When it comes to understanding the internal setup of any complex home equipment, it is essential to break down its structure into individual sections. These sections are crucial for ensuring the device operates smoothly and efficiently. By focusing on the various components and their interconnections, one can gain a better understanding of how each element contributes to the overall performance of the system.

Each element plays a unique role, whether it’s regulating the system’s operation, facilitating movement, or providing necessary support. Understanding these critical details can help identify potential issues or areas for improvement, enhancing the reliability and lifespan of the device. With a deeper look into the arrangement, users can also gain the knowledge required for routine maintenance or replacement.

Overview of Key Components

This section provides a detailed explanation of the essential elements that contribute to the proper functioning of the appliance. Each component works together to ensure efficient operation, and understanding their roles can be helpful for troubleshooting and maintenance.

Main Control Unit

The central unit is responsible for managing the overall operation. It coordinates the functions of other elements, ensuring that processes run smoothly and in the correct sequence. This includes regulating various settings, managing power distribution, and responding to user inputs.

Internal Mechanisms

The internal mechanisms include a variety of moving parts that work together to facilitate the primary function. These include elements that handle fluid control, rotation, and temperature regulation. Each part must be in optimal condition to ensure reliable performance and

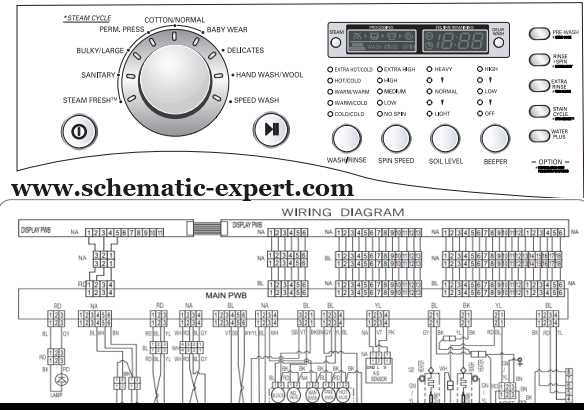

Control Panel Layout and Functions

The interface provides a streamlined way to operate the system, offering quick access to all key features. Understanding the arrangement of elements on the control surface is essential for smooth and efficient usage. Each component has a specific role in managing the various operational modes, ensuring the user can easily navigate through the available settings.

- Display Screen: Offers real-time feedback and status updates, displaying important information related to the current operation.

- Selector Knob: Enables the user to choose from a variety of available functions. The knob smoothly rotates, providing a tactile experience when selecting different options.

- Start/Stop Button: A dedicated button for beginning or

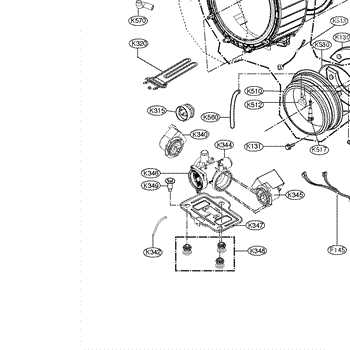

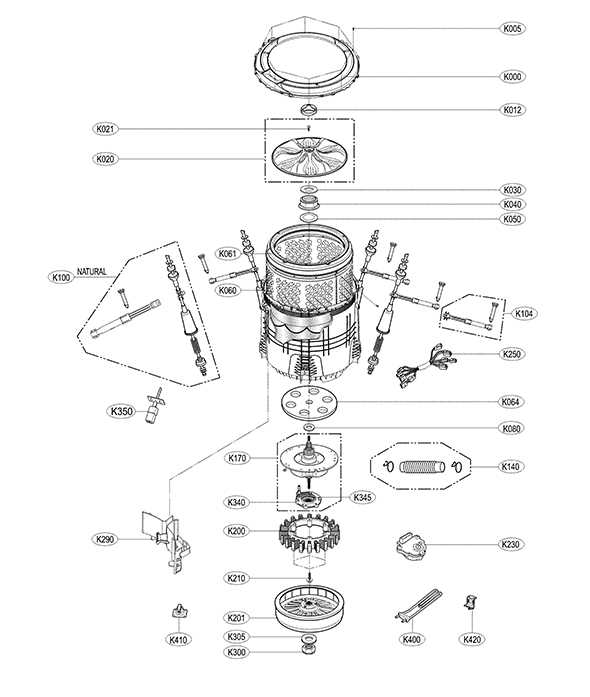

Drum Assembly Breakdown

The internal system responsible for rotation plays a key role in the overall function. Each element within this mechanism works together to ensure efficient performance. By understanding how these components interact, it’s possible to identify areas that may require attention or maintenance over time.

