In the realm of gardening machinery, the intricate design and functionality of each component play a crucial role in ensuring optimal performance. Familiarity with the various elements that constitute these machines can significantly enhance maintenance and repair efforts. Knowledge about individual parts and their interconnections helps users to troubleshoot issues effectively and prolong the lifespan of their equipment.

Detailed illustrations that depict the arrangement and functionality of different elements provide valuable insights for both novice and experienced users. By studying these visuals, one can gain a deeper understanding of how each piece contributes to the overall efficiency of the machinery. This knowledge empowers users to make informed decisions when seeking replacements or upgrades, ultimately enhancing their gardening experience.

Moreover, having access to clear representations of equipment components fosters confidence in performing maintenance tasks. Whether addressing minor adjustments or major repairs, a well-informed user is better equipped to handle challenges that may arise during the upkeep of their gardening tools. This proactive approach not only saves time and effort but also ensures that the equipment operates smoothly and reliably.

This section aims to provide a comprehensive understanding of the features and components of a specific model designed for lawn maintenance. The objective is to highlight the importance of each element and how they contribute to the overall functionality of the machine.

Key Features of the Model

The model in question offers several essential characteristics that enhance its performance. Below are some of the notable features:

- Efficient cutting mechanism

- User-friendly controls

- Durable construction materials

- Versatile attachment options

Essential Components Explained

Understanding the various components is crucial for effective maintenance and troubleshooting. Here is a list of key parts that play a significant role:

- Engine assembly

- Chassis and frame

- Cutting deck

- Wheels and tires

- Control panel

Key Components of Scotts L2548

Understanding the fundamental elements of this machine is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance, contributing to both functionality and efficiency.

Essential Parts

- Engine: The powerhouse of the unit, responsible for providing the necessary energy for operation.

- Chassis: The main framework that supports all other components and ensures stability.

- Cutting Deck: The section where grass is trimmed, designed for precision and durability.

- Transmission: This mechanism transfers power from the engine to the wheels, affecting speed and maneuverability.

Supporting Features

- Control Panel: Allows the operator to manage settings and monitor performance easily.

- Wheels: Provide mobility, designed for various terrains to enhance traction and stability.

- Grass Collector: An optional attachment that aids in collecting clippings, promoting a clean lawn.

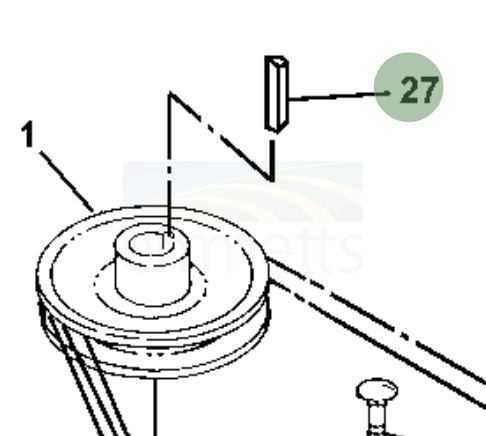

Importance of Parts Diagrams

Understanding the layout of components within a device is crucial for effective maintenance and repairs. These visual representations serve as a valuable tool for both technicians and users, providing clear guidance on the arrangement and function of each element. By facilitating easier identification of components, these illustrations help streamline the troubleshooting process.

Enhancing Repair Efficiency

When issues arise, having a comprehensive visual reference allows for quicker diagnosis and resolution. It aids technicians in pinpointing the exact area that requires attention, reducing the time spent searching for parts. Efficiency in repairs can lead to lower costs and improved service quality, which ultimately benefits the end user.

Assisting in Maintenance

Regular upkeep is essential for prolonging the lifespan of equipment. Visual aids play a significant role in maintenance routines, enabling users to understand which components need inspection or replacement. Proactive maintenance can prevent minor issues from escalating into major problems, ensuring smooth operation over time.

How to Interpret Diagrams

Understanding visual representations can greatly enhance your ability to analyze and troubleshoot machinery. These illustrations serve as essential guides, providing a clear overview of components and their relationships. Familiarizing yourself with the structure and symbols used in these visuals is crucial for effective comprehension.

