When working with various fastening tools, having a clear understanding of their individual components is essential for effective operation and maintenance. Each element plays a crucial role in ensuring that the device functions smoothly and efficiently, allowing users to achieve the best results in their projects. Recognizing how these parts interact can significantly enhance the overall experience and performance of the tool.

In this section, we will explore the intricate layout of a fastening device, highlighting the significance of each component. From the mechanism that drives the fasteners to the housing that protects the internal workings, every aspect is designed with precision. By familiarizing yourself with this configuration, you can better troubleshoot issues and conduct necessary repairs, ultimately prolonging the lifespan of your equipment.

Whether you’re a professional craftsman or a DIY enthusiast, understanding the structure of your fastening tool will empower you to use it more effectively. Knowledge of its anatomy will not only improve your skill set but also increase your confidence when tackling various projects. Let’s delve into the specifics and uncover the essential elements that contribute to the successful operation of these invaluable instruments.

This section aims to provide a comprehensive overview of the essential elements that make up a specific tool used in construction and carpentry. Understanding these components can greatly enhance one’s ability to troubleshoot issues, perform maintenance, and optimize performance during various tasks.

| Component | Description |

|---|---|

| Housing | The outer casing that protects the internal mechanisms and provides a handle for operation. |

| Trigger Mechanism | A system that activates the tool, allowing for controlled firing of fasteners. |

| Piston | A crucial element that drives the fastener into the material, powered by air pressure or combustion. |

| Magazine | The compartment that holds the fasteners, enabling continuous use without frequent reloading. |

| Safety Mechanism | A feature designed to prevent accidental discharge, ensuring safe operation. |

| Exhaust Port | A section that allows for the release of air, keeping the tool cool and functioning effectively. |

Overview of Nail Gun Mechanism

This section delves into the essential workings of a fastening device, outlining how its internal components interact to achieve efficient performance. Understanding this mechanism is crucial for both users and technicians, ensuring effective operation and maintenance.

The primary function of the device is to drive fasteners into various materials quickly and accurately. Several key elements contribute to this process:

- Power Source: The energy required to operate the tool can come from different sources, including compressed air, electricity, or combustion.

- Actuation Mechanism: This component controls how the fastener is released, which can be either sequential or contact-triggered.

- Feeding System: A reliable feeding mechanism ensures a steady supply of fasteners, allowing for uninterrupted work.

- Driving Mechanism: This is responsible for pushing the fastener into the material with precision and force.

In summary, each of these elements plays a vital role in the overall functionality of the fastening device, enhancing its effectiveness in various applications.

Common Parts and Their Functions

Understanding the essential components of a fastening tool can enhance its usage and maintenance. Each element plays a significant role in the overall functionality, ensuring efficiency and precision in operations. Familiarizing oneself with these crucial elements will facilitate troubleshooting and enhance performance.

Main Components

- Trigger: This initiates the fastening process and provides user control over the operation.

- Motor: Powers the mechanism, driving the movement necessary for securing materials together.

- Guide: Ensures proper alignment of the fastening material, contributing to accuracy in placement.

- Housing: The outer shell that protects internal mechanisms and provides structural integrity.

Supporting Elements

- Spring: Stores energy and assists in the return motion after each fastening action.

- Piston: Transfers the force generated by the motor to the fastening element, impacting it with precision.

- Exhaust Port: Allows for the release of air pressure, maintaining optimal function and preventing buildup.

- Depth Adjustment Wheel: Enables users to modify the depth of the fastening for various materials.

