In the world of agricultural equipment, comprehending the intricate arrangement of machine elements is essential for effective maintenance and repair. Every operator must familiarize themselves with how individual components interact within the larger system. This knowledge not only enhances operational efficiency but also prolongs the lifespan of the machinery.

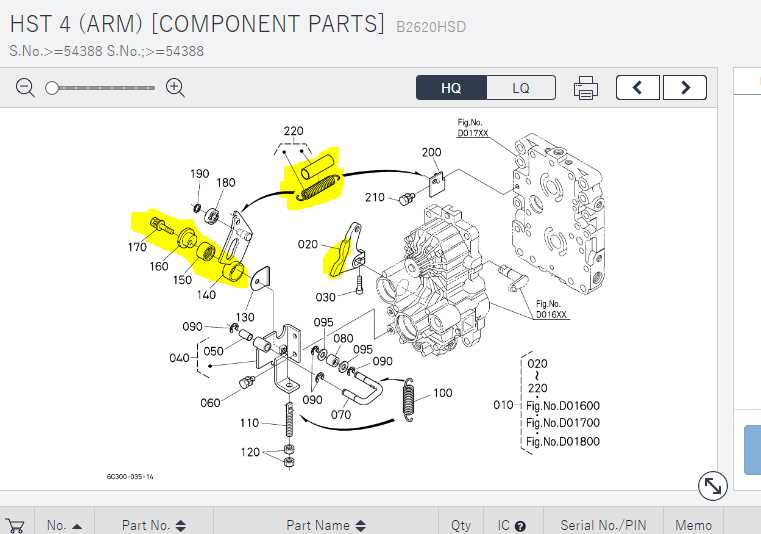

