Understanding the structure of complex outdoor machines can simplify their maintenance and repair. This section aims to provide clarity on how individual elements come together, ensuring smooth operation. Each detail plays a vital role, contributing to the overall performance and efficiency of the system.

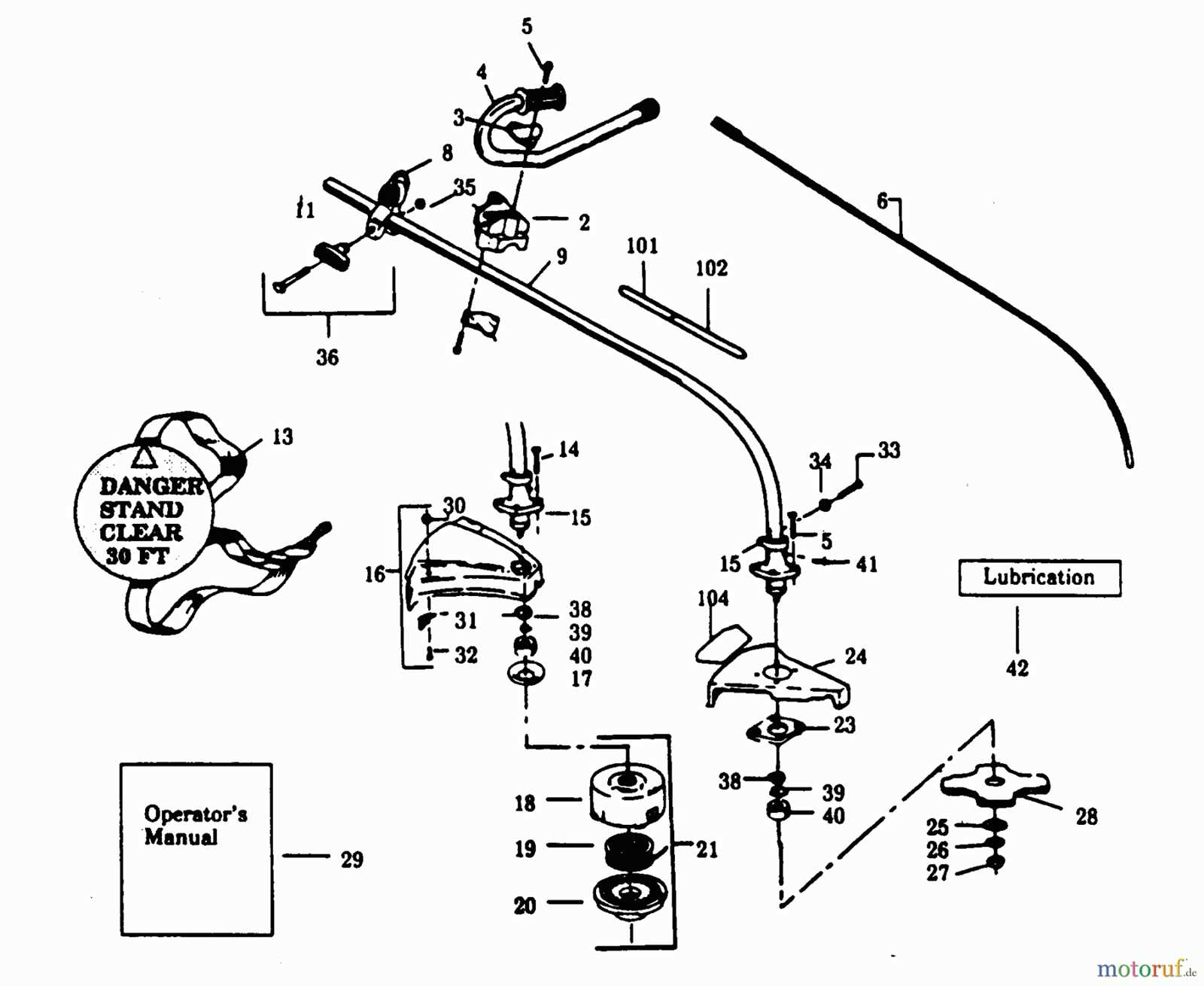

Maintaining such equipment involves knowing which components interact and how to identify them accurately. Whether it’s a small fastening element or a key functional part, having a visual breakdown helps users confidently address common issues.

