Efficient design and maintenance of sanitation systems play a crucial role in ensuring proper functionality. A detailed breakdown of each component within these systems is essential for users who wish to maintain, repair, or optimize their systems. Understanding the interactions between various elements is key to ensuring long-lasting performance and reliability.

From the core mechanisms to the auxiliary elements, each piece of equipment serves a unique purpose. The assembly requires careful consideration to ensure that all components work together harmoniously. Whether it’s the flushing mechanism, sealing components, or water intake system, knowing the exact role of each part can aid in troubleshooting and upgrades.

This guide will explore the intricate setup of these systems, offering a closer look at their individual functions, connections, and maintenance tips. It provides valuable insights for anyone looking to enhance the performance of their installation.

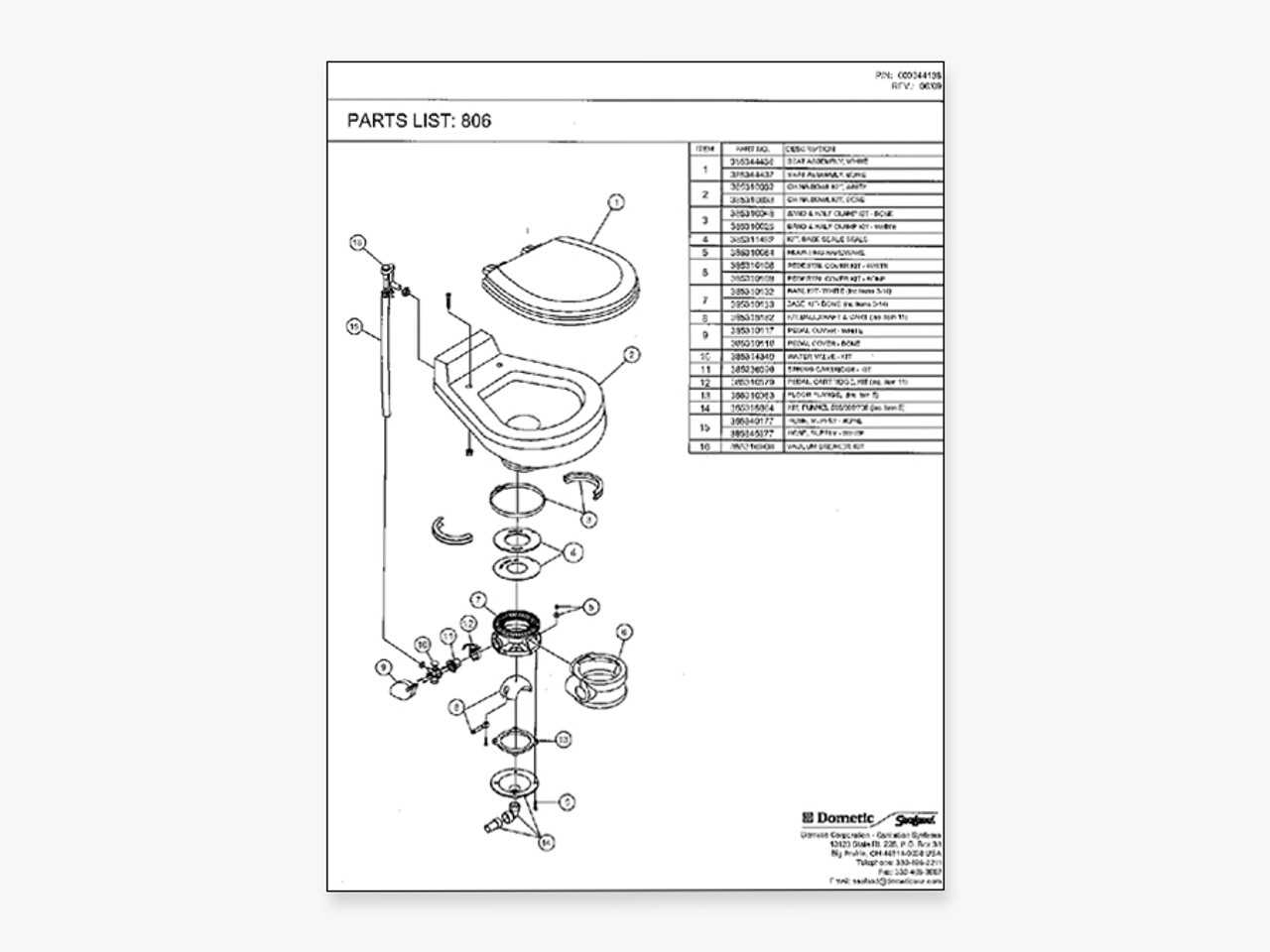

Understanding Dometic Toilet Components

In every modern restroom system, there are various essential components working together to ensure smooth and efficient operation. These elements, though often hidden from plain view, are crucial for maintaining comfort and functionality. Understanding how each piece contributes to the overall mechanism is key to ensuring proper maintenance and troubleshooting.

The system is designed with a focus on longevity and ease of use. Key elements include mechanisms that control waste disposal, water flow, and flushing cycles. Each of these plays a vital role in ensuring optimal performance over time. Durability and reliability are fundamental considerations in the design, with specific parts tailored to work under various environmental conditions.

By familiarizing oneself with the structure and function of these components, one can easily identify potential issues, perform regular maintenance, and enhance the overall user experience. The system’s design aims for both simplicity and efficiency, making it accessible for users with minimal technical knowledge while providing reliable results.

