Chainsaw users often face challenges in understanding how various mechanisms work together to deliver reliable performance. Knowing how individual elements fit within the larger system can help users maintain, repair, and optimize their tools for better functionality. By familiarizing yourself with the layout and core components, you can ensure smoother operation and prolonged equipment life.

In this section, we will explore the key elements that make up one of the most commonly used chainsaw models. We will provide a detailed breakdown of various internal and external mechanisms, highlighting their purpose and significance. Whether you’re a seasoned operator or new to the field, understanding these structural components will enhance your ability to troubleshoot and maintain your tool effectively.

Our guide will walk you through the entire setup, ensuring that each part’s role is clear and easy to identify. With this knowledge, you’ll be better equipped to handle repairs, replacements, and routine maintenance, keeping your chainsaw in peak condition for years to come.

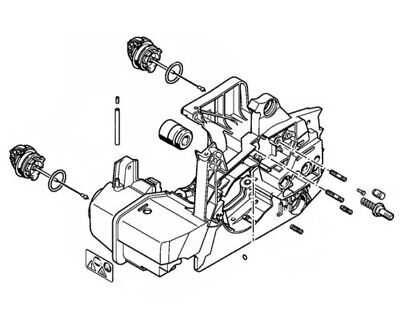

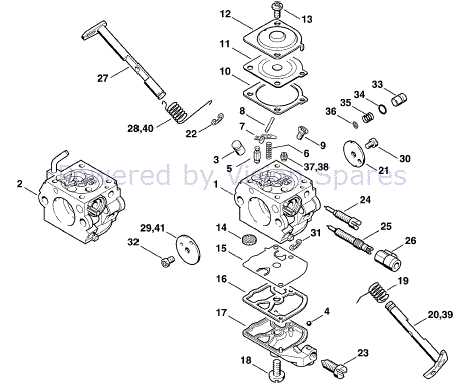

Comprehensive Overview of MS230 Components

This section provides a detailed exploration of key elements found within the mechanism of a widely used chainsaw model. Understanding these components helps ensure optimal performance and easier maintenance, whether for repair or regular upkeep. Each piece works in harmony, playing a crucial role in the machine’s efficiency and durability.

- Engine Assembly: This is the core of the system, responsible for converting fuel into power, allowing the machine to perform cutting tasks efficiently.

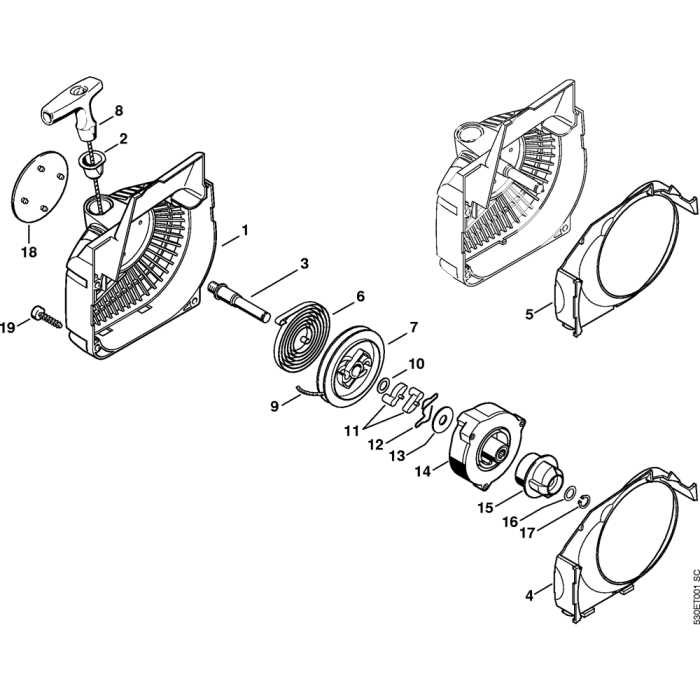

- Starter Mechanism: A crucial element that initiates the machine’s function, this part allows for easy activation through manual effort.

- Fuel System: Includes components such as the fuel tank, lines, and filters, ensuring that the engine receives a steady supply of clean fuel.