Component Description Outer Casing Protects the internal mechanism and provides structural support during operation. Inner Container Holds the items being processed and rotates to ensure proper Water Inlet Valve Configuration

The water inlet valve is a crucial component in household appliances, controlling the flow of water into the system. Its configuration ensures that the appliance receives the correct amount of water needed for efficient operation. Understanding how this element works can help in troubleshooting issues related to water supply and performance.

Key Functions

- Regulates the water supply to the appliance.

- Prevents backflow and maintains pressure within the system.

- Interacts with sensors to ensure optimal filling levels.

Typical Configuration Elements

- Connection Points: Inlet valves typically feature multiple connection points for water lines.

- Electrical Components: These include solenoids that open and close the valve based on signals from the control board.

- Flow Control Mechanisms: Designed to manage the volume and pressure of water entering the system.

Proper configuration and maintenance of the water inlet valve are essential for the reliable performance of the appliance. Regular inspections can prevent issues such as leaks and inconsistent water levels during operation.

Motor and Belt Assembly Details

The motor and belt assembly is a crucial component in the functioning of washing machines, responsible for driving the drum and facilitating the washing process. Understanding the intricacies of this assembly is essential for maintenance and repair tasks, ensuring optimal performance and longevity of the appliance.

Motor Specifications

The motor plays a vital role in the operation of the washing machine. Here are some key features:

- Type: Typically an induction motor designed for efficiency and reliability.

- Power Rating: The motor generally operates at a specific wattage, suitable for various washing cycles.

- Speed: It usually features multiple speed settings to accommodate different laundry requirements.

Belt Characteristics

The belt serves as a connection between the motor and the drum, transmitting power effectively. Important attributes include:

- Material: Often constructed from durable rubber or synthetic materials to withstand wear and tear.

- Length: The belt must be of precise length to ensure proper tension and functionality.

- Width: Sufficient width is necessary to support the motor’s power transmission without slippage.

Proper inspection and maintenance of the motor and belt assembly can prevent common issues such as slipping or excessive noise, ultimately enhancing the washing experience.

Pump System and Drain Mechanism

The efficient removal of water is crucial in washing appliances, ensuring that cycles run smoothly and effectively. This section delves into the components and functionalities of the water expulsion system, highlighting how each element contributes to optimal performance.

At the core of this system lies the pump, designed to facilitate the movement of water from the drum to the drainage outlet. Understanding the various elements involved can help in troubleshooting issues related to drainage and overall functionality.

Component Function Drain Pump Removes water from the drum after the washing cycle is complete. Filter Catches lint and debris, preventing blockages in the drainage system. Drain Hose Transfers expelled water from the appliance to the household drainage system. Check Valve Prevents backflow of water into the drum, ensuring efficient drainage. Maintaining the pump system is essential for avoiding common issues such as flooding or ineffective drainage. Regular inspection of the components can enhance the longevity and reliability of the washing appliance.

Heating Element Structure

The heating component in a washing appliance plays a crucial role in regulating water temperature during various cycles. This assembly is designed to convert electrical energy into heat, ensuring effective cleaning and optimal performance. Understanding its configuration is essential for both maintenance and troubleshooting.

The structure of the heating element typically consists of several key components that work together seamlessly. These include the heating coil, insulation materials, and connecting terminals. Each part is engineered to withstand high temperatures and prevent electrical hazards.

Component Description Heating Coil A metal wire, often made of nickel-chromium alloy, that generates heat when electrical current passes through it. Insulation Material that surrounds the heating coil to prevent heat loss and protect other components from overheating. Connecting Terminals Points where the electrical supply connects to the heating element, allowing current flow for heating. By examining these elements, users can better appreciate how the heating assembly functions and its importance in maintaining the effectiveness of the appliance.

Door Locking System Overview

The door locking mechanism plays a crucial role in ensuring the safety and proper operation of laundry appliances. This system is designed to prevent access to the interior during operation, providing both security and operational efficiency. Understanding its components and functionality is essential for effective troubleshooting and maintenance.

