Understanding the individual elements that contribute to the efficient operation of machinery can greatly enhance its longevity and performance. Identifying key elements and their roles ensures proper maintenance and seamless functionality.

By delving into the structure of these vital mechanisms, users can gain valuable insights into how each section interacts with the whole. This not only aids in troubleshooting but also helps in optimizing the system for peak efficiency.

For those seeking detailed visual references, accessing a well-organized schematic can provide clarity and guide accurate replacements or repairs. This becomes especially useful in scenarios where precision and compatibility are crucial.

Understanding the Key Components of Stihl MS 462

Grasping the essential elements of this powerful machine is crucial for maintaining its efficiency and performance. Each component plays a pivotal role in ensuring smooth operation and longevity. By familiarizing yourself with these main parts, you can better handle maintenance tasks, troubleshoot issues, and enhance overall performance without the need for professional assistance.

The engine, cutting mechanism, and control systems work in harmony to deliver optimal results. Proper knowledge of their functions and how they interact allows you to ensure peak efficiency, minimizing wear and tear, while keeping your tool running smoothly.

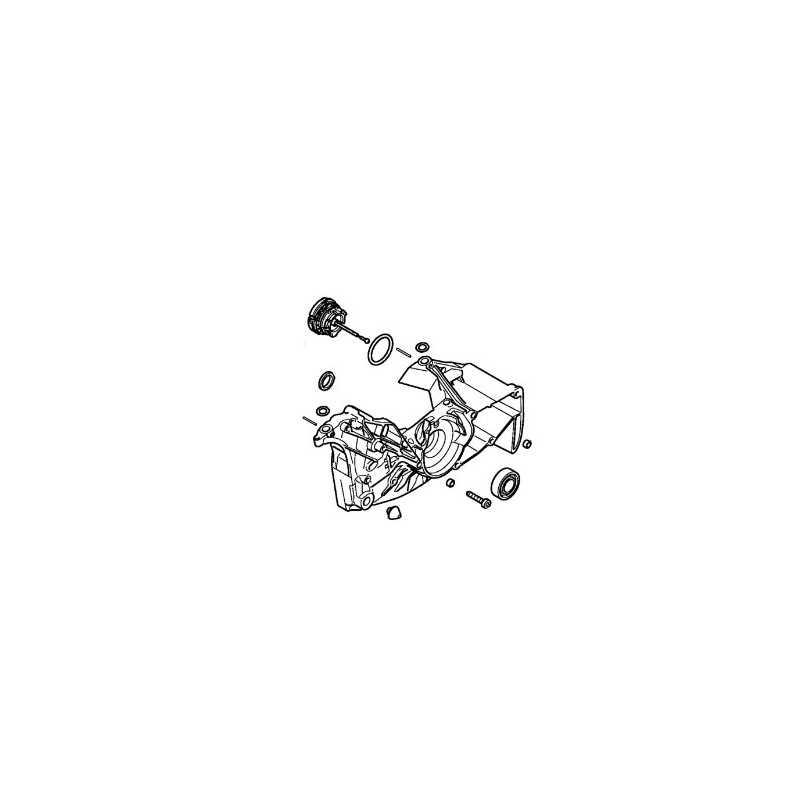

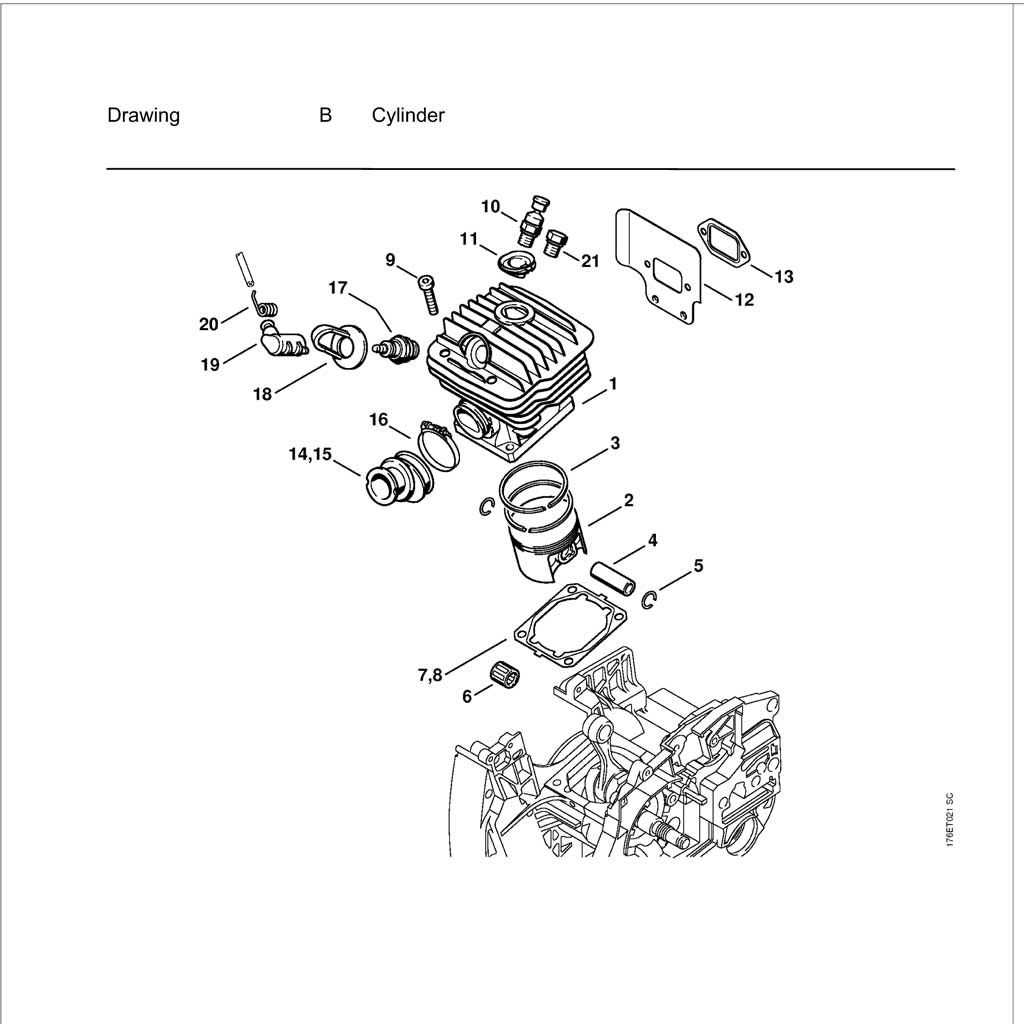

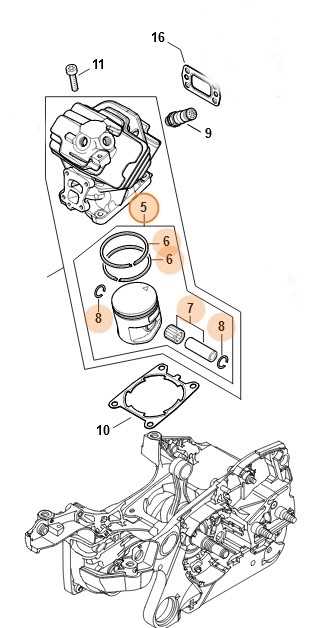

Essential Engine Parts Overview

The engine is composed of several critical elements that ensure smooth and efficient operation. Each component works in harmony, contributing to the overall performance and reliability of the system. Understanding these key elements helps maintain the engine in optimal condition and ensures a longer lifespan.

Main Structural Components

The engine’s foundation relies on robust structural components designed to withstand high levels of stress and heat. These include the core housing unit, fasteners, and support elements that hold everything together, allowing for efficient power generation and smooth operation.

Key Mechanical Elements

Mechanical parts play a vital role in converting fuel into mechanical energy. These include the primary moving components responsible for initiating combustion and transferring force. Their precision and durability are essential to the engine’s performance and overall functionality.

