For anyone who relies on their equipment for heavy-duty tasks, having a clear grasp of its individual elements is essential. This knowledge not only enhances performance but also extends the lifespan of the machinery. Exploring the intricate arrangement of components allows users to troubleshoot issues effectively and maintain optimal functionality.

In this section, we will delve into the structure of a specific model, breaking down its various elements and their relationships. By familiarizing yourself with these components, you empower yourself to tackle repairs and replacements with confidence, ensuring that your tool operates at its best.

Whether you are a seasoned professional or a hobbyist, understanding the assembly of your machinery can greatly influence your overall experience. We will provide a comprehensive look at each part’s role, making it easier to identify potential wear and tear, as well as necessary upgrades. Embrace this opportunity to deepen your knowledge and enhance your skills.

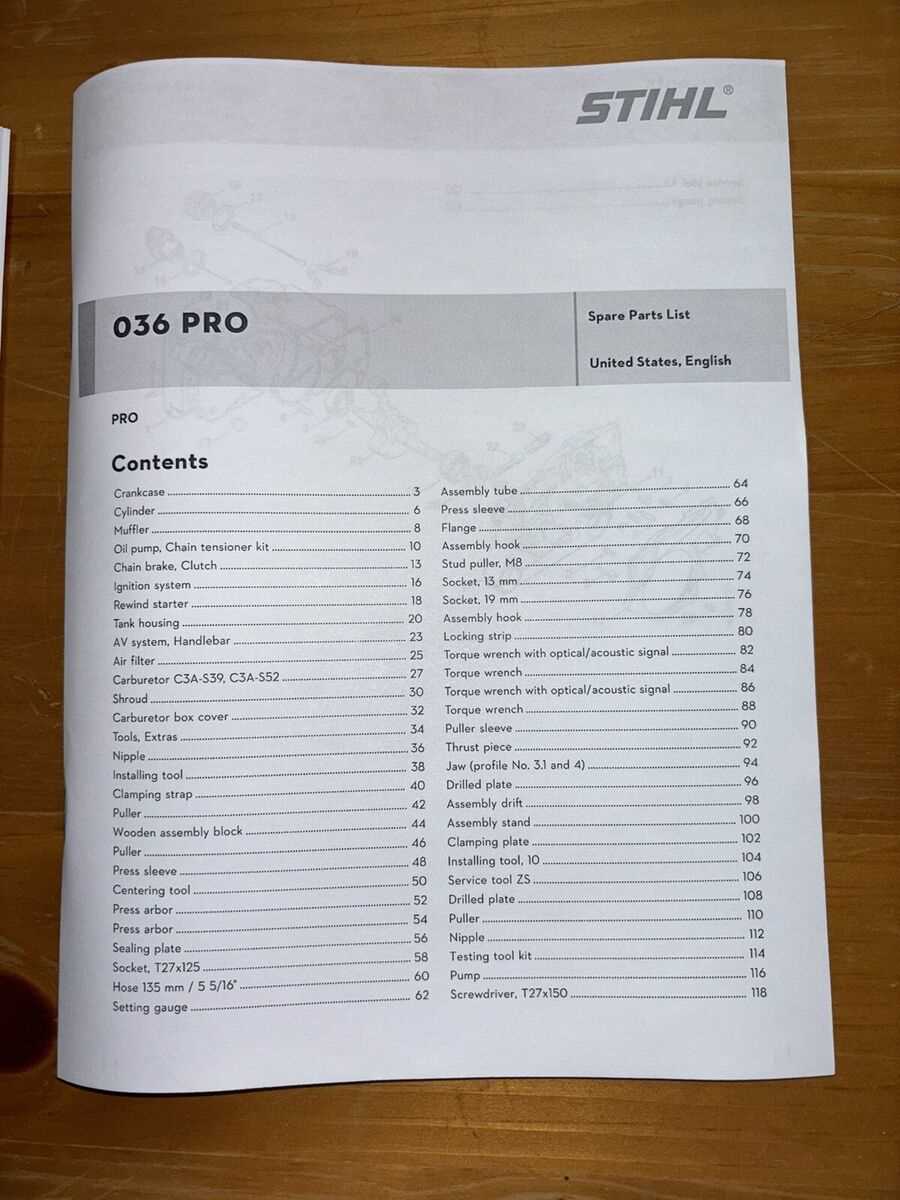

Understanding Stihl 036 Parts

When working with outdoor power equipment, familiarity with the various components is essential for effective maintenance and repair. Each element plays a critical role in the overall functionality, ensuring that the tool operates efficiently and reliably. Knowing the specific functions of these individual items can significantly enhance the user’s experience and prolong the lifespan of the machinery.