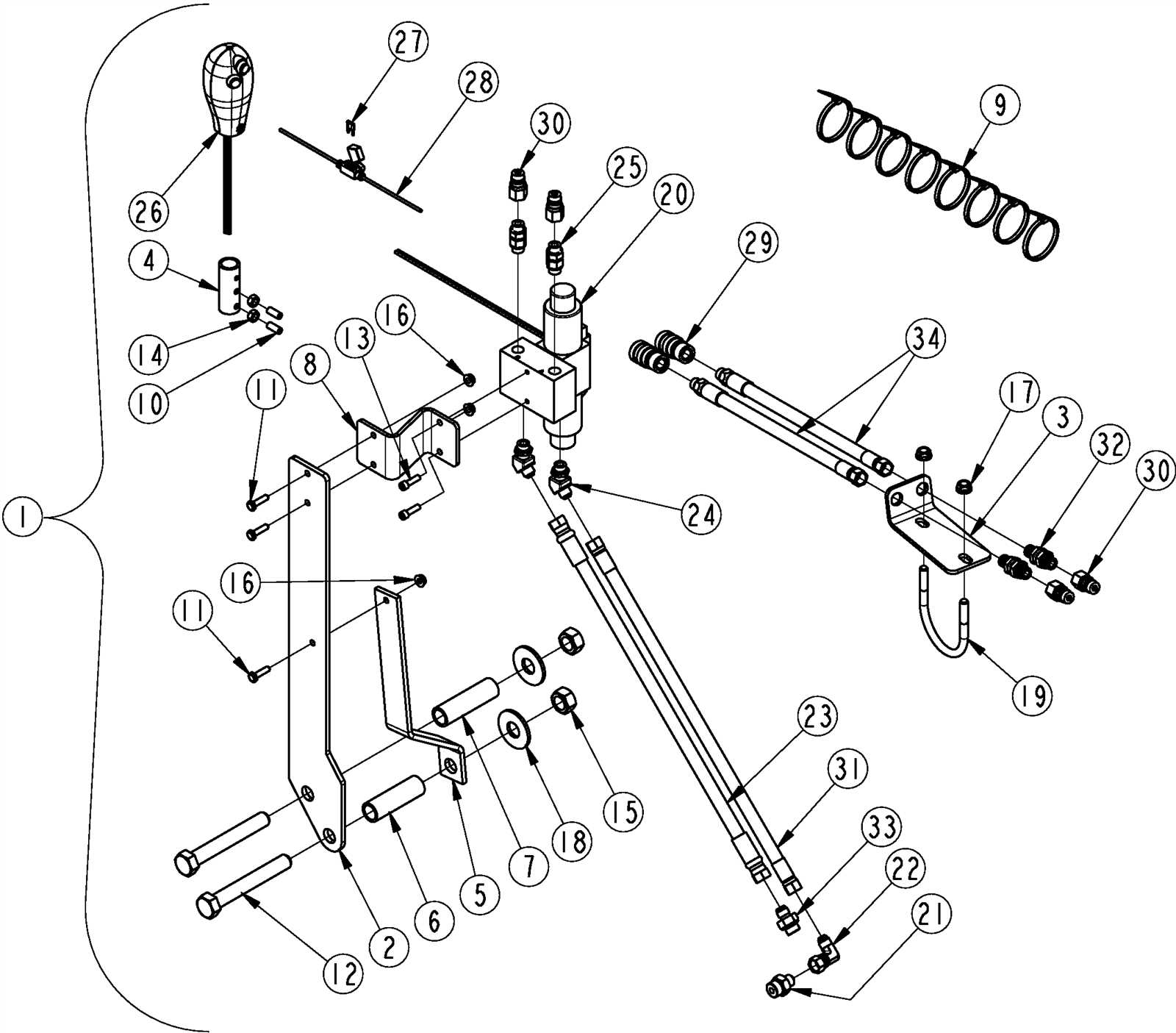

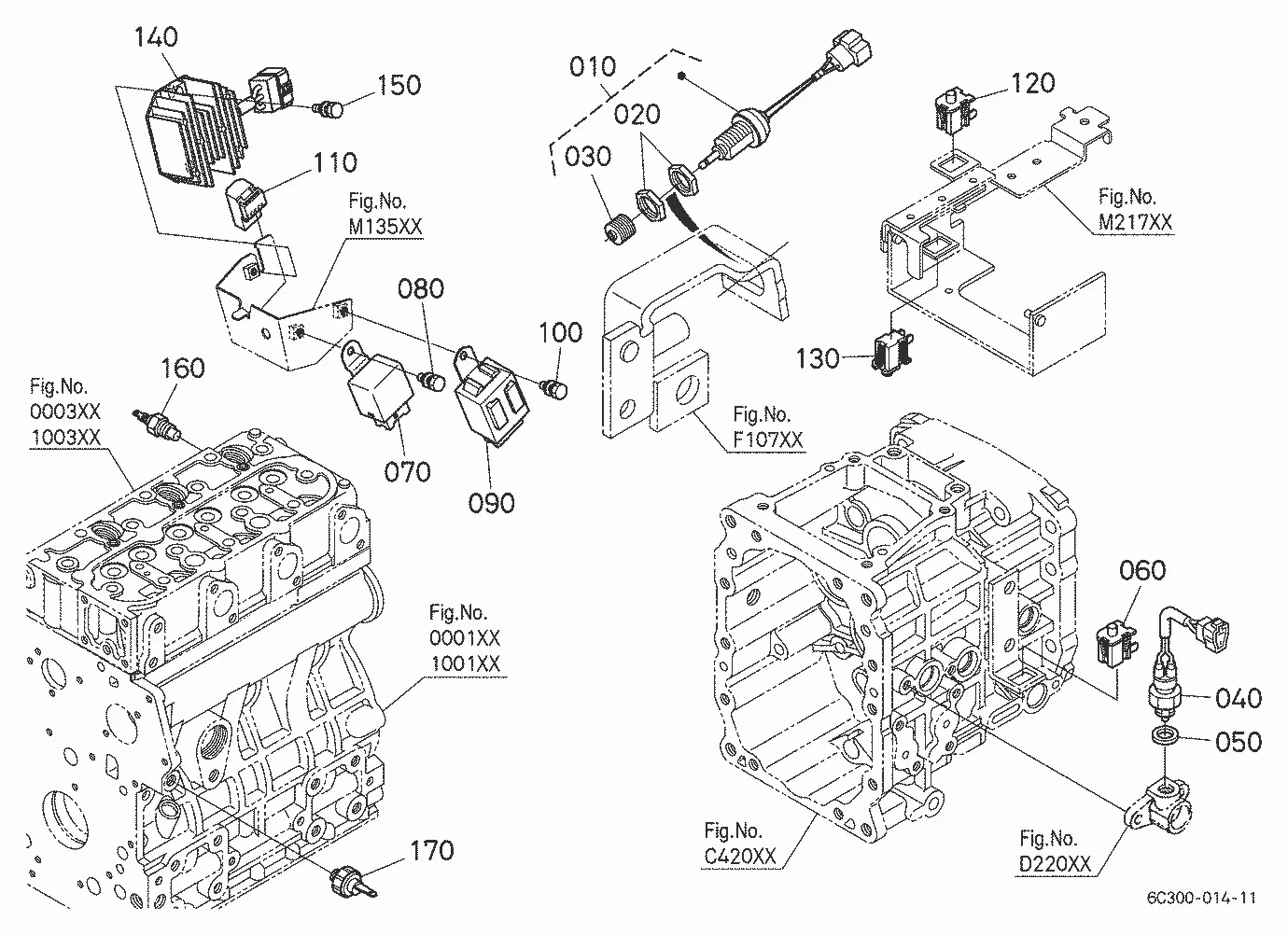

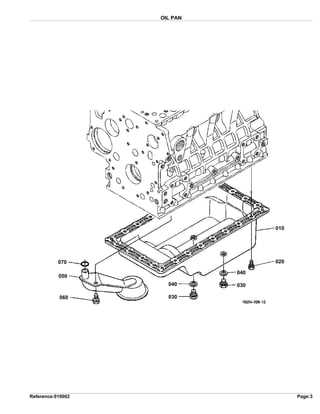

Having access to a detailed visual representation of these elements allows users to identify parts quickly, facilitating timely interventions when issues arise. Such illustrations serve as invaluable resources for both novice and experienced technicians, making troubleshooting a more straightforward process.

