In the realm of winter maintenance, the efficient operation of machinery is crucial for ensuring clear pathways and driveways. A thorough comprehension of the various elements involved in such equipment enhances its functionality and longevity. Each section contributes uniquely to the overall performance, making knowledge of these parts essential for users and technicians alike.

By exploring the intricate workings and relationships between these essential components, one can appreciate the design and engineering that go into crafting reliable solutions for snowy conditions. This exploration not only empowers users to troubleshoot effectively but also inspires confidence in managing maintenance tasks.

Ultimately, delving into the specifics of these mechanisms reveals how they synergize to tackle the challenges posed by winter weather. Understanding their roles allows for informed decisions regarding care and operation, ensuring optimal performance throughout the season.

Understanding Snowblower Components

In the realm of winter equipment, comprehending the various elements that contribute to effective operation is crucial. Each component plays a significant role in ensuring efficiency and reliability, especially in challenging weather conditions. By exploring these essential pieces, users can enhance their knowledge and ultimately improve their handling of the machinery.

Core Elements

The primary elements encompass a range of functionalities, from power generation to propulsion. These components work in harmony, ensuring the device can effectively clear pathways and driveways. Understanding how each part interacts helps in troubleshooting and maintenance, prolonging the lifespan of the equipment.

Operational Insights

Knowledge of the intricate workings allows users to make informed decisions regarding usage and care. For instance, recognizing the importance of a well-maintained engine can significantly influence performance. Thus, a deeper insight into these crucial features leads to better outcomes during winter storms.

