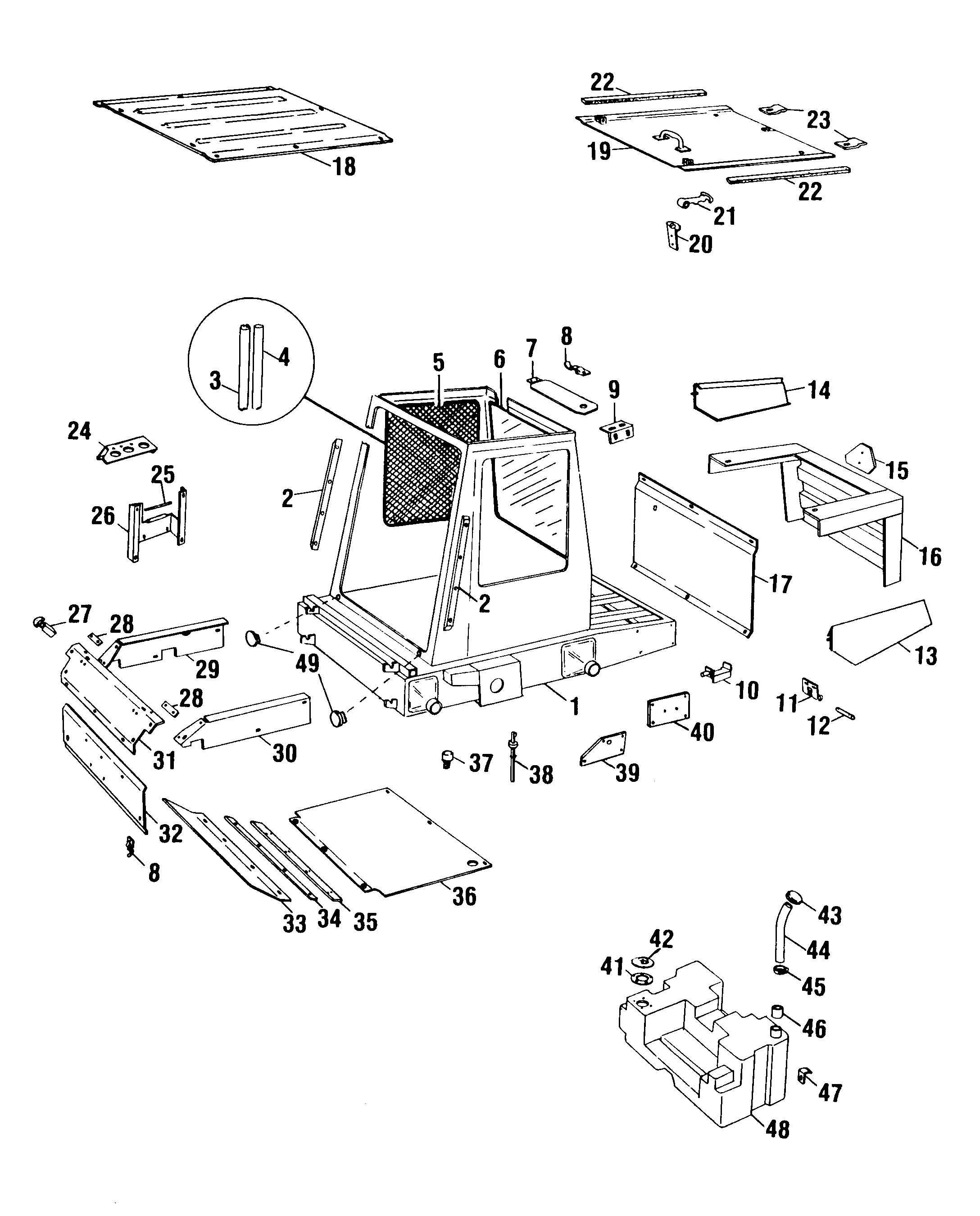

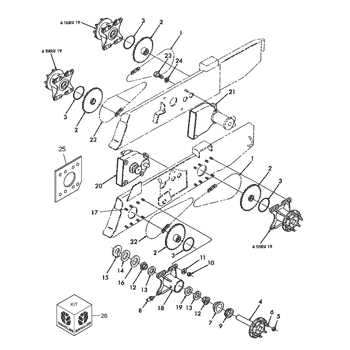

In the realm of machinery, comprehending the arrangement and functionality of various elements is crucial for effective maintenance and operation. A clear illustration showcasing these components can greatly enhance one’s ability to troubleshoot and optimize performance.

These visual representations serve as valuable resources, allowing users to identify and understand the relationships between different parts. Whether for routine inspections or in-depth repairs, having access to a well-organized schematic can streamline processes and minimize downtime.

By exploring such diagrams, operators and technicians can develop a deeper insight into the mechanics at play, ultimately leading to improved efficiency and longevity of the equipment. Proper knowledge of component positioning fosters informed decision-making, ensuring that maintenance is carried out with precision.