Moreover, understanding the layout of machinery components promotes safer operation. When users can pinpoint where specific elements reside, they can navigate the equipment more confidently, reducing the likelihood of accidents and enhancing overall safety during maintenance tasks. This insight is particularly beneficial in preventing misunderstandings that could lead to costly mistakes.

Kubota B2620 Overview

This section provides a comprehensive look at a versatile compact tractor that excels in various agricultural tasks. Known for its reliability and performance, this machine is designed to meet the demands of both professionals and hobbyists in the field.

Key Features

Equipped with a powerful engine, this tractor offers excellent torque and efficiency. Its compact size allows for maneuverability in tight spaces, making it ideal for landscaping and small farm operations. The ergonomic controls ensure ease of use, enhancing the overall user experience.

Applications

This tractor is suitable for a wide range of tasks, from mowing and tilling to snow removal and hauling. Its adaptability makes it an ultimate choice for anyone looking to maximize productivity in various environments.

Importance of Parts Diagrams

Understanding the intricacies of machinery relies heavily on visual representations that detail individual components and their relationships. These illustrations serve as essential tools for technicians and operators alike, offering clarity and aiding in maintenance and repairs. By simplifying complex systems, they enhance the overall efficiency of troubleshooting processes.

Facilitating Maintenance

Clear visual aids significantly streamline the maintenance process. Technicians can quickly locate specific elements, ensuring that service tasks are executed efficiently and accurately. This ultimately reduces downtime and increases productivity.

Enhancing Repair Accuracy

When faced with repairs, having a detailed visual reference enables individuals to identify the correct parts needed for replacement. This precision minimizes the chances of errors, leading to effective restoration of equipment and improved operational reliability.

Key Components of Kubota B2620

This section explores the essential elements that contribute to the functionality and performance of this compact tractor. Understanding these key components is crucial for maintenance and operational efficiency.

Engine and Transmission

The engine serves as the powerhouse, delivering the necessary torque and horsepower. Coupled with a robust transmission system, it ensures seamless power transfer to the wheels, enhancing overall maneuverability and control.

Hydraulic System

A sophisticated hydraulic system allows for the efficient operation of various attachments, providing versatility in tasks. Its design ensures optimal fluid flow and pressure management, critical for effective performance in diverse applications.

How to Access Parts Diagrams

Accessing detailed schematics for machinery components is essential for maintenance and repairs. Knowing where to find these resources can save time and ensure proper functionality.

- Check the Manufacturer’s Website: Most manufacturers provide online resources, including detailed illustrations and manuals.

- Utilize Dealer Services: Authorized dealers often have access to comprehensive resources and can assist with specific inquiries.

- Explore Online Forums: Many enthusiasts and professionals share valuable insights and links to resources in dedicated communities.

- Refer to Repair Manuals: Printed or digital repair guides often contain detailed visuals and descriptions of various components.

By following these steps, you can efficiently delve into the essential resources needed for your equipment maintenance.

Common Issues with B2620 Parts

In the realm of compact machinery, certain challenges frequently arise concerning components and their performance. Understanding these common problems can help owners maintain efficiency and extend the lifespan of their equipment.

Wear and Tear: Over time, various elements may experience significant degradation due to regular usage. This deterioration often leads to reduced functionality, making it essential to monitor the condition of each part closely.

Compatibility Issues: When replacing elements, it is crucial to ensure that new components are compatible with existing ones. Mismatched parts can cause operational failures and may lead to further damage if not addressed promptly.

Leakage Problems: Fluid leaks are a common concern that can affect overall performance. Identifying the source of a leak early on is vital for preventing more serious complications down the line.

Alignment and Calibration: Proper alignment of moving components is necessary for smooth operation. Misalignment can result in increased wear and may necessitate frequent adjustments or replacements.

Overheating: Components may overheat due to excessive strain or inadequate maintenance. Regular inspections can help prevent this issue, ensuring that machinery operates within safe temperature ranges.

Addressing these challenges proactively can lead to improved efficiency and longevity, ultimately benefiting the overall performance of the machinery involved.

Replacing Worn-Out Components

Maintaining optimal performance of machinery requires the timely replacement of deteriorated elements. Over time, components can wear down, leading to decreased efficiency and potential breakdowns. Addressing these issues promptly is crucial for ensuring longevity and reliable operation.