In order to grasp the intricacies of these components, it is helpful to categorize them based on their functions and interrelationships. Below is a table that outlines some of the essential elements, their functions, and their significance in the overall system.

| Component | Function | Significance |

|---|---|---|

| Engine | Powers the unit | Crucial for operation |

| Bar and Chain | Cuts through materials | Essential for effectiveness |

| Fuel System | Delivers energy to the engine | Vital for performance |

| Air Filter | Prevents dirt entry | Maintains engine health |

| Starter Mechanism | Initiates engine operation | Key for usability |

By understanding these components and their roles, users can better maintain their equipment, troubleshoot issues, and make informed decisions regarding repairs or replacements. This knowledge not only improves performance but also enhances safety and efficiency during operation.

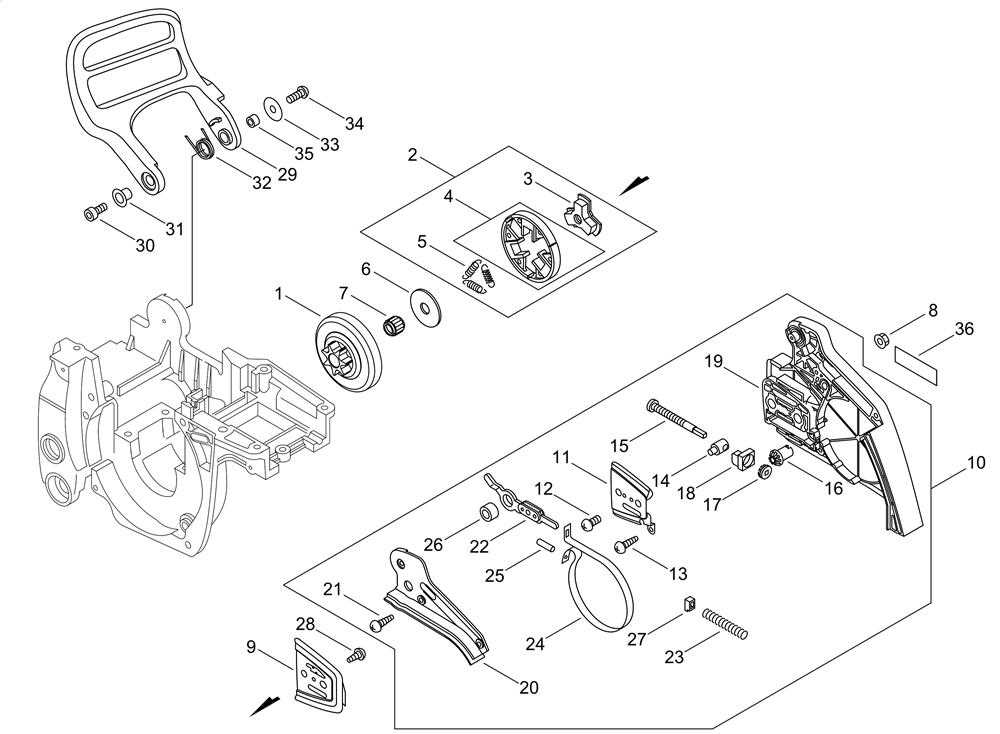

Importance of a Parts Diagram

Understanding the components of a machine is crucial for efficient maintenance and repair. A visual representation aids in identifying each element, ensuring that users can quickly locate and address any issues that arise. This clarity can significantly enhance the overall functionality and longevity of the equipment.

Moreover, having a reference layout fosters a deeper comprehension of how individual pieces work together, promoting better troubleshooting practices. This knowledge not only saves time but also reduces the risk of errors during assembly or disassembly.

| Benefit | Description |

|---|---|

| Efficiency | Streamlines repair processes by clearly showing where each component fits. |

| Accuracy | Minimizes mistakes in identifying and replacing components. |

| Education | Enhances understanding of the machinery’s structure and function. |

Overview of Stihl 036 Chainsaw

This section provides a comprehensive look at a well-regarded model in the realm of cutting tools, known for its reliability and performance. Designed for both professional and recreational users, this device has earned a solid reputation for handling various tasks efficiently. Its robust construction and user-friendly features make it a popular choice among enthusiasts and experts alike.