Guide to Chain Assembly for Stihl MS 462

Assembling the cutting chain is a crucial step in ensuring the tool functions effectively and safely. Proper installation requires attention to detail and careful handling of the chain components. In this section, we will guide you through the process, helping you to avoid common mistakes and achieve the correct setup.

- Step 1: Start by positioning the cutting bar onto the main body, ensuring it aligns with the adjustment holes.

- Step 2: Carefully place the chain onto the bar, making sure the teeth face the correct direction for cutting.

- Step 3: Adjust the tension using the tensioning mechanism, checking that the chain moves freely without excessive slack.

- Step 4: Secure the chain cover over the bar, tightening the nuts evenly to hold everything in place.

- Fuel Tank: Acts as the reservoir where the liquid is stored before being transferred to the engine.

- Fuel Line: A conduit that carries fuel from the tank to the carburetor.

- Carburetor: Mixes the fuel with air in the proper ratio before it’s fed into the combustion chamber.

- Fuel Filter: Ensures that only

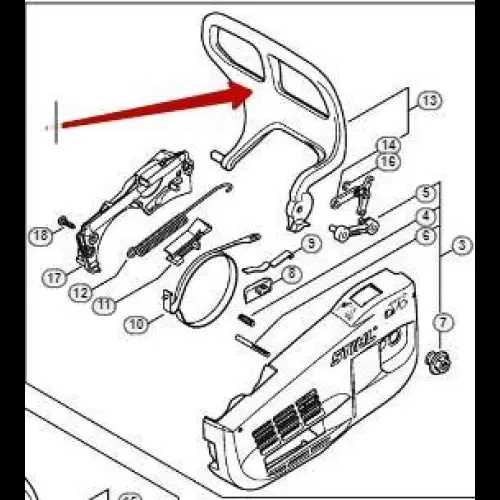

How the Chain Brake System Works

The chain brake system is a crucial safety feature designed to prevent accidents during operation. It engages automatically or can be activated manually, providing an essential layer of protection for the user.

This system primarily consists of several components that work together to halt the chain’s movement rapidly. Understanding how each part functions can help users maintain their equipment effectively. Here are the main elements involved:

- Brake Band: This flexible band wraps around the chain and is tightened to stop it.

- Brake Lever: Located on the handle, this lever allows the operator to engage the brake with ease.

- Spring Mechanism: This component helps return the brake band to its original position once the lever is released.

- Chain Stop: A fixed point that helps in securing the chain when the brake is applied.

When the brake lever is pulled, the brake band tightens around the chain, causing it to stop almost instantaneously. This action significantly reduces the risk of kickback incidents, which can occur if the chain recoils unexpectedly.

Regular inspection and maintenance of the chain brake system are vital for ensuring its proper function. Users should check for wear and tear on the brake band and ensure the lever operates smoothly to maintain safety during use.

Maintenance of Air Filtration Components

Regular upkeep of the air filtration elements is essential for optimal performance and longevity of outdoor power equipment. These components play a crucial role in ensuring that clean air reaches the engine, thus preventing contamination and wear. Proper maintenance not only enhances efficiency but also minimizes the risk of operational issues that could arise from neglect.

Inspection and Cleaning Procedures

Routine checks and cleaning of the filtration components are vital. Inspect the filters for any signs of dirt, debris, or damage. If any blockage is detected, clean the filters with a gentle brush or compressed air to remove particulates. In cases where filters are excessively soiled or damaged, replacement is necessary to maintain effective airflow.

Replacement Guidelines

Timely replacement of air filtration elements is crucial for maintaining equipment performance. Follow the manufacturer’s recommendations regarding replacement intervals. Using genuine components is advisable to ensure compatibility and reliability. Always refer to the specific guidelines to ensure proper installation and functionality.

