In any establishment where water flow is essential, the efficient operation of water dispensing mechanisms is paramount. A thorough comprehension of their individual elements can greatly enhance both functionality and longevity. By dissecting the anatomy of these systems, one can identify the critical features that contribute to their overall performance.

The interaction between various elements plays a crucial role in ensuring seamless water delivery. Recognizing how each component works in harmony not only aids in maintenance but also empowers users to make informed decisions when it comes to repairs or upgrades. The visual representation of these elements serves as a valuable tool in demystifying their functions.

As we delve deeper into the specifics of these systems, it becomes evident that understanding their configuration can lead to improved efficiency and reduced operational challenges. Whether for new installations or troubleshooting existing setups, grasping the intricacies of these units is essential for achieving optimal results.

Understanding Commercial Faucet Components

In the realm of plumbing fixtures, comprehending the individual elements is essential for efficient operation and maintenance. Each component plays a pivotal role, influencing functionality, longevity, and performance. By familiarizing oneself with these elements, one can ensure optimal usage and troubleshoot issues effectively.

Key Elements Overview

The following table outlines the main components, along with their functions and significance:

| Component | Function | Importance |

|---|---|---|

| Spout | Directs water flow | Essential for proper water delivery |

| Handle | Controls water temperature and flow | Crucial for user convenience |

| Cartridge | Regulates water flow and temperature | Key for precise adjustments |

| Base | Stabilizes and supports the structure | Ensures durability and stability |

Maintenance and Care

Regular inspection of these elements is vital for ensuring seamless operation. Identifying wear and tear early can prevent costly repairs and extend the lifespan of the fixture. Familiarity with each component allows for informed decision-making regarding maintenance and replacements.

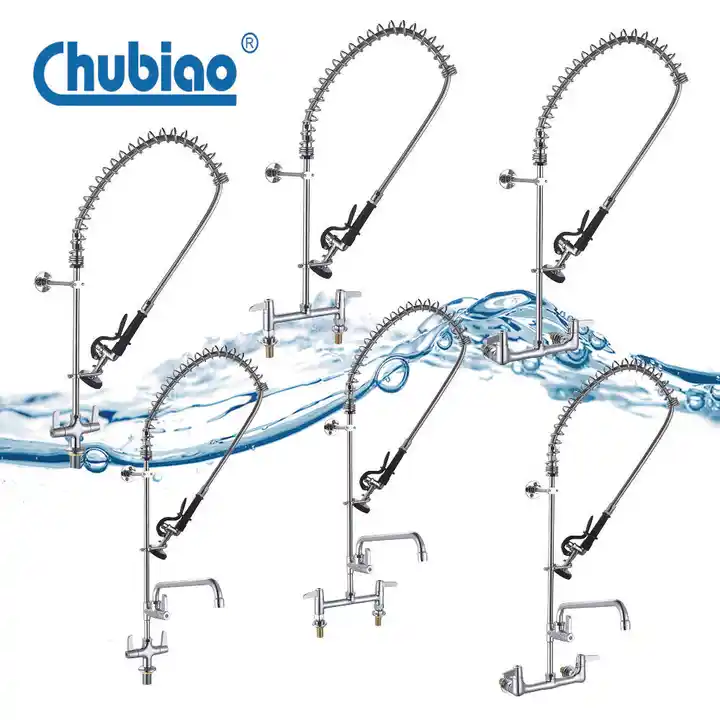

Types of Commercial Faucets

In various settings where water access is essential, different styles of fixtures cater to specific needs and functionalities. These options are designed to enhance usability, efficiency, and hygiene, making them indispensable in high-traffic environments.

| Fixture Type | Description |

|---|---|

| Single-Handle | Features a single lever for controlling both temperature and flow, allowing for quick adjustments. |

| Double-Handle | Equipped with separate handles for hot and cold water, providing precise temperature control. |

| Sensor-Activated | Operates through motion detection, promoting hands-free use for improved sanitation. |

| Wall-Mounted | Attached to the wall rather than the sink, saving counter space and offering a unique aesthetic. |

| Pre-Rinse | Designed for rinsing dishes and utensils before washing, featuring a flexible spray head for versatility. |