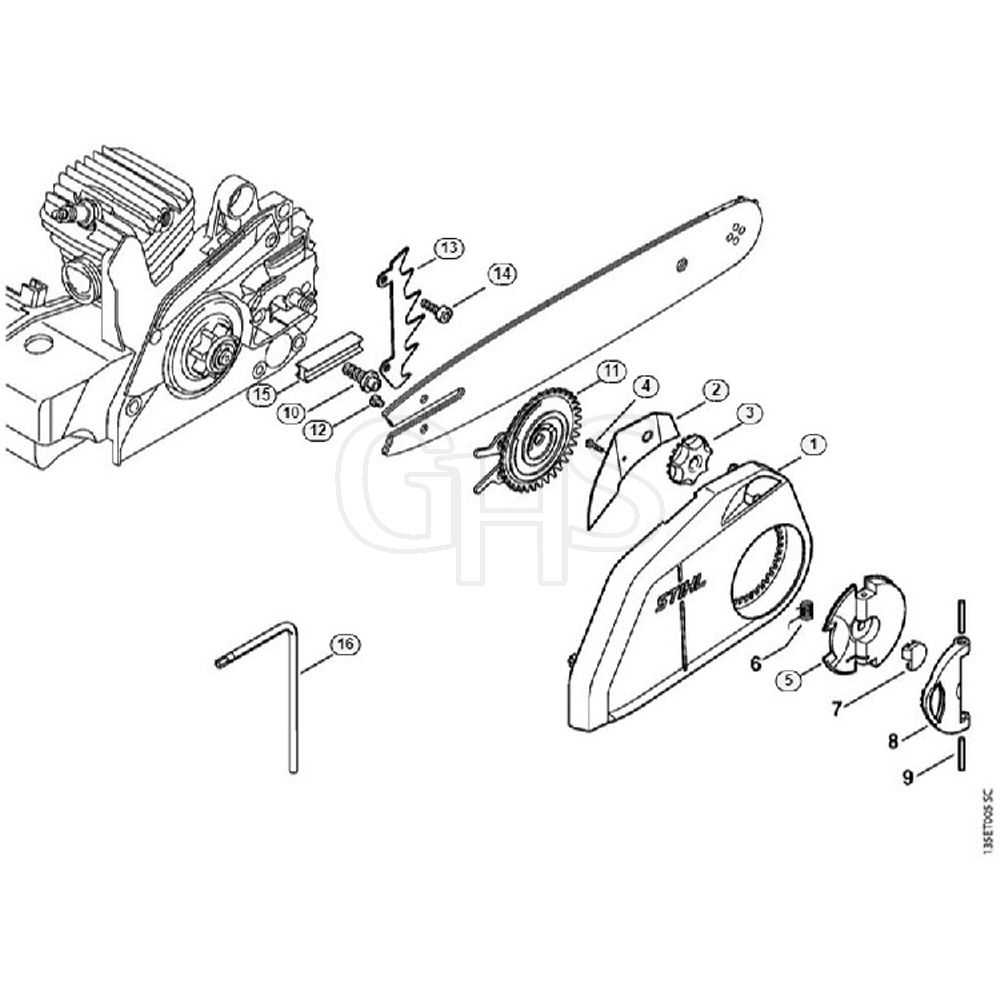

- Chain and Bar: These essential parts work together to execute the cutting action,

Key Engine Parts and Their Functions

In any combustion mechanism, there are critical components that work together to ensure smooth operation. Understanding these elements helps in identifying possible issues and optimizing performance. This section focuses on the primary components and their respective roles in ensuring efficient functionality.

Component Function Cylinder Provides the chamber where fuel combustion occurs, driving the piston. Piston Moves up and down within the cylinder, converting combustion energy into mechanical motion. Crankshaft Transforms the reciprocating motion of the piston into rotational motion, powering the tool. Spark Plug Ignites the fuel-air Guide to Chainsaw Cutting Attachments

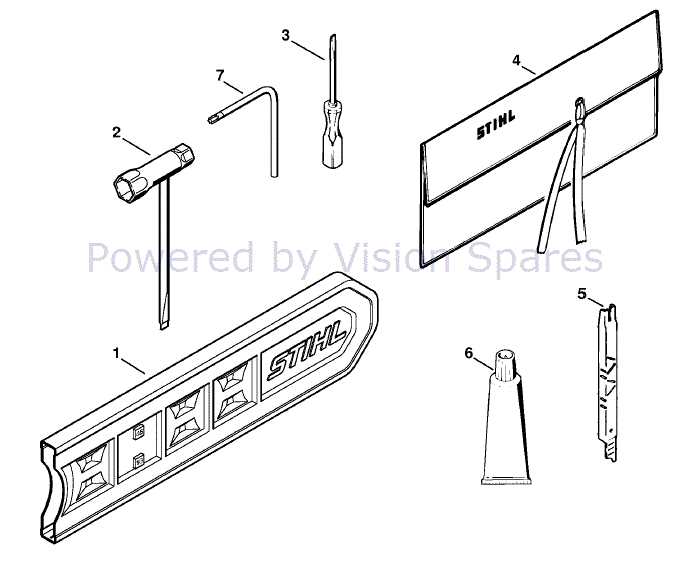

Understanding the various cutting attachments for chainsaws is essential for maximizing both performance and safety. Whether you’re handling light tasks or tackling heavy-duty projects, the right accessory can make a significant difference. This guide will help you navigate through the different options available and choose the best tool for your needs.

Standard Cutting Bar – The most common attachment, ideal for general woodcutting. This bar comes in various lengths to accommodate different jobs, from small branches to thicker logs. Choosing the appropriate size ensures smooth and efficient operation.

Low-Kickback Chains – These are designed to minimize the risk of dangerous kickback, enhancing safety during operation. They are especially suitable for beginners or those working in tighter spaces where precision and control are critical.

Specialized Blades for Hardwood – For cutting through dense or hardwood materials, specialized blades are available that provide greater durability and cutting strength. These are engineered to withstand tougher conditions

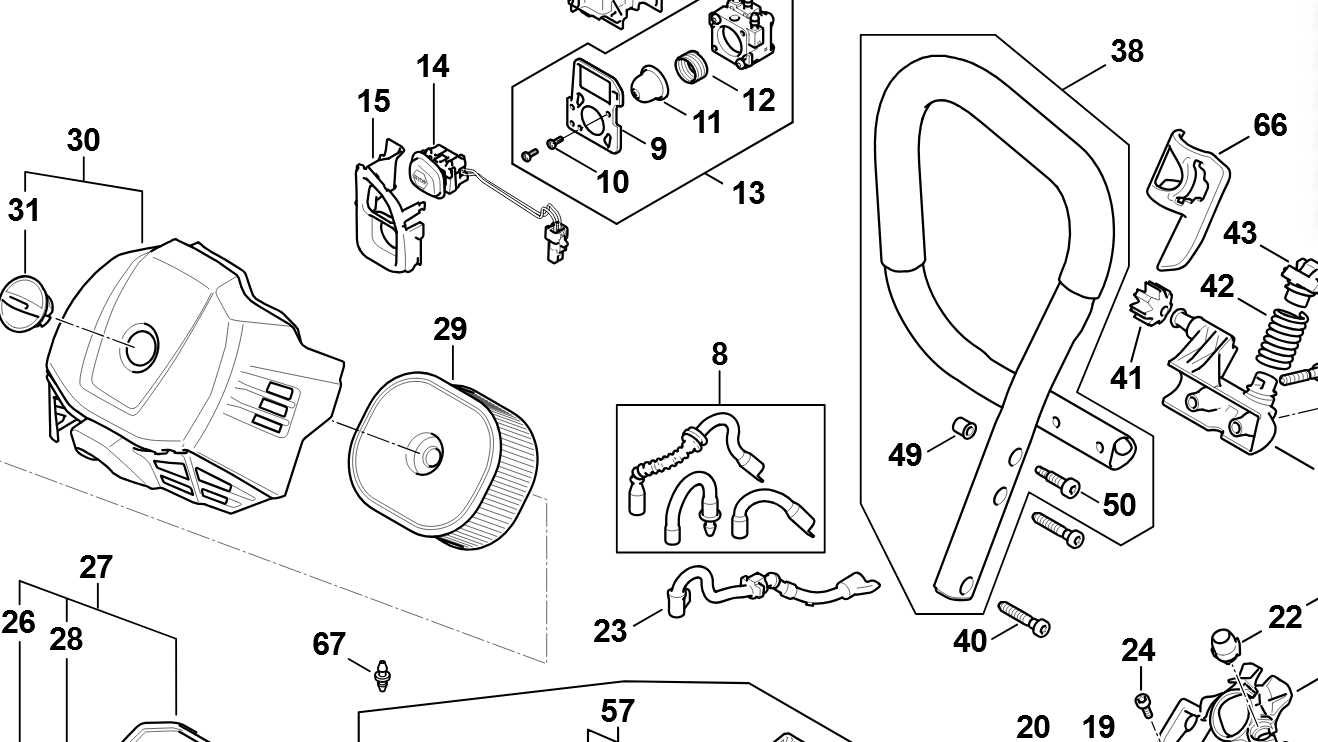

Fuel System: Essential Elements and Maintenance

The fuel system plays a crucial role in ensuring smooth operation by providing a steady flow of energy. Proper maintenance of this system is essential for optimal performance, preventing issues related to efficiency or power loss.

Key components within the system work together to regulate fuel flow and combustion. Regular upkeep of these elements ensures the system runs reliably, minimizing the risk of breakdowns.

- Fuel Filter: Helps prevent contaminants from entering, ensuring clean fuel reaches the engine.

- Fuel Line: Transports liquid to the necessary components, maintaining a consistent supply.

- Carburetor: Mixes the fuel with air in proper proportions for efficient combustion.

To maintain the system, periodically inspect and clean the components. Replace any worn or damaged parts to avoid disruptions during operation. Regular care ensures long-lasting and efficient functionality.

Understanding the Ignition Mechanism

The ignition system plays a crucial role in ensuring smooth engine operation. It is responsible for generating the necessary energy to ignite the fuel-air mixture within the engine’s combustion chamber, ultimately powering the entire machine. A solid grasp of how this mechanism works can greatly aid in diagnosing any potential issues and maintaining efficient engine performance.

Below is a simple breakdown of key components involved in this process and their functions:

Component Function Spark Plug Generates the spark needed to ignite the fuel mixture. Ignition Coil Transforms low voltage into a high-voltage current required by the spark plug. Flywheel Works in conjunction with the ignition system to create the magnetic field needed for spark generation. Understanding how each part contributes to the overall ignition process will help you troubleshoot and maintain the system more effectively.

Exhaust System Parts and Troubleshooting

The exhaust assembly is crucial for the efficient operation of any power tool, playing a vital role in the expulsion of combustion gases. A well-functioning exhaust system ensures optimal performance, reducing emissions and preventing potential damage to the engine. Understanding the components involved and common issues that may arise is essential for maintaining the longevity and efficiency of your equipment.

Key Components of the Exhaust Assembly

The exhaust assembly comprises several essential elements, including the muffler, exhaust pipe, and gaskets. Each of these components works together to facilitate the safe release of exhaust gases. The muffler minimizes noise produced during operation, while the exhaust pipe directs the gases away from the engine. Gaskets provide a tight seal, preventing any leaks that could lead to performance issues.

Troubleshooting Common Issues

When problems arise within the exhaust assembly, they can manifest in various ways, such as decreased power output, unusual noises, or increased emissions. One common issue is a clogged muffler, which can hinder exhaust flow and lead to overheating. Regular inspection and cleaning of the exhaust components are essential to address any buildup. Additionally, checking the gaskets for wear and replacing them when necessary can help maintain proper sealing and prevent exhaust leaks.

Handle Assembly and Vibration Control

The handle assembly plays a crucial role in the overall functionality and user experience of outdoor power equipment. This component not only provides a secure grip for operation but also significantly contributes to managing the vibrations generated during use. Understanding the design and mechanisms involved in the handle assembly is essential for ensuring optimal performance and user comfort.

Effective vibration control is vital in reducing operator fatigue and enhancing precision during tasks. Modern designs often incorporate various materials and techniques aimed at dampening vibrations. These innovations can include vibration-absorbing grips and specialized mounting systems that isolate the user from excessive movement. As a result, operators can work for extended periods without discomfort, improving both safety and efficiency.

In summary, the handle assembly is integral not only for user interaction but also for minimizing vibration impacts. By focusing on ergonomic design and advanced vibration control methods, manufacturers aim to enhance the overall usability of their equipment, ensuring that users can perform their tasks effectively while maintaining comfort.

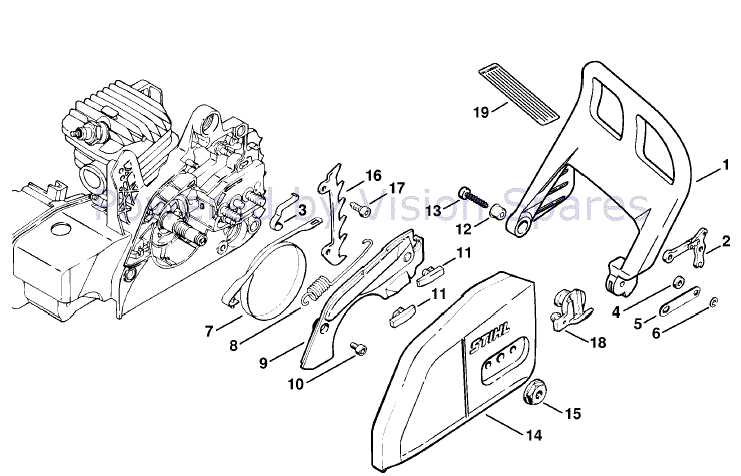

How the Chain Brake System Works

The chain brake system is a critical safety feature in many cutting devices. Its primary purpose is to prevent accidents by stopping the chain from moving when certain conditions are met. Understanding how this mechanism operates can enhance user safety and improve overall handling of the equipment.

