In the realm of machinery and equipment, a thorough comprehension of the intricate arrangements of various elements is crucial for effective upkeep and operation. A well-structured visual representation can serve as an invaluable tool, facilitating the identification and organization of each unit. This knowledge not only aids technicians during repairs but also enhances the overall efficiency of the device.

By delving into the specifics of how individual pieces interact within a system, users can better appreciate the complexities involved in their functionality. Such insights empower operators to troubleshoot issues swiftly and confidently. Moreover, a detailed overview can illuminate the pathways for upgrades and modifications, ultimately leading to improved performance and longevity.

In this exploration, we will examine the various configurations that underpin the assembly, allowing for a clearer perspective on maintenance strategies. Understanding these layouts can significantly contribute to a smoother operational experience and reduce downtime, ensuring that the equipment remains in peak condition.

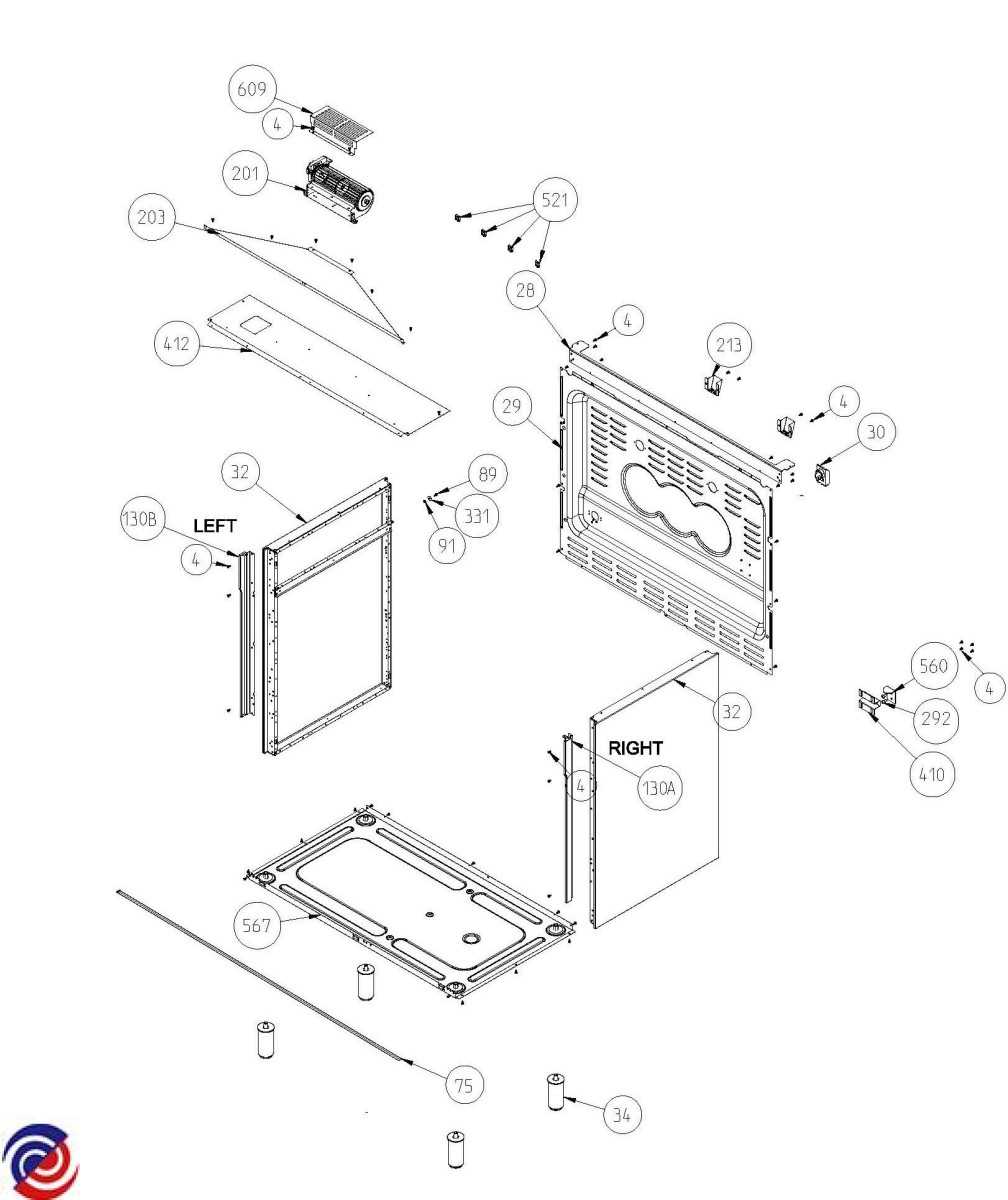

Understanding the Koce500ess Components

This section aims to explore the essential elements that comprise a specific mechanical system. Each component plays a vital role in the overall functionality and performance, contributing to the seamless operation of the machinery.