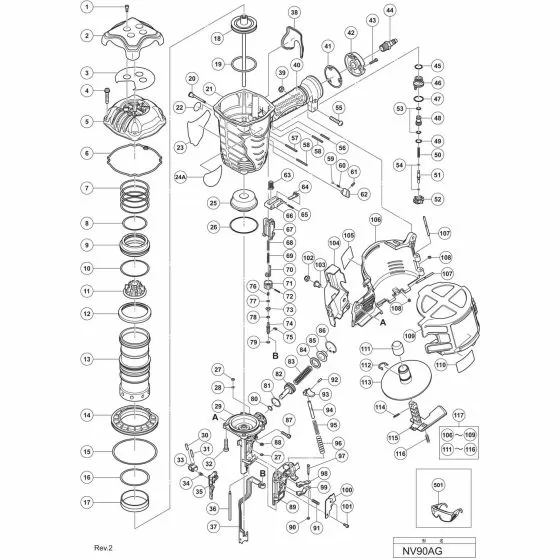

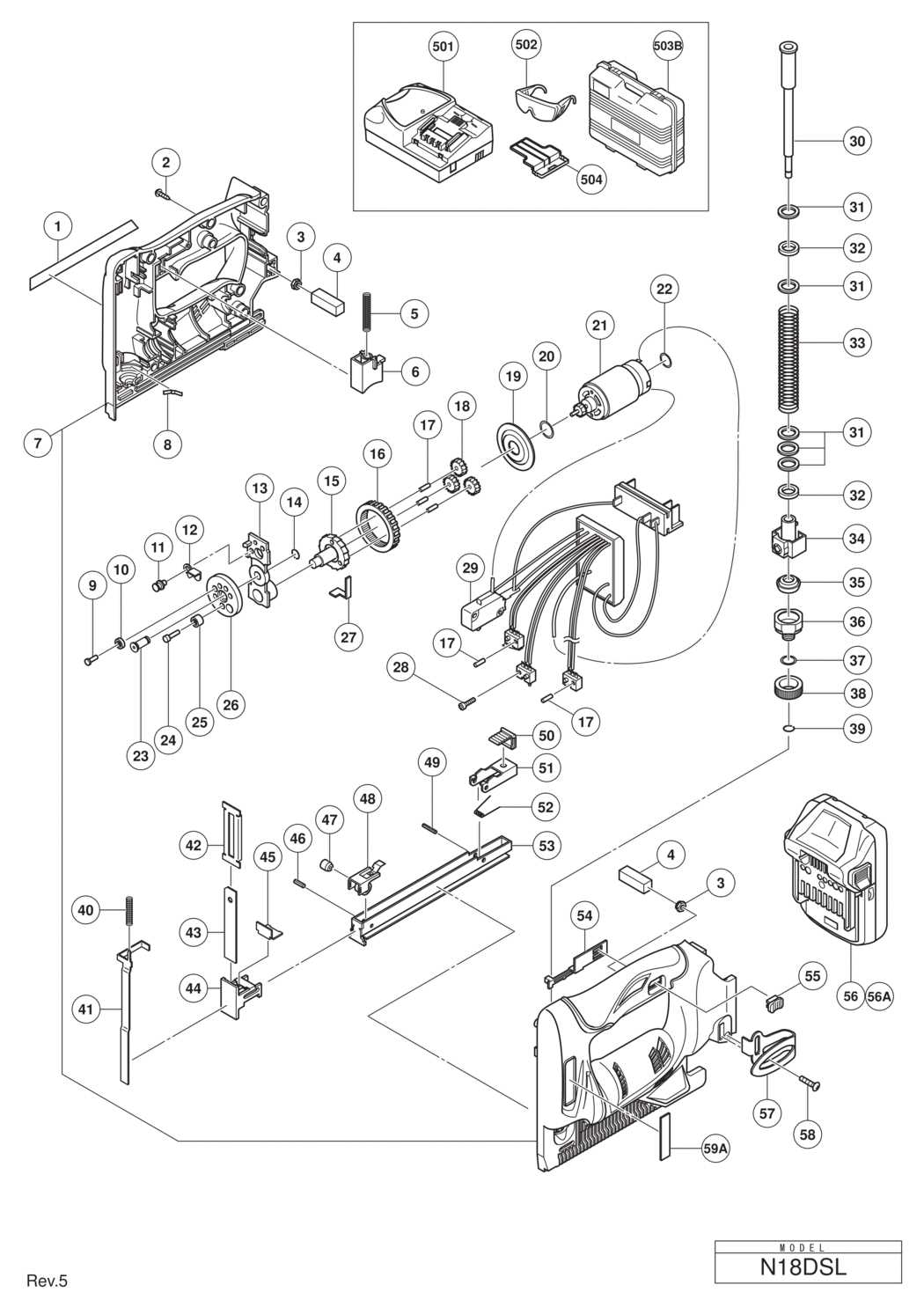

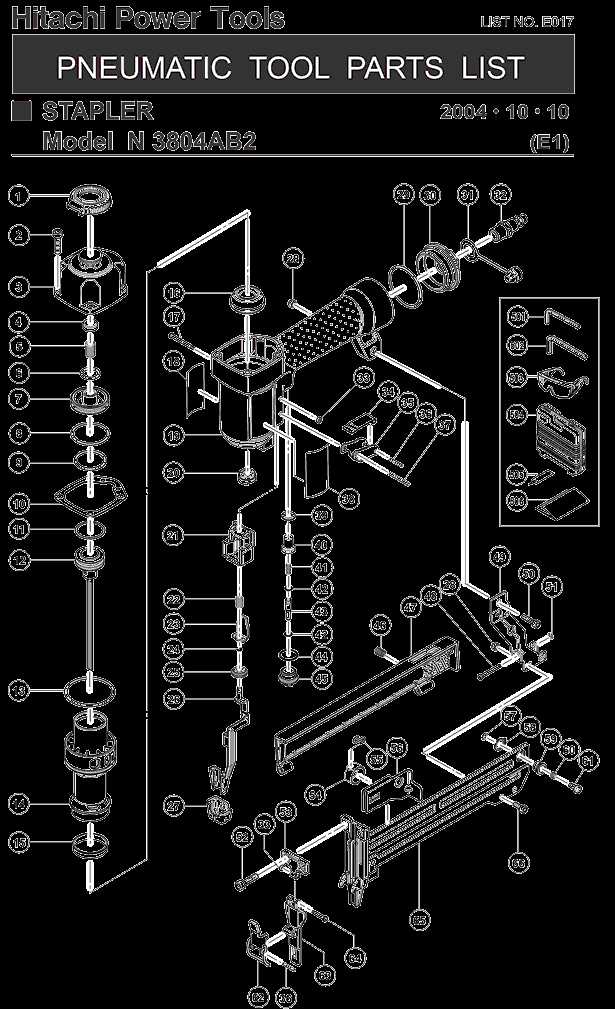

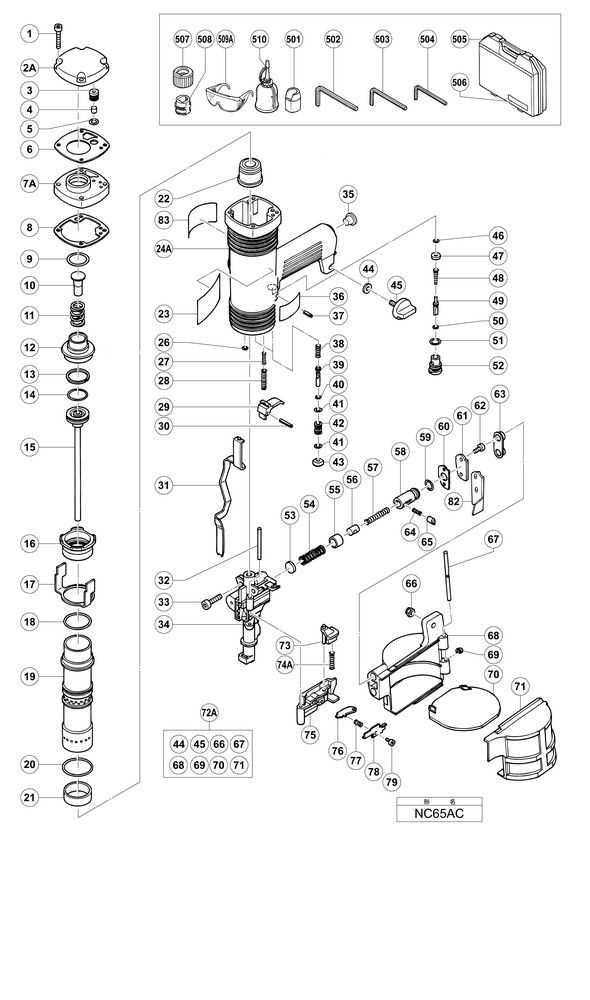

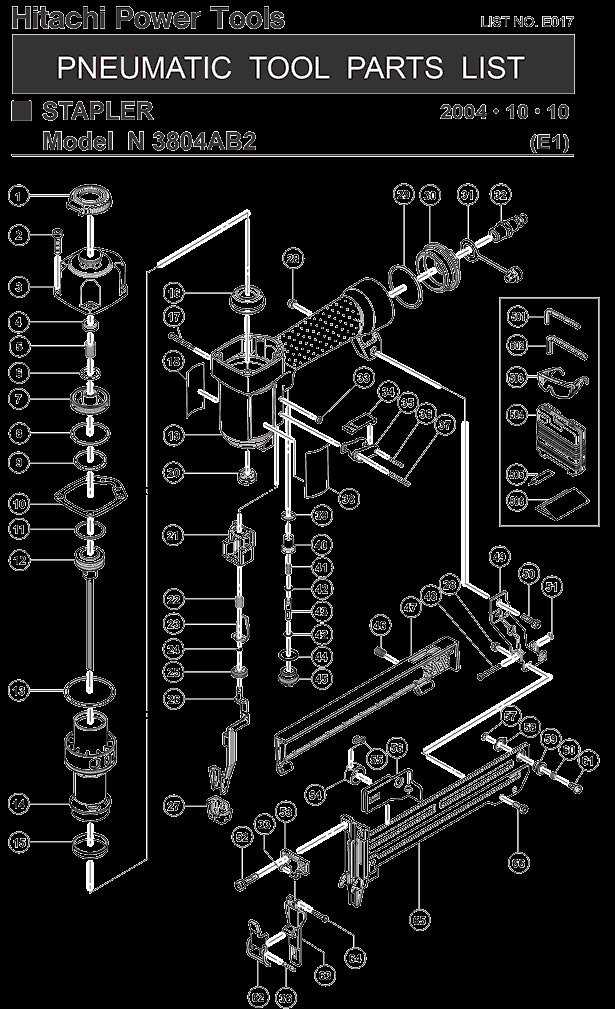

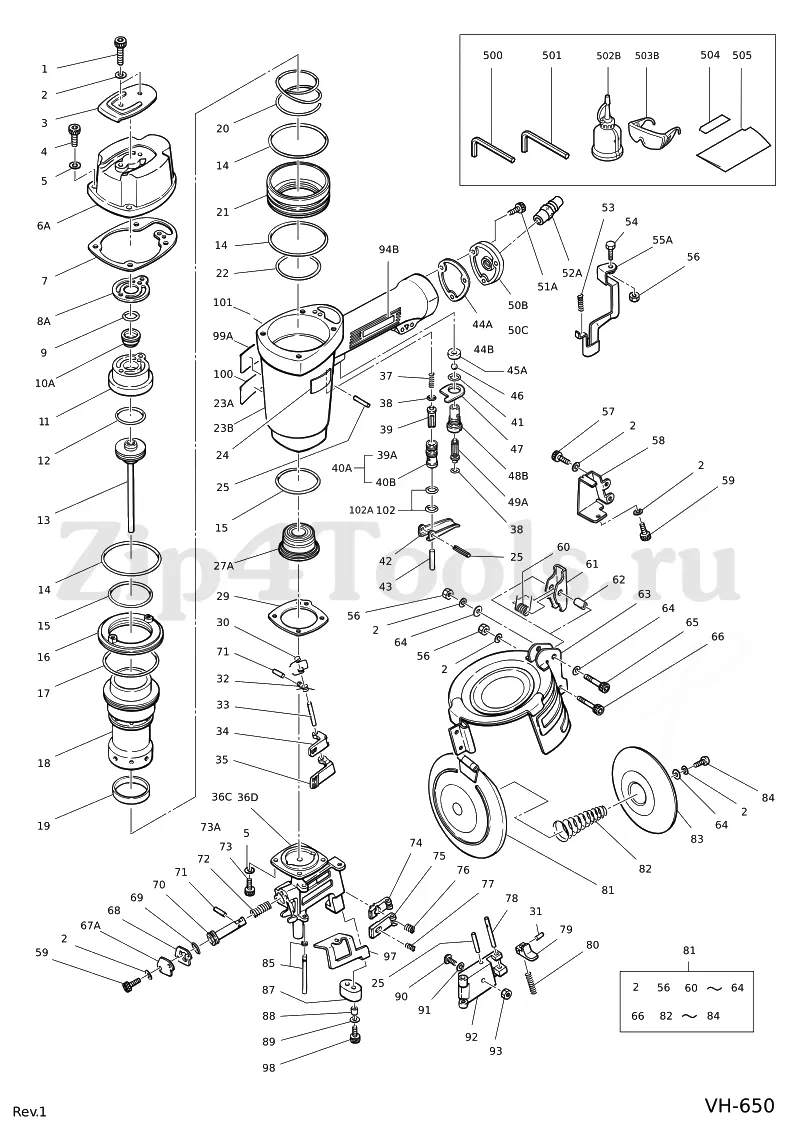

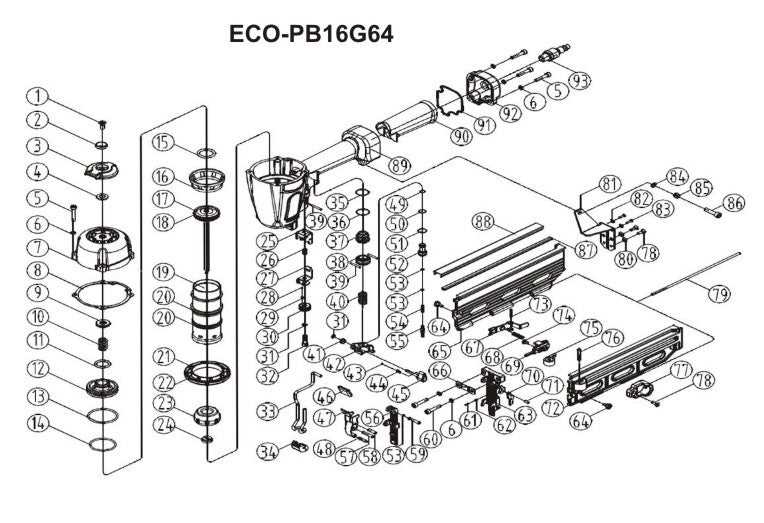

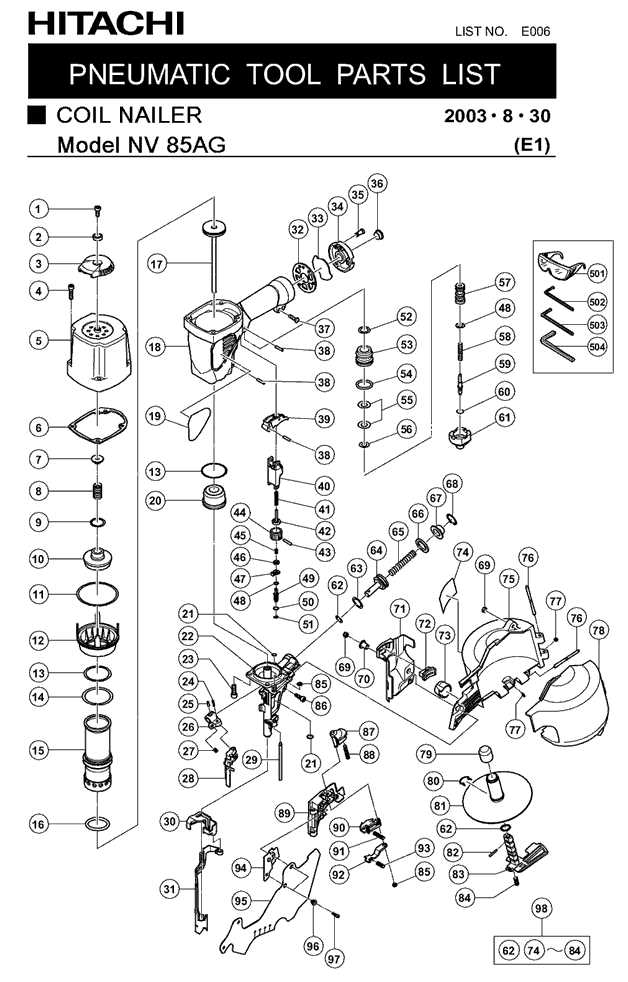

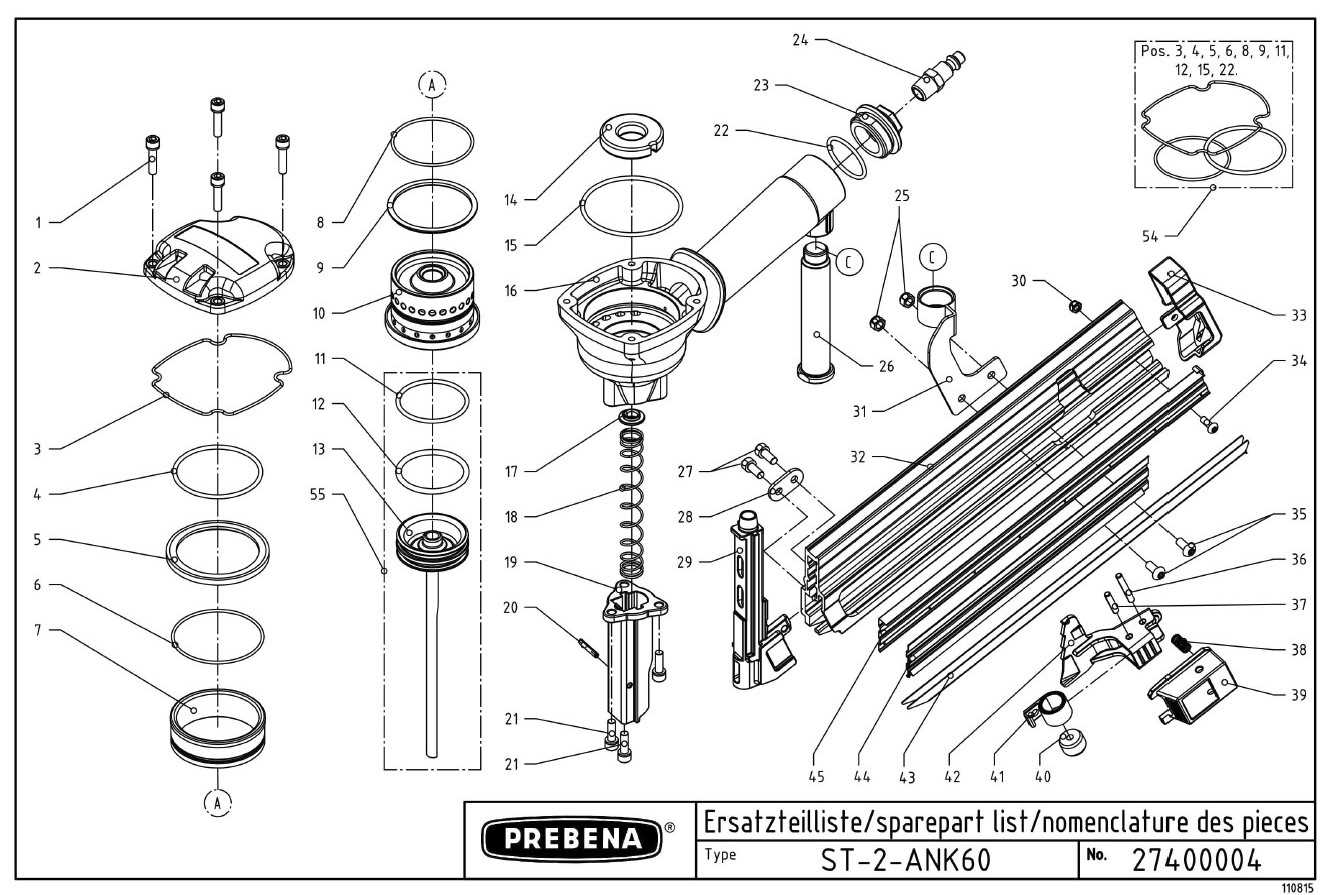

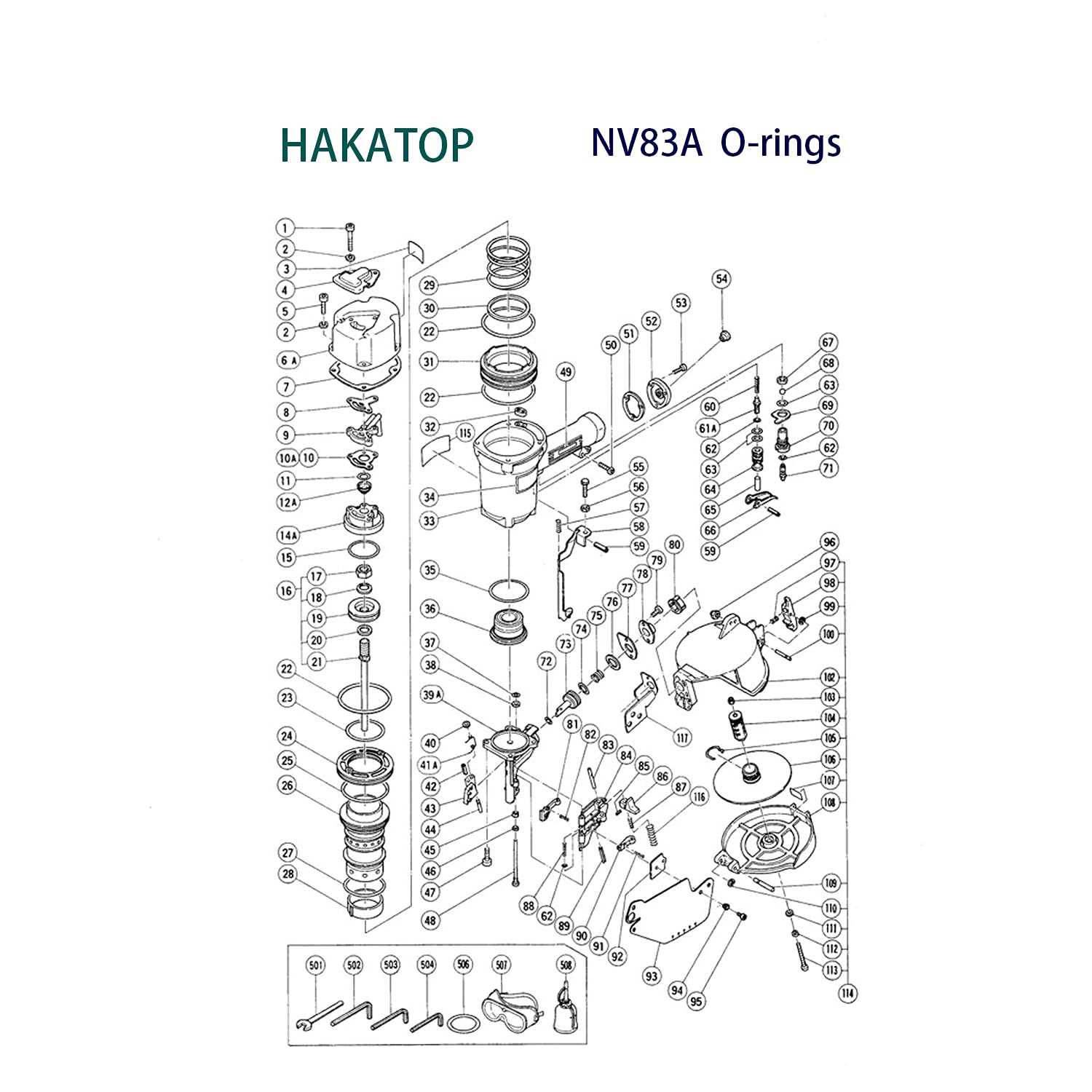

Identifying Key Components in Diagrams

Understanding the essential elements represented in visual schematics is crucial for effective comprehension and utilization. These illustrations serve as a guide, outlining the relationships and functions of various components within a system. By familiarizing oneself with these key features, users can enhance their ability to troubleshoot, maintain, and optimize performance.

When examining these visuals, consider the following fundamental aspects:

- Labels and Annotations: Clear markings that provide insight into each element’s function.

- Shapes and Symbols: Distinct forms that represent specific types of components, aiding in quick identification.

- Connections: Lines or arrows indicating how different parts interact or are linked together.

- Numbering Systems: A method for referencing components, often seen in lists or accompanying documentation.

By focusing on these features, users can develop a more intuitive understanding of the schematics and improve their ability to apply this knowledge practically.

Importance of Each Part Explained

Understanding the significance of individual components within a tool is crucial for optimal performance and longevity. Each element plays a specific role, contributing to the overall functionality and efficiency. Recognizing how these elements work together can help in both maintenance and troubleshooting.

The power source is fundamental, as it drives the entire mechanism. Its reliability ensures consistent operation, which is essential for achieving precise results. When this component malfunctions, it can significantly hinder productivity.

The firing mechanism is another critical element, responsible for the accurate application of force. This part must operate smoothly to guarantee that every action is executed flawlessly. Any irregularity here can lead to improper functioning and potential safety hazards.

Guide rails assist in maintaining alignment during operation. They ensure that the tool operates in a straight line, which is vital for achieving the desired outcome. Proper maintenance of these rails prevents misalignment and enhances accuracy.

Safety features are designed to protect users during operation. These components act as safeguards, minimizing the risk of accidental discharge. Understanding their function and ensuring they are in good working order is essential for safe usage.

Exhaust ports play a key role in maintaining air quality and preventing overheating. They help in the dissipation of excess heat and pressure, which can prolong the life of the tool. Keeping these ports clear is important for efficient operation.

By comprehending the importance of each component, users can ensure their tools perform at their best, enhancing both productivity and safety during tasks.

How to Read a Parts Diagram

Understanding the visual representation of components is essential for efficient assembly, maintenance, or troubleshooting. A well-constructed illustration can provide clarity on how different elements fit together, enabling users to grasp the overall structure and functionality of the device.

Identifying Components

