searching for substitutes:

| Criteria | Description |

|---|---|

| Authenticity | Opt for original or certified components to guarantee compatibility and performance. |

| Reviews | Check customer feedback and ratings to assess the reliability of suppliers and their products. |

| Warranty | Look for components that come with a warranty, indicating confidence in their durability. |

| Source | Choose reputable dealers or authorized distributors who specialize in marine engine components. |

| Price | While seeking value, be cautious of prices that seem too low, as they may indicate inferior quality. |

By focusing on these essential criteria, you can enhance the likelihood of obtaining superior replacements, ensuring your marine engine runs smoothly and efficiently for years to come.

Installation Guide for Mercruiser Components

This section provides essential instructions for effectively setting up various components within an engine system. Proper installation is crucial for optimal performance and longevity. Following these guidelines ensures that each part functions correctly and enhances overall reliability.

Before starting the installation process, gather all necessary tools and components. Ensure that the workspace is clean and organized to facilitate a smooth procedure. It is also advisable to refer to the manufacturer’s specifications for detailed information regarding compatibility and requirements.

| Step | Description | Tools Needed |

|---|---|---|

| 1 | Prepare the workspace by ensuring it is clean and all components are available. | Cleaning supplies |

| 2 | Carefully review the installation instructions for each individual component. | Instruction manual |

| 3 | Install the first component, ensuring proper alignment and secure fastening. | Wrenches, screwdrivers |

| 4 | Repeat the installation process for all remaining parts, checking for compatibility. | Torque wrench |

| 5 | Conduct a thorough inspection of all installed components to ensure stability. | Inspection tools |

Upon completion of the installation, it’s vital to test the system under various conditions to confirm functionality. Address any issues immediately to avoid complications during operation. Adhering to these steps will contribute to the successful integration of new components into the engine system.

Performance Enhancements for Mercruiser 260

Improving the efficiency and output of marine engines is a common pursuit among enthusiasts. By focusing on specific modifications and upgrades, one can achieve significant gains in power, responsiveness, and overall performance. This section explores various strategies and components that can elevate engine capabilities, ensuring a more exhilarating experience on the water.

Upgrading Exhaust Systems

Enhancing the exhaust system is crucial for increasing engine efficiency. Replacing stock components with high-performance alternatives can reduce back pressure and improve exhaust flow. This upgrade not only contributes to better engine output but also results in a more aggressive sound that many boaters desire. Consider options such as stainless steel headers or performance mufflers for optimal results.

Optimizing Fuel Delivery

Improving fuel delivery can dramatically affect performance. Upgrading to a high-flow fuel pump and injectors can ensure that the engine receives adequate fuel under high-demand conditions. Additionally, tuning the engine’s electronic control unit (ECU) can optimize air-fuel ratios, leading to improved throttle response and overall efficiency. This attention to fuel delivery mechanics can lead to a noticeable difference in acceleration and power.

Tools Required for Maintenance Tasks

Effective upkeep of mechanical systems necessitates a well-curated selection of instruments. Proper tools not only facilitate tasks but also enhance safety and efficiency, ensuring that each procedure is executed with precision. Understanding the appropriate equipment needed for various maintenance activities is crucial for both novice and experienced technicians.

Essential Hand Tools

Basic hand instruments are fundamental for any maintenance task. Wrenches, screwdrivers, and pliers are indispensable for loosening or tightening components. Additionally, having a good quality socket set can simplify the removal of fasteners in tight spaces, making access to critical areas much easier.

Specialized Equipment

In some cases, specific maintenance procedures may require more specialized tools. For example, a torque wrench is vital for applying the correct amount of force to bolts, preventing damage from over-tightening. Furthermore, multimeters and diagnostic tools can assist in troubleshooting electrical systems, allowing for accurate diagnosis and repairs.

Safety Precautions During Repairs

When undertaking maintenance or repairs on mechanical equipment, adhering to safety protocols is essential. These measures not only protect the individual performing the work but also ensure the integrity of the equipment being serviced. Here are some critical guidelines to follow for a safe working environment.

- Personal Protective Equipment (PPE): Always wear appropriate gear such as gloves, goggles, and steel-toed boots to minimize the risk of injury.

- Work Area Organization: Maintain a tidy workspace free from clutter to reduce hazards and improve efficiency.

- Proper Tools: Utilize the correct tools for each task to avoid accidents and damage to components.

Additionally, follow these practices:

- Electrical Safety: Disconnect power sources before starting any electrical repairs to prevent shock hazards.

- Hydraulic Systems: Be cautious when working with hydraulic components; release pressure before disassembly.

- Documentation: Keep a repair log and reference manuals close to ensure adherence to specifications and procedures.

By observing these safety measures, you can significantly reduce risks and promote a successful repair process.

Understanding Wiring Schematics

Wiring schematics serve as essential tools for interpreting electrical systems. They provide a visual representation of connections and components, allowing users to understand how electricity flows through a device. By breaking down complex systems into manageable parts, these diagrams simplify troubleshooting and repairs.

Each symbol in a schematic corresponds to a specific component, such as switches, connectors, and power sources. Familiarity with these symbols is crucial for accurate interpretation. Additionally, wiring diagrams often include labels that indicate wire colors and types, enhancing clarity for the technician.

| Symbol | Description |

|---|---|

| ⚫ | Battery or Power Source |

| ⚪ | Ground Connection |

| Connector or Plug | |

| Switch | |

| Load or Light |

Understanding these elements facilitates effective navigation through intricate systems, enabling timely diagnostics and ensuring proper functionality. By mastering wiring schematics, technicians enhance their ability to maintain and repair electrical configurations efficiently.

Upgrading Your Mercruiser 260 System

Enhancing the performance and efficiency of your marine engine can significantly improve your boating experience. By integrating modern components and advanced technologies, you can achieve better fuel economy, increased power, and improved reliability. This section explores various upgrades that can elevate your engine’s capabilities and ensure optimal operation in various conditions.

One of the primary areas to consider is the replacement of outdated components with more efficient alternatives. Upgrading the fuel system, ignition system, and exhaust components can lead to noticeable performance gains. Additionally, incorporating advanced electronic systems can enhance diagnostics and monitoring, allowing for more precise management of the engine’s performance.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Fuel System | High-performance fuel injectors | Improved fuel atomization and efficiency |

| Ignition System | Digital ignition system | Better spark timing and reliability |

| Exhaust System | Stainless steel headers | Increased flow and reduced weight |

| Electronics | Advanced ECU | Enhanced control and diagnostics |

When considering enhancements, it’s essential to research compatible options and consult with professionals to ensure proper installation. Upgrading key components not only boosts performance but also extends the lifespan of your engine, providing a more enjoyable and reliable experience on the water.