In the realm of compact machinery, comprehending the layout of individual elements is crucial for effective operation and maintenance. Each machine is a culmination of various systems working in harmony, and recognizing how these components interact can significantly enhance performance and longevity. This section aims to provide insights into the configuration of these vital elements, ensuring users can navigate the intricacies of their equipment with confidence.

The complexity of modern machinery necessitates a clear visual representation of its structure. By examining the arrangement of different sections, operators can better appreciate how each unit contributes to the overall functionality. This knowledge not only aids in routine checks but also streamlines troubleshooting processes, allowing for quicker resolutions when issues arise.

Whether you are a seasoned professional or a novice, familiarizing yourself with the arrangement of various units will empower you to optimize the use of your equipment. This understanding paves the way for improved operational efficiency and helps prevent potential malfunctions by ensuring that every component is in its rightful place.

Key Features of the Model

This equipment is designed with a range of essential attributes that enhance its functionality and user experience. From its robust construction to advanced capabilities, every aspect is crafted to meet the demands of various tasks while ensuring efficiency and reliability.

Versatile Performance

The machinery is equipped with a powerful engine that delivers outstanding performance across different applications. Its adaptability allows operators to easily switch between tasks, making it suitable for landscaping, construction, and maintenance jobs. The intuitive controls ensure that users can operate the unit with ease, maximizing productivity.

Durability and Reliability

Built with high-quality materials, this model offers exceptional durability, capable of withstanding challenging working conditions. Its sturdy frame and components reduce wear and tear, ensuring longevity. Regular maintenance is straightforward, contributing to sustained performance and reliability over time.

Importance of Parts Diagrams

Understanding the various components of machinery is essential for effective maintenance and repair. Visual representations serve as crucial tools that help operators and technicians identify each element’s function and placement within the equipment. By utilizing these illustrations, individuals can ensure that they address issues accurately and efficiently, leading to better performance and longevity of the machines.

Enhancing Maintenance Efficiency

Clear visual aids facilitate quick recognition of components, allowing technicians to pinpoint problems swiftly. This not only saves time during repairs but also minimizes the risk of errors that could lead to further complications. When individuals can easily navigate through the various sections of a machine, they can focus on implementing the necessary fixes without unnecessary delays.

Training and Familiarization

For new operators, visual representations serve as excellent educational resources. They provide a comprehensive overview of how each component interacts within the whole system. Familiarity with these illustrations can significantly shorten the learning curve, enabling new personnel to become proficient in equipment handling and maintenance tasks more rapidly.

Understanding Component Functions

In any complex machinery, each element plays a crucial role in the overall operation. Grasping the function of these individual parts is essential for effective maintenance and troubleshooting. By comprehending how each component interacts with others, operators can enhance performance and extend the lifespan of the equipment.

Key Elements and Their Roles

Every machine consists of various integral components, each contributing to specific tasks. Recognizing the significance of these elements enables users to optimize their usage and address any issues that may arise promptly.

| Component | Function |

|---|---|

| Engine | Generates power to operate the machine. |

| Hydraulic System | Facilitates movement and control of attachments. |

| Tracks | Provide stability and mobility on various terrains. |

| Cabin | Ensures operator comfort and visibility during operation. |

| Control Panel | Allows the operator to manage various functions and settings. |

Importance of Regular Maintenance

Understanding the functions of these components is not only vital for operation but also for ensuring longevity. Regular inspection and maintenance of each part can prevent unexpected breakdowns and costly repairs, ultimately leading to more efficient operation.

