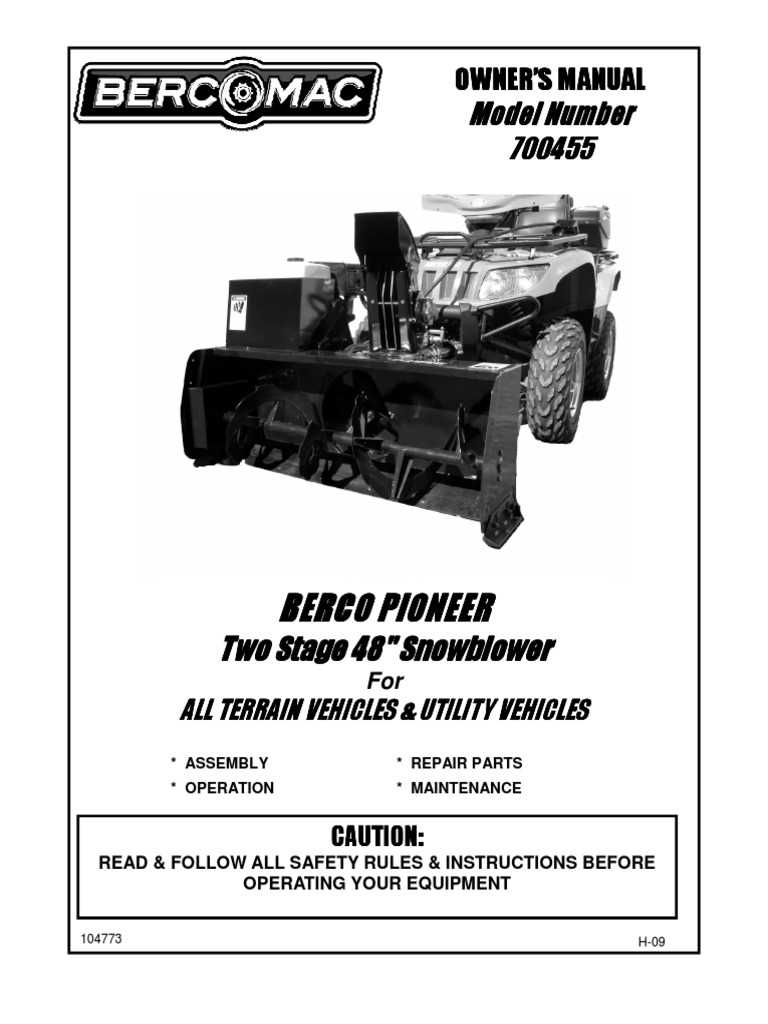

When it comes to maintaining your winter equipment, having a clear understanding of its various elements is essential. This section aims to provide a comprehensive overview of the different components that contribute to the functionality of your snow-clearing machine. Recognizing how each part works in conjunction with the others can enhance your ability to troubleshoot issues and perform necessary maintenance.

Each component plays a vital role in ensuring that the machine operates efficiently. By familiarizing yourself with these individual elements, you can make informed decisions regarding repairs and upgrades. This knowledge not only improves performance but also extends the lifespan of your equipment, saving you time and resources in the long run.