Throughout this guide, emphasis will be placed on recognizing essential components and their placement. By getting familiar with the internal and external parts, you’ll be able to extend the operational life of your equipment and avoid unnecessary downtime.

Proper identification and routine inspections are essential practices that ensure longevity and consistent performance. A deeper understanding of the equipment’s internal layout can reduce maintenance costs and prevent unexpected malfunctions.

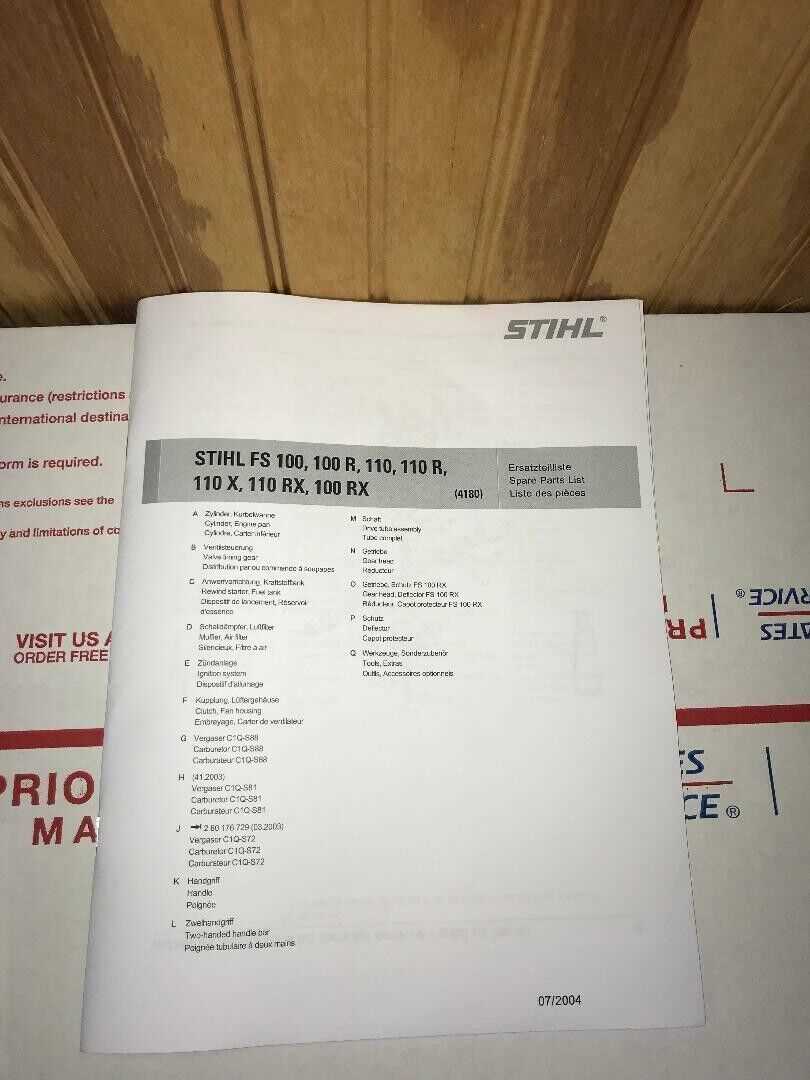

Essential Components of the Stihl FS 66

The machinery relies on a range of interconnected elements to deliver effective and smooth operation. Each part plays a critical role in ensuring optimal performance and durability, allowing users to complete tasks efficiently. This section provides an overview of the key mechanisms involved, offering insight into how these elements contribute to the tool’s functionality.

Power Unit and Mechanical Drive

The energy source powers the entire system, feeding through a mechanical transmission that directs the motion. This ensures that rotational force reaches the cutting section with minimal loss. Maintaining these elements ensures long-lasting operation, preventing mechanical stress over time.

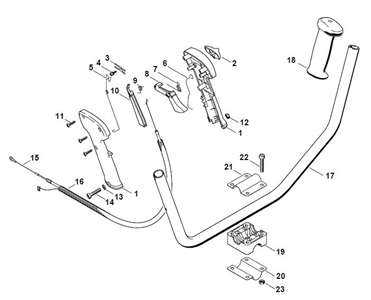

Handle Assembly and Safety Features

The gripping area is designed to offer comfort and control during extended use. Safety mechanisms integrated into the design, such as emergency stops and vibration reduction, protect the user from fatigue and potential hazards. Regular inspection of these features ensures both usability and security.

Understanding the Fuel System Layout

The structure responsible for delivering fuel plays a critical role in ensuring smooth operation and efficiency. A well-maintained setup allows for consistent performance by regulating the flow of fuel from the storage container to the engine.

Below is an overview of key elements involved in the fuel system:

| Component | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Tank | Stores fuel for extended operation and prevents leakage during use. | ||||||||||||

| Fuel Line | Connects the tank to the engine, ensuring a smooth fuel transfer. | ||||||||||||

| Primer Bulb | Assists in pumping fuel into the system to make starting easier. | ||||||||||||

| Filter | Removes impurities from the fuel to protect the engine from damage. | ||||||||||||

| Carburetor | Mixes fuel with air to

Exploring the Trimmer’s Engine AssemblyThe heart of any grass-cutting machine lies in its mechanical system, where multiple components work together to generate motion and power. Understanding how these pieces fit and interact can offer valuable insights into maintaining smooth operation and diagnosing potential issues. Key Elements of the Power System

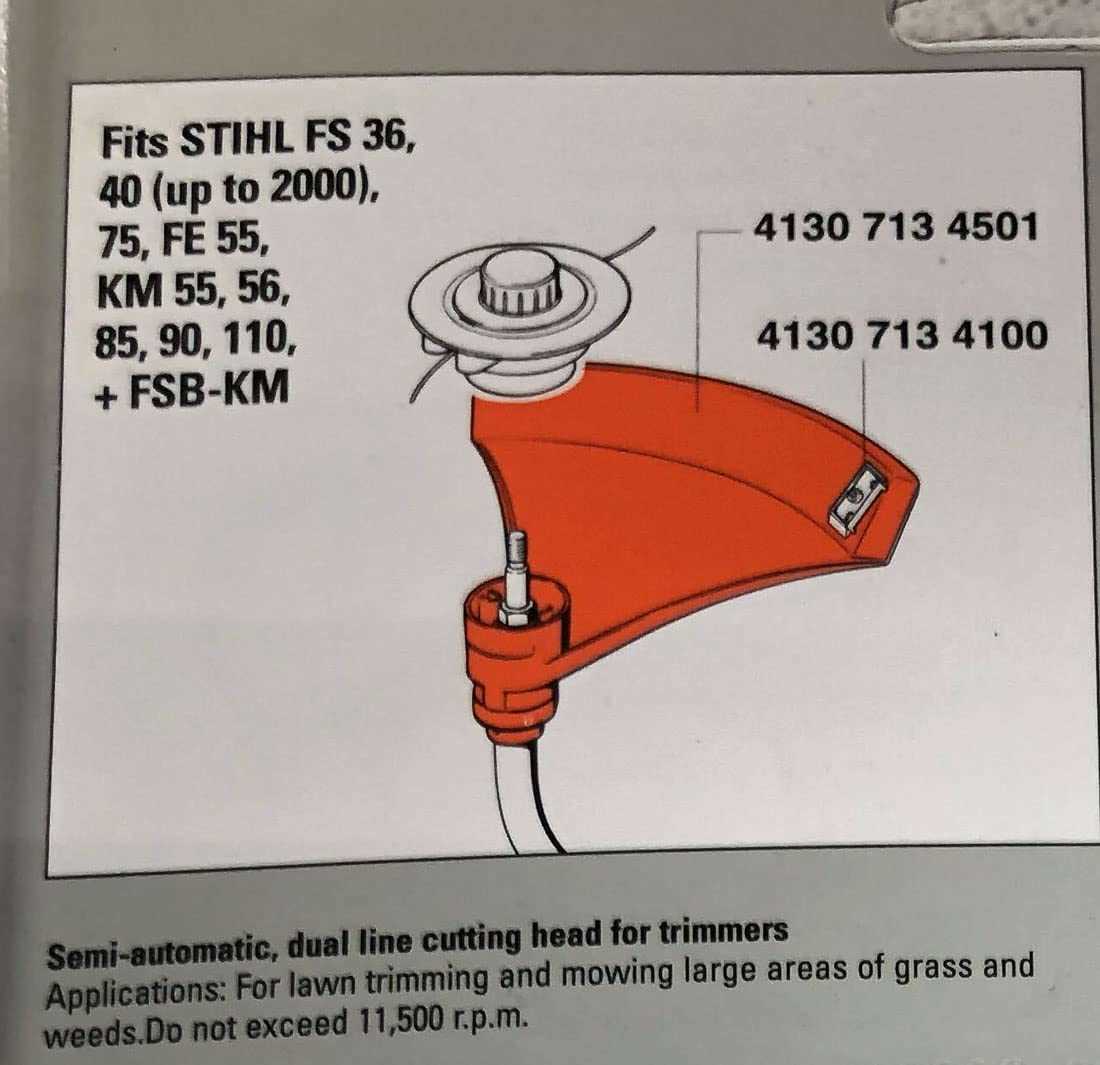

The power source is typically a compact combustion unit. Within this system, the crankshaft plays a pivotal role, transforming linear motion into rotational force. The spark ignition and fuel delivery system ensure that each cycle of the engine operates efficiently, providing the necessary force for the blades or string. Importance of Proper MaintenanceRegular checks of the motor housing and lubrication points are essential to prolonging the engine’s lifespan. Keeping the air intake clean and ensuring tight seals on gaskets prevent unnecessary wear and improve efficiency. Neglecting these areas can lead to overheating, reduced performance, or even component failure over time. Overview of the Cutting Head MechanismThe cutting head serves as the core component responsible for efficiently slicing through vegetation. It operates by rotating at high speeds, ensuring smooth and precise performance in various outdoor tasks. This section will explore the structure and functioning of this essential element, highlighting key features involved in its operation. Main Components

How It Works

By understanding the arrangement and role of these elements, users can ensure proper maintenance and enhance the overall performance of their equipment. A well-maintained cutting head guarantees effective operation, reducing downtime and improving results. Air Filter Setup and Maintenance TipsAn air filter plays a vital role in keeping outdoor equipment running smoothly by ensuring that only clean air reaches the engine. Proper installation and regular upkeep of this component can prevent performance issues and prolong the lifespan of the machinery. Installation Process: Ensure the filter fits securely in its compartment, with no gaps that could allow dust or debris to enter. Align it correctly according to the designated slot or holder, and double-check that it is fastened properly to avoid dislodging during use. Routine Cleaning: Depending on usage frequency, clean the filter regularly by tapping it gently to remove loose dirt. For deeper cleaning, use mild soap and water if the material allows, ensuring it is thoroughly dried before reinstallation. Avoid harsh chemicals that could damage the filter. Replacement Guidelines: Inspect the filter frequently for signs of wear, such as tears or excessive buildup. When it shows visible damage or reduced airflow, replacing it promptly will prevent engine strain and ensure consistent performance. Always use a suitable filter that matches the equipment’s specifications. Replacing the Spark Plug for Better PerformanceMaintaining optimal function in small engine machinery often hinges on the condition of essential components. One crucial element that significantly influences overall efficiency is the ignition device. Over time, this part may wear down or become fouled, leading to decreased performance and reliability. Regularly inspecting and replacing this component can enhance operation and ensure smoother performance. To begin, ensure the equipment is turned off and cool to the touch. Carefully disconnect the wire from the ignition device to prevent accidental starting. Using the appropriate tool, remove the worn part from its socket, taking care to inspect the surrounding area for debris or corrosion. A clean connection will promote better spark generation, which is vital for effective combustion. When installing the new ignition device, ensure it is correctly aligned and securely fastened. A snug fit will prevent misfiring and enhance the engine’s responsiveness. After installation, reconnect the ignition wire, and your machinery will be ready to deliver improved performance. Regularly replacing the ignition device not only enhances efficiency but also prolongs the lifespan of your equipment. It is a simple yet effective maintenance task that can make a significant difference in your machinery’s performance. Detailed Look at the Ignition ModuleThe ignition module plays a crucial role in the overall functionality of outdoor power equipment. It serves as the key component responsible for initiating the combustion process by generating the necessary spark. Understanding its workings can enhance the maintenance and performance of the equipment. Functionality of the Ignition ModuleThis component is designed to manage the timing and intensity of the spark that ignites the fuel-air mixture within the engine. By accurately controlling these parameters, it ensures optimal performance and efficiency, contributing to smoother operation and reduced emissions. Common Issues and Maintenance TipsRegular inspection of the ignition module is essential for identifying potential problems such as misfiring or difficulty starting the engine. Common signs of malfunction include inconsistent sparking or complete failure to start. Cleaning the module and checking the connections can often resolve these issues, ensuring reliable performance. Troubleshooting Common Starter IssuesStarting mechanisms can sometimes present challenges that prevent smooth operation. Identifying and addressing these common issues is essential for ensuring reliable functionality. Various factors can contribute to starter malfunctions, including fuel supply, electrical connections, and mechanical components. One frequent problem is the absence of proper fuel delivery. Ensure the fuel tank is filled with the appropriate mixture and that the fuel lines are clear of obstructions. Additionally, check for any leaks that may impede performance. Another potential cause of starting difficulties is related to the ignition system. Inspect the spark plug for wear or damage, as a faulty plug can prevent ignition. Replacing a worn spark plug can significantly improve the starting process. Moreover, make sure that the electrical connections are secure and free from corrosion. Lastly, mechanical components such as the recoil spring and starter rope should be examined for wear. If these parts are damaged or frayed, they may hinder the starter’s ability to function correctly. Regular maintenance and timely replacements can help avoid these issues in the future. Importance of the Throttle Control SystemThe throttle control system is crucial for managing the performance and efficiency of a handheld tool. This mechanism allows the user to adjust the power output, ensuring optimal operation for various tasks. A well-functioning throttle contributes significantly to both usability and safety, making it an essential component in any device designed for cutting and trimming. Functionality of the Throttle Control

The primary role of the throttle control is to regulate the engine speed. By modifying the amount of air and fuel mixture entering the engine, it enables precise control over the tool’s power. This adaptability allows users to:

Impact on User ExperienceEffective throttle control directly influences the user experience. A responsive system allows for greater maneuverability and control, leading to more efficient and comfortable operation. Moreover, a malfunctioning throttle can result in:

Maintaining the Drive Shaft Assembly

Ensuring the longevity and efficiency of the drive shaft assembly is crucial for optimal performance. Regular maintenance helps prevent issues that may arise from wear and tear, ultimately prolonging the lifespan of the equipment. This section outlines key practices to keep the drive shaft in top condition. Regular InspectionConducting routine inspections is essential for identifying any signs of damage or wear. Look for cracks, bends, or any irregularities in the shaft. Ensure that all connections are secure and that there is no excessive play in the assembly. Promptly addressing any issues can prevent more significant problems down the line. Lubrication PracticesProper lubrication is vital for the smooth operation of the drive shaft. Use an appropriate lubricant to reduce friction between moving parts. Ensure that all joints and bearings are adequately lubricated to minimize wear. Regularly applying lubricant will enhance performance and reduce the risk of overheating during operation. Safety Guards and Their Proper UseWhen handling outdoor equipment, ensuring safety is paramount. Protective barriers are designed to shield users from potential hazards during operation. Understanding their function and correct application is crucial for maintaining a safe working environment. Using safety guards effectively requires familiarity with their features. Below is a table summarizing the essential aspects of these protective components:

By adhering to safety guidelines and using protective barriers properly, operators can significantly reduce the risk of injury while ensuring efficient operation of their equipment. |