In the realm of technical design, comprehending the arrangement and function of various elements is crucial for effective analysis and maintenance. Each component plays a specific role, contributing to the overall efficiency and reliability of the system. This understanding not only aids in troubleshooting but also enhances the capability to innovate and improve existing frameworks.

Detailed visual representations are invaluable resources for engineers and technicians alike. They provide a clear overview of how individual units interact within a larger assembly, allowing for streamlined communication and knowledge transfer. By utilizing these schematics, professionals can easily identify issues, assess performance, and implement necessary adjustments.

Whether you are a seasoned expert or just beginning your journey in this field, familiarizing yourself with these layouts will empower you to navigate complex systems with confidence. Mastery of this knowledge is essential for anyone looking to optimize functionality and ensure longevity in their projects.

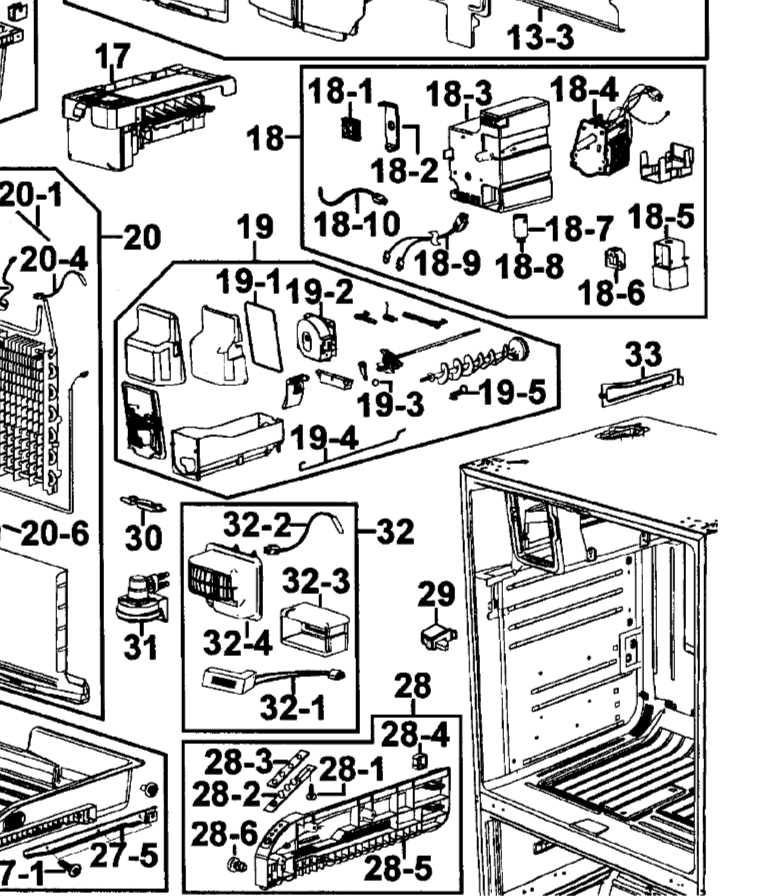

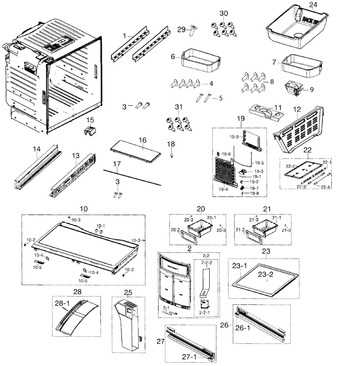

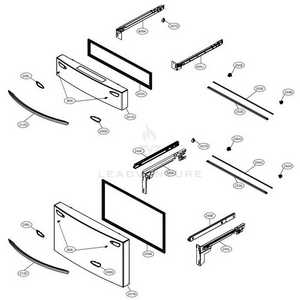

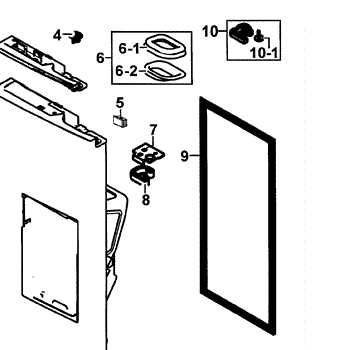

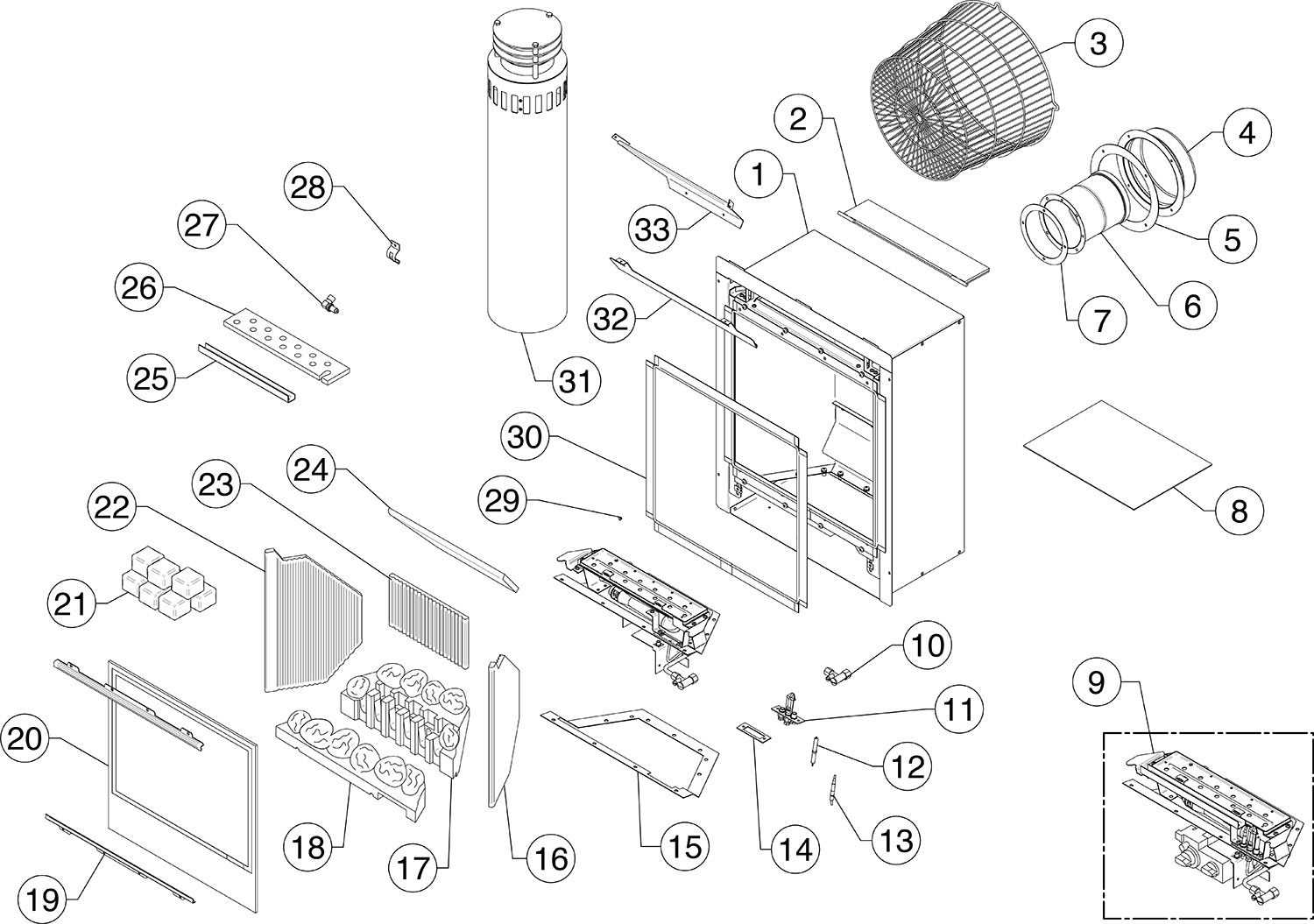

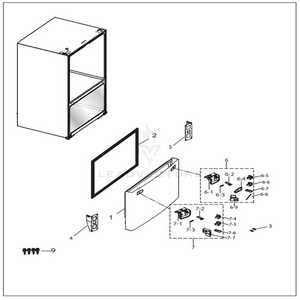

Understanding Rf263beaesr Components

When delving into the intricate world of mechanical assemblies, it is essential to grasp the various elements that contribute to the overall functionality. Each component plays a vital role, ensuring that the system operates smoothly and efficiently. Understanding these individual pieces enables one to troubleshoot issues and optimize performance effectively.

Each segment of the assembly serves a specific purpose, whether it be facilitating movement, providing support, or enabling control. Familiarity with these functions is crucial for anyone looking to engage deeply with the equipment. By examining the characteristics and interrelationships of these elements, users can gain valuable insights into the workings of the entire system.

Additionally, recognizing how these components interact with one another highlights the importance of precision engineering. Any misalignment or malfunction can lead to significant performance degradation. Therefore, a thorough understanding is not just beneficial; it is essential for maintenance and optimization.

Importance of Accurate Parts Diagrams

In any technical field, precision in documentation is crucial for effective maintenance and repair. Visual representations serve as essential tools for understanding complex assemblies, guiding users through the necessary steps for troubleshooting and reconstruction.

Accurate illustrations provide several key benefits:

- Enhanced Clarity: Clear visuals help in identifying components and their interrelationships, reducing confusion during repairs.