Identifying the signs of wear is the first step in the replacement process. Look for irregular noises, reduced functionality, or visible damage. Once identified, sourcing the correct replacements is essential to restore the equipment to its peak condition.

| Component | Signs of Wear | Replacement Frequency |

|---|---|---|

| Belts | Cracks or fraying | Every 500 hours |

| Filters | Clogging or discoloration | Every 100 hours |

| Seals | Leaks or brittleness | Annually |

| Fluids | Discoloration or contamination | Every 50 hours |

By regularly inspecting and replacing worn elements, operators can ensure their machinery functions at its ultimate efficiency, minimizing downtime and maximizing productivity.

Finding Genuine Kubota Parts

When it comes to maintaining machinery, sourcing authentic components is crucial for ensuring optimal performance and longevity. Counterfeit or substandard items may seem appealing due to their lower prices, but they can lead to inefficiencies and costly repairs in the long run. Therefore, understanding how to locate reliable suppliers is essential for any owner.

Identifying Authorized Dealers

One of the best ways to secure quality components is by purchasing from certified retailers. These establishments are often backed by the manufacturer, ensuring that the items they offer meet strict standards. Checking for a dealer’s credentials can save you from potential headaches.

Utilizing Online Resources

In the digital age, numerous online platforms provide access to a vast inventory of genuine components. Researching reputable websites and reading customer reviews can guide you toward trustworthy options. Always verify the authenticity of the seller to avoid pitfalls associated with imitations.

Understanding Part Numbers and Codes

Deciphering the alphanumeric codes associated with machinery components is essential for effective maintenance and repair. These identifiers provide vital information about specifications, compatibility, and manufacturing details, ensuring users can accurately source replacements or enhancements.

Structure of Codes

Part identifiers typically consist of several segments, each signifying specific characteristics:

- Prefix: Often indicates the type of component.

- Numerical Sequence: Represents unique identification.

- Suffix: May denote revisions or variations.

Importance of Accuracy

Using the correct codes is crucial to avoid mismatches. Consider these tips:

- Always verify compatibility with existing equipment.

- Consult manufacturer resources for clarity.

- Keep a reference guide for quick access to common identifiers.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that can enhance the performance and longevity of machinery. These items are designed specifically for the equipment, ensuring optimal compatibility and reliability. By choosing these quality components, users can avoid the pitfalls often associated with generic alternatives.

Quality Assurance

One of the primary benefits of opting for authentic components is the assurance of quality. OEM items undergo rigorous testing and meet stringent industry standards, which guarantees their effectiveness. This commitment to excellence often translates into better performance and a reduced risk of malfunctions, ultimately saving time and money on repairs.

Enhanced Longevity

Original components are engineered to fit seamlessly with the machinery, promoting smoother operation and reducing wear and tear. By investing in these quality parts, operators can expect enhanced durability and a longer service life for their equipment. This not only minimizes downtime but also maximizes productivity in the long run.

Maintenance Tips for B2620 Owners

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By adhering to a structured maintenance routine, you can prevent potential issues and enhance performance.

- Check Fluid Levels: Regularly inspect oil, coolant, and hydraulic fluid levels to ensure optimal functioning.

- Inspect Filters: Change air and fuel filters periodically to maintain clean operation.

- Tire Maintenance: Monitor tire pressure and tread depth to ensure safe handling and efficiency.

By implementing these practices, owners can delve into the ultimate experience of reliable performance and increased lifespan for their machinery.

- Clean Components: Regularly clean external parts to prevent buildup of dirt and debris.

- Battery Care: Inspect battery terminals and connections to prevent electrical issues.

- Service Schedule: Follow a routine maintenance schedule to address wear and tear proactively.

Resources for Kubota Parts

Finding the right components for your machinery is essential for maintaining performance and longevity. Numerous resources exist to assist enthusiasts and professionals alike in locating the necessary items to keep their equipment running smoothly.

Online Marketplaces: Various platforms offer a wide range of items, often with user reviews and detailed descriptions. These sites allow you to compare prices and find the best deals.

Manufacturer Websites: Official websites often provide comprehensive catalogs and guides. These resources ensure you have access to genuine components, which can enhance reliability.

Forums and Community Groups: Engaging with fellow owners in online communities can yield valuable insights and recommendations for sourcing materials. Sharing experiences often leads to discovering trusted suppliers.

Local Dealers: Visiting nearby dealerships can provide personalized service and immediate access to items. Many dealers also offer expertise that can assist in selecting the right components for your needs.

Repair Manuals: These documents are invaluable for understanding the specific requirements of your machinery. They often include detailed information on assembly and compatibility.

Utilizing these resources will ensure that you have everything necessary for optimal performance and durability of your equipment.