Overview of New Holland LX565

This section provides a comprehensive understanding of a versatile machine widely used in various applications. Its robust design and efficient functionality make it a valuable asset for both agricultural and construction tasks. Users can expect exceptional performance, facilitating a range of operations with ease.

The equipment is characterized by its powerful engine and innovative features, enhancing productivity and reliability. Its compact size allows for maneuverability in tight spaces, making it ideal for diverse environments. With various attachments available, it can be adapted to meet specific job requirements effectively.

Key Features of LX565 Model

The LX565 model is designed to offer exceptional performance and reliability, making it a preferred choice among operators. This compact yet powerful machine combines efficiency with versatility, enabling it to excel in various tasks across different terrains.

Durability and Strength

Constructed with robust materials, this equipment ensures longevity and resilience under demanding conditions. The frame is engineered to withstand heavy loads, enhancing stability during operation.

Advanced Hydraulic System

Featuring a sophisticated hydraulic mechanism, the model provides enhanced lifting capabilities and smooth operation. This system allows for precise control, making it easier to handle various attachments effectively.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations provide clarity, enabling users to identify elements and their functions easily. This knowledge is crucial for ensuring optimal performance and longevity of equipment.

These visual aids serve several key purposes:

- Facilitate quick identification of components, streamlining the repair process.

- Enhance communication among technicians and mechanics, reducing misunderstandings.

- Support troubleshooting efforts by clearly illustrating connections and configurations.

- Assist in inventory management by providing a clear reference for required items.

- Enable efficient training for new personnel, allowing them to grasp complex systems more rapidly.

Overall, visual references are invaluable tools in the realm of equipment management, promoting efficiency and reducing downtime.

Components of New Holland LX565

This section explores the essential elements that contribute to the functionality and performance of the machinery. Understanding these components is crucial for effective maintenance and operation, ensuring that the equipment runs smoothly and efficiently. Each part plays a significant role in the overall system, supporting various tasks and enhancing productivity.

The key elements include the engine, which powers the machine, and the hydraulic system that facilitates movement and control. The frame provides structural integrity, while the transmission ensures the transfer of power. Additionally, various attachments can enhance versatility, allowing for a range of applications. Regular inspection and care of these components are vital for prolonging the lifespan of the equipment.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide valuable insights into the assembly and arrangement of various elements within a machine, helping users identify each part’s location and function.

When examining such illustrations, it is crucial to focus on the accompanying labels and legends. They often provide context and clarify the relationships between different components. Here are some key aspects to consider:

| Aspect | Description |

|---|---|

| Legend | Indicates the symbols used to represent different elements in the illustration. |

| Callouts | Numbers or letters linked to specific components, helping to reference them easily. |

| Views | Different angles or perspectives that show how parts fit together within the assembly. |

| Scale | Provides a sense of size and proportion, ensuring accurate interpretation of dimensions. |

By familiarizing yourself with these elements, you can effectively interpret illustrations and enhance your understanding of the equipment’s construction and functionality.

Common Issues with LX565 Parts

Maintaining machinery often involves addressing various complications that can arise over time. Understanding frequent problems associated with components is essential for ensuring optimal performance and longevity. By recognizing these issues early, users can take proactive steps to mitigate potential disruptions in operation.

| Issue | Description | Potential Solutions |

|---|---|---|

| Wear and Tear | Components can degrade due to prolonged usage, leading to decreased efficiency. | Regular inspections and timely replacements are recommended. |

| Overheating | Excessive heat can affect performance and lead to component failure. | Ensure proper lubrication and cooling systems are functioning correctly. |

| Leaks | Fluid leaks may occur, compromising functionality and safety. | Inspect seals and connections regularly, replacing damaged parts as needed. |

| Electrical Issues | Faulty wiring or connections can disrupt power supply. | Conduct routine electrical checks and repair any damaged wiring promptly. |

Where to Find Replacement Parts

Locating suitable components for machinery can often be a straightforward process with the right resources. Various options are available for individuals seeking to procure these essential elements, ensuring optimal performance and longevity of equipment.

Local dealers frequently stock a range of items and can provide expert guidance on compatibility. Online marketplaces also offer a vast selection, allowing for easy comparison of prices and availability. Additionally, specialized websites dedicated to machinery can serve as valuable hubs for sourcing quality replacements. Networking with fellow operators or joining relevant forums can yield useful recommendations and insights on trustworthy suppliers.

Maintenance Tips for LX565

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. By adhering to a systematic maintenance routine, operators can prevent potential issues and enhance performance over time.

Routine Checks

- Inspect fluid levels frequently, including hydraulic fluid and engine oil.

- Examine filters and replace them as needed to ensure optimal operation.

- Check tire pressure and condition to maintain stability and safety.

Seasonal Care

- Clean the exterior and undercarriage to remove dirt and debris.

- Store equipment in a sheltered area to protect it from harsh weather conditions.

- Conduct a thorough inspection before and after seasonal use.

