The intricate design of agricultural machinery plays a crucial role in enhancing productivity on farms. Understanding the various elements that make up these machines can greatly aid in effective maintenance and troubleshooting. Each segment is engineered for specific functions, ensuring that operations run smoothly and efficiently.

In this section, we will delve into the structure of a specific agricultural vehicle, focusing on its numerous components. Identifying and comprehending the relationships between these elements can help operators and technicians perform necessary repairs and upgrades, ultimately extending the lifespan of the machinery.

Whether you are a seasoned professional or a newcomer to the field, familiarizing yourself with the configuration of these vital tools is essential. This knowledge not only aids in everyday operations but also empowers individuals to make informed decisions regarding repairs and replacements.

This section provides a comprehensive insight into a popular agricultural machinery model known for its durability and efficiency. Understanding its components is essential for maintenance and repair, enabling operators to optimize performance and extend the equipment’s lifespan. Familiarity with the various elements that make up this machine allows users to identify parts easily and address any issues that may arise during operation.

| Component | Description | Function |

|---|---|---|

| Engine | A robust power unit that drives the machinery. | Provides the necessary power for operation. |

| Transmission | System for transferring power from the engine to the wheels. | Enables speed variation and control. |

| Hydraulic System | Fluid-driven system for lifting and operating attachments. | Facilitates efficient operation of implements. |

| Chassis | The frame that supports the entire structure. | Ensures stability and strength during operation. |

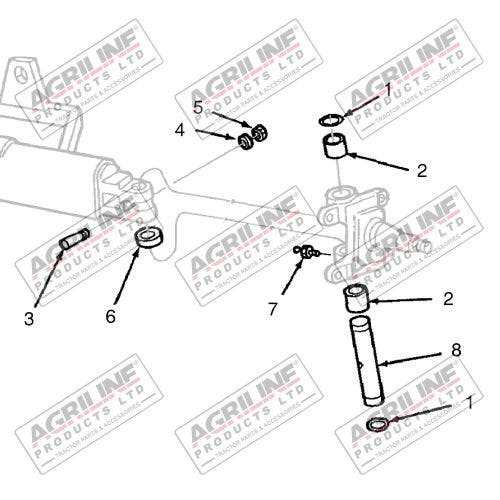

Importance of Parts Diagrams

The use of visual representations of components plays a crucial role in the maintenance and repair of machinery. These illustrations provide detailed insights, enabling users to identify specific elements and their functions within a system.

Understanding assemblies is significantly enhanced through these visual aids, as they break down complex structures into manageable parts. By clearly showing how each piece fits together, users can develop a deeper comprehension of the overall configuration and operations.

Facilitating effective repairs is another key benefit. When individuals have access to clear visuals, they can easily pinpoint faulty components and determine the appropriate actions needed for replacement or adjustments. This not only streamlines the repair process but also minimizes the risk of errors that could arise from misunderstandings.

Moreover, these representations serve as a valuable reference for ordering new components. Users can accurately identify the required items, ensuring they acquire the correct replacements and reducing downtime. In summary, the availability of comprehensive visuals is essential for efficient maintenance practices and optimal performance of machinery.

Common Parts of Ford 6610

This section provides an overview of essential components found in a specific tractor model, focusing on their significance and functionality within the machine’s operation. Understanding these elements can enhance maintenance and repair processes.

- Engine Assembly: The powerhouse of the vehicle, responsible for converting fuel into mechanical energy.

- Transmission System: Facilitates the transfer of power from the engine to the wheels, allowing for various speeds and torque.

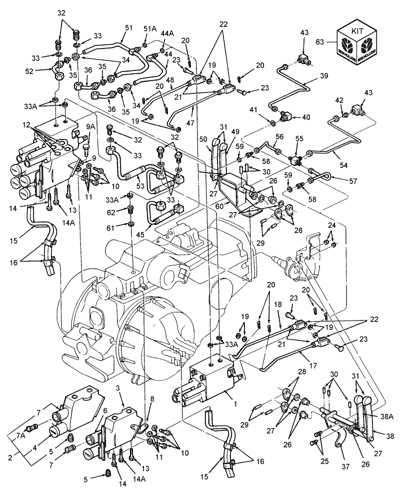

- Hydraulic System: Enables the operation of attachments and implements, providing the necessary force for lifting and moving loads.

- Cooling System: Maintains optimal operating temperatures for the engine, preventing overheating and ensuring efficiency.

- Electrical System: Powers various components, including lights, ignition, and instrumentation, crucial for functionality.

Regular inspection and understanding of these key components contribute to the longevity and reliability of the machinery.

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to identify and locate specific elements within a machine. These illustrations serve as a guide, detailing the relationships and functions of various pieces, allowing for efficient assembly and maintenance. Grasping the layout and notations is essential for effective interpretation.

1. Familiarize Yourself with the Legend: Most illustrations include a legend that explains symbols and color coding used. This is crucial for understanding what each mark signifies, such as different component types or materials.

2. Follow the Flow: Often, these visuals are organized in a way that shows the order of assembly or disassembly. Start from the top or left and move through the sections systematically to avoid confusion.

3. Identify Key Elements: Look for highlighted or bolded sections that indicate critical parts. These are usually the ones that require attention during maintenance or replacement.

4. Use Reference Numbers: Each element typically has a corresponding reference number that links to further details in a catalog or manual. Make sure to match these numbers with their descriptions to ensure you are getting the correct replacements.

5. Practice with Examples: The more you engage with these visuals, the easier it becomes to read and understand them. Use different illustrations to build your familiarity with various layouts and notations.

Sources for Parts Diagrams

Finding accurate representations of components is essential for effective maintenance and repairs. Various resources can aid in locating these visual aids, ensuring you have the necessary information to keep machinery running smoothly.

- Manufacturer Websites: Official sites often provide detailed illustrations of their equipment, including exploded views and component lists.

- Online Retailers: Many suppliers offer comprehensive catalogs featuring images and specifications of available items, making it easy to identify the right parts.

- Forums and Community Groups: Engaging with online communities can yield valuable insights, including shared documents and user-contributed images of specific assemblies.

- Technical Manuals: Obtaining service manuals or guides can provide in-depth visual references alongside troubleshooting advice.

- Dealerships and Local Distributors: Local representatives can offer printed materials or digital resources that include essential visuals and information.

Utilizing these resources can significantly enhance your ability to locate and understand the various components of your equipment, ultimately aiding in effective maintenance and repair processes.

Identifying Ford 6610 Components

Understanding the essential elements of agricultural machinery is crucial for effective maintenance and operation. Each component plays a significant role in the overall functionality of the equipment, ensuring optimal performance during various tasks.

Key Elements: Familiarity with the various segments can enhance troubleshooting efforts. Recognizing these elements allows operators to identify potential issues more swiftly, ultimately leading to timely interventions and repairs.

Visual References: Utilizing illustrations or schematics can provide clarity on where each segment is located and how they interact with one another. This knowledge aids in performing routine inspections and understanding the mechanics of the machine.

Common Components: Key features include the engine assembly, transmission system, hydraulic components, and steering mechanisms. Knowing the function of each of these parts facilitates better operational practices and informs users about maintenance schedules.

Regular Inspection: Routine checks on these essential segments can prevent significant malfunctions. Operators should make it a practice to familiarize themselves with the layout and function of each part to ensure their machinery remains in peak condition.

Maintenance Tips for Ford 6610

Proper upkeep of agricultural machinery is essential for optimal performance and longevity. Routine maintenance helps prevent breakdowns, enhances efficiency, and ensures that equipment operates smoothly throughout its lifespan. This section offers practical guidance to keep your machine in excellent condition.

Routine Checks

Conducting regular inspections is crucial for identifying potential issues before they escalate. Key components to examine include:

| Component | Inspection Frequency | Action Required |

|---|---|---|

| Fluid Levels | Weekly | Check and top up as necessary. |

| Filters | Monthly | Replace as needed to ensure efficiency. |

| Tires | Bi-weekly | Inspect for wear and proper inflation. |

Seasonal Maintenance

Seasonal tasks are important for preparing the machinery for different operational demands. Before heavy usage periods, consider the following:

- Change engine oil and replace the oil filter.

- Inspect belts and hoses for wear or damage.

- Ensure that all safety features are functional.

Ordering Replacement Parts

When it comes to maintaining your machinery, securing the right components is essential for optimal performance. Understanding the process of acquiring new items can significantly enhance the efficiency and longevity of your equipment.

Researching Options: Begin by identifying the necessary components for your machine. Utilize reliable resources such as manufacturer manuals or authorized dealer websites to gather accurate information. Make note of specific details such as model numbers and specifications to ensure compatibility.

Finding Suppliers: Once you have determined what you need, explore various suppliers. Online marketplaces, local distributors, and specialized retailers can provide a range of options. Comparing prices and availability is crucial to making an informed decision.

Placing Your Order: After selecting a supplier, proceed to place your order. Double-check the details of the components to avoid any discrepancies. It may be beneficial to inquire about shipping times and return policies to ensure a smooth transaction.

Tracking Your Shipment: Upon placing your order, monitor its progress. Many suppliers offer tracking services, allowing you to stay informed about the expected delivery date. This information can help you plan for the installation of the new components.

Installation Considerations: Once your items arrive, review them for accuracy before installation. If you encounter any issues, don’t hesitate to reach out to your supplier for assistance. Proper installation is key to maintaining the efficiency and reliability of your machinery.

Popular Upgrades for Ford 6610

Enhancing the functionality and performance of agricultural machinery can significantly improve productivity. Many owners opt for various modifications to optimize their equipment for specific tasks. Below are some widely recommended enhancements that can elevate the efficiency of your machinery.

- Improved Hydraulics: Upgrading to a more powerful hydraulic system can enhance lifting capacity and speed, making it easier to operate attachments.

- Aftermarket Exhaust Systems: Installing a high-performance exhaust can improve engine efficiency, leading to better fuel economy and reduced emissions.