Begin by familiarizing yourself with the various symbols and markings used in the illustration. Each item typically corresponds to a specific element within the equipment. Take note of any numbers or letters that may indicate the order of assembly or the type of each component, as this information is crucial for accurate identification.

Interpreting Connections

Pay attention to lines or arrows that represent relationships between different elements. These indicators often show how parts interact or connect with each other. Understanding these connections is vital for determining how to assemble or disassemble the system effectively, ensuring proper operation and safety.

Maintenance Tips for Nail Gun Parts

Proper upkeep is essential for ensuring the longevity and optimal performance of your tool. Regular attention to its components can prevent breakdowns and improve efficiency during use. Implementing a routine maintenance schedule can help identify issues before they escalate, leading to a smoother operation.

Regular Cleaning

Keeping the device clean is crucial for its functionality. After each use, wipe down the exterior and remove any debris or dust accumulation. This practice prevents the buildup of materials that could interfere with the mechanism. Additionally, periodically disassemble the unit to clean internal areas, ensuring that all components are free from grime.

Lubrication

Applying appropriate lubricants to moving elements is vital for reducing friction and wear. Ensure that you use the recommended oils or greases specified by the manufacturer. Regularly lubricate joints and pivots, paying close attention to areas that experience high levels of movement. This will not only extend the life of the tool but also enhance its overall performance.