The locking system consists of various elements that work together to secure the door. When the machine is in use, the door lock engages to prevent accidental openings, which could lead to leaks or mechanical failure. Once the cycle is complete, the mechanism releases, allowing the user to open the door safely.

Component Description Lock Assembly Secures the door in place during operation. Actuator Triggers the locking and unlocking process. Latch Engages with the door frame to hold the door closed. Sensor Detects if the door is securely closed. Control Module Coordinates the locking mechanism’s functions with the appliance’s cycle. Maintaining the door locking system is vital for the appliance’s overall performance. Regular inspections can help identify wear or malfunction, ensuring the locking mechanism operates smoothly and efficiently.

Internal Tubing and Hoses

The internal tubing and hoses in a washing machine play a crucial role in facilitating the flow of water and ensuring efficient operation. These components connect various parts of the appliance, allowing for the circulation and drainage of water during different cycles. Understanding the layout and function of these tubes is essential for troubleshooting and maintenance.

Types of Tubes and Hoses

There are several types of tubes and hoses found within the appliance. Each type serves a specific function, whether it’s to supply water, drain wastewater, or facilitate air circulation. Proper identification of these components can aid in repairs and replacements when necessary.

Common Issues

Common issues associated with internal tubing and hoses include leaks, clogs, and deterioration over time. Regular inspection and maintenance can help identify problems early, ensuring the appliance operates smoothly and efficiently.

Component Function Inlet Hose Supplies fresh water to the machine Drain Hose Removes wastewater from the appliance Recirculation Tube Circulates water within the drum Overflow Hose Prevents water overflow by directing excess water away Electronic Circuit Board Components

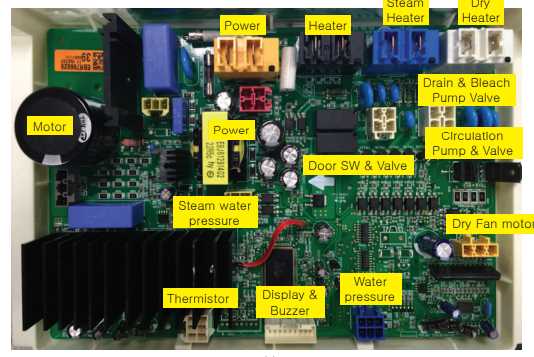

In modern electronics, the effectiveness and functionality of devices are largely determined by the quality and arrangement of their internal elements. These essential components work in harmony to perform a wide range of tasks, from powering devices to processing information. Understanding the various types of elements found in these assemblies is crucial for anyone involved in the design, repair, or enhancement of electronic equipment.

Key Elements of Circuit Boards

Typically, a circuit board consists of several critical elements, including resistors, capacitors, and integrated circuits. Resistors limit the flow of electric current, ensuring that components receive the appropriate voltage. Capacitors, on the other hand, store and release energy as needed, playing a vital role in stabilizing voltage and filtering signals. Integrated circuits, often referred to as microchips, are complex assemblies that perform numerous functions within a compact space, enabling advanced capabilities in modern devices.

Importance of Layout and Design

The layout and design of a circuit board are equally important as the components themselves. Proper arrangement affects performance, signal integrity, and thermal management. Effective design practices ensure minimal interference and optimal power distribution, ultimately enhancing the reliability and efficiency of electronic systems.

Sensor Locations and Purposes

Understanding the various sensor placements within a washing machine is crucial for optimal functionality and efficiency. These devices monitor essential parameters, ensuring that the machine operates smoothly and safely. Each sensor plays a specific role, contributing to the overall performance of the appliance.

Water Level Sensor: This sensor is typically located near the water inlet. It measures the amount of water in the drum and ensures the machine fills to the correct level. By doing so, it prevents overflows and helps maintain the efficiency of each cycle.

Temperature Sensor: Usually positioned near the heating element, this sensor tracks the water temperature during wash cycles. Its role is vital for activating the heater when needed and maintaining the appropriate temperatures for different fabrics, thus protecting garments from damage.

Door Lock Sensor: Found near the door latch, this sensor ensures that the door is securely closed before the wash cycle begins. It prevents the machine from operating if the door is ajar, enhancing user safety and preventing leaks.