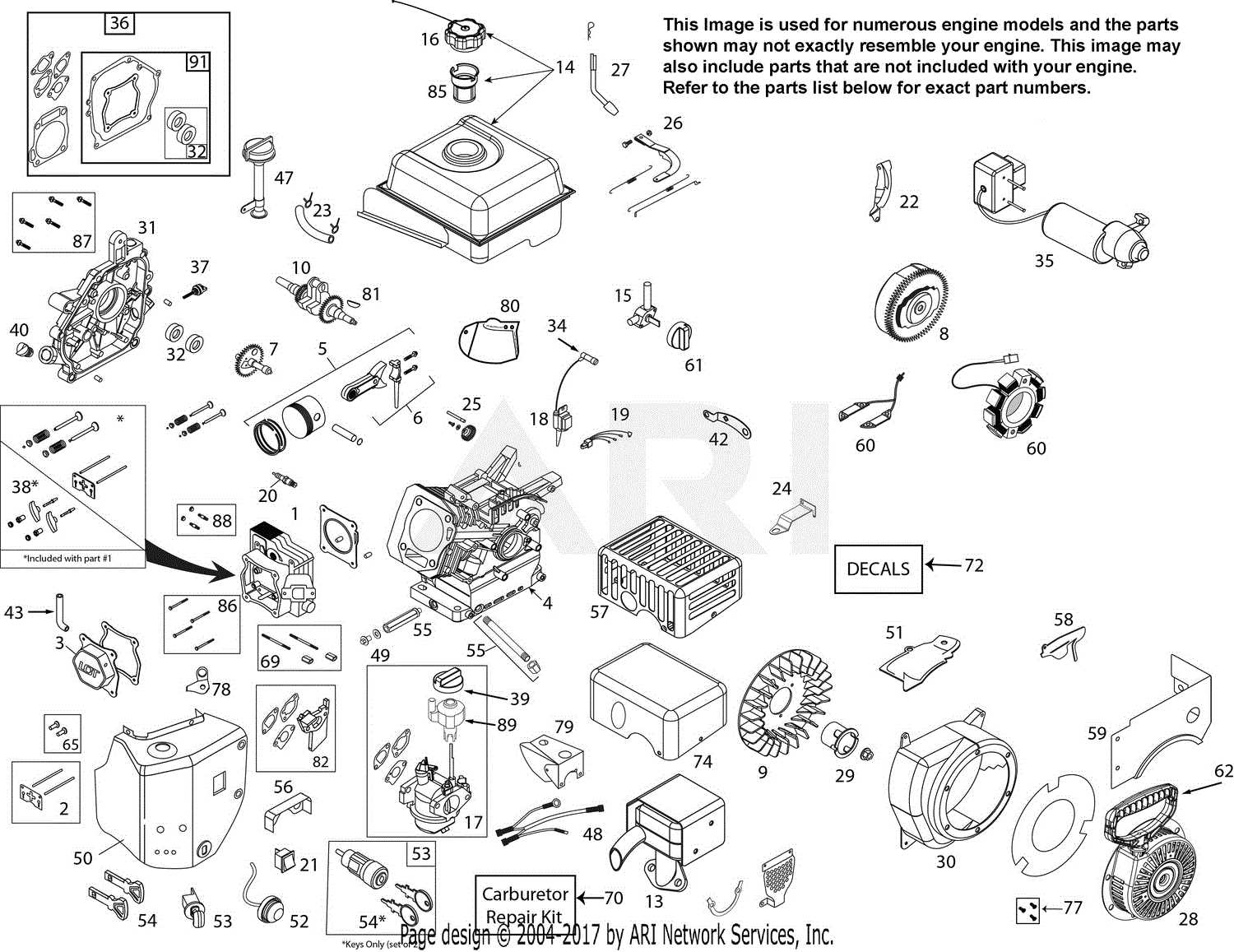

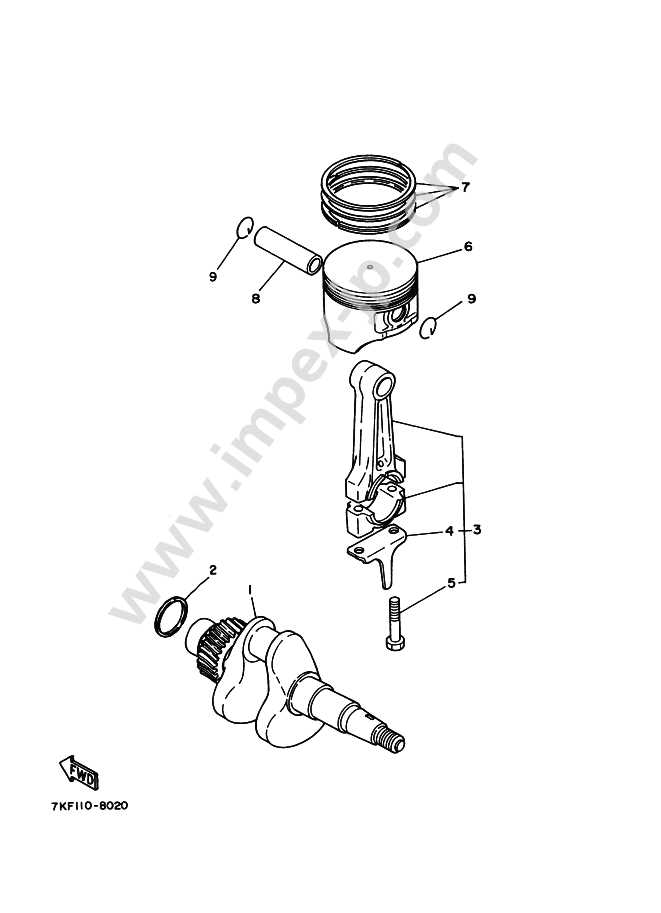

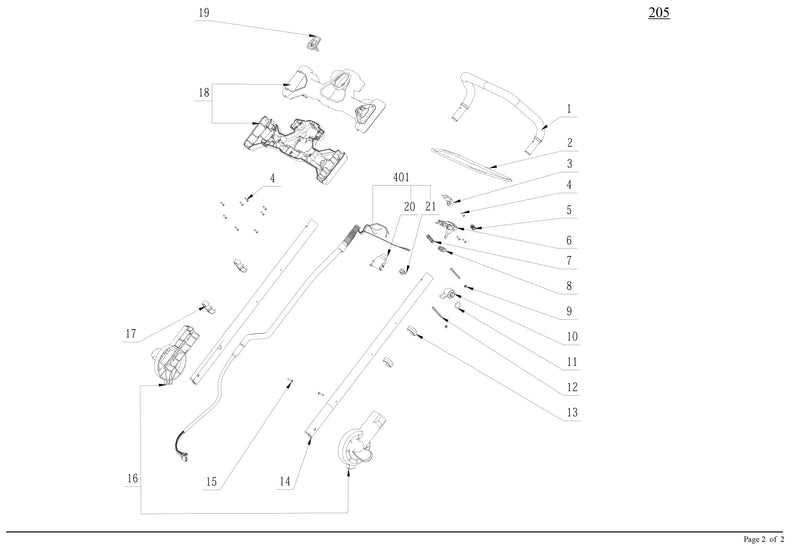

In the following sections, detailed illustrations will serve as a valuable reference for understanding the arrangement and functionality of each component. These visual aids will help you easily identify specific areas of interest, making it simpler to locate the parts you need for any necessary adjustments or replacements.

Kimpex Snowblower Parts Overview

This section provides a comprehensive look at the various components utilized in a snow-clearing machine. Understanding the individual elements is essential for effective maintenance and optimal performance during the winter season. Each component plays a crucial role in ensuring the device operates smoothly and efficiently.

Essential Components

The main constituents of these machines include the engine, auger, and discharge chute. The engine serves as the power source, driving the entire mechanism. The auger is responsible for gathering and moving the snow, while the discharge chute directs the cleared snow away from the path. Regular inspection and replacement of these key parts can significantly enhance the device’s functionality.

Maintenance and Upkeep

Proper maintenance of each component is vital for longevity. This includes routine checks, lubrication, and timely replacements. Keeping the machine in good condition will not only ensure reliability but also improve efficiency, allowing for faster and more effective snow removal.

Identifying Key Components