- Enhanced Lighting: Upgrading to LED lights can improve visibility during night operations, increasing safety and efficiency.

- Advanced GPS Technology: Integrating precision farming tools can enhance accuracy in planting and fertilization, leading to higher crop yields.

- Comfortable Cab Accessories: Adding ergonomic seating and climate control systems can enhance operator comfort, resulting in improved productivity during long hours of use.

These modifications not only improve the operational capabilities of your machinery but also contribute to longevity and reliability. Investing in quality upgrades ensures that your equipment remains competitive and efficient in the ever-evolving agricultural landscape.

Tools Needed for Repairs

When tackling maintenance tasks on machinery, having the right equipment is crucial for efficiency and success. This section outlines essential tools that will help ensure repairs are performed effectively, minimizing downtime and enhancing performance.

Basic Hand Tools

Start with a collection of basic hand tools. A set of wrenches and screwdrivers in various sizes will allow you to handle most fasteners. Additionally, pliers and ratchets are invaluable for gripping and loosening components during disassembly.

Specialized Equipment

For more intricate repairs, consider investing in specialized equipment. A torque wrench ensures that bolts are tightened to the manufacturer’s specifications, while a multimeter is essential for diagnosing electrical issues. Keeping a selection of filters and gaskets on hand will also facilitate smoother repairs and replacements.

Common Issues and Solutions

In the realm of agricultural machinery, various challenges can arise that impact efficiency and performance. Understanding these issues is crucial for ensuring optimal operation and longevity of the equipment. Below are some frequent complications encountered, along with effective strategies to address them.

1. Engine Overheating: A common problem that may lead to severe damage is overheating. This can be caused by low coolant levels, a malfunctioning thermostat, or a clogged radiator. To resolve this issue, regularly check coolant levels, replace faulty thermostats, and ensure the radiator is clean and free from obstructions.

2. Hydraulic System Failures: Hydraulic systems are vital for functionality but can experience leaks or pressure drops. Inspect hydraulic lines for wear and tear, and replace any damaged components. Additionally, ensure that the hydraulic fluid is at the proper level and quality.

3. Electrical Issues: Electrical failures can lead to starting problems or erratic behavior of systems. Check the battery condition and connections, as well as inspect wiring for any signs of corrosion or damage. Replacing worn-out batteries and securing loose connections can often restore functionality.

4. Transmission Problems: Difficulties in shifting gears may indicate transmission issues. Regularly check fluid levels and condition, and consider flushing the system if the fluid appears dirty or contaminated. This maintenance can help prevent more serious transmission failures.

5. Tire Wear and Alignment: Uneven tire wear and misalignment can significantly affect performance. Regularly inspect tire pressure and tread depth, and ensure proper alignment through professional servicing when necessary. Keeping tires in good condition enhances safety and efficiency.

By proactively addressing these typical challenges, operators can maintain the functionality and extend the life of their agricultural machinery.

Community Resources and Forums

Engaging with online communities can significantly enhance your experience when seeking information and assistance related to machinery maintenance and repair. Various platforms allow enthusiasts and professionals alike to share their insights, troubleshoot issues, and exchange valuable resources. These spaces foster collaboration and provide a wealth of knowledge, making them indispensable for anyone looking to deepen their understanding of equipment servicing.

Online Discussion Boards

Numerous discussion boards exist where users can ask questions and receive answers from fellow enthusiasts and experts. These platforms often feature categorized topics, allowing users to navigate easily through discussions about specific models or issues. Participating in these forums can lead to valuable connections and prompt solutions to common challenges.

Social Media Groups

Social media has transformed how people connect, and dedicated groups on platforms like Facebook or Reddit serve as excellent resources for individuals seeking help. Members frequently share tips, experiences, and even instructional content that can guide you through various processes. Engaging with these communities can enhance your knowledge and provide ongoing support from like-minded individuals.

Finding a Qualified Technician

When it comes to maintaining and repairing machinery, the expertise of a skilled professional is essential. Identifying a technician who possesses the right knowledge and experience can significantly impact the efficiency and longevity of your equipment. This section will guide you through the key aspects of selecting a qualified specialist to meet your needs.

Begin by considering the following criteria when searching for a technician:

| Criteria | Description |

|---|---|

| Experience | Look for professionals with a solid track record in servicing similar machinery. Their hands-on experience can ensure they understand the nuances of your equipment. |

| Certifications | Verify any relevant certifications that demonstrate their qualifications. Certified technicians have often undergone rigorous training and assessments to validate their skills. |

| Reviews and References | Seek feedback from previous clients. Positive testimonials can provide insights into the technician’s reliability and quality of work. |

| Availability | Ensure the technician can accommodate your schedule, especially if urgent repairs are necessary. Prompt availability can minimize downtime. |

| Cost Estimates | Request detailed quotes from multiple technicians to compare pricing. Be cautious of unusually low estimates, as they may indicate a lack of thoroughness. |

By carefully assessing these factors, you can find a technician who is not only qualified but also aligns with your specific requirements, ensuring optimal performance and maintenance of your machinery.