Here’s a breakdown of the essential components and their functions:

- Brake Band: This flexible strap wraps around the clutch drum. When engaged, it tightens to halt the chain’s movement.

- Activation Mechanism: Often activated by a lever or guard, this mechanism allows the user to engage the brake quickly in case of an emergency.

- Spring: A tension spring helps return the brake to its original position once the lever is released, allowing the chain to operate normally.

- Indicator: Some models feature a visual indicator to inform the operator whether the brake is engaged or disengaged, ensuring clear communication about the system’s status.

Operationally, when the user pulls the brake lever or the guard is pushed forward, the brake band tightens around the drum, stopping the chain. This process occurs swiftly to minimize potential injuries.

Regular maintenance of the chain brake system is crucial. Keeping the components clean and well-lubricated ensures proper functionality and longevity. Inspecting the activation mechanism regularly can also prevent malfunctions, ensuring the safety features remain reliable during operation.

Air Filtration Components and Upkeep

Proper air filtration is crucial for maintaining the efficiency and longevity of outdoor power equipment. The effectiveness of the air intake system directly impacts performance and engine health. Understanding the various components involved and adhering to regular maintenance practices can significantly enhance functionality.

The key components of an air filtration system include:

- Air Filter: This is the primary barrier that prevents dirt and debris from entering the engine. It is essential to choose the right type and ensure it is clean and intact.

- Pre-Filter: Often a foam or mesh layer that captures larger particles, extending the life of the main air filter.

- Filter Housing: This encases the filter, ensuring a secure fit and proper airflow. It should be checked for cracks or wear.

To maintain optimal performance, follow these upkeep tips:

- Regular Cleaning: Inspect and clean the air filter according to the manufacturer’s recommendations. A clean filter promotes better airflow and engine efficiency.

- Replacement Schedule: Adhere to a replacement schedule based on usage. A clogged filter can restrict airflow and cause engine issues.

- Inspect Surroundings: Ensure that the air intake area is free from obstructions and debris that may affect airflow.

By staying proactive with these components and maintenance practices, you can ensure your equipment operates smoothly and reliably over time.

Bar and Chain Tension Adjustment

Proper adjustment of the guide and cutting element tension is crucial for optimal performance and longevity of the equipment. A correctly tensioned system ensures efficient cutting while minimizing wear on components. This section outlines the steps necessary to achieve the ideal tension for the bar and chain.

Before beginning the adjustment process, ensure that the machine is turned off and placed on a stable surface. Gather the necessary tools for the task, which typically include a wrench and a screwdriver.

- Loosen the tensioning mechanism slightly to relieve pressure on the chain.

- Check the chain for sagging or excessive tightness by pulling it away from the guide.

- Adjust the tension by turning the tensioning screw or lever clockwise to increase tension or counterclockwise to decrease it.

- Once the desired tension is achieved, secure the tensioning mechanism by tightening it while ensuring that the chain can still be rotated by hand.

- Test the chain’s movement to confirm it glides smoothly along the guide without excessive slack.

Regular checks and adjustments will not only enhance cutting efficiency but also prolong the lifespan of the components. Adopting a routine maintenance schedule can prevent issues that arise from improper tension settings.

Commonly Replaced Parts in Stihl MS230

Maintenance and longevity of equipment often rely on the timely replacement of key components. Understanding which elements typically require attention can enhance performance and reliability. Various factors contribute to wear and tear, necessitating periodic updates to specific pieces for optimal functionality.

High-Impact Components

Air Filters are crucial for maintaining engine efficiency. Regular replacement prevents dirt and debris from entering, ensuring a smooth operation. Additionally, spark plugs play a vital role in ignition; worn or damaged plugs can lead to misfires or difficulty starting the engine.

Wear-Prone Items

Another frequently changed item includes fuel lines, which can degrade over time, affecting fuel delivery. Likewise, chains and bars experience wear due to constant friction, requiring regular inspection and replacement to ensure cutting efficiency and safety.