Here are some key points to consider when interpreting visual representations:

- Familiarize with Symbols: Different symbols often denote specific components. Learning these can help you quickly identify parts.

- Understand the Layout: The arrangement of elements can indicate how they connect or function together. Pay attention to their positioning.

- Follow the Flow: Many illustrations show a process or sequence. Tracing the flow can clarify the order of operations or assembly.

- Consult the Legend: If available, refer to the legend or key that explains symbols and terms used within the visual. This will aid in better understanding.

- Take Notes: Jot down important information or references as you analyze the illustration. This can help solidify your understanding.

By applying these strategies, you can effectively decode visual aids, making your maintenance and repair tasks more manageable and efficient.

Common Replacement Parts Explained

When it comes to maintaining outdoor equipment, understanding the essential components that may require substitution is crucial. Many devices rely on specific elements that wear out over time, affecting performance and efficiency. Recognizing these vital components can help users ensure their machinery runs smoothly and lasts longer.

One of the most frequently replaced items is the blade. This critical part is responsible for achieving a clean cut and must be sharp for optimal performance. Over time, blades can become dull or damaged, necessitating their replacement to maintain the desired results.

Another important component is the drive belt. This element transfers power from the engine to the wheels or blades, enabling movement and operation. If the belt becomes frayed or worn, it can lead to decreased efficiency or even complete failure, making timely replacement essential.

The air filter is also a key part to consider. It ensures that the engine receives clean air, which is vital for efficient combustion. A clogged or dirty air filter can hinder performance and may lead to engine damage if not addressed regularly.

Finally, the spark plug plays a vital role in starting the engine. Over time, it can become fouled or worn out, causing starting issues or rough operation. Regular inspection and replacement of the spark plug can help maintain engine performance.

By understanding these essential components and their significance, users can make informed decisions regarding maintenance and ensure their equipment remains in optimal condition for years to come.

Maintenance Tips for Longevity

Ensuring the longevity of your outdoor equipment requires regular upkeep and attention. By implementing a few key maintenance practices, you can significantly extend the lifespan of your machinery while optimizing its performance. Here are some essential tips to help you keep your equipment running smoothly for years to come.

Regular Cleaning

Maintaining cleanliness is vital for the efficiency and durability of your tools. Accumulated dirt and debris can lead to mechanical issues. Consider the following cleaning practices:

- Wipe down surfaces after each use to prevent buildup.

- Check and clean air filters regularly to ensure optimal airflow.

- Remove any clippings or residue from undercarriages to avoid rust and corrosion.

Routine Inspections

Conducting routine inspections can help you identify potential issues before they become major problems. Pay attention to the following:

- Examine belts and cables for signs of wear or damage.

- Check fluid levels and top off as necessary to ensure proper operation.

- Look for loose screws or parts and tighten them to prevent further complications.

Identifying Parts by Model Number

Recognizing components by their model number is essential for effective maintenance and repair. This practice ensures that you can locate the correct elements needed for a particular machine, enhancing its performance and longevity. Understanding how to navigate model specifications can save time and prevent unnecessary errors.

To effectively identify the right elements, consider the following steps:

- Consult the user manual: Manuals often provide detailed information on model specifications and component identification.

- Utilize online resources: Manufacturer websites and parts retailers typically feature searchable databases where you can enter model numbers to find compatible components.

- Join community forums: Engaging with other users can offer insights and recommendations on identifying and sourcing components.

Following these guidelines will help streamline the process of locating the right elements, ensuring that repairs and maintenance are carried out efficiently.

Where to Find Replacement Parts

Finding the necessary components for your equipment can sometimes be challenging. However, there are several reliable sources available where you can locate high-quality replacements to ensure your machinery runs smoothly. Whether you are looking for a specific item or general supplies, exploring various options will help you get what you need effectively.

Online Retailers

Many online platforms specialize in offering a wide selection of equipment components. These retailers typically provide detailed product descriptions, user reviews, and competitive pricing, making it easier for you to make informed decisions. Below are some popular online options:

| Retailer | Website | Special Features |

|---|---|---|

| Amazon | www.amazon.com | Extensive selection, user reviews |

| eBay | www.ebay.com | New and used items available |

| Specialty Parts Store | www.specialtypartsstore.com | Expert support and guidance |

Local Dealers and Repair Shops

Visiting local dealers or repair shops can also be a valuable option. These establishments often carry inventory or can quickly order what you need. Additionally, they may provide installation services or expert advice, ensuring you find the right fit for your equipment.

Using the Diagram for Repairs

When it comes to maintenance and fixing machinery, having a visual representation of the components can be invaluable. Such illustrations not only provide clarity on how different elements are organized but also guide users through the process of troubleshooting and replacement. Utilizing these visual aids effectively can significantly enhance the efficiency of repairs and ensure a thorough understanding of the system.

To begin, carefully examine the visual layout to familiarize yourself with each component’s location and function. This knowledge allows for quicker identification of issues when they arise. As you navigate through the maintenance process, refer back to the illustration to confirm the correct parts are being addressed. This practice minimizes errors and aids in maintaining the integrity of the machinery.

Moreover, having access to a detailed representation makes it easier to plan your repair strategy. It enables you to gather all necessary tools and replacement elements beforehand, saving time and effort. By following the outlined steps in conjunction with the visual reference, you can perform repairs with greater confidence and precision.

In conclusion, leveraging visual resources during repair work not only streamlines the process but also enhances overall understanding. With careful attention to detail and a methodical approach, you can ensure your machinery remains in optimal working condition.

DIY Repair vs. Professional Help

When it comes to fixing equipment or appliances, individuals often face the decision of tackling the repair themselves or seeking assistance from a skilled technician. Each approach has its own benefits and drawbacks, which can significantly impact the outcome of the repair process.

Opting for a DIY approach can be appealing for several reasons:

- Cost Savings: Performing repairs yourself can save money on labor costs.

- Learning Experience: Engaging in the repair process can enhance your skills and knowledge.

- Flexibility: You can work on the repairs at your convenience without scheduling appointments.

However, there are also challenges associated with DIY repairs:

- Lack of Expertise: Not having the necessary skills can lead to mistakes, causing further damage.

- Time-Consuming: Researching and executing repairs can take more time than expected.

- Limited Tools: You may lack the specialized tools required for certain repairs.

On the other hand, choosing professional help offers distinct advantages:

- Expertise: Professionals possess the training and experience to diagnose and fix issues efficiently.

- Warranty Protection: Repairs by certified technicians often come with guarantees, providing peace of mind.

- Time Efficiency: Professionals can often complete repairs more quickly due to their expertise and tools.

Ultimately, the choice between DIY repair and hiring a professional depends on individual circumstances, including skill level, the complexity of the issue, and budget considerations. Weighing the pros and cons of each option can lead to a more informed decision.

Customer Reviews on Parts Quality

Feedback from users plays a crucial role in assessing the reliability and durability of components in lawn care equipment. Many consumers share their experiences, shedding light on how well these elements perform over time and their overall satisfaction with the materials used.

Positive Experiences

- Numerous customers appreciate the durability of the components, noting that they withstand rigorous use without significant wear.

- Users have expressed satisfaction with the precision of the fittings, which allows for seamless integration into existing machinery.

- Many reviews highlight the excellent performance of the materials, contributing to improved efficiency and effectiveness during operation.

Areas for Improvement

- Some users report occasional issues with availability, indicating that certain items can be difficult to find when needed.

- A few customers mention that the initial quality may vary, with some components not meeting their expectations for longevity.

- Feedback suggests that clearer instructions for installation could enhance the user experience, especially for those less experienced with assembly.

Resources for Further Information

For those seeking additional insights and details, a variety of resources are available to enhance your understanding of related components and mechanisms. Whether you are looking for troubleshooting guides, maintenance tips, or comprehensive overviews, numerous platforms offer valuable information.

Consider exploring the following avenues for a deeper dive into the subject:

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Website | Official source for product specifications and manuals. | Visit Site |

| Online Forums | Community-driven platforms for sharing experiences and advice. | Join Forum |

| YouTube Channels | Video tutorials and demonstrations by experts and enthusiasts. | Watch Videos |

| Repair Manuals | Detailed guides covering repair and maintenance procedures. | Download Manuals |