Vibration Sensor: Positioned within the main body of the appliance, this sensor detects excessive vibrations during the spin cycle. If irregular vibrations are identified, the machine can adjust its operation to minimize noise and prevent potential damage.

Drain Sensor: Located near the drain pump, this sensor monitors the drainage process. It detects whether water is being expelled properly, ensuring the machine does not get flooded and operates effectively throughout the washing cycle.

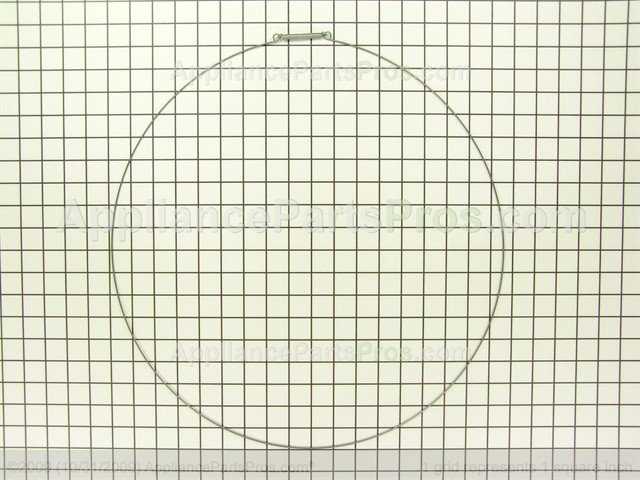

Seals, Gaskets, and Insulation

The effectiveness of any appliance largely depends on the quality of its components that ensure proper sealing and insulation. These elements play a crucial role in preventing leaks, maintaining efficiency, and enhancing the overall performance of the device.

Seals are essential for preventing the escape of fluids and gases, ensuring that the system operates efficiently without unnecessary loss of resources. They are designed to fit tightly between two surfaces, creating a barrier that minimizes wear and tear.

Gaskets serve a similar purpose but are typically used in more complex junctions where two parts meet. They are available in various materials, each tailored for specific conditions, such as heat resistance or chemical compatibility, ensuring longevity and reliability.

Insulation is equally important as it reduces energy loss and protects sensitive components from external temperature fluctuations. High-quality insulating materials help maintain optimal operating conditions, which ultimately contributes to the durability and efficiency of the unit.

Understanding the roles of these components is vital for anyone involved in maintenance or repairs, as proper selection and installation directly impact the performance and longevity of the appliance.

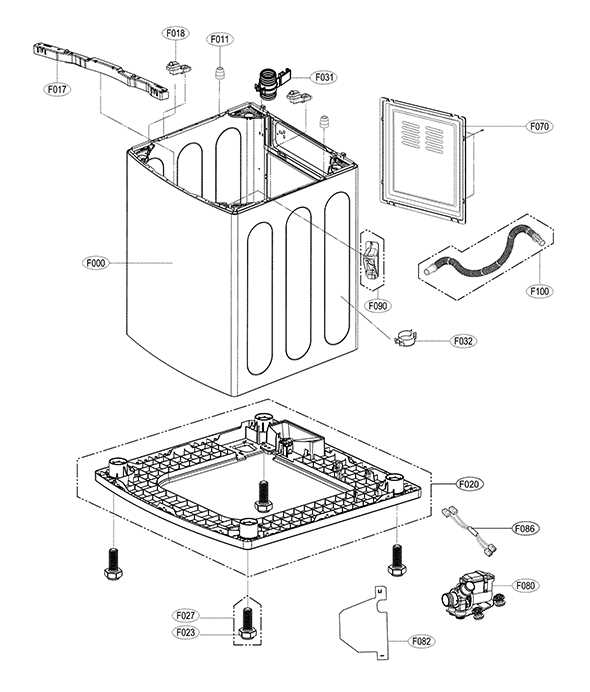

Outer Casing and Support Parts

The external structure plays a crucial role in maintaining the overall durability and functionality of the machine. It not only provides protection for internal elements but also ensures that the entire system remains stable during operation. Various sections of the outer shell and supporting framework work together to shield the device from external impacts while offering a sturdy foundation for other components.

- Front and Rear Panels: These panels form the primary barriers, protecting internal mechanisms from physical damage and wear.

- Side Covers: Designed to enclose sensitive elements, the side sections help prevent debris and dust from entering the unit.

- Base Support: A critical part that stabilizes the entire structure, ensuring that the