Main Functions of a Snowblower

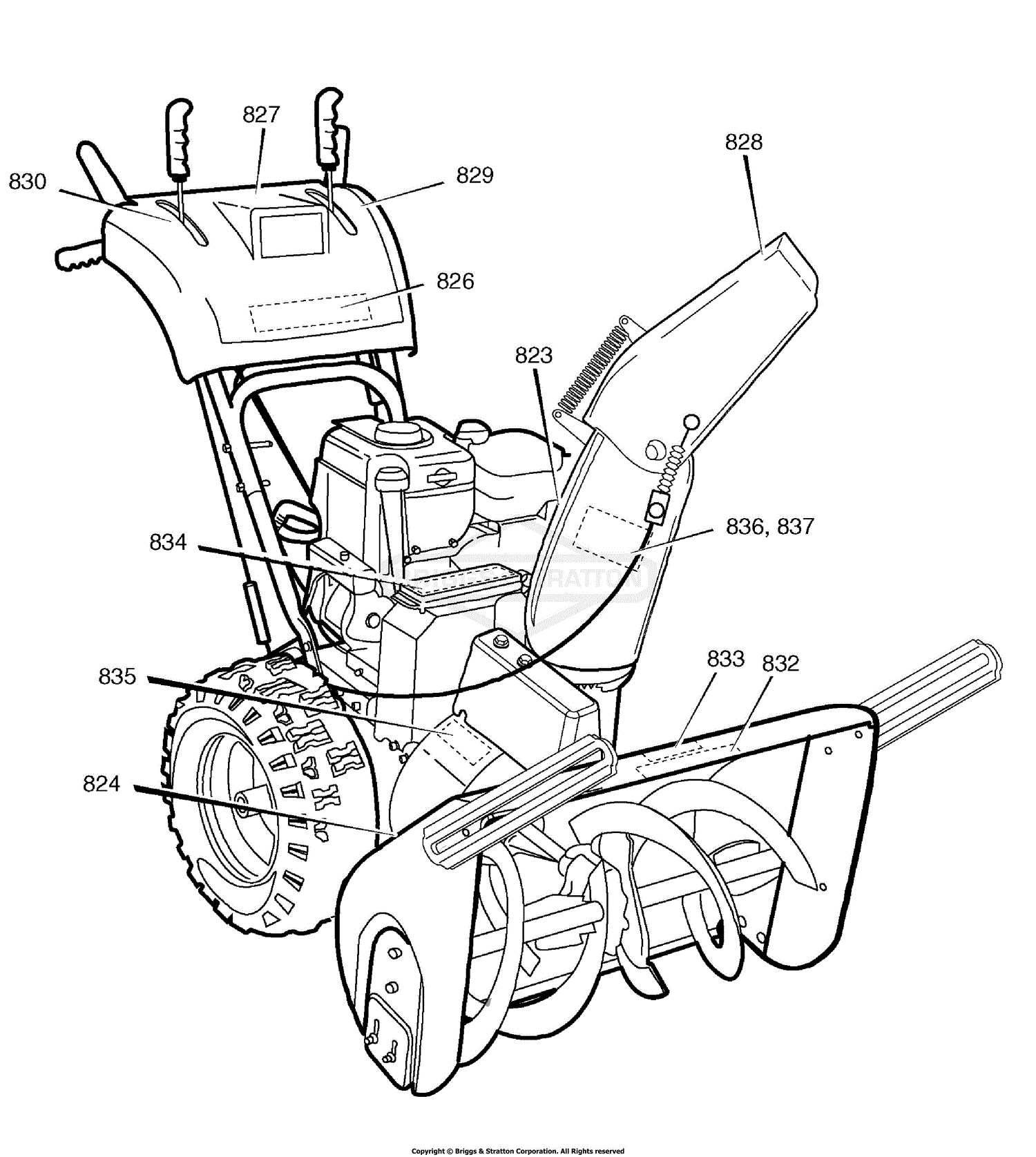

This machine is designed to efficiently clear away accumulated snow, making pathways accessible and safe. Its operation involves several key actions that contribute to its overall effectiveness in winter conditions.

- Clearing Snow: The primary role is to remove snow from driveways, sidewalks, and other surfaces.

- Throwing Snow: Once collected, it propels the snow to the side, preventing it from obstructing paths.

- Adjusting Direction: Many models allow users to control the angle and distance the snow is thrown.

- Handling Different Snow Types: It can tackle various snow conditions, from light flurries to heavy accumulations.

By incorporating these functions, the machine significantly reduces the time and effort needed for snow removal, providing convenience and efficiency during winter months.