| Component Name | Description | Function |

|---|---|---|

| Element A | Main driving unit | Provides the necessary power for operation |

| Element B | Control module | Regulates performance and settings |

| Element C | Support frame | Houses and stabilizes other components |

| Element D | Cooling system | Maintains optimal temperature during operation |

Essential Parts of the Koce500ess

Understanding the fundamental components of a machine is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring the overall functionality and longevity of the equipment. Familiarity with these elements can enhance performance and facilitate troubleshooting when issues arise.

Core Components

The primary elements include the power unit, control interface, and structural frame. The power unit drives the entire mechanism, while the control interface allows users to manage settings and operations effectively. The structural frame provides stability and support, housing the essential systems securely.

Supporting Elements

Additional features such as sensors, connectors, and safety mechanisms contribute to optimal performance. Sensors monitor operational parameters, connectors facilitate communication between components, and safety mechanisms ensure secure usage, preventing accidents and malfunctions.

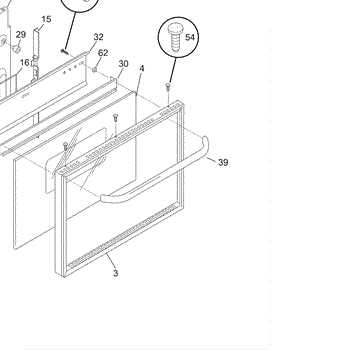

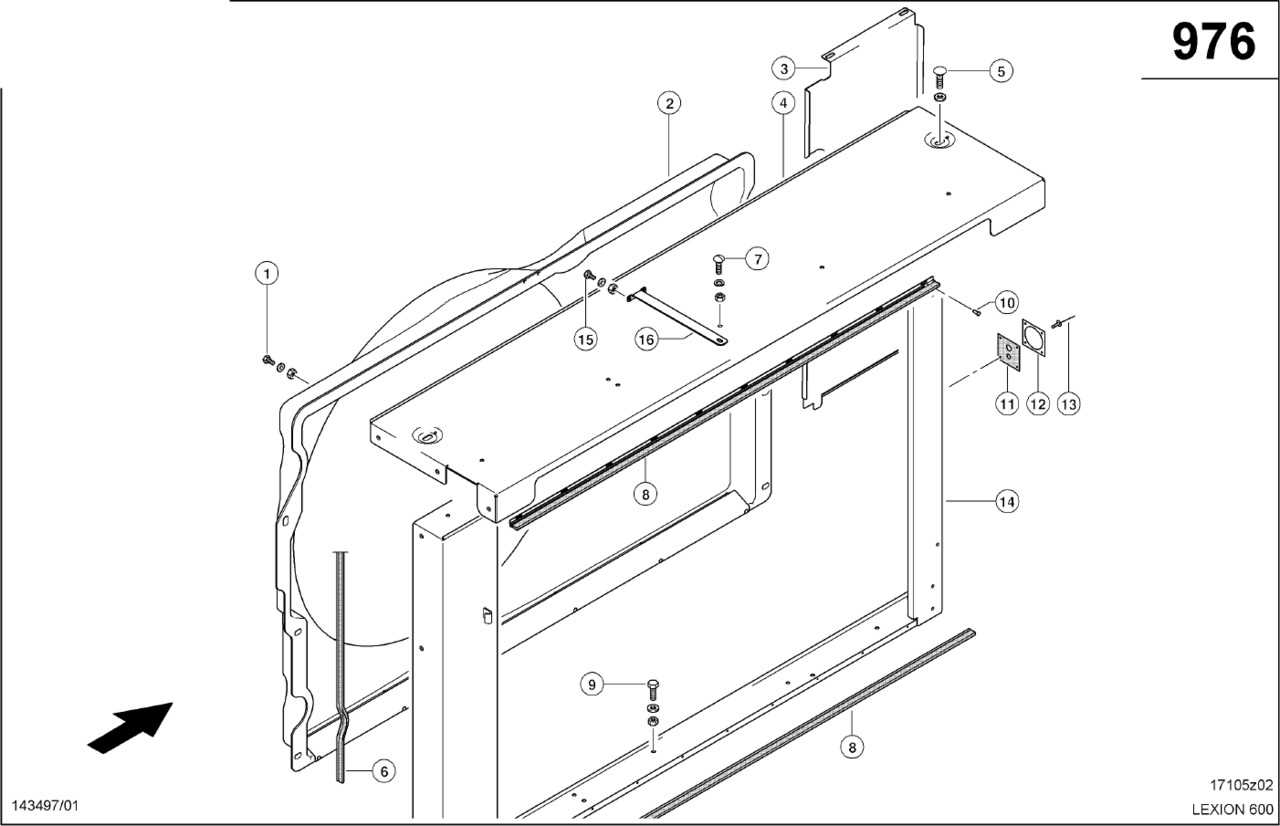

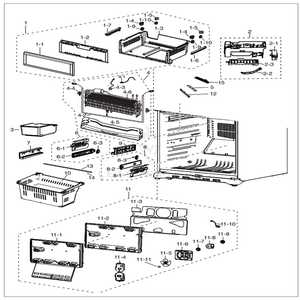

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to identify and work with individual elements in any system. Mastering this skill allows you to navigate complex structures effectively.

Here are some key steps to help you comprehend these visuals:

- Familiarize Yourself with Symbols: Different illustrations use unique symbols for various elements. Learn what each symbol represents.

- Identify the Layout: Recognize how the components are arranged. This can indicate how they interact within the system.

- Look for Labels: Many visuals include labels that provide additional context. Pay attention to these annotations.

- Trace Connections: Follow lines or arrows that show how different elements connect. This can reveal relationships and functions.

- Use a Legend: If available, refer to the legend for explanations of specific icons or markings.

By delving into these aspects, you can develop a comprehensive understanding of how each element contributes to the overall functionality.

Common Issues with Koce500ess Parts

When dealing with mechanical components, several challenges can arise that affect functionality and performance. Understanding these common obstacles can help in maintaining optimal operation and prolonging lifespan.

- Wear and Tear: Over time, components may degrade, leading to inefficiencies.

- Misalignment: Improper installation can result in parts not fitting correctly, causing strain.

- Corrosion: Exposure to moisture can lead to rust, which compromises integrity.

- Foreign Object Ingress: Debris can obstruct functionality, necessitating regular cleaning.

Regular inspection and maintenance can help mitigate these issues, ensuring reliable operation.

Maintenance Tips for Longevity