Understanding the essential elements of a snow-clearing machine is crucial for effective maintenance and troubleshooting. Each component plays a vital role in ensuring optimal functionality, making it important to recognize and comprehend their specific purposes. This section will guide you in identifying these fundamental parts, enhancing your knowledge and capability to manage the equipment efficiently.

| Component Name | Description | Function |

|---|---|---|

| Engine | The power source that drives the machine. | Generates the necessary energy for operation. |

| Auger | A rotating device that gathers and processes snow. | Collects snow and pushes it towards the discharge chute. |

| Discharge Chute | A chute that directs the expelled snow. | Controls the direction and distance the snow is thrown. |

| Skid Shoes | Adjustable components that control the height of the machine. | Protects the auger and helps maneuver on various surfaces. |

| Gearbox | A mechanical device that transmits power. | Facilitates speed adjustments for the auger and wheels. |

Common Replacement Parts Available

When maintaining outdoor machinery, it is essential to understand the components that may require periodic replacement. Regular wear and tear can lead to decreased performance, making it crucial to identify and source the right elements for efficient operation.

Here are some frequently needed components for maintenance:

- Drive Belts: Essential for transferring power from the engine to the working mechanism.

- Filters: These ensure clean air intake and fluid circulation, preventing damage to internal systems.

- Blades: Sharp edges are vital for effective operation; replacing dull or damaged blades enhances performance.

- Fuel Lines: Maintaining the integrity of fuel lines is critical to ensure efficient fuel delivery and prevent leaks.

- Spark Plugs: These components are necessary for starting the engine and maintaining optimal combustion.

Having these elements on hand can help minimize downtime and ensure smooth operation throughout the season. Regular inspection and timely replacement are key to maintaining optimal functionality.

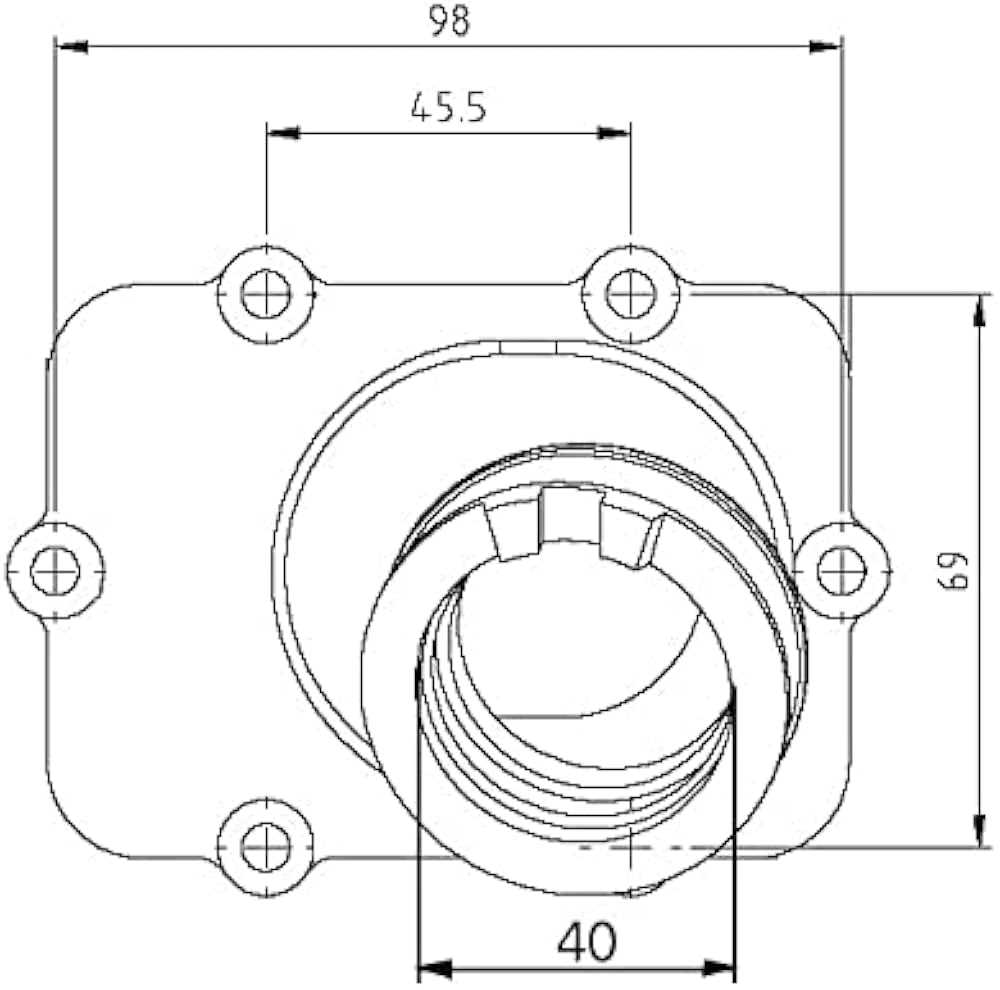

Understanding the Parts Diagram

Comprehending the visual representation of components within a mechanical device is crucial for efficient maintenance and repair. This illustration serves as a guide, simplifying the identification and understanding of various elements involved in the assembly. Familiarity with this representation aids users in locating specific parts and comprehending their functions, ultimately enhancing overall operational knowledge.

Each component is typically labeled, indicating its unique identification number or name, which corresponds to a list of items or specifications. Understanding this framework not only streamlines the repair process but also minimizes errors during assembly or disassembly. This knowledge is invaluable for both novice users and seasoned technicians alike.

| Component Number | Description | Function |

|---|---|---|

| 1 | Drive System | Controls movement and speed. |

| 2 | Chassis | Provides structural support. |

| 3 | Cutting Mechanism | Facilitates material removal. |

| 4 | Handle Assembly | Enables user control and maneuverability. |

| 5 | Power Source | Supplies energy for operation. |

By thoroughly analyzing the representation, individuals can enhance their comprehension of how each part interrelates within the overall assembly. This insight fosters better decision-making during repairs, ensuring that users can address issues efficiently and effectively.

Tools Needed for Assembly

Assembling equipment requires a specific set of tools to ensure proper functionality and safety. Having the right instruments at hand will facilitate a smoother assembly process, allowing for efficient and effective construction.

Essential Tools

- Wrenches: Adjustable and socket types for securing various fasteners.

- Screwdrivers: Both flathead and Phillips to accommodate different screws.

- Pliers: Needle-nose and standard for gripping and bending materials.

- Torque wrench: To ensure bolts are tightened to the correct specifications.

- Measuring tape: For precise measurements to ensure correct assembly.

Safety Equipment

- Safety goggles: To protect your eyes from debris and dust.

- Gloves: To prevent injuries while handling sharp or rough components.

- Ear protection: Useful when working with power tools that generate noise.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficient operation of your equipment. By implementing a consistent maintenance routine, you can prevent common issues and extend the lifespan of your machinery.

Here are some key practices to follow:

- Inspect Regularly: Frequent checks help identify wear and tear before they escalate into larger problems.

- Clean After Use: Removing debris and dirt from components prevents buildup that can hinder performance.

- Lubricate Moving Parts: Proper lubrication reduces friction and minimizes the risk of damage, ensuring smooth operation.

- Check Fluid Levels: Regularly monitor oil and fuel levels to ensure optimal functioning and prevent overheating.

- Store Properly: When not in use, keep the equipment in a dry and sheltered location to protect it from the elements.

Following these maintenance tips will not only enhance the performance of your machinery but also contribute to its long-term reliability. Make maintenance a priority to enjoy trouble-free operation for years to come.

Troubleshooting Common Issues

When operating outdoor equipment designed for clearing snow, encountering various complications can be a common occurrence. Understanding how to identify and resolve these typical problems can significantly enhance the efficiency and longevity of the machinery. This section provides guidance on diagnosing frequent issues that may arise during use, allowing for effective solutions to be implemented.

1. Engine Won’t Start: If the engine fails to ignite, check the fuel level and ensure that fresh fuel is being used. Additionally, inspect the spark plug for any signs of wear or damage, and clean or replace it if necessary. Examining the battery connections for corrosion can also be beneficial.

2. Insufficient Clearing Power: In cases where the equipment is not effectively removing snow, examine the auger and impeller for blockages or damage. Ensure that all moving parts are free from ice or debris. Proper adjustment of the chute angle can also improve performance.

3. Unusual Noises: If unfamiliar sounds are emanating from the machine, it is crucial to stop operation immediately. Check for loose components or foreign objects that may be interfering with the moving parts. Lubricating the bearings and joints can also help reduce noise.

4. Difficulty Maneuvering: If the equipment is hard to steer or control, inspect the tires for proper inflation and tread wear. Adjusting the skid shoes to the correct height can enhance stability and ease of movement on various surfaces.

By regularly performing these checks and maintenance tasks, users can ensure their equipment remains in optimal working condition and ready for effective snow removal.

Where to Purchase Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. There are several avenues available for sourcing the necessary elements to ensure your machine runs smoothly.

Local Retailers: Visiting nearby hardware or specialty shops can be a convenient way to obtain what you need. Many stores stock a variety of items, allowing you to inspect the quality before making a purchase.

Online Marketplaces: Numerous e-commerce platforms offer a wide selection of items at competitive prices. These websites often feature user reviews and detailed descriptions, helping you make informed decisions.

Manufacturer’s Website: Exploring the official website of the equipment manufacturer can provide access to a comprehensive catalog of available components. Often, they have a dedicated section for inquiries, ensuring you get the exact fit for your model.

Salvage Yards: For those looking for budget-friendly options, salvage yards can be a treasure trove of usable components. While it may take some searching, you might find quality items at a fraction of the original cost.

Community Forums: Engaging with online communities or forums can yield valuable information on where to find specific items. Fellow enthusiasts often share their experiences and recommend trusted suppliers.

Safety Precautions While Repairing

When undertaking maintenance or repairs on machinery, adhering to safety measures is essential to prevent accidents and ensure a secure working environment. Proper precautions can significantly reduce the risk of injuries and facilitate a smoother repair process. Understanding and implementing these guidelines is crucial for anyone involved in the upkeep of equipment.

Always wear appropriate personal protective equipment such as gloves, safety goggles, and sturdy footwear to shield against potential hazards. Protective gear serves as a first line of defense against sharp edges, moving components, and debris that may be encountered during the repair process.

Ensure the equipment is turned off and disconnected from power sources before beginning any maintenance work. This prevents unintentional starts and safeguards against electrical shock. Taking this step is vital for both personal safety and the integrity of the machinery being serviced.

Keep the workspace clean and organized to minimize distractions and avoid accidents. Clutter can lead to trips and falls, while having tools and parts readily accessible streamlines the repair process. A tidy environment promotes focus and efficiency.

Follow the manufacturer’s instructions carefully when performing repairs or replacements. Familiarize yourself with the specific guidelines and recommendations provided, as they often contain crucial safety information tailored to the equipment in question.

By prioritizing safety, individuals can protect themselves and others while effectively performing necessary repairs. Implementing these precautions creates a more efficient and risk-free working atmosphere.

Exploring Aftermarket Alternatives

When considering enhancements or replacements for equipment components, many users find themselves exploring options beyond the original manufacturers. Aftermarket solutions can provide a range of benefits, including cost-effectiveness, enhanced performance, and the availability of hard-to-find items. These alternatives often come from specialized manufacturers who focus on producing compatible components that meet or exceed the specifications of the originals.

Benefits of Aftermarket Components

One of the primary advantages of choosing aftermarket options is the potential for significant cost savings. Often, these components are priced lower than their original counterparts while maintaining comparable quality. Additionally, aftermarket manufacturers may offer a wider variety of choices, allowing users to customize their equipment to better suit their specific needs.

Considerations When Choosing Alternatives

While aftermarket components can offer various advantages, it’s essential to approach the selection process with care. Not all alternatives are created equal; some may vary in quality or compatibility. It’s crucial to conduct thorough research, read reviews, and consult with other users to ensure that the chosen components will perform reliably.

| Factor | Aftermarket Components | Original Manufacturer Components |

|---|---|---|

| Cost | Typically lower | Generally higher |

| Availability | Often more accessible | May be limited |

| Variety | Wider selection | Narrower options |

| Quality | Variable; research needed | Consistent and reliable |

Seasonal Maintenance Checklist

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. A comprehensive maintenance checklist can help identify areas that need attention, preventing issues before they arise. Following a structured routine will not only enhance functionality but also contribute to safe operation during use.

Below is a detailed checklist for seasonal maintenance:

- Inspection of Components:

- Examine all moving parts for wear and tear.

- Check for any loose or damaged connections.

- Ensure that belts and cables are in good condition.

- Cleaning:

- Remove debris from all surfaces.

- Clean filters to maintain airflow.

- Wash exterior surfaces to prevent rust.

- Fluid Levels:

- Check oil levels and replace if necessary.

- Inspect coolant and fuel levels; refill as needed.

- Safety Features:

- Test safety switches and controls.

- Examine the condition of the emergency stop mechanisms.

- Final Checks:

- Verify that all fasteners are securely tightened.

- Perform a test run to ensure everything is functioning smoothly.

Following this checklist will help maintain your equipment’s efficiency and reliability throughout the season.

Importance of Genuine Parts

Utilizing authentic components in machinery maintenance is crucial for ensuring optimal performance and longevity. Original elements are designed specifically to fit and function perfectly with the equipment, providing reliability and enhancing efficiency. When owners choose genuine replacements, they contribute to the overall safety and effectiveness of their devices, minimizing the risk of breakdowns and costly repairs.

Quality Assurance

Authentic components undergo rigorous testing and adhere to strict manufacturing standards. This guarantees that they meet the required specifications for durability and reliability. Using these verified items not only ensures compatibility but also reduces the likelihood of premature failure, leading to a smoother operational experience.

Warranty Protection

Many manufacturers offer warranties on their equipment, which often stipulate the use of genuine components for coverage. By opting for original replacements, owners safeguard their warranty rights and protect their investment. This peace of mind can prove invaluable, especially in instances where unexpected repairs could lead to significant financial burdens.