Essential Parts Explained

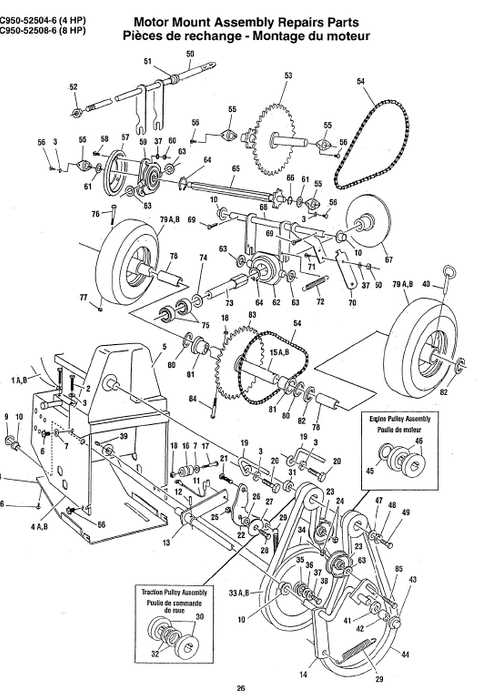

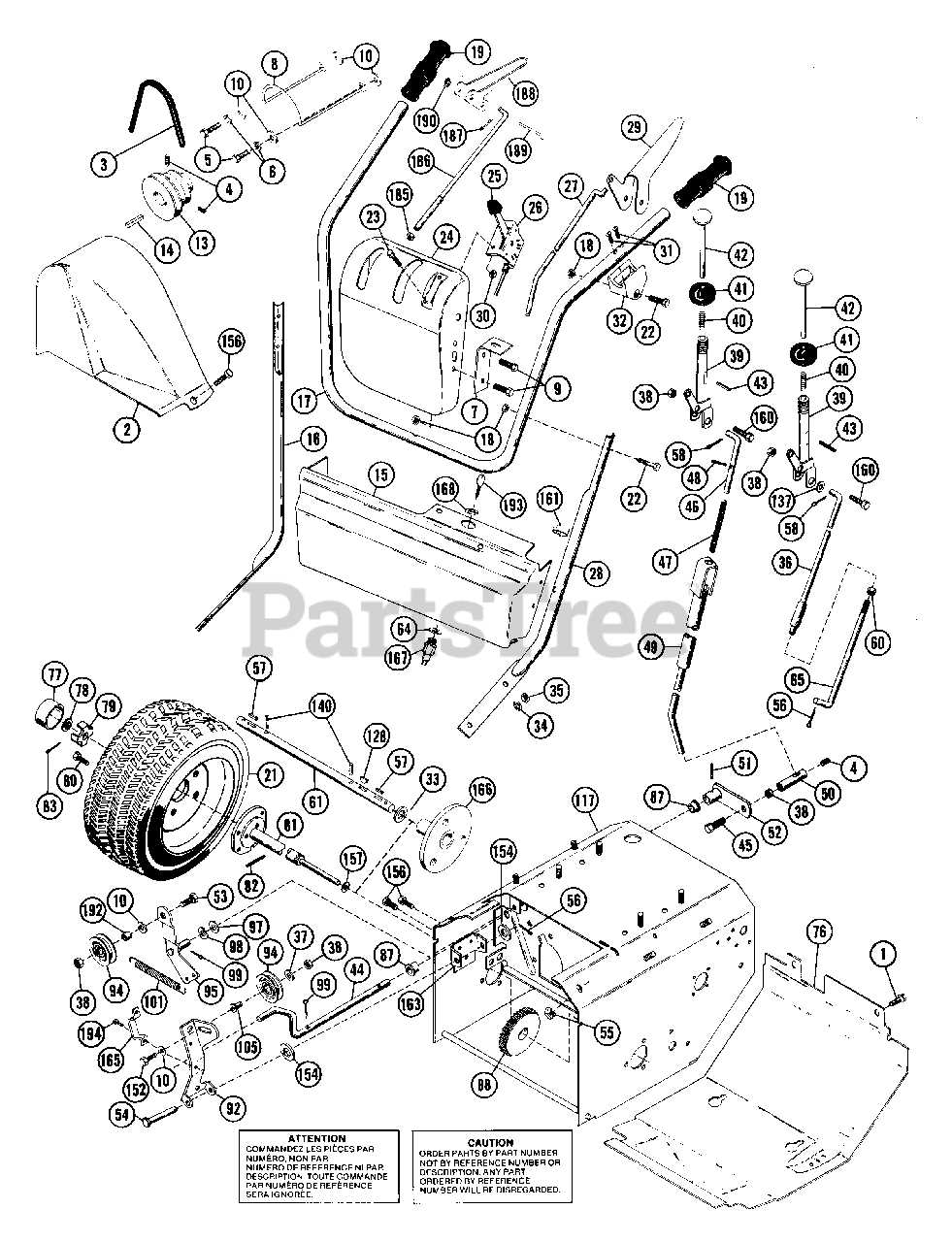

Understanding the key components of this powerful machine is crucial for optimal performance and maintenance. Each element plays a significant role in the overall functionality, ensuring efficiency and reliability during use. By familiarizing yourself with these vital sections, you can enhance your operational knowledge and extend the lifespan of the equipment.

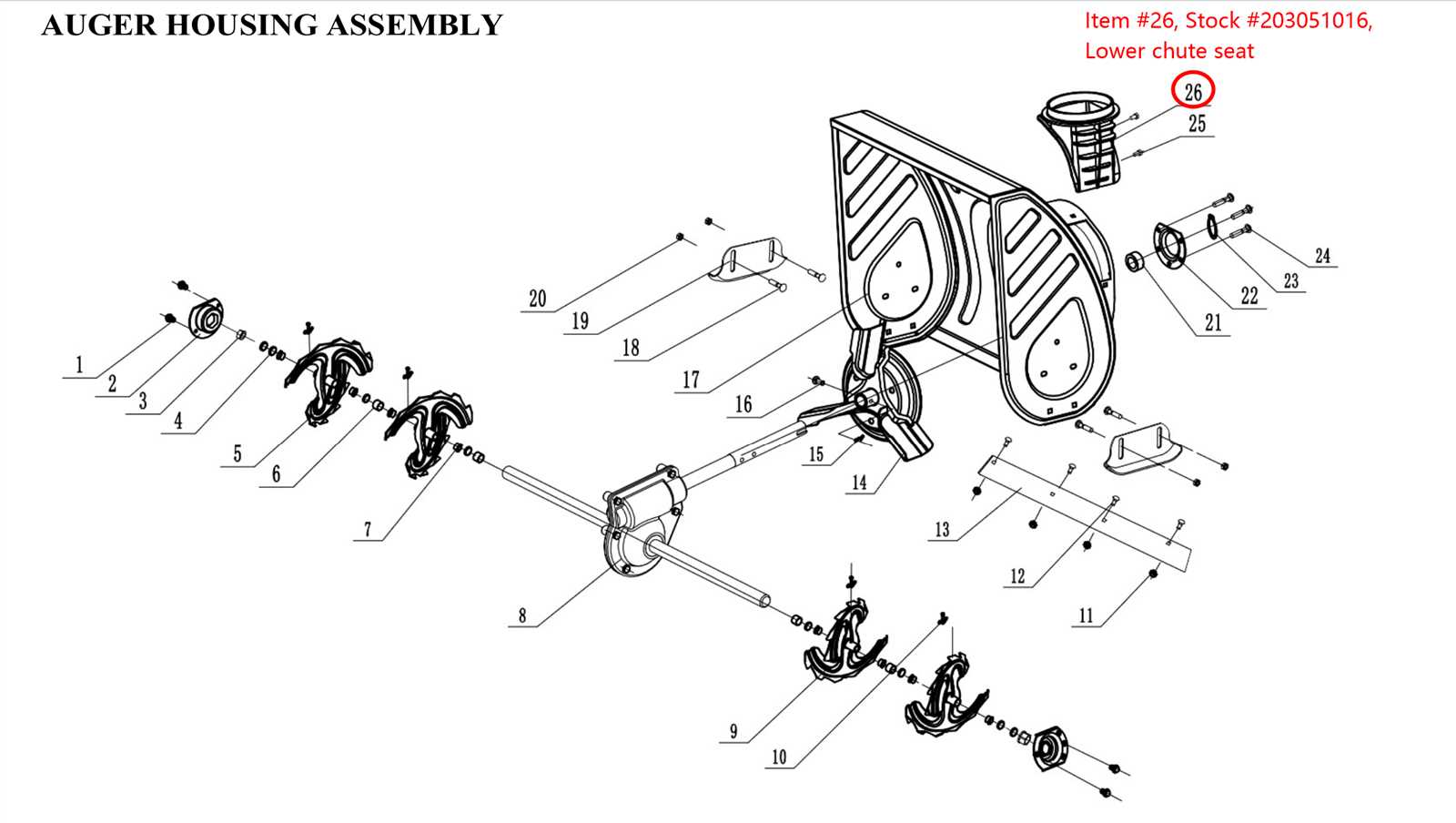

The intake housing is where the snow is initially gathered, directing it toward the auger. This component is designed to handle heavy loads and ensures smooth processing. Next, the auger itself is responsible for breaking up and moving the snow, featuring sharp blades that facilitate effective clearing.

The impeller follows, propelling the snow out of the chute with force, allowing for precise discharge direction. The chute itself can often be adjusted, giving the user control over where the snow is expelled, which is particularly useful in various environments.

Finally, the drive system, including the engine and transmission, powers the entire unit, providing the necessary torque and speed for different conditions. By delving into these essential elements, you can better appreciate the intricate design that makes this machine an invaluable tool during winter months.

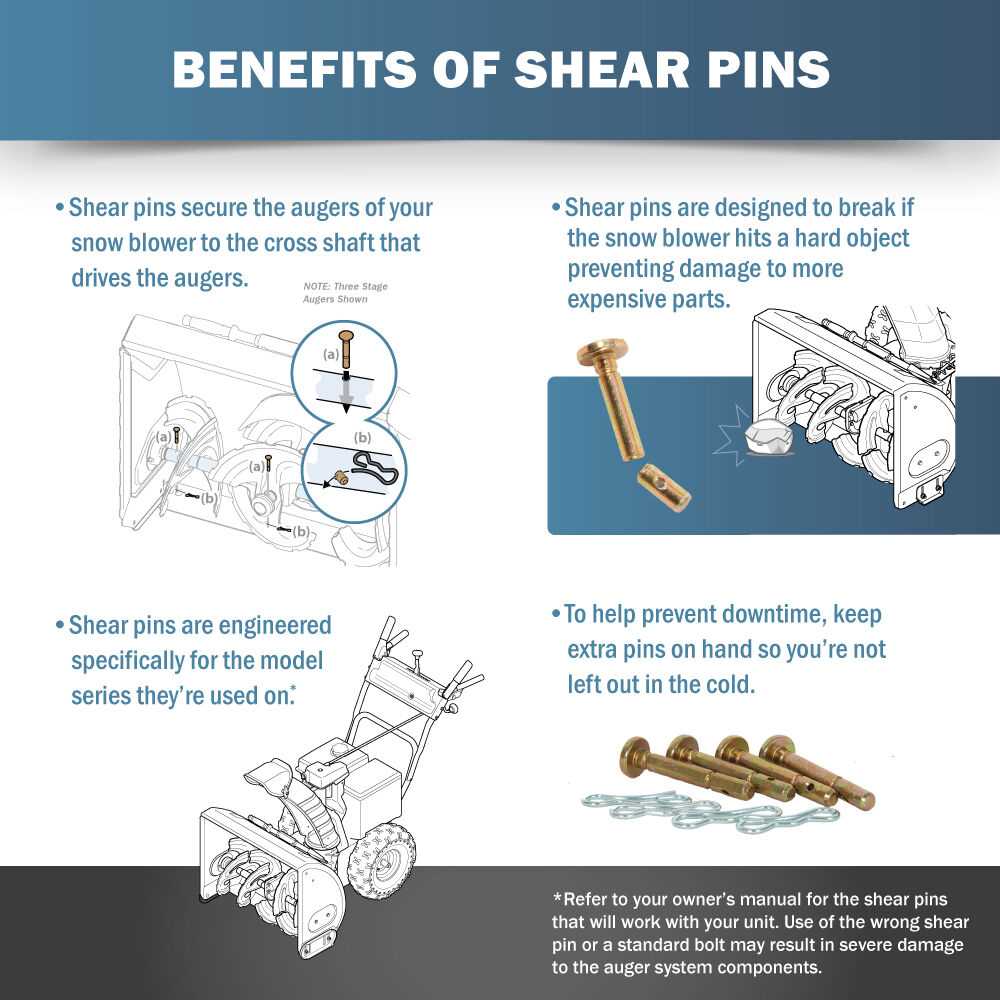

How the Auger Works

The auger is a vital component that plays a crucial role in the efficient clearing of frozen precipitation. Its design allows for effective movement and dislodging of accumulated snow, ensuring a smooth operation. Understanding its functionality can enhance the overall performance of the equipment.

Here’s how the auger operates:

- Rotation: As the mechanism engages, the auger rotates swiftly, creating a powerful motion that breaks up the snow.

- Collection: The spiraled blades scoop up the snow, drawing it into the center of the unit.

- Discharge: Once collected, the snow is propelled towards the discharge chute, allowing for effective removal from the area.

This sequential process is critical for maintaining efficiency during operation. Regular maintenance of the auger can lead to improved performance and longevity of the equipment.

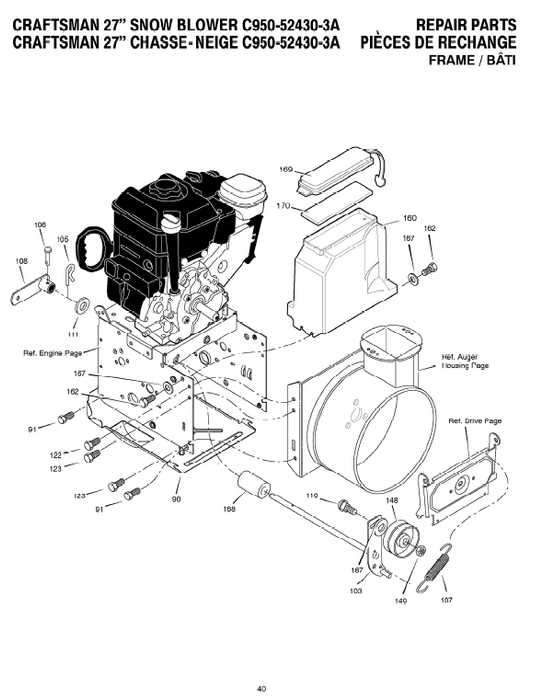

The Role of the Chassis

The chassis serves as the foundational structure that supports various components and ensures stability during operation. Its design significantly influences performance and maneuverability, making it a crucial element in the overall functionality of the machine.

Stability and Durability

A robust frame is essential for withstanding the rigors of heavy use, providing stability while navigating challenging terrains. The materials used in its construction contribute to its longevity, ensuring that it can endure harsh weather conditions and rigorous tasks.

Integration of Components

The chassis acts as the central hub for connecting different elements, facilitating seamless interaction among them. Proper alignment and support enhance the ultimate efficiency of the entire system, allowing for smoother operation and reduced wear on individual parts.