Key Features

Among the standout attributes of this chainsaw are its powerful engine, lightweight design, and ergonomic handling. The machine is engineered for optimal cutting efficiency, allowing users to tackle thick timber and smaller branches with ease. Durability is also a key consideration, as it is built to withstand the rigors of frequent use while maintaining peak performance.

Maintenance and Care

Proper upkeep is essential to ensure longevity and optimal function. Regular checks on the cutting chain, bar oil levels, and air filters can prevent potential issues and enhance performance. Additionally, following manufacturer guidelines for maintenance will help preserve the tool’s efficiency and safety for all users.

Key Components of the Stihl 036

This section explores the essential elements that contribute to the functionality and performance of this particular power tool. Understanding these components can enhance maintenance practices and improve overall efficiency.

Primary Elements

- Engine Assembly

- Fuel System

- Ignition Module

- Air Filter

- Bar and Chain

Supporting Parts

- Clutch Mechanism

- Handle and Control System

- Housing and Frame

- Exhaust System

Where to Find Authentic Parts

When seeking high-quality components for your outdoor equipment, it’s essential to ensure their authenticity. Genuine parts not only guarantee optimal performance but also enhance the longevity of your machinery. There are various reliable sources to consider when looking for these essential items.

Authorized Dealers

One of the best ways to acquire genuine components is through authorized dealers. These retailers are recognized by the manufacturer and often carry a wide range of original replacements. They can provide expert advice and assistance in selecting the correct items for your equipment.

Online Marketplaces and Manufacturer Websites

Another convenient option is to explore online marketplaces and the manufacturer’s official website. Many companies offer direct sales of their products, ensuring that you receive only authentic items. Be sure to check customer reviews and ratings to avoid counterfeit goods. Additionally, specialized online retailers may also have extensive inventories of original components.

How to Read the Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These visual guides simplify the complexity of the machinery, allowing users to identify and locate individual elements with ease.

Follow these steps to enhance your comprehension:

- Familiarize Yourself with Symbols: Each element is represented by specific icons or notations. Knowing these will help you recognize different parts quickly.

- Trace Connections: Pay attention to how components are linked. Arrows or lines usually indicate relationships or flow, which is crucial for troubleshooting.

- Refer to the Legend: Most schematics include a legend explaining the symbols and their meanings. Use this as a guide while you study the layout.

- Break It Down: Start with one section at a time. Understanding each segment before moving on prevents feeling overwhelmed.

- Take Notes: Write down any observations or questions as you explore. This will aid in recalling information later.

By practicing these techniques, you will ultimately become proficient in interpreting technical visuals, enhancing your repair skills.

Common Issues with Stihl 036

When operating outdoor power equipment, users may encounter various challenges that affect performance and reliability. Identifying these common problems is essential for maintaining optimal functionality and prolonging the lifespan of the machine.

Frequent Problems

Users often report issues such as difficulty starting, poor fuel efficiency, and inconsistent power output. These can stem from several underlying factors that need to be addressed promptly.

Maintenance Recommendations

Regular maintenance is crucial for preventing these issues. Keeping components clean and well-lubricated can significantly improve performance.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Difficulty Starting | Clogged air filter, faulty spark plug | Clean or replace filter, check spark plug |

| Poor Fuel Efficiency | Incorrect fuel mixture, dirty carburetor | Ensure proper mix, clean carburetor |

| Inconsistent Power Output | Worn piston rings, fuel blockage | Inspect and replace rings, clear fuel lines |

Replacement Parts You Might Need

When maintaining your outdoor equipment, it’s essential to be aware of the components that may require replacement over time. Understanding the various elements that contribute to the functionality of your tool ensures optimal performance and longevity.

Common Components to Consider

Several key elements often need to be addressed during routine maintenance. These include the fuel system, ignition parts, and the cutting mechanism. Regular inspection of these items can prevent unexpected breakdowns.

Essential Accessories

In addition to critical components, certain accessories can enhance your equipment’s efficiency. Consider acquiring filters for improved air quality and blades that maintain sharpness for better cutting results. Investing in quality replacements is vital for ultimate performance.

