Understanding the structure and organization of various systems is crucial for maintaining and enhancing vehicle performance. This section aims to provide a detailed exploration of the mechanical and electrical systems that work together to ensure efficient functionality. The layout we will explore serves as a visual representation, simplifying complex setups into manageable and understandable sections.

By examining key elements and their respective roles, you will gain insight into the interactions between different mechanisms. Whether you are performing routine checks or troubleshooting issues, having a clear perspective on the arrangement of various components is essential. Through this guide, you will enhance your ability to pinpoint specific elements and understand their operation within the overall structure.

In the following section, we will break down these elements in a logical and accessible way, ensuring that even those unfamiliar with intricate technical details can follow along easily. From the simplest connectors to more advanced modules, each part of the system will

Understanding Club Car Components Layout

The structural arrangement of an electric or gas-powered vehicle is crucial for ensuring efficient performance and smooth operation. Familiarity with the positioning and function of various elements will help in the maintenance and repair process, enhancing overall system functionality. This section explores the main components, highlighting their roles and relationships within the overall design.

Primary Sections and Their Functions

- Power Source: Whether electric or fuel-driven, the core power unit is strategically placed to provide maximum efficiency and easy access for routine checks.

- Control Systems: The steering mechanism and throttle control are typically found in the central area, allowing intuitive handling and immediate response during operation.

- Transmission and Drive: The transmission setup connects to the drive system, transferring power from the engine or motor to the wheels

Key Elements of a Golf Cart Structure

The basic structure of a golf cart consists of various interconnected components that work together to ensure smooth performance and reliability. Each part plays a crucial role in providing a functional and efficient ride, whether navigating the green or moving across other terrain. Understanding these elements can help enhance maintenance and functionality.

Chassis and Frame

The foundation of the vehicle lies in its frame, which provides the necessary support for the entire setup. Built to be durable yet lightweight, it ensures stability and balance during movement. The chassis supports the suspension and drive systems, distributing weight evenly to improve handling.

Power Source and Drivetrain

Another significant component is the power source, which propels the vehicle forward. It can be powered by either a combustion engine or an electric motor, depending on the type of vehicle. The drivetrain then

Identifying Essential Parts for Maintenance

Regular upkeep of mechanical systems is key to ensuring long-term performance and reliability. To carry out this process effectively, it’s important to know which elements need attention and when. This section will focus on pinpointing critical components that play a role in maintaining optimal function and minimizing the risk of unexpected breakdowns.

Key Areas to Inspect

When performing routine upkeep, several elements are more likely to require examination and, potentially, replacement. These include areas directly linked to motion, power transmission, and safety.

- Energy sources: Ensuring uninterrupted power delivery is vital, and related elements often need attention due to wear over time.

- Steering and control: Mechanisms that influence direction and maneuverability should be checked frequently for any signs of wear or misalignment.

- Braking system: Crucial for safety,

Exploring the Electrical System Design

The electrical layout of any transport vehicle is a complex network designed to ensure efficient energy distribution. This system integrates various components, each playing a specific role in maintaining functionality. Understanding this framework helps to grasp how the interconnected elements work together to power and control essential functions, from propulsion to lighting.

Key Elements and Power Distribution

The power delivery starts with the primary energy source, typically a battery or alternative energy storage unit. From here, circuits manage and regulate the flow of current to critical systems. Wiring paths are carefully designed to minimize energy loss and optimize performance, allowing for smooth transitions between different operational modes. Circuit protection devices, such as fuses, safeguard against electrical surges or faults.

Control Mechanisms and Safety Features

Control systems, including switches and relays, are responsible for managing various functions. These components interact with sensors and actuators to maintain a

Common Steering System Components Overview

The steering system plays a crucial role in maintaining control and direction. It is composed of several key elements that work together to ensure stability and maneuverability. Each element has a specific function, contributing to the overall safety and performance of the vehicle. Below is an overview of the main components involved in this essential system.

- Steering Wheel: The primary interface for the driver, this mechanism allows for directional input, transmitting motion down to other components.

- Steering Column: A shaft that connects the wheel to the rest of the system, providing support and housing additional mechanisms like tilt or telescoping adjustments.