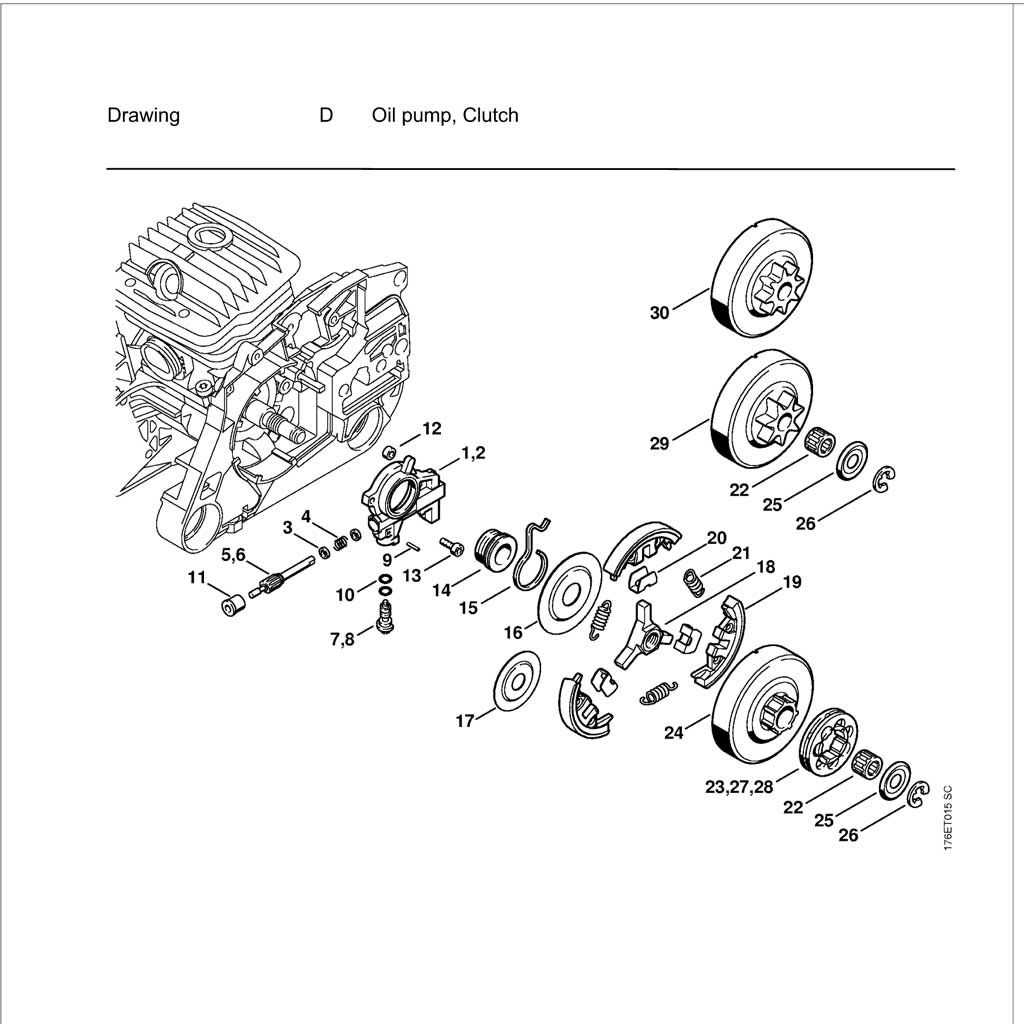

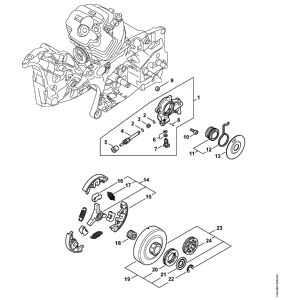

Detailed Look at the Clutch System

The clutch system serves as a vital component in the operation of a power tool, facilitating the transfer of energy from the engine to the cutting mechanism. Understanding its structure and function is essential for maintaining optimal performance and ensuring safety during use.

Functionality and Importance

This mechanism plays a crucial role in managing torque, allowing the operator to control the tool’s power effectively. When engaged, it ensures a smooth transition of energy, enabling efficient cutting without excessive strain on the motor. A well-functioning clutch system prevents slippage and enhances overall tool reliability.