Troubleshooting Common Issues

When working with your equipment, encountering various challenges is not uncommon. Understanding these potential problems can help in identifying and resolving them effectively. This section provides insights into typical difficulties and how to address them efficiently.

- Device Fails to Operate:

If the device does not turn on, check the power source. Ensure the battery is charged or the device is properly plugged in. Additionally, inspect the switch for any faults.

- Inconsistent Performance:

Inconsistent operation may arise from clogged components. Regularly clean the internal mechanisms to maintain optimal functionality.

- Improper Attachment Placement:

If the attachments do not fit correctly, examine the specifications for compatibility. Ensure that the correct size and type are being used.

- Unusual Noises:

Strange sounds during operation can indicate internal wear or loose parts. Inspect the unit for any signs of damage and tighten any loose components.

- Frequent Jams:

Jamming can be a frustrating issue. To prevent this, ensure that the materials being used are suitable and inspect for any debris in the feeding mechanism.

By following these guidelines, users can enhance the reliability of their equipment and minimize downtime. Regular maintenance and prompt attention to issues will ensure a smoother experience.

Replacement Parts: What to Consider

When maintaining your tool, it’s essential to evaluate the various components that may need to be replaced over time. Understanding what to look for can help ensure optimal performance and longevity of your equipment. Whether you’re dealing with wear and tear or specific malfunctions, recognizing the key factors in replacement will aid in making informed decisions.

Compatibility and Quality

Before purchasing new components, it’s crucial to verify that they are compatible with your specific model. High-quality replacements not only improve functionality but also enhance safety. Investing in reputable brands can prevent issues in the long run.

Cost Considerations

Budgeting for replacements is another important aspect. While it might be tempting to opt for the cheapest options available, consider the potential costs of frequent replacements. Striking a balance between cost and quality is vital for effective maintenance.

| Factor | Considerations |

|---|---|

| Compatibility | Ensure parts fit your specific model. |

| Quality | Opt for reputable brands to enhance durability. |

| Cost | Evaluate long-term expenses vs. upfront costs. |

Where to Find Original Parts

When searching for authentic components for your equipment, it is essential to identify reliable sources that guarantee quality and compatibility. Genuine items ensure optimal performance and longevity, making it crucial to source them from reputable vendors. There are several avenues you can explore to find what you need without compromising on quality.

Authorized Dealers and Retailers

One of the best options is to visit authorized dealers and retailers. These establishments are certified to sell genuine components and often have a comprehensive inventory. They can provide expert advice and assistance, ensuring that you select the right items for your specific needs. Additionally, many of these retailers offer warranties on their products, giving you peace of mind with your purchase.

Online Marketplaces and Manufacturer Websites

Another effective approach is to search online marketplaces and the official websites of manufacturers. These platforms often have a wide range of components available for order, making it convenient to compare prices and options. However, it is vital to verify the authenticity of the seller to avoid counterfeit products. Reading customer reviews and ratings can help you assess the credibility of the vendor before making a purchase.

Comparing Different Hitachi Models

This section provides an overview of various models from a well-known manufacturer, highlighting their unique features and specifications. Understanding the differences among these models can help users make informed decisions based on their specific needs and applications.

Key Features and Specifications

Each model in this range offers distinct characteristics suited for different tasks. The comparison below outlines the primary features that set each unit apart.

| Model | Weight | Power Source | Max Pressure |

|---|---|---|---|

| Model A | 4.5 lbs | Electric | 120 PSI |

| Model B | 5.0 lbs | Pneumatic | 110 PSI |

| Model C | 6.0 lbs | Battery | 130 PSI |

Choosing the Right Model

Selecting the appropriate model depends on the specific requirements of the project. Factors such as weight, power source, and maximum pressure should be considered to ensure optimal performance and efficiency.

Safety Precautions During Repairs

When undertaking any maintenance tasks on machinery, ensuring safety is paramount. Proper precautions not only protect the individual performing the repairs but also contribute to the longevity and efficiency of the equipment. Understanding and implementing these measures can prevent accidents and ensure a smooth repair process.

Personal Protective Equipment

Utilizing the appropriate personal protective equipment (PPE) is crucial. This includes wearing safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges, and ear protection if the machinery produces loud noises. Ensure that clothing is fitted correctly to avoid any entanglement with moving parts.

Workspace Organization

A well-organized workspace minimizes hazards. Keep tools and materials within reach and ensure that the area is free of clutter. Proper lighting is essential to avoid accidents and ensure visibility while working. Additionally, securing the machine before beginning repairs can prevent unintended activation, enhancing safety during the procedure.

By following these precautions, individuals can significantly reduce the risks associated with repairs, making the process safer and more efficient.