- Improved Efficiency: Well-structured representations allow technicians to quickly locate and address issues, minimizing downtime.

- Reduced Errors: Detailed guides lower the chances of mistakes, ensuring that replacements and repairs are performed correctly.

- Facilitated Training: New team members can learn more effectively with precise visuals, speeding up their integration into the workforce.

In conclusion, the importance of clear and accurate visual representations cannot be overstated. They are vital for ensuring smooth operations and effective problem-solving in any mechanical or technical context.

Common Issues with Rf263beaesr Parts

In any mechanical system, certain challenges can arise, impacting functionality and efficiency. Understanding these frequent problems is essential for maintenance and longevity. Identifying symptoms early can lead to quicker resolutions and improved performance.

Wear and Tear

Over time, components can experience degradation due to regular use. This can lead to diminished effectiveness and potential failure. Regular inspections can help catch these issues before they escalate.

Compatibility Concerns

Incompatibility between various elements can cause operational disruptions. Ensuring that all parts are suited for one another is crucial for seamless functioning. Always refer to specifications for optimal alignment.

How to Interpret Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and assembly. These illustrations provide a roadmap for identifying each element and its relation to others, streamlining troubleshooting and repairs. Grasping how to read these visuals empowers users to navigate complex machinery with confidence.

| Element | Description |

|---|---|

| Labeling | Elements are typically marked with alphanumeric codes for easy identification. |

| Legend | A key that explains symbols and codes used throughout the representation. |

| Connections | Lines indicating how different elements interact or connect with one another. |

| Orientation | Understanding the layout helps in visualizing how components fit within the overall assembly. |

Where to Find Rf263beaesr Schematics

Locating detailed blueprints and illustrations for complex machinery can be crucial for effective maintenance and repair. Various resources can provide valuable information, enabling users to access the necessary diagrams for troubleshooting and assembly purposes.

Online Resources

- Manufacturer Websites: Check the official sites of the product’s manufacturer, which often offer downloadable resources.

- Technical Forums: Engage in community discussions on specialized forums where enthusiasts share documents and insights.

- DIY Repair Websites: Visit websites dedicated to DIY repairs, which may host user-uploaded diagrams and guides.

Local Resources

- Library Archives: Local libraries often have technical manuals and reference materials that include schematics.

- Repair Shops: Contact local repair technicians who might have access to proprietary schematics.

- Trade Shows: Attend industry events where vendors may distribute technical literature and resources.

Maintaining Your Rf263beaesr Device

Proper upkeep of your appliance is essential to ensure optimal performance and longevity. Regular maintenance can prevent potential issues and enhance the efficiency of your unit, allowing it to serve you well for years to come. This section outlines key practices to keep your device in top condition.

Regular Cleaning

Cleaning is a fundamental aspect of maintenance. Dust and debris can accumulate, leading to reduced efficiency and potential malfunctions. Follow these steps for effective cleaning:

- Turn off the device and unplug it before cleaning.

- Use a soft, damp cloth to wipe down the exterior surfaces.

- For internal components, refer to the user manual for specific cleaning instructions.

- Regularly check and clean any filters to ensure proper airflow.

Periodic Inspections

Conducting periodic inspections helps identify any wear or issues before they escalate. Consider the following:

- Check all connections for signs of wear or corrosion.

- Listen for unusual noises during operation, which could indicate a problem.

- Monitor performance for any changes that may suggest maintenance is needed.

- Consult the user manual for specific components that should be inspected regularly.

By incorporating these practices into your routine, you can significantly enhance the functionality and lifespan of your appliance. Regular attention will ensure that it remains reliable and efficient for all your needs.

Comparing Rf263beaesr to Similar Models

In the realm of advanced machinery, it is essential to assess how specific models measure up against their counterparts. This analysis focuses on key features, functionalities, and overall performance, providing a comprehensive understanding of where these models stand in relation to each other.

When evaluating various options, consider the following aspects:

- Design and Build Quality: Examine the structural integrity and materials used, as these influence durability and longevity.

- Efficiency: Analyze how effectively each model performs its designated tasks, taking into account energy consumption and output levels.

- Technological Integration: Assess the incorporation of modern technology, such as automation features and smart connectivity, which can enhance usability.

- Maintenance Requirements: Consider how easy it is to service and maintain each option, as this impacts operational downtime.

- Cost-effectiveness: Evaluate initial investment versus long-term operational costs, including repairs and energy consumption.

By comparing these factors, users can make informed decisions, ensuring they select a model that best fits their specific needs while optimizing performance and reliability.