Upgrades for Enhanced Performance

Improving machinery efficiency can significantly impact productivity and longevity. By implementing various enhancements, operators can achieve optimal functionality and reliability, ensuring that equipment performs at its best.

One effective approach involves upgrading the hydraulic system. Enhancing fluid flow and pressure can lead to quicker response times and increased lifting capabilities. High-performance hydraulic components may reduce wear and improve overall operational efficiency.

Another area to consider is the powertrain. Installing a more robust engine or optimizing existing components can provide greater torque and efficiency, which is essential for heavy-duty tasks. Additionally, improved fuel systems can enhance fuel economy, reducing operational costs over time.

Lastly, ergonomic modifications to the operator’s environment can lead to increased comfort and reduced fatigue, allowing for longer work periods without compromising performance. Investing in quality upgrades not only boosts capabilities but also prolongs the lifespan of the equipment.

OEM vs. Aftermarket Parts Comparison

When it comes to replacement components for machinery, there are two primary categories to consider: original equipment manufacturer (OEM) and aftermarket alternatives. Each option presents distinct advantages and considerations that can significantly impact performance, cost, and reliability.

Quality and Reliability

One of the most critical factors when choosing between OEM and aftermarket components is the assurance of quality:

- OEM Components: Typically, these are produced by the same manufacturer as the original parts, ensuring a perfect fit and adherence to specific standards.

- Aftermarket Options: While some aftermarket alternatives can offer comparable quality, the standards can vary widely depending on the manufacturer.

Cost Considerations

Budget constraints often influence the decision between these two types of components:

- OEM Components: Generally, these can be more expensive due to brand reputation and guaranteed compatibility.

- Aftermarket Options: Often available at a lower price, they can be appealing for those looking to save money; however, potential compromises in quality should be considered.

Understanding Hydraulic Systems in LX565

Hydraulic systems play a crucial role in enhancing the functionality of machinery by utilizing fluid power to generate movement and force. These systems are designed to perform various tasks, offering efficiency and reliability in operation. A thorough understanding of their components and mechanics is essential for effective maintenance and troubleshooting.

Key Components of Hydraulic Systems

- Pumps: These devices are responsible for moving hydraulic fluid through the system, converting mechanical energy into hydraulic energy.

- Actuators: These components convert hydraulic energy back into mechanical motion, enabling the machinery to perform specific tasks.

- Valves: Control the flow and direction of the hydraulic fluid, ensuring that the system operates smoothly and efficiently.

- Reservoirs: Store hydraulic fluid, allowing for the system to maintain consistent performance and pressure levels.

Maintenance Tips for Hydraulic Systems

- Regularly check fluid levels and replace any contaminated fluid to ensure optimal performance.

- Inspect hoses and connections for leaks or wear, replacing them as necessary.

- Test system pressure and functionality periodically to identify any potential issues before they escalate.

- Keep components clean to prevent contamination and wear, prolonging the life of the system.

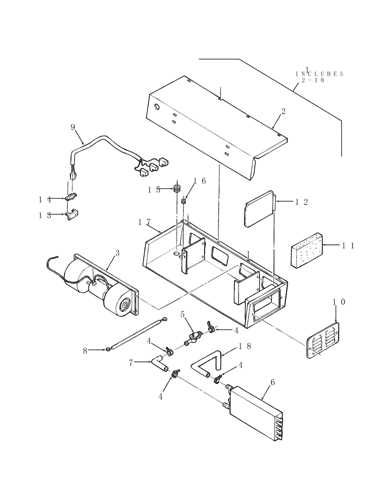

Electrical Components and Wiring Diagram

This section provides an overview of the essential electrical elements and their interconnections within the machinery. Understanding these components is crucial for effective troubleshooting and maintenance, ensuring optimal functionality.

The main electrical components typically include:

- Batteries

- Fuses

- Relays

- Switches

- Wiring harnesses

- Connectors

Each component plays a vital role in the overall system, contributing to the efficient operation of the equipment. Proper wiring practices are necessary to avoid electrical faults and enhance reliability.

When examining the wiring layout, consider the following points:

- Ensure connections are secure and free from corrosion.

- Check for any signs of wear or damage in the wiring.

- Refer to the schematics for accurate component placement.

- Maintain clear labeling of all wires and connectors for easy identification.

By familiarizing yourself with these electrical aspects, you can better manage the upkeep and functionality of the machinery.

Customer Reviews and Experiences

This section highlights the feedback and insights shared by users who have interacted with the equipment. Customers often provide valuable perspectives based on their hands-on experiences, which can guide potential buyers in making informed decisions.

Many users appreciate the durability and reliability of the machinery, noting that it performs exceptionally well under various conditions. One common sentiment is that the ease of maintenance contributes significantly to overall satisfaction, allowing operators to focus on productivity rather than troubleshooting.

Additionally, customers frequently mention the effectiveness of the customer support provided by dealers, emphasizing how timely assistance enhances their experience. Overall, these testimonials reveal a positive relationship between users and the equipment, showcasing its reputation for performance and dependability.