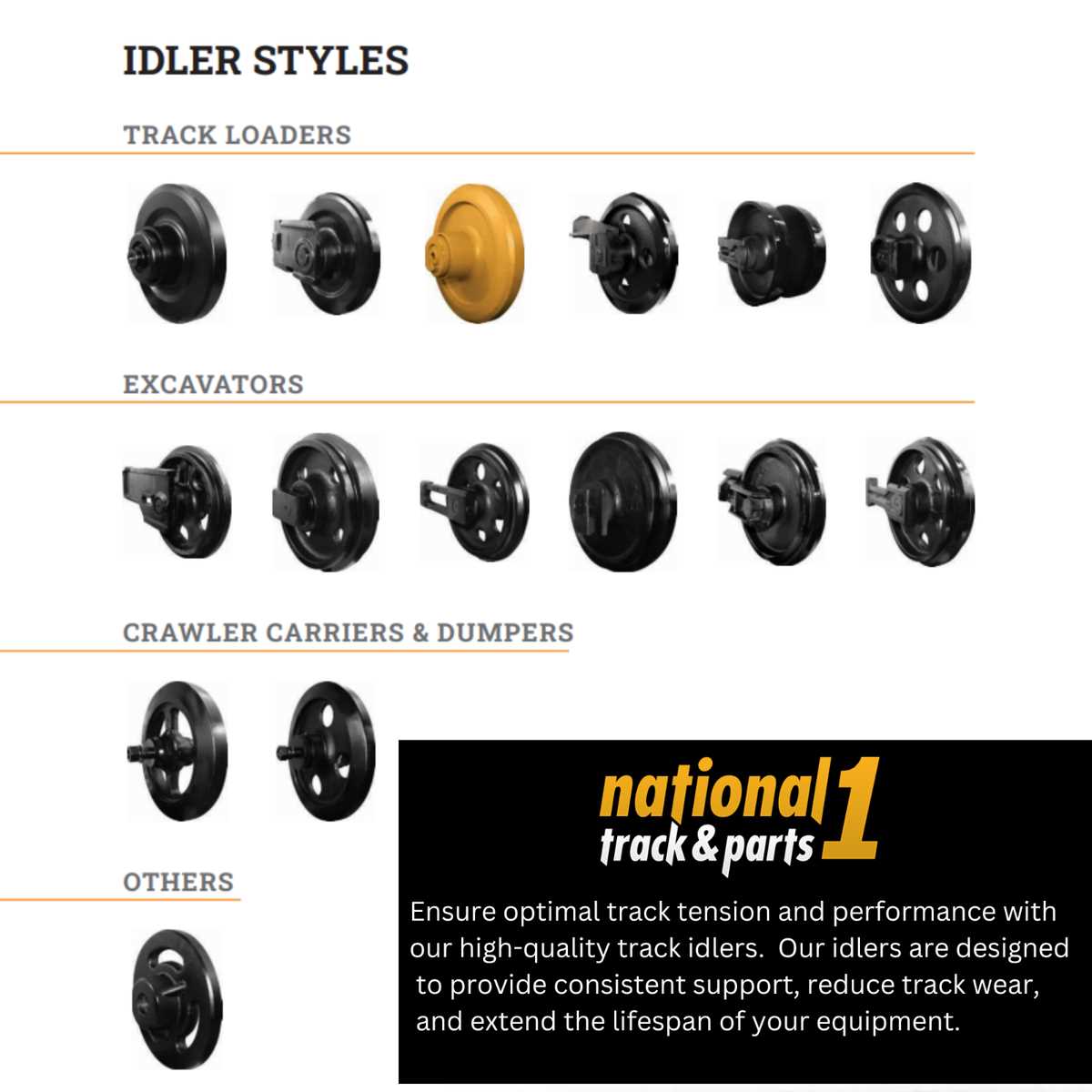

Common Replacement Parts

When maintaining equipment, certain components frequently require substitution due to wear and tear. Understanding which elements are commonly replaced can enhance operational efficiency and prolong the lifespan of the machine.

One of the most vital elements to monitor is the filter, which plays a crucial role in keeping the system clean and functioning optimally. Regularly replacing filters helps prevent dirt and debris from entering sensitive areas, ensuring smoother operation.

Another significant component is the drive belt, which is essential for transferring power. Over time, these belts can stretch or wear down, leading to reduced performance. Regular inspection and timely replacement can help avoid unexpected breakdowns.

Additionally, batteries are critical for starting the machine and powering various functions. As they age, their capacity diminishes, making it necessary to replace them periodically to maintain reliable performance.

Lastly, seals and gaskets should not be overlooked, as they prevent leaks and maintain proper pressure within the system. Regular checks and replacements of these components are essential to prevent more significant issues down the line.