- Rack and Pinion: This gear system converts the rotational input from the

Brake Mechanisms and Their Functions

Understanding the braking system is essential for ensuring safety and performance in various types of vehicles. This system plays a crucial role in controlling movement and bringing the vehicle to a stop, highlighting the importance of its components and their interconnections.

Several types of braking mechanisms are commonly utilized, each designed to serve specific functions:

- Drum Brakes: These utilize friction generated by a set of shoes pressing against a cylindrical drum. They are known for their reliability and effectiveness in providing stopping power.

- Disc Brakes: In this system, friction is applied to a flat disc, typically providing superior performance, especially in high-speed scenarios. Their design allows for better heat dissipation.

- Hydraulic Brakes: Leveraging hydraulic fluid, these brakes offer increased force with less effort from the driver, enhancing responsiveness and control.

- Electric Brakes: These employ electric actuators to engage the braking mechanism, often used in modern systems for precise control and efficiency.

Each mechanism comprises several essential components that work together to facilitate smooth operation:

- Pads/Shoes: Friction materials that create the necessary resistance against the rotating elements.

- Calipers: Hold the pads and exert pressure to ensure effective contact with the braking surface.

- Rotors/Drums: The surfaces against which the pads or shoes make contact, critical for generating stopping power.

- Brake Lines: Convey hydraulic fluid from the master cylinder to the calipers in hydraulic systems, allowing for efficient force transfer.

Regular maintenance and understanding of these mechanisms are vital for optimal performance and safety. Familiarity with their functions can aid in diagnosing issues and ensuring effective operation.

Battery and Power Source Placement Guide

This section provides essential guidance for the effective arrangement of energy storage units and their corresponding supply systems. Proper placement ensures optimal performance and reliability, which are critical for enhancing overall functionality. A well-organized layout minimizes potential issues and enhances accessibility for maintenance and inspections.

When positioning energy sources, consider the following factors:

Factor Details Location Choose a space that is sheltered from the elements to prevent damage and prolong lifespan. Accessibility Ensure that the placement allows for easy access for routine checks and replacements. Weight Distribution Position the units in a way that balances the overall weight to improve stability during operation. Connection Points Place components near relevant wiring and connection points to reduce strain and wear on cables. Ventilation Ensure sufficient airflow to prevent overheating, especially in enclosed spaces. By adhering to these guidelines, you can enhance the effectiveness and safety of the energy storage and supply systems, contributing to improved performance and longevity.

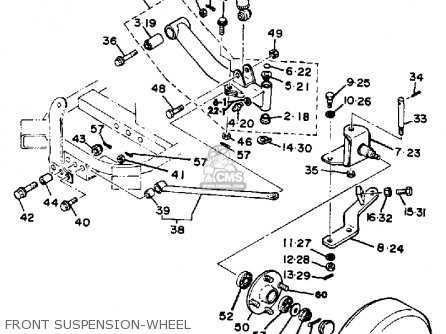

Suspension System and Frame Diagram

The suspension mechanism and structural framework of a vehicle play a crucial role in ensuring a smooth ride and stability. These components work together to absorb shocks, maintain contact with the ground, and provide support for the overall structure. Understanding their arrangement and functionality is essential for maintaining optimal performance and safety.

Key Components of the Suspension Mechanism

The suspension mechanism consists of several critical elements, including springs, shock absorbers, and control arms. Springs help to absorb impact from uneven terrain, while shock absorbers control the rebound of the springs, enhancing ride quality. Control arms connect the wheel assembly to the frame, allowing for controlled movement and alignment.

Importance of the Structural Framework

The structural framework serves as the backbone of the vehicle, providing essential support for various components. It ensures proper alignment and stability while distributing weight evenly across the chassis. A robust framework is vital for overall safety and performance, especially during turns and sudden stops.

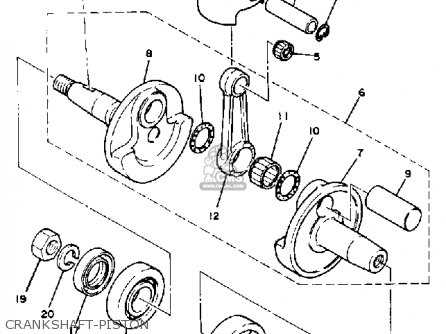

Club Car Drive System Explained

The driving mechanism in these vehicles is a crucial aspect that determines their performance and efficiency. Understanding this system is essential for both maintenance and optimal usage. This section delves into the components and functionality of the drive system, highlighting its significance in the overall operation of the vehicle.