Maintenance Tips

Regular inspection and maintenance of the clutch are essential for longevity and performance. Users should check for wear and tear on components, ensuring that all parts are lubricated and functioning correctly. Addressing any signs of malfunction early can prevent further damage and costly repairs.

Decoding the Oil Pump Mechanism

The oil pump is a crucial component in ensuring the optimal performance and longevity of a machine. Its primary function is to circulate lubricant throughout the engine, minimizing friction and wear on internal parts. Understanding the inner workings of this mechanism can greatly enhance maintenance practices and troubleshooting efforts.

Functionality and Design

This mechanism typically operates through a series of gears and channels that work together to draw oil from a reservoir and distribute it efficiently. The design often includes adjustable settings, allowing users to modify the oil flow rate based on specific operational needs. This adaptability is essential for achieving peak performance across various tasks.

Common Issues and Solutions

Like any mechanical component, the oil pump can encounter issues that may hinder its effectiveness. Common problems include blockages, wear and tear, and improper calibration. Regular inspection and timely maintenance can prevent these issues, ensuring that the lubrication system operates smoothly. If malfunctions arise, diagnosing the source promptly can save time and resources.

Guide to Handlebar and Vibration Control

The handlebar and vibration management system is crucial for the comfort and efficiency of outdoor power tools. Understanding how to properly utilize these components can enhance user experience while reducing fatigue during prolonged operation. This guide outlines essential aspects to consider for optimal control and comfort.

Handlebar Adjustments

Correctly positioning the handlebar is vital for maintaining a comfortable grip and ensuring effective maneuverability. Users should adjust the height and angle to suit their preferences and physical stature. A well-adjusted handlebar minimizes strain on the arms and back, allowing for extended use without discomfort.

Vibration Dampening Techniques

Effective vibration control mechanisms are designed to reduce the impact of vibrations on the operator. Regular maintenance of these systems is essential for longevity and performance. Utilizing tools with built-in vibration reduction features can significantly enhance comfort, allowing for smoother operation and decreased risk of injury.

Tips for Replacing Key Parts Efficiently

Replacing essential components of equipment can be a straightforward process when approached methodically. Efficient replacement not only saves time but also ensures optimal performance of the machine. Here are some strategies to consider when tackling this task.

Preparation and Tools

Before beginning the replacement, gather all necessary tools and components. Having everything ready allows for a smooth workflow. Make sure to consult the manufacturer’s guidelines for specific instructions regarding the components being replaced.

Step-by-Step Approach

Adopting a systematic method can significantly ease the replacement process. Follow these steps:

Step Action 1 Disconnect the equipment from power sources to ensure safety. 2 Remove the old component carefully, taking note of how it is installed. 3 Install the new part, ensuring it fits securely and aligns correctly. 4 Reconnect power sources and test the equipment to confirm proper functionality. By following these guidelines, replacing crucial components can be accomplished with minimal hassle, leading to better maintenance and longevity of the machinery.

Examining the Ignition System Setup

The ignition mechanism plays a crucial role in ensuring the smooth operation of any engine-driven equipment. Understanding how the system initiates and maintains power delivery can greatly aid in troubleshooting and overall maintenance. Proper alignment and timely firing of the components are essential for optimal functionality.

Key components of this system include the spark generation device and related connections. These work together to ignite the fuel, ensuring consistent performance. Periodic checks on these elements can prevent malfunctions and extend the lifespan of the equipment.

Regular maintenance of the ignition setup involves inspecting connections, verifying component integrity, and ensuring there are no signs of wear or damage. A well-maintained ignition system guarantees reliable starts and efficient energy transfer.

Exploring the Fuel Delivery Mechanism

The fuel delivery system in chainsaws is designed to ensure a steady and efficient supply of fuel to the engine. Understanding how this mechanism operates can help users maintain optimal performance and resolve common issues related to engine power or fuel consumption.

Below is a breakdown of key components involved in the fuel system: