The efficient operation of a chainsaw relies heavily on its various interconnected elements. To maintain peak performance, knowing how each element fits into the overall design is essential for repairs and upkeep. This section aims to give a clear overview of the essential components involved in this specific chainsaw model.

Key mechanisms include those responsible for engine power, cutting performance, and safety features. By understanding how these individual elements function, users can more easily identify potential issues and keep their tool in prime working condition. Regular inspection and proper alignment of each component is vital for long-term durability.

In this guide, we will explore the crucial segments that form the framework of this tool, offering a step-by-step insight into its internal structure. With this knowledge, users can confidently approach both maintenance and troubleshooting.

Essential Components of the Stihl MS180C-BE

The internal structure of this versatile tool is comprised of key elements that ensure its reliable operation and performance. Understanding these components is crucial for maintaining and troubleshooting this machine.

- Engine Unit – The core of the device, delivering the power needed for efficient cutting and handling various tasks.

- Starter Mechanism – Designed for easy ignition, this feature enhances user experience by minimizing effort during startup.

- Fuel System – Ensures the right balance of air and fuel, critical for optimal engine function and durability.

- Chain Assembly – Responsible for the cutting action, this element requires proper tensioning and lubrication for smooth operation.

- Bar – The guiding frame for the chain, designed for stability and precise cuts in different conditions.

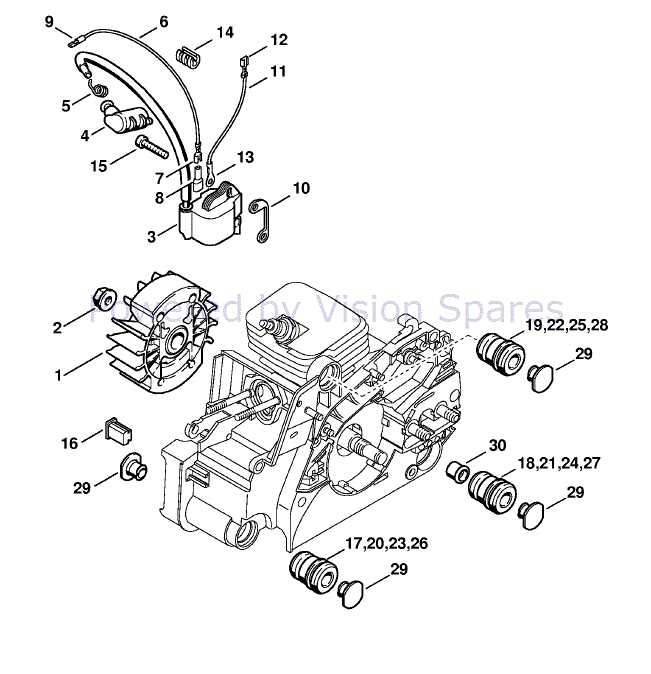

Detailed Breakdown of Engine Parts

The internal components of a small two-stroke motor are designed to work in harmony, ensuring efficient performance. Each element plays a vital role in converting fuel into mechanical energy, with various sections contributing to airflow, ignition, and combustion.

Key Components Overview

- Cylinder: Houses the piston, where the fuel mixture combusts.

- Piston: Moves within the cylinder, transferring energy to the crankshaft.

- Crankshaft: Converts the piston’s linear motion into rotational energy.

- Carburetor: Mixes air and fuel in the correct ratio for combustion.

Additional Components and Their Functions

- Flywheel: Stabilizes engine speed and powers the ignition system.

- Recoil Starter: Initiates

Understanding the Ignition System Layout

The ignition system is a crucial component that ensures reliable starting and efficient operation of the engine. By coordinating electrical signals, it generates the necessary spark to ignite the fuel mixture, leading to combustion. Understanding how each element connects and interacts is key to maintaining and troubleshooting the mechanism effectively.

- Ignition Coil: Converts low voltage into a high-voltage current required for spark generation.

- Spark Plug: Receives the high-voltage current from the coil and creates the spark to ignite the fuel.

- Flywheel Magnet: A rotating component that helps generate the initial magnetic field to trigger the ignition.

- Kill Switch: Interrupts the circuit to stop the engine by cutting off the spark.

Each part of

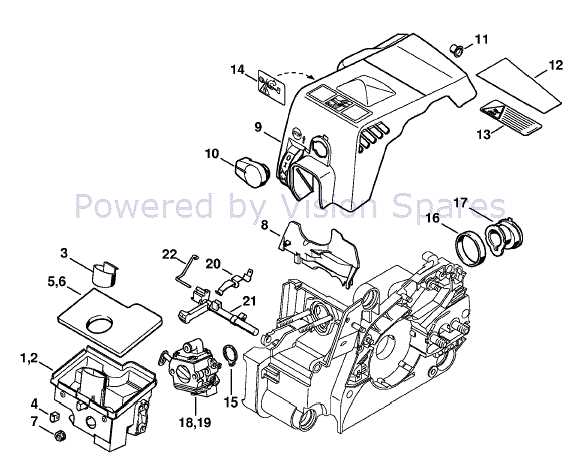

Guide to the Carburetor Assembly

The carburetor is a crucial component responsible for blending fuel and air to maintain engine efficiency. Its assembly and proper maintenance ensure smooth operation, avoiding potential issues with performance and reliability.

Main Components of the Carburetor

The carburetor consists of several interconnected elements that work together to regulate fuel flow. Below are the key components:

- Fuel inlet valve

- Float mechanism

- Throttle and choke levers

- Jets and air passages

Steps for Reassembly

- Ensure all parts are clean and free of debris.

Air Filter Components and Functions

The air filter is a crucial element in ensuring the engine remains clean and free of contaminants. It plays an essential role in trapping particles that could otherwise harm internal mechanisms. Maintaining proper airflow while filtering debris is vital for the system’s overall performance and longevity.

Main Components of the Filter

The core elements of the air filtration system include the outer casing, the filtering material, and the seal. Each part contributes to effective filtration by creating barriers that prevent dust and dirt from entering the engine.

Functions of the Air Filter

The primary function of the air filter is to maintain a balance between allowing sufficient air into the engine while stopping harmful particles. By performing this task, it helps improve fuel efficiency, protects the engine, and ensures smooth operation over time.

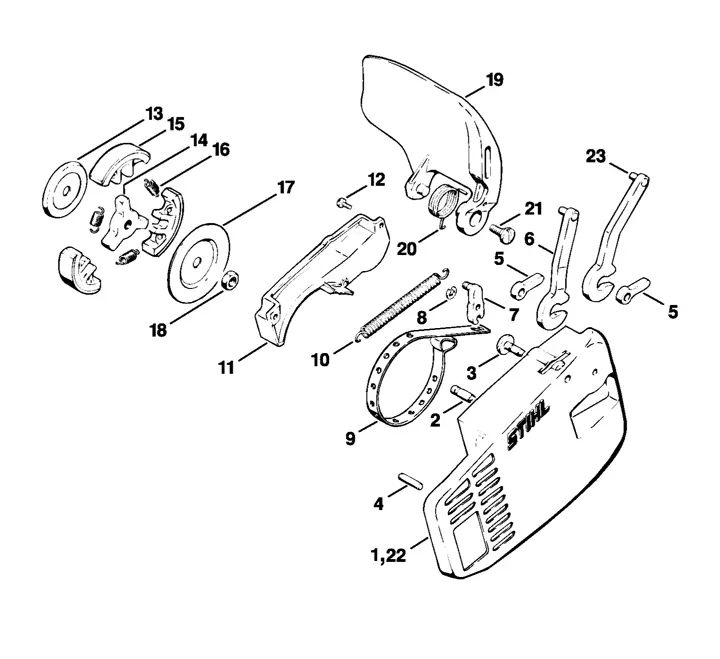

Chain Tensioner Mechanism Explained

The chain tensioning system is a crucial component of any cutting tool, ensuring optimal performance and safety during operation. This mechanism regulates the tightness of the cutting chain, preventing it from becoming too loose or too tight, which can lead to inefficient cutting or potential hazards. Understanding how this system operates is essential for maintaining the longevity and effectiveness of the tool.

Components of the Tensioning System

The tensioning system typically comprises several key elements, including a tensioning screw, a guide bar, and a chain. The tensioning screw allows for precise adjustments to the chain’s tightness, while the guide bar provides support and alignment for the chain during cutting tasks. The interaction between these components ensures that the cutting chain remains securely in place, maximizing cutting efficiency.

Adjustment and Maintenance

Regular maintenance of the tensioning system is vital for optimal performance. Users should periodically check the tension of the chain and make necessary adjustments using the tensioning screw. A well-maintained tensioning mechanism not only enhances cutting efficiency but also extends the lifespan of both the chain and the cutting tool.

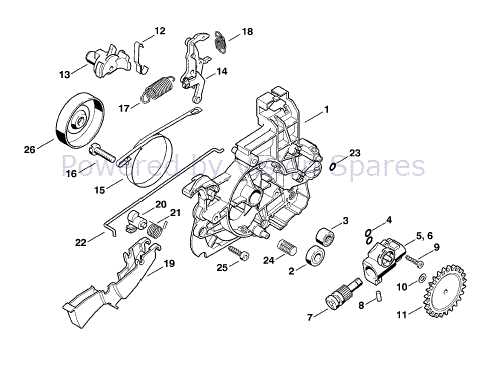

Overview of Clutch Assembly Parts

The clutch assembly is a critical component in the operation of many small engine machines, ensuring smooth power transfer between the engine and the cutting tool. Understanding its individual components can aid in troubleshooting and maintenance, enhancing overall performance and longevity.

Key Components of the Clutch Assembly

Below are the primary elements that constitute the clutch assembly:

- Clutch Drum: This component houses the clutch mechanism and plays a vital role in transferring power from the engine.

- Shoe Assembly: The shoes engage and disengage with the drum, allowing the cutting tool to operate smoothly.

- Spring: Springs provide the necessary tension for the clutch shoes, ensuring they function correctly under varying load conditions.

- Drive Shaft: This component connects the engine to the clutch, facilitating power transmission.

- Mounting Plate: The plate secures the entire assembly and maintains alignment within the housing.

Maintenance Tips for Clutch Assembly

Regular inspection and maintenance of the clutch assembly can prevent operational issues. Here are some helpful tips:

- Check for wear and tear on the clutch shoes and replace them as needed.

- Ensure the springs are intact and free from corrosion.

- Lubricate the moving parts to reduce friction and enhance performance.

- Inspect the drum for cracks or damage that may affect functionality.

Fuel System Diagram and Key Parts

The fuel delivery system is essential for the efficient operation of a power tool. This section outlines the fundamental components that facilitate fuel flow and discusses their functions within the overall assembly. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance.

Essential Components

Below are the key components found in the fuel delivery assembly:

- Fuel Tank: The reservoir that holds the gasoline or fuel mixture.

- Fuel Filter: Removes impurities from the fuel to prevent clogging.

- Fuel Lines: Tubes that transport fuel from the tank to the carburetor.

- Carburetor: Mixture of air and fuel is created for combustion in the engine.

- Primer Bulb: A pump used to draw fuel into the carburetor for easier starting.

Functionality Overview

The fuel system operates through a series of interconnected components that ensure a steady supply of fuel to the engine. The process begins with the fuel being drawn from the tank through the fuel filter, ensuring cleanliness before reaching the carburetor. The carburetor then combines the fuel with air, creating a combustible mixture that powers the engine.

Proper maintenance of these components is vital to prevent performance issues. Regularly checking for leaks in fuel lines and ensuring the filter is clean can enhance the lifespan and efficiency of the equipment.

Oil Pump and Lubrication Components

The effective operation of any cutting tool relies heavily on its lubrication system, which ensures that moving parts operate smoothly and efficiently. This system minimizes friction and wear, prolonging the lifespan of the equipment. The oil pump plays a crucial role in this process, delivering the necessary lubricant to various components, thus maintaining optimal performance.

Functionality of the Oil Pump

The oil pump is responsible for circulating lubricant throughout the engine, ensuring that all critical areas receive adequate protection. It works by drawing oil from the reservoir and distributing it under pressure to the necessary components, such as the chain and bar. This mechanism not only helps in cooling but also in reducing the risk of overheating and damage.

Essential Lubrication Components

In addition to the pump, several other parts contribute to the overall lubrication process. These include oil filters that trap contaminants, hoses that facilitate the flow of lubricant, and nozzles that direct oil to specific areas. Each component plays a vital role in ensuring that the lubrication system functions effectively, allowing the cutting tool to perform at its best.

Handle and Trigger Assembly Structure

The handle and trigger assembly plays a vital role in the overall functionality and safety of power tools. This component is designed to provide users with a secure grip while ensuring precise control over the operation of the equipment. Understanding the arrangement and function of this assembly is essential for effective maintenance and repair.

Key Components

This assembly consists of various parts that work together to facilitate ease of use. Each component contributes to the ergonomic design, allowing for comfortable handling and efficient operation. Below is a summary of the essential parts:

Component Function Handle Grip Provides comfort and control during use. Trigger Mechanism Activates the engine and controls the power output. Safety Switch Prevents accidental activation, enhancing user safety. Mounting Bracket Secures the assembly to the main body of the tool. Importance of Proper Maintenance

Regular inspection and maintenance of the handle and trigger assembly are crucial for safe operation. Ensuring that all components are functioning correctly can prevent accidents and extend the lifespan of the tool. It is advisable to replace worn or damaged parts promptly to maintain optimal performance.

Recoil Starter Mechanism Components

The recoil starter mechanism is an essential feature in many handheld power tools, providing a reliable way to initiate the engine’s operation. Understanding the components of this system can enhance maintenance and troubleshooting efforts. Each element plays a crucial role in ensuring smooth functionality and efficient starting performance.

Key Elements of the Mechanism

At the heart of the recoil starter is the pull cord, which, when pulled, engages the starter pawl. This action spins the flywheel, generating the necessary momentum to start the engine. The return spring is another vital component, responsible for retracting the cord and ensuring it is ready for the next use. Together, these parts work harmoniously to deliver a seamless starting experience.

Importance of Proper Maintenance

Regular inspection and maintenance of the recoil starter components are critical for optimal performance. Worn or damaged parts can lead to starting issues or engine failure. Ensuring that the cord is intact and the spring is properly tensioned will help maintain the efficiency and reliability of the starting system, ultimately extending the lifespan of the equipment.

Chain Brake and Safety Mechanisms

The effective operation of cutting equipment relies heavily on integrated safety features. Among these, the chain brake plays a crucial role in ensuring the user’s protection by preventing unintended chain movement during operation. This section explores the function and importance of these safety components, highlighting their design and impact on user safety.

Functionality of the Chain Brake

The primary purpose of the chain brake is to halt the chain’s motion swiftly in case of kickback or loss of control. When engaged, the brake system utilizes a mechanism that blocks the chain, effectively stopping any further movement. This feature not only enhances safety but also instills confidence in the user, allowing for a more secure cutting experience.

Additional Safety Features

In addition to the chain brake, various safety mechanisms are incorporated into cutting tools to further protect the operator. These may include hand guards and throttle locks, which work together to minimize the risk of accidental activation. Regular maintenance and understanding of these safety systems are vital for optimal performance and user safety.

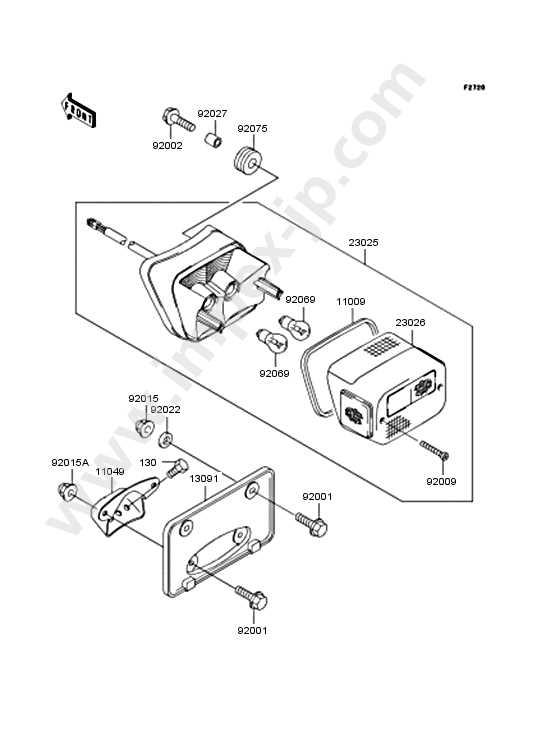

Muffler and Exhaust System Breakdown

The exhaust apparatus plays a critical role in the overall performance and efficiency of a power tool. Understanding its components and functionality is essential for maintaining optimal operation. The system not only expels gases produced during combustion but also influences noise levels and engine performance.

The muffler is designed to reduce engine noise while facilitating the safe release of exhaust fumes. It typically consists of various chambers and baffles that help in sound attenuation. Proper functioning of the muffler ensures a quieter operation and contributes to a more pleasant working environment.

Exhaust pipes connect the engine to the muffler, directing gases away from the engine and out of the tool. Any blockages or damage in these pipes can lead to increased back pressure, affecting engine efficiency. Regular inspection and maintenance of both the muffler and exhaust pipes are vital to ensure longevity and reliable performance.