Components of the Drive Mechanism

At the core of the driving system lies the motor, which generates the necessary power for movement. This power is transmitted through a series of belts and pulleys, ensuring smooth operation. Additionally, the drivetrain incorporates various gears that enhance torque and speed, allowing for versatile handling in different terrains. Each element works in harmony to create a reliable and efficient propulsion system.

Functionality and Performance

The efficiency of this driving mechanism is influenced by factors such as maintenance and environmental conditions. Regular checks on the motor, belts, and gears are vital to ensure that the system operates at peak performance. A well-maintained driving setup not only extends the lifespan of the vehicle but also enhances its responsiveness and overall driving experience. Understanding these aspects empowers users to make informed decisions regarding care and modifications.

Lighting and Indicator Components Layout

The arrangement of illumination and signaling elements plays a crucial role in ensuring safety and visibility. Understanding the configuration of these components allows for better maintenance and troubleshooting. Each element is strategically positioned to maximize functionality and effectiveness, facilitating clear communication between the vehicle and its surroundings.

Key components include headlights, taillights, turn signals, and hazard lights. The headlights are typically mounted at the front, providing essential visibility during low-light conditions. Taillights, located at the rear, serve to signal braking and position, while turn indicators, situated on both sides, communicate directional intentions to other drivers. Hazard lights are usually placed prominently, ensuring they are easily visible to alert others of potential issues.

The wiring and connectors that link these components are equally important, ensuring a reliable power supply and seamless operation. Regular inspection of these systems is vital for optimal performance, preventing malfunctions that could compromise safety on the road.

Exploring HVAC System in Electric Models

The heating, ventilation, and air conditioning (HVAC) system in electric vehicles plays a crucial role in ensuring passenger comfort and air quality. These systems are designed to manage the temperature and humidity levels within the cabin while maintaining optimal air circulation. Understanding the components and functionality of these systems can enhance the overall experience of operating electric models.

Electric vehicles typically employ different approaches to HVAC systems compared to traditional internal combustion models. By utilizing electric compressors and advanced climate control technology, these systems can provide efficient heating and cooling, leading to improved energy consumption. The following table outlines the key components commonly found in HVAC systems of electric models:

Component Description Electric Compressor Utilizes electric power to circulate refrigerant throughout the system. Heat Exchanger Transfers heat to and from the cabin, helping to regulate temperature. Evaporator Absorbs heat from the interior air, cooling the cabin. Condenser Releases heat absorbed by the refrigerant, allowing it to cool down. Blower Motor Distributes conditioned air throughout the passenger area. Thermostat Regulates the temperature settings based on user preferences. Incorporating energy-efficient technologies and advanced controls, these systems not only enhance comfort but also contribute to the overall performance of electric models. As technology advances, the integration of smarter HVAC solutions is expected to further improve energy efficiency and user experience.

Tips for Reading Technical Diagrams Efficiently

Understanding visual representations of systems can significantly enhance your ability to troubleshoot and assemble components effectively. These illustrations convey complex information succinctly, making it essential to approach them with the right techniques.

Here are some strategies to improve your comprehension:

- Familiarize Yourself with Symbols: Each visual may use specific icons or notations. Take time to learn what each symbol represents.

- Follow the Flow: Many visuals display a directional flow. Identify the starting point and trace the path to better understand relationships between elements.

- Utilize a Key or Legend: Most visuals will have an accompanying key. Refer to this as you analyze the illustration to decode any unfamiliar symbols.

- Take Notes: Jot down important details or questions as you review the visual. This can help reinforce your understanding and highlight areas for further exploration.

- Break it Down: Divide the representation into smaller sections. Focus on one area at a time to prevent feeling overwhelmed.

- Cross-Reference with Documentation: Use supplementary manuals or guides to clarify complex aspects. This can provide additional context that enhances your understanding.

By employing these techniques, you can navigate technical illustrations more effectively and gain deeper insights into the systems they represent.