Identifying Key Parts and Functions

Understanding the components and their roles in a sanitation system is crucial for proper maintenance and operation. Each element serves a specific purpose, contributing to the overall functionality and efficiency of the system. Familiarizing oneself with the primary components can help diagnose issues and ensure smooth operation over time.

- Water Control Mechanism: This component regulates the flow of water, ensuring the correct amount is used for each operation. It typically features a valve or lever system to control the water supply.

- Waste Storage Unit: Responsible for holding waste material after use, this part is designed to be durable and easy to empty, offering long-term storage capacity.

- Flushing System: The mechanism that activates the flow of water to clean the unit after each use. It can be activated manually or through an automated system, depending on the model.

- Seal and Gasket: Essential for maintaining a tight closure, these prevent leaks and ensure the integrity of the system by creating a secure seal between moving parts.

- Control Panel: This interface allows the user to operate various functions, such as flushing and water control, providing ease of access and operation.

Each component works together in harmony, and understanding their individual functions is key to troubleshooting and maintenance. Regular inspection of these components helps extend the lifespan and maintain optimal performance.

How to Maintain Dometic Toilets

Proper upkeep of sanitation systems ensures their longevity and efficient operation. Regular maintenance helps prevent common issues such as clogging, leaks, or malfunctioning components. By following a few simple steps, you can extend the lifespan and performance of your unit.

Key Steps for Effective Maintenance

- Inspect seals and gaskets regularly for wear or damage.

- Clean all moving parts to prevent buildup of debris.

- Check for any signs of leakage around the system.

- Lubricate mechanical components to ensure smooth operation.

Troubleshooting Common Issues

- If the system does not flush properly, check for clogs in the piping or blockage in the valve system.

- If you notice odors, inspect seals and gaskets to ensure they are intact and functioning properly.

- If the flushing mechanism is unresponsive, verify the power supply or mechanical linkages for any malfunctions.

Simple Steps for Long-Lasting Use

Proper maintenance and care are essential to ensure that your equipment remains in optimal working condition for an extended period. By following a few simple steps, you can prevent frequent breakdowns and extend the lifespan of key components. Consistency in upkeep will help you avoid costly repairs and enhance overall efficiency.

- Regularly check for leaks and cracks to ensure there are no areas where damage could spread.

- Clean all relevant surfaces with appropriate cleaning agents to avoid build-up that could hinder functionality.

- Ensure seals and connections are tight to maintain proper operation and prevent malfunctions.

- Lubricate moving parts periodically to reduce wear and tear, ensuring smooth operation.

- Inspect the system for any signs of wear and replace components as needed to maintain performance.

By following these guidelines, you will be able to maintain your equipment’s efficiency and extend its usable life, minimizing the need for extensive repairs.

Common Issues with Toilet Parts

When it comes to maintaining your restroom system, certain components often face wear and tear, leading to common challenges. These issues can range from leakage to malfunctioning mechanisms, causing inconvenience and discomfort. Identifying these problems early can help in taking prompt corrective action, ensuring proper functioning for a long time.

Clogging is one of the most frequent problems, often resulting from blockages in the piping or malfunctioning flush mechanisms. Over time, accumulation of waste and debris can restrict the flow, leading to operational failures.

Leaks around seals or connections can also cause significant issues. If water is consistently found outside the expected areas, it may indicate poor sealing, broken connectors, or damaged valves, all of which can compromise the system’s efficiency.

Another common concern is the failure of flushing mechanisms, which can be due to worn-out seals or faulty sensors. These malfunctions prevent the flushing action from occurring smoothly, requiring attention to the internal components to restore proper function.

Identifying and Solving Problems

When a malfunction occurs in your system, it can often disrupt its functionality and comfort. To address these issues effectively, it’s essential to identify the source of the problem and take the necessary steps to resolve it. Recognizing common signs of wear or failure early on can save time, effort, and prevent more significant damage in the future.

Common Signs of Malfunctions

- Weak or inconsistent flushing action

- Strange noises during operation

- Leaking or water accumulation around the unit

- Unpleasant odors despite cleaning

Steps for Troubleshooting

- Inspect seals and connections for leaks or deterioration.

- Check the water supply system to ensure there are no blockages or disruptions.

- Test the flushing mechanism to ensure it operates smoothly without interruptions.

- Clean all components, paying special attention to any buildup that may be affecting performance.

Exploring Water Supply Mechanisms

Understanding the dynamics of water flow in various systems is essential for ensuring efficient performance. The way water enters and exits through specific conduits plays a crucial role in maintaining consistent operation. This mechanism involves a careful balance of pressure and timing to deliver the required amount of liquid to the desired location.

Key Components involved in water delivery systems include valves, pipelines, and control units that regulate flow. Each element is designed to manage water distribution, ensuring smooth operation and preventing potential issues such as leaks or overflows.

The integration of these components must be seamless to avoid interruptions in functionality. Proper maintenance and regular checks of the supply lines are crucial in preserving long-term reliability.

How Water Flows in Dometic Toilets

The process of liquid circulation within these systems is designed to ensure efficient rinsing and disposal. The movement of water is crucial to maintaining hygiene and operational effectiveness, following a controlled path from the source to the final exit point. Understanding this movement helps in troubleshooting and optimizing system performance.

| Stage | Description |

|---|---|

| 1. Entry | Water enters through a controlled valve, which regulates the pressure and volume based on user input. |

| 2. Distribution | The liquid flows into a chamber where it is evenly distributed across the internal surfaces for thorough rinsing. |

| 3. Drainage | Once the cleaning cycle is complete, the excess water is drained through a dedicated outlet, ensuring efficient removal. |

| 4. Refill |