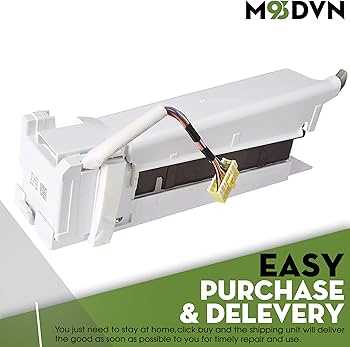

Essential Tools for Repairing Rf263beaesr

When undertaking repairs on any appliance, having the right tools is crucial for efficiency and effectiveness. Each task may require specific instruments that not only facilitate the process but also ensure safety and accuracy. Below is a list of essential equipment that can aid in resolving common issues.

- Screwdriver Set: A variety of screwdrivers, including Phillips and flathead, are necessary for accessing internal components.

- Socket Wrench: Ideal for loosening and tightening nuts and bolts, a socket wrench provides better torque compared to traditional wrenches.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts, pliers come in various types to suit different tasks.

- Multimeter: An essential tool for diagnosing electrical issues, this device measures voltage, current, and resistance.

- Tape Measure: Accurate measurements are vital for fitting replacement components; a tape measure ensures precision.

Additionally, having a few specialized tools can enhance your repair experience:

- Utility Knife: Great for cutting through insulation or packaging materials.

- Wire Stripper: This tool helps in safely stripping the insulation off electrical wires, ensuring clean connections.

- Flashlight: Adequate lighting is important when working in dark spaces, making a flashlight an indispensable companion.

- Safety Gear: Gloves and goggles protect against potential hazards, ensuring a safe working environment.

Equipping yourself with these tools will not only make repairs more manageable but also contribute to a successful outcome. Being prepared is the first step to effective problem-solving.

Identifying Components in Diagrams

Understanding the elements represented in technical illustrations is crucial for effective communication and analysis. Recognizing individual components and their relationships enhances one’s ability to interpret complex information accurately. This section explores methods to identify and analyze these elements systematically.

Common Features to Look For

- Labels: Clear annotations often accompany components, providing essential information about their function or specifications.

- Shapes: Different geometric figures typically represent specific types of elements, such as circles for connectors and squares for junctions.

- Lines and Arrows: These indicate connections and the flow of processes, helping to understand how components interact.

Strategies for Effective Identification

- Familiarization: Spend time reviewing common symbols and conventions used in your field to build a strong foundational knowledge.

- Cross-referencing: Utilize reference materials or manuals that explain the meanings of various symbols, aiding in quicker identification.

- Practice: Regularly analyze different illustrations to improve your recognition skills and confidence in interpreting them.

Benefits of Regular Maintenance

Consistent upkeep of machinery and equipment is crucial for ensuring optimal performance and longevity. Regular checks and services can prevent minor issues from escalating into major problems, ultimately saving time and resources. Moreover, routine maintenance helps maintain safety standards and enhances the efficiency of operations.

Here are some key advantages of regular maintenance:

| Benefit | Description |

|---|---|

| Increased Lifespan | Routine attention can significantly extend the life of your assets, reducing the need for premature replacements. |

| Cost Savings | Addressing issues early can prevent costly repairs and downtime, leading to significant financial savings. |

| Improved Safety | Regular inspections help identify potential hazards, ensuring a safer working environment for everyone involved. |

| Enhanced Efficiency | Well-maintained equipment operates more smoothly and efficiently, optimizing productivity and performance. |

| Better Compliance | Regular maintenance helps meet industry regulations and standards, avoiding legal complications. |

In summary, dedicating time to regular maintenance not only preserves the functionality of your equipment but also contributes to a safer and more efficient operational environment.

Expert Tips for Efficient Repairs

When tackling repairs, having a structured approach can significantly enhance efficiency and effectiveness. Understanding the components involved and how they interact is crucial for a successful outcome. Below are some expert recommendations to streamline your repair process.

1. Organize Your Workspace: A clutter-free environment is essential. Keep tools and materials within easy reach to minimize distractions and maximize productivity. Consider labeling containers for small items to prevent misplacement.

2. Research Before You Begin: Gather information on the specific issues you may encounter. Online resources, manuals, and forums can provide valuable insights. Understanding common challenges allows you to prepare for them in advance.

3. Use Quality Tools: Investing in high-quality tools not only makes the job easier but also improves safety. Ensure you have the right equipment for the task at hand, as using inappropriate tools can lead to errors and accidents.

4. Take Detailed Notes: Document each step of the process, including any adjustments or observations. This practice not only aids in current repairs but serves as a reference for future projects.

5. Test Thoroughly: Once repairs are complete, conduct thorough tests to ensure everything functions as intended. This step is vital in identifying any lingering issues before concluding the task.

6. Seek Professional Advice When Needed: Don’t hesitate to consult experts for complex problems. Their experience can save you time and prevent costly mistakes.

By applying these strategies, you can enhance your repair skills, save time, and achieve better results in your projects.