Tips for Maintenance and Care

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular attention not only enhances functionality but also minimizes the risk of unexpected failures. By adhering to a consistent maintenance routine, users can enjoy a smoother experience and avoid costly repairs.

Start by regularly inspecting the device for any signs of wear or damage. Pay close attention to critical components, ensuring they are clean and free from debris. Keeping the engine and other parts well-lubricated can significantly improve efficiency and reduce friction-related issues.

It’s also advisable to replace filters and spark plugs as per the manufacturer’s recommendations. Fresh components contribute to better fuel efficiency and overall performance. Furthermore, always use the recommended fuels and lubricants to prevent potential damage from incompatible substances.

Finally, storing the equipment in a dry, sheltered area when not in use will help protect it from environmental factors that could lead to deterioration. By following these straightforward practices, users can maintain their tools in peak condition for years to come.

Benefits of Using Original Parts

When it comes to maintaining and enhancing the performance of machinery, the choice of components plays a crucial role. Utilizing authentic replacements ensures optimal functionality and longevity, providing significant advantages over generic alternatives.

Quality Assurance: Genuine components are manufactured to meet rigorous standards, ensuring superior quality and reliability. This attention to detail minimizes the risk of malfunction and enhances the overall efficiency of the equipment.

Perfect Fit: Original components are designed specifically for the machinery they support. This guarantees a precise fit, reducing wear and tear and promoting seamless operation. A perfect fit also simplifies installation, saving time and effort.

Enhanced Performance: Using authentic replacements can significantly improve the performance of the equipment. These components are engineered to work in harmony with the machine, delivering optimal power and efficiency, which can ultimately lead to better productivity.

Long-Term Savings: Although the initial investment in genuine components may be higher, the long-term benefits often outweigh the costs. The durability and reliability of authentic parts lead to fewer repairs and replacements, resulting in cost savings over time.

Warranty Protection: Many manufacturers offer warranties on their machinery, which often require the use of original components for coverage. Using genuine replacements helps maintain this warranty, providing peace of mind and financial protection in case of issues.

Resale Value: Keeping equipment in top condition with authentic replacements can enhance its resale value. Potential buyers are often more inclined to purchase well-maintained machinery that has used original components throughout its life.

Step-by-Step Repair Guide

This guide aims to provide a comprehensive approach to troubleshooting and fixing common issues with outdoor power equipment. Following these detailed steps will help ensure effective maintenance and restore functionality.

- Identify the Problem:

Begin by diagnosing the issue. Listen for unusual sounds or observe any performance irregularities.

- Gather Necessary Tools:

Collect all required tools for the repair, such as screwdrivers, wrenches, and replacement components.

- Refer to the Manual:

Consult the equipment manual for specifications and troubleshooting tips specific to your model.

- Disassemble Carefully:

Take apart the unit step by step, keeping track of each component and hardware.

- Inspect Components:

Examine each part for signs of wear or damage. Replace any faulty pieces.

- Reassemble the Unit:

Put the equipment back together, ensuring all parts are secured properly.

- Test the Equipment:

Run the machine to confirm that it operates smoothly. Make adjustments if necessary.

By following these steps, you can delve into the repair process and achieve the ultimate goal of restoring your equipment’s performance.

Resources for Further Assistance

When dealing with machinery maintenance and repairs, having access to reliable resources is crucial. Whether you need technical guidance, replacement components, or expert advice, various platforms and services can provide valuable support to ensure your equipment runs smoothly.

Online Communities and Forums

Engaging with fellow enthusiasts and professionals in online forums can be incredibly helpful. These platforms allow users to share experiences, troubleshooting tips, and recommendations for reliable suppliers. Active participation can lead to quick solutions and a deeper understanding of your equipment.

Official Manufacturer Support

Many manufacturers offer dedicated support channels, including websites with comprehensive manuals and troubleshooting guides. Utilizing these resources can help you find accurate information tailored to your specific model.

| Resource Type | Examples | Benefits |

|---|---|---|

| Online Forums | Reddit, Specialized forums | Peer support, diverse insights |

| Manufacturer Websites | Official websites, Customer service | Accurate information, Warranty support |

| Video Tutorials | YouTube, DIY channels | Visual guidance, step-by-step instructions |