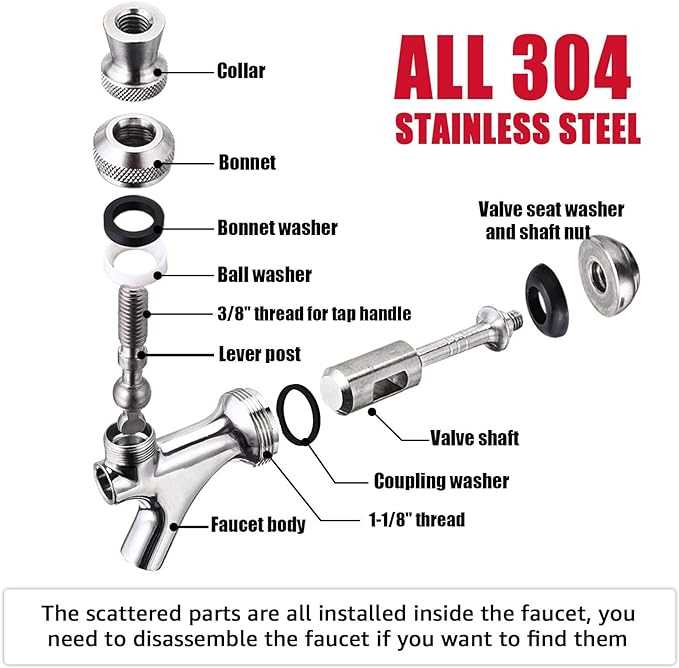

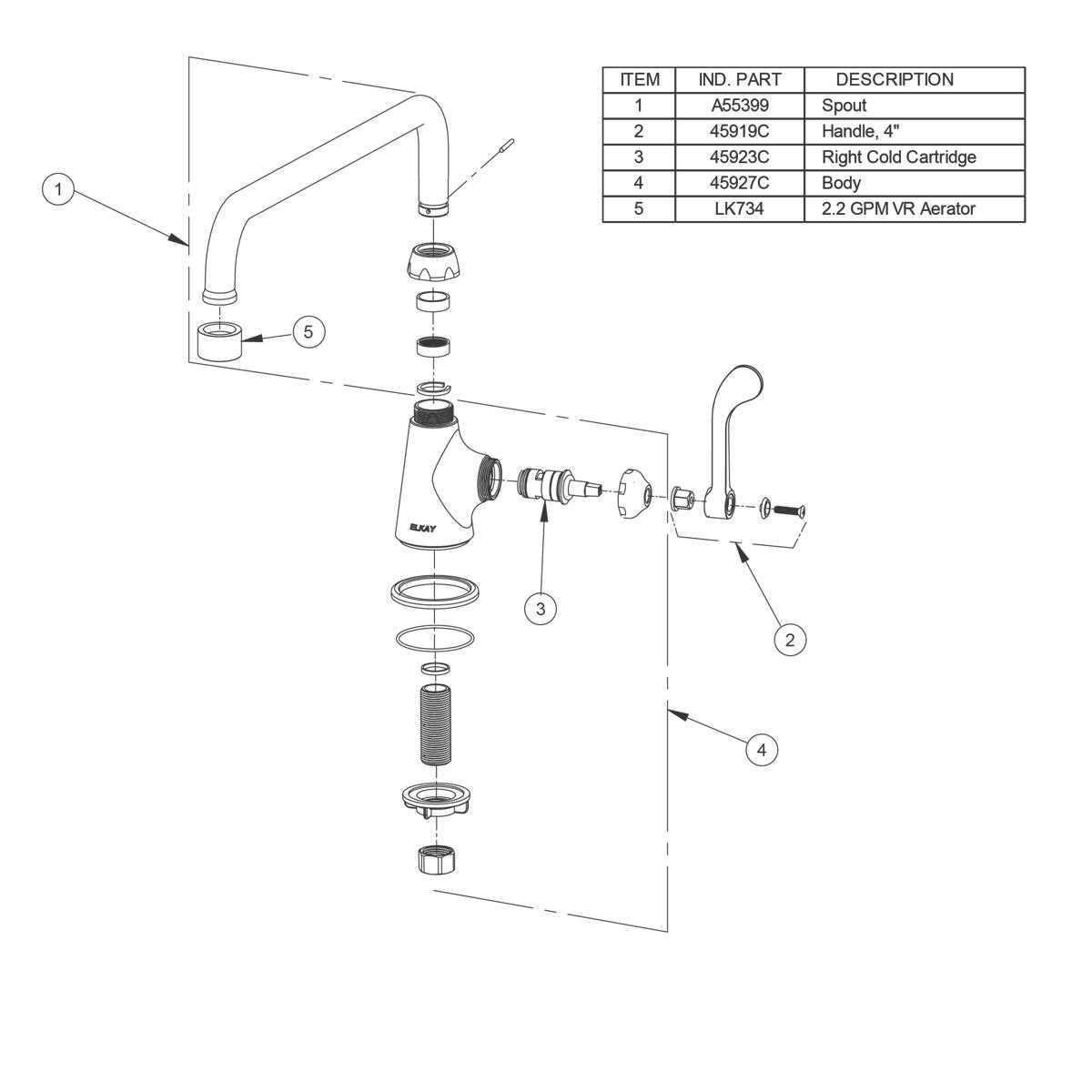

Key Parts of Faucet Assembly

Understanding the essential components of a water dispensing fixture is crucial for maintenance and repairs. Each element plays a vital role in the overall functionality, ensuring a smooth operation and reliable performance. Below are the main elements involved in the assembly.

Main Components

- Spout: Directs water flow to the desired location.

- Handle: Controls water flow and temperature.

- Cartridge: Regulates the mixture of hot and cold water.

- Base: Anchors the fixture to the sink or countertop.

- O-Rings: Provide seals to prevent leaks.

- Supply Lines: Connect the fixture to the water supply.

Supporting Elements

- Mounting Nuts: Secure the fixture in place.

- Flow Restrictor: Regulates water usage for efficiency.

- Drain Assembly: Facilitates the removal of used water.

- Strainer: Prevents debris from clogging the drain.

Familiarizing yourself with these components can greatly aid in troubleshooting and enhancing the longevity of your water dispensing system.

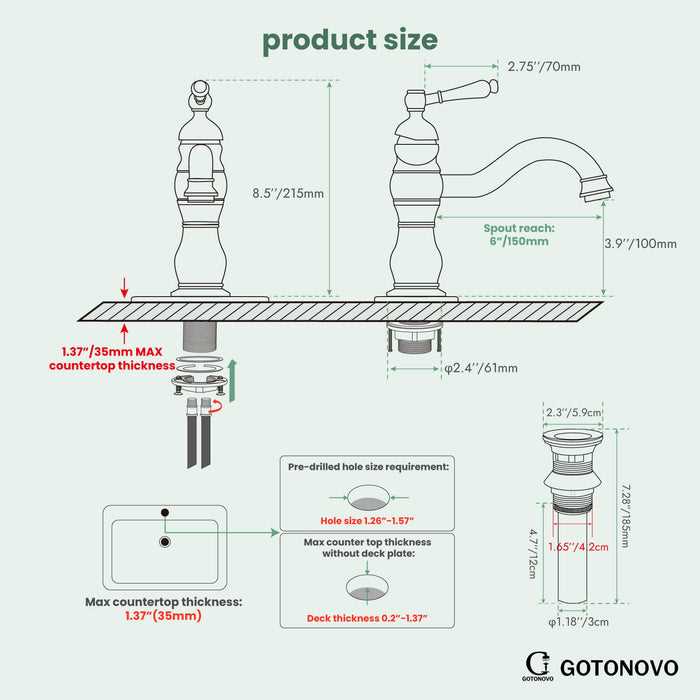

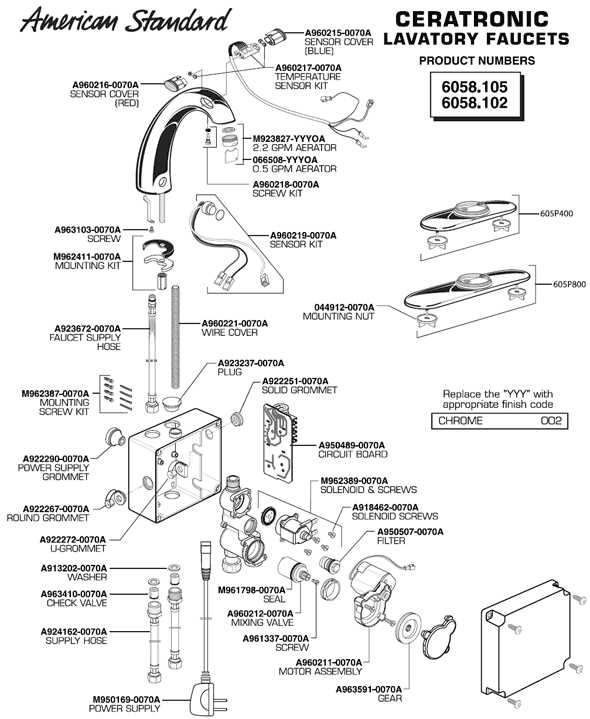

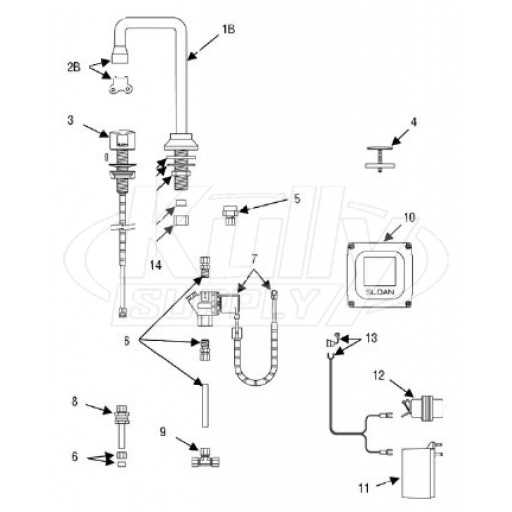

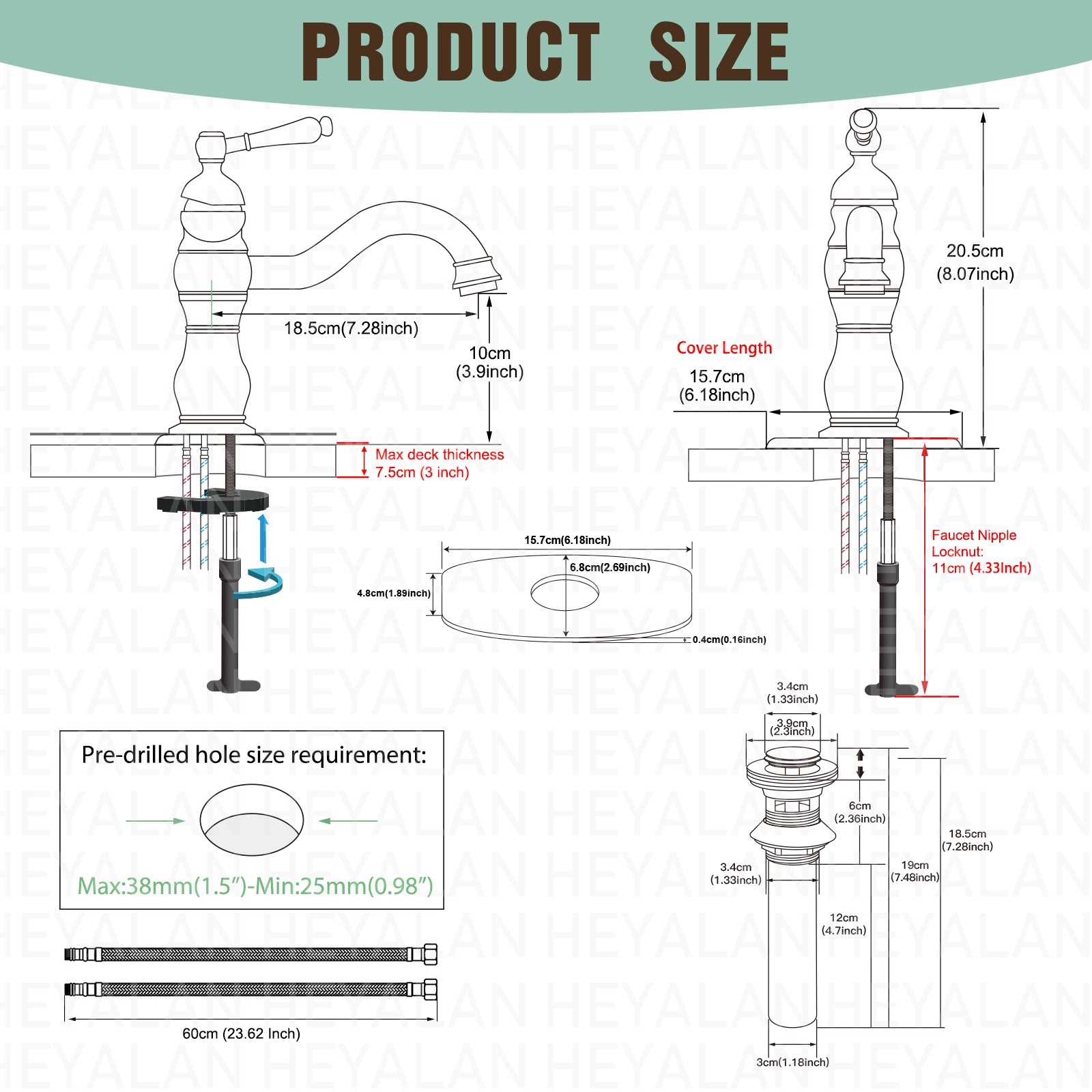

Diagram Overview of Faucet Parts

This section provides a comprehensive look at the various components that make up the water dispensing system. Understanding these elements is crucial for proper maintenance and functionality, ensuring that the flow and temperature of water can be controlled effectively.

Key elements typically include the spout, which directs water, and the handle, responsible for adjusting the flow. Additionally, cartridges play a vital role in regulating water temperature and pressure. The base supports the entire structure, while various washers and seals prevent leaks, contributing to the overall efficiency of the system.

By familiarizing oneself with these components, users can better diagnose issues and perform repairs when necessary, ultimately enhancing their experience and ensuring longevity in usage.

Common Issues with Faucet Components

Understanding the frequent challenges associated with plumbing fixtures can greatly enhance their longevity and performance. Many individuals encounter issues that, while common, can lead to significant inconveniences if not addressed promptly. Identifying these problems early on allows for more effective maintenance and repairs.

Leakage is one of the most prevalent issues, often stemming from worn-out seals or gaskets. When these components degrade, they fail to create a tight seal, resulting in water escaping where it shouldn’t. Regular inspection can help detect early signs of wear.

Low Water Pressure is another frustrating concern. This can arise due to mineral buildup in aerators or pipes, restricting water flow. Cleaning or replacing affected parts can restore optimal performance.