Regular care is essential to ensure your appliance continues to function efficiently over time. Consistent attention to key areas can significantly extend its operational life, preventing issues that may lead to costly repairs. By following simple guidelines, you can avoid unnecessary wear and tear, keeping everything running smoothly.

First, make sure to clean surfaces frequently, removing any buildup of debris that can impact performance. Secondly, inspect connections periodically to confirm that everything remains secure and functional. If any components seem worn out or damaged, addressing these promptly will minimize the risk of further complications.

Lastly, ensure that the device operates within its recommended conditions, such as temperature or load capacity, to avoid overexertion. Regular servicing by professionals is also a good way to identify potential issues before they escalate, contributing to long-term reliability.

Upgrading Components: What to Know

When it comes to enhancing the performance or extending the life of your equipment, replacing or upgrading certain elements can make a significant difference. Whether you’re looking to improve efficiency, address wear and tear, or integrate more advanced technologies, it’s important to understand the key factors involved before proceeding with changes.

Key Factors to Consider

Before beginning any update, it’s essential to evaluate compatibility with existing elements, as well as the specifications of the new items you plan to introduce. Ensuring that the chosen components fit seamlessly with the original setup can prevent unnecessary problems and ensure smooth operation. You should also consider any potential performance gains or long-term durability improvements.

Commonly Updated Elements

Some components may require more frequent updates than others due to exposure to high wear, technological advancements, or specific operational demands. Below is a table listing typical areas of focus during upgrades:

| Component | Purpose

Where to Find Replacement PartsWhen it’s time to refresh or repair your device, knowing where to source compatible components is essential. Many options are available, from local stores to online platforms, providing solutions for maintaining the functionality and longevity of your appliance. Whether you’re looking for internal mechanisms or external hardware, a variety of reliable sources can be explored. Authorized DealersOne of the most dependable options is to contact certified sellers or service centers. These vendors specialize in providing manufacturer-approved materials, ensuring compatibility and quality. It’s an excellent choice for those who prioritize original standards and longevity in their equipment. Online PlatformsIn the digital age, various e-commerce platforms provide an array of components for virtually any model. These platforms offer customer reviews and ratings, which help you make informed choices. They also often provide a wide selection, from newer versions to older Comparing Koce500ess to Similar Models

When evaluating appliances in this category, it is essential to consider the unique features that set one model apart from another. Each product offers a blend of innovative design, functionality, and performance, tailored to meet the needs of modern users. By comparing various models, it becomes easier to determine which unit best suits specific preferences and kitchen configurations.

|

|---|