Maintenance Guidelines for Longevity

Ensuring the durability and efficient performance of your machinery requires a proactive approach to upkeep. Regular maintenance not only extends the life of the equipment but also enhances its reliability during operation. Following a structured maintenance routine can prevent unexpected failures and costly repairs.

Routine Inspection

- Check fluid levels and top up as needed.

- Inspect for any signs of wear or damage on critical components.

- Examine the condition of belts and hoses for cracks or fraying.

- Ensure that all fasteners are tightened to the recommended specifications.

Cleaning and Lubrication

- Clean the exterior surfaces to prevent dirt buildup that can cause overheating.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Remove debris from air filters to maintain optimal airflow.

- Check and clean hydraulic systems to ensure fluid integrity.

Implementing these guidelines will help maintain optimal functionality and significantly enhance the operational lifespan of your equipment.

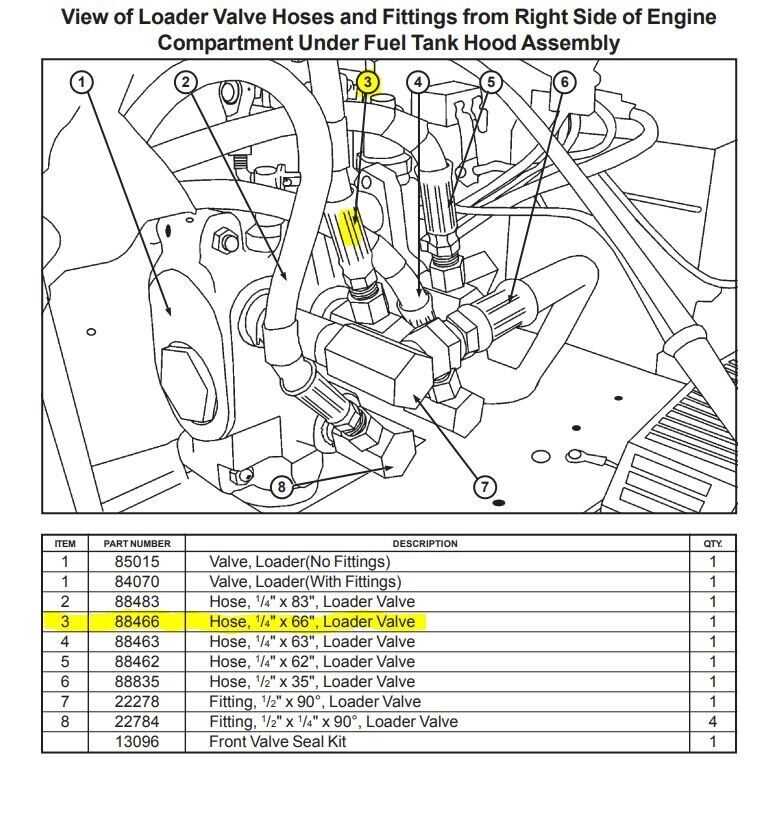

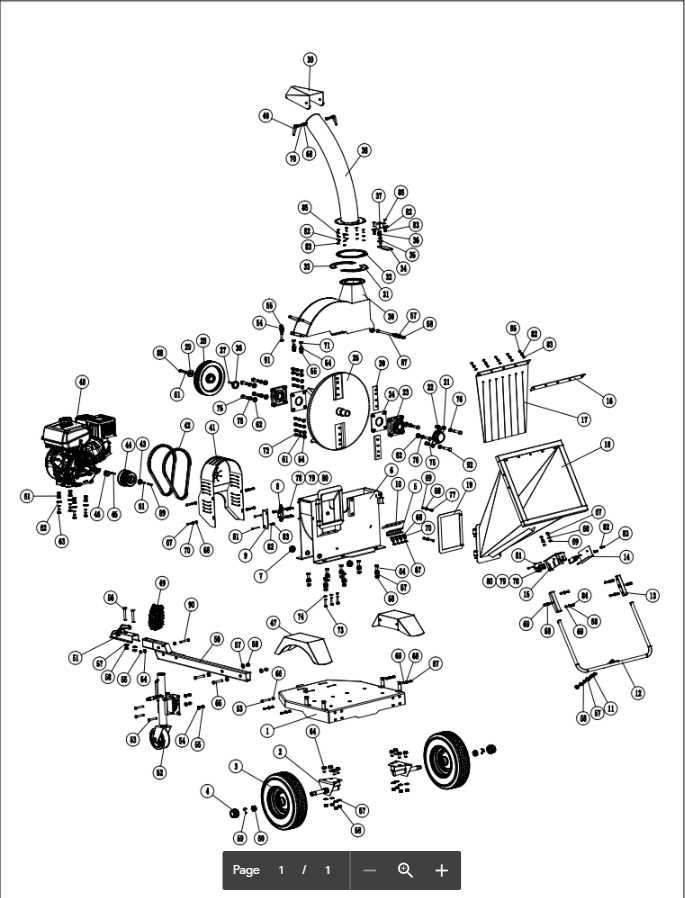

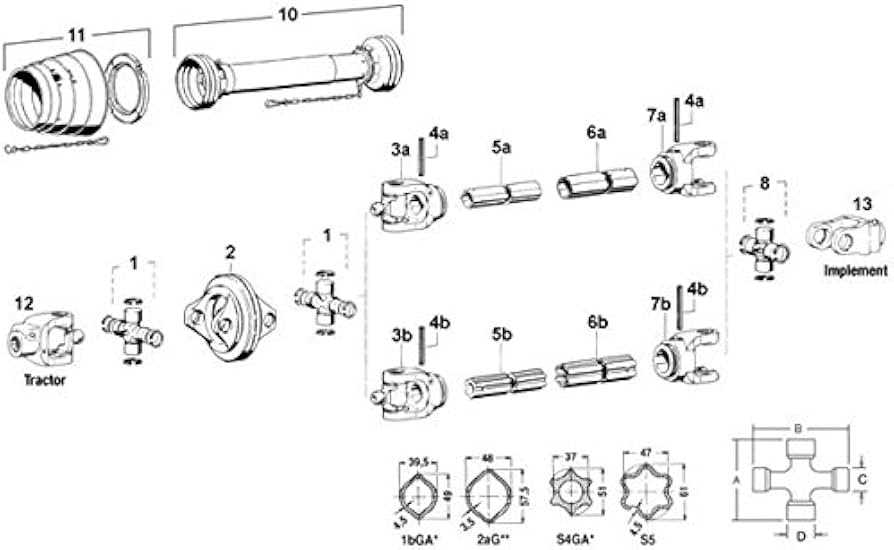

How to Read Parts Diagrams

Understanding schematic representations is essential for anyone involved in maintenance and repairs. These illustrations provide a visual breakdown of components, helping users identify individual elements and their relationships within a system. By mastering the interpretation of these visuals, you can efficiently troubleshoot issues and plan for necessary replacements or upgrades.

Identifying Components

The first step in deciphering these visuals is to familiarize yourself with the various symbols and labels used to denote different elements. Each symbol typically corresponds to a specific part, and understanding these symbols will enable you to quickly locate what you need. Look for a legend or key, which often accompanies the schematic, as it provides detailed explanations of each symbol.

Understanding Relationships

Once you have identified the individual elements, it is crucial to analyze how they interact with each other. Pay attention to lines and connections that illustrate how components are linked. This understanding can aid in diagnosing problems and recognizing which parts may require attention when issues arise. Taking the time to thoroughly review these connections will enhance your overall comprehension of the system.

Identifying Parts with Diagrams

Understanding the components of machinery is essential for effective maintenance and troubleshooting. Visual representations serve as invaluable tools, allowing operators to recognize different elements quickly and accurately. By analyzing these illustrations, users can enhance their familiarity with equipment, leading to improved operational efficiency.

The Importance of Visual Aids

Visual aids simplify the learning process by breaking down complex assemblies into manageable sections. Here are some key advantages:

- Enhanced clarity in understanding how parts interact.

- Facilitated identification of individual components.

- Improved ability to locate specific elements during repairs.

- Streamlined communication among technicians.

Using Visual Representations Effectively

To maximize the benefits of visual aids, consider the following strategies:

- Familiarize yourself with the overall layout before diving into specifics.

- Take notes on critical components to reinforce memory retention.

- Utilize the visuals during maintenance checks to guide your actions.

- Refer to illustrations frequently until you feel confident identifying parts independently.

Sources for Genuine Parts

When it comes to maintaining machinery, acquiring authentic components is essential for ensuring optimal performance and longevity. Reliable suppliers offer quality products that adhere to strict manufacturing standards, providing users with peace of mind. Accessing genuine items can significantly enhance the efficiency and reliability of equipment, making it crucial for operators to know where to find these resources.

Authorized Dealers

One of the most trustworthy sources for authentic components is authorized dealerships. These establishments are directly connected to manufacturers and ensure that every item they offer meets original specifications. Customers can expect expert advice and a wide range of offerings tailored to their specific machinery needs.

Online Retailers

In addition to physical stores, numerous online platforms specialize in providing genuine items. These websites often feature extensive inventories, allowing users to conveniently browse and order components from the comfort of their homes. It is advisable to choose well-reviewed and reputable sites to ensure the authenticity of the products.

| Source Type | Advantages |

|---|---|

| Authorized Dealers | Expert advice, guaranteed authenticity, warranty options |

| Online Retailers | Convenience, broad selection, competitive pricing |

| Local Distributors | Personalized service, immediate availability, community support |

DIY Repairs Using Diagrams

Engaging in home repairs can be a rewarding experience, especially when you have access to visual aids. These resources simplify the process, guiding you through the steps necessary to address common issues with your equipment. With clear illustrations, even those new to maintenance can confidently tackle various tasks, ensuring efficient and successful outcomes.

Understanding Your Tools and Components

Before embarking on any repair, it’s crucial to familiarize yourself with the different elements involved. Knowing how each component fits together and operates will enhance your ability to diagnose and fix problems effectively. Below is a table that outlines common components and their functions:

| Component | Description |

|---|---|

| Engine | The core part that powers the machinery. |

| Transmission | Transfers power from the engine to the wheels. |

| Hydraulic System | Utilizes fluid power to operate various functions. |

| Electrical System | Controls the operation of electrical components. |

Step-by-Step Repair Process

Utilizing visual aids can streamline your repair process. Start by identifying the issue at hand, then consult the illustrations to locate the necessary components. Follow the outlined steps carefully, and don’t hesitate to refer back to the images as needed. This method not only enhances your understanding but also minimizes the risk of mistakes during the repair process.

FAQs About CTX100 Parts

This section addresses common inquiries regarding components associated with the CTX100 model. Understanding these elements is essential for effective maintenance and operation. Below are some frequently asked questions that provide clarity on various aspects of these components.

| Question | Answer |

|---|---|

| What types of components are available for this model? | A wide range of components is available, including drive systems, hydraulic elements, and attachment accessories designed to enhance performance. |

| How can I identify the correct component for my machine? | Refer to the user manual or consult with a dealer to ensure compatibility with your specific machine configuration. |

| Where can I purchase replacement components? | Replacement elements can be sourced from authorized dealers or through online marketplaces specializing in machinery supplies. |

| Is there a warranty for these components? | Many components come with a manufacturer’s warranty; check with the supplier for specific details. |

| How often should I inspect the components? | Regular inspections are recommended, typically every few months or as specified in the maintenance guidelines, to ensure optimal functionality. |

Contacting Customer Support

When seeking assistance for equipment-related inquiries, reaching out to customer service can provide the necessary guidance. This support system is designed to address various concerns, whether you have questions about functionality, troubleshooting, or require information on specific components.

To ensure a smooth experience, it is advisable to have relevant details on hand, such as the model and serial number of your machinery. This information enables representatives to assist you more effectively. You can contact the support team via phone, email, or through the official website’s support portal.

In addition, consider checking the resources available online, as they may include FAQs, user manuals, and instructional videos. These materials often provide quick answers to common issues and can save you time.

Whether you prefer direct communication or exploring self-help options, customer support is a valuable resource for resolving your concerns and enhancing your equipment experience.