Noisy Operation can be attributed to various factors, including loose fittings or air trapped in the lines. Addressing these noises often requires tightening connections or purging air from the system.

Corrosion is a serious issue that affects many metal components. Exposure to moisture can lead to rust, which not only degrades appearance but also compromises functionality. Regular maintenance and the use of protective coatings can mitigate this risk.

By being aware of these common challenges, individuals can take proactive steps to ensure their fixtures operate smoothly and efficiently, ultimately saving time and resources.

Materials Used in Faucet Construction

The choice of materials in the construction of water dispensing fixtures plays a crucial role in their durability, functionality, and aesthetic appeal. Different substances offer varying advantages, which can significantly influence the performance and longevity of the fixtures. Understanding these materials helps in making informed decisions when selecting or maintaining them.

Common Materials

Brass is a favored choice due to its resistance to corrosion and strength. Its natural antimicrobial properties also make it suitable for environments requiring high hygiene standards. Stainless steel, known for its modern look, offers excellent durability and resistance to rust, making it a popular alternative.

Finishes and Coatings

Many fixtures are treated with protective finishes to enhance their appearance and functionality. Chrome plating provides a shiny, reflective surface that is easy to clean, while matte or brushed finishes offer a more understated elegance. Additionally, ceramic and plastic components are often utilized for internal mechanisms, providing smooth operation and reducing wear.

In summary, the materials selected for water dispensing systems not only affect their performance and longevity but also influence their visual appeal, making informed choices essential for any installation or upgrade.

Importance of Regular Maintenance

Ensuring the longevity and optimal performance of any plumbing fixture is essential for both efficiency and cost-effectiveness. Regular upkeep not only enhances functionality but also prevents potential issues that can lead to more significant problems over time. By establishing a routine maintenance schedule, users can safeguard their investments and minimize disruptions in daily operations.

Routine inspection and care can help identify wear and tear before it escalates into costly repairs. Additionally, it contributes to improved water efficiency, which is crucial in reducing utility bills and promoting sustainability. Proper maintenance practices foster a healthier environment by minimizing leaks and preventing water waste.

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Visual Inspection | Monthly | Early detection of leaks and damages |

| Cleaning Components | Quarterly | Improved efficiency and hygiene |

| Lubrication of Moving Parts | Bi-Annually | Prevention of wear and smooth operation |

| Replacement of Worn Out Elements | As Needed | Avoidance of unexpected failures |

In conclusion, prioritizing consistent maintenance practices is vital for sustaining the performance and reliability of plumbing installations. By committing to a structured approach, users can ensure that their systems remain in peak condition, providing peace of mind and reducing long-term expenses.

How to Identify Faucet Parts

Understanding the components of a water delivery system is essential for maintenance and repairs. Proper identification of each element not only facilitates troubleshooting but also enhances the efficiency of the entire setup. Here are some steps to help you recognize the various elements involved.

Visual Inspection

Start by examining the exterior of the installation. A careful look can provide insights into the types of mechanisms used. Consider the following:

- Look for handles and their configurations–single or dual.

- Check the spout type–swivel, pull-down, or fixed.

- Notice any visible screws or fasteners that may indicate removable sections.

Understanding Components

Once you’ve completed the visual inspection, familiarize yourself with common components:

- Handles: These control the flow and temperature of water.

- Spout: This is where water exits; its design affects usability.

- Cartridge: A critical element that regulates water flow and temperature.

- Base: The section that connects the system to the surface.

By taking the time to learn about these individual elements, you can ensure a smoother experience when performing any necessary repairs or upgrades.

Tools Needed for Faucet Repair

When it comes to fixing leaks or replacing components in your kitchen or bathroom fixtures, having the right tools is essential for a smooth and efficient repair process. Below is a list of tools that will help you tackle these common tasks with ease.

- Adjustable Wrench: Useful for gripping and turning nuts and bolts of various sizes.

- Screwdriver Set: A variety of flathead and Phillips screwdrivers are necessary for removing screws.

- Plumber’s Tape: This helps create a watertight seal on threaded connections.

- Pliers: Handy for gripping and twisting parts that may be difficult to reach.

- Pipe Wrench: Ideal for loosening or tightening pipe fittings.

In addition to these basic tools, consider the following specialized items:

- Utility Knife: Great for cutting through old tape or other materials.

- Bucket: Useful for catching any water that may spill during repairs.

- Flashlight: Provides additional light for hard-to-see areas under sinks.

By having these tools on hand, you’ll be better prepared to tackle any issues that arise with your fixtures, ensuring a successful repair experience.

Replacement Parts and Where to Find Them

When it comes to maintaining your fixtures, having access to the right components is essential for ensuring their longevity and functionality. Understanding the various elements that may require replacement can save both time and money, allowing you to address issues efficiently and effectively.

Identifying Components: Before you start searching for replacements, it’s crucial to identify the specific items that need attention. Common issues often arise from wear and tear, leading to leaks or decreased performance. Take the time to inspect the assembly closely to determine which elements are malfunctioning.

Where to Source Replacements: Numerous outlets offer the necessary components. Local hardware stores frequently carry a range of options suitable for various models. Additionally, online retailers provide extensive catalogs, allowing you to compare prices and availability from the comfort of your home. Manufacturer websites can also be valuable resources, often featuring detailed lists of compatible components for your specific model.

Considerations for Selection: When selecting replacements, prioritize quality and compatibility. It may be tempting to choose the most affordable option, but investing in high-quality items can lead to better performance and durability in the long run. Always double-check the specifications to ensure a proper fit.

Conclusion: Accessing the right components is vital for the proper upkeep of your fixtures. By knowing where to look and what to consider, you can ensure that your replacements meet your needs and contribute to the overall efficiency of your system.

Step-by-Step Assembly Guide

Assembling a water delivery mechanism can be a straightforward process if approached methodically. This guide provides clear steps to help you successfully combine various components, ensuring optimal performance and functionality.

- Gather Your Tools and Components

- Ensure you have all necessary components at hand.

- Prepare the required tools such as wrenches, screwdrivers, and seals.

- Inspect Each Component

- Check for any signs of wear or damage.

- Ensure that all seals are intact and free from defects.

- Prepare the Base

- Clean the surface where the assembly will take place.

- Ensure that the base is level and stable for accurate installation.

- Attach the Main Body

- Align the main body with the mounting surface.

- Secure it in place using screws or bolts, ensuring a tight fit.

- Install the Control Mechanism

- Connect the control handle or lever to the main body.

- Test the movement to confirm smooth operation.

- Connect the Water Supply

- Attach the water supply lines to the designated inlets.

- Ensure that all connections are tight to prevent leaks.

- Finalize the Assembly

- Check all connections once more for security.

- Install any remaining components such as aerators or covers.

- Conduct a Function Test

- Turn on the water supply and check for leaks.

- Test the operation of the control mechanism to ensure proper flow.

Following these steps will help ensure a successful assembly, resulting in a well-functioning system. Regular maintenance checks can further enhance longevity and efficiency.

Upgrading Your Commercial Faucet System

Enhancing your water delivery system can significantly improve efficiency and user satisfaction. This process involves not just replacing old components, but also considering the latest technologies and designs that can elevate functionality and style.

Benefits of Upgrading

- Improved water flow and pressure

- Energy efficiency leading to cost savings

- Enhanced durability and longevity of the system

- Modern aesthetics that complement your establishment’s design

- Increased hygiene with advanced materials

Steps to Consider

- Assess your current setup and identify areas for improvement.

- Research new technologies and materials available on the market.

- Consult with professionals to get expert recommendations.

- Plan a budget that covers all aspects of the upgrade.

- Implement the changes while minimizing disruption to operations.

By investing in a modernized system, you not only enhance the functionality of your facility but also contribute to a more sustainable and efficient future.