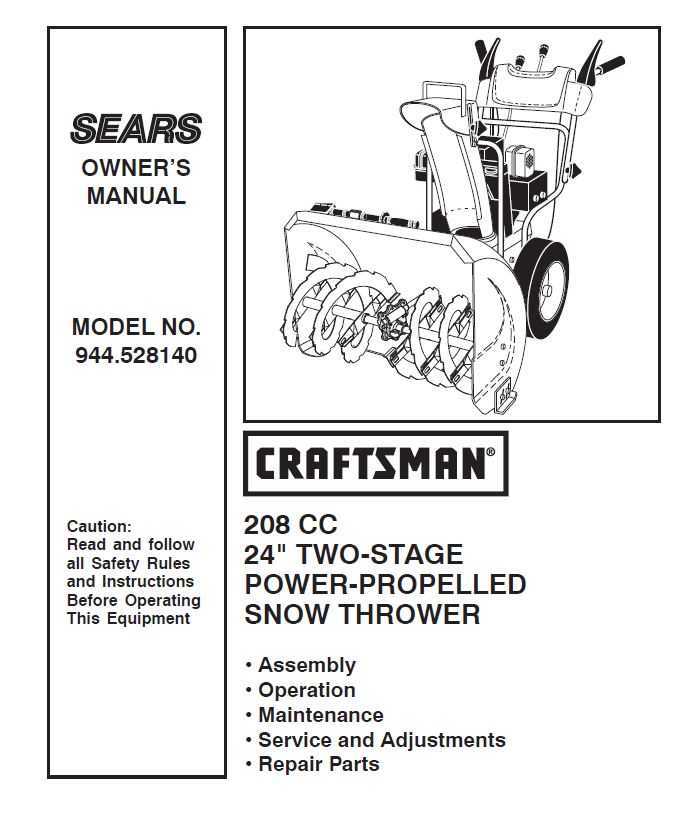

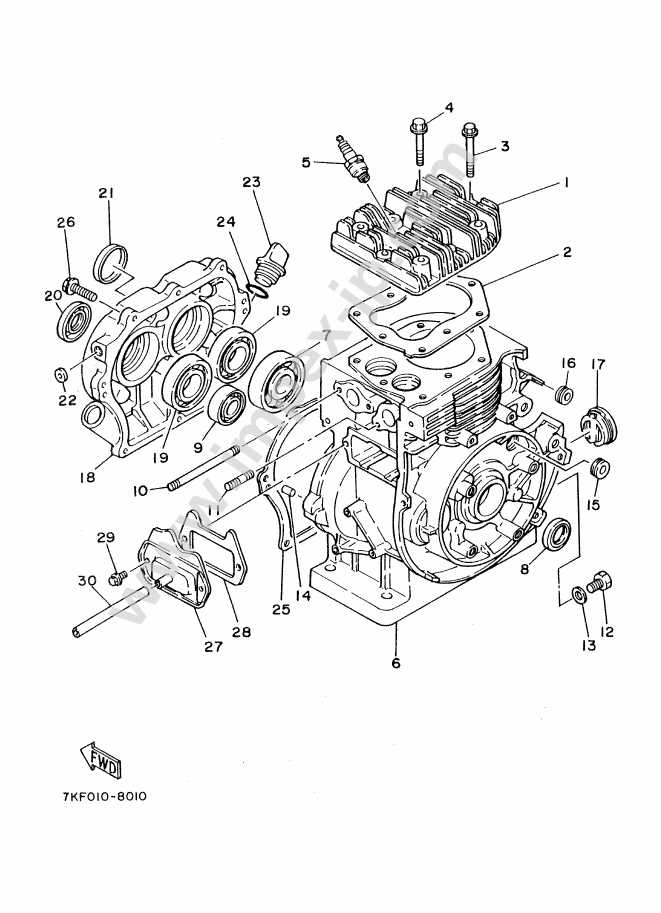

Engine Specifications and Types

Understanding the core components that drive these machines is essential for optimizing performance and efficiency. The engine plays a pivotal role, influencing everything from power output to fuel consumption. Various designs and configurations are available, catering to different needs and preferences.

Types of Engines

Engines can be broadly categorized into two main types: two-stroke and four-stroke. Two-stroke engines are lightweight and offer high power-to-weight ratios, making them suitable for smaller models. In contrast, four-stroke engines are known for their fuel efficiency and lower emissions, ideal for larger, more robust machines.

Specifications to Consider

When selecting an engine, consider horsepower, displacement, and torque. Horsepower indicates the power available for operation, while displacement affects the engine’s ability to perform under various conditions. Torque is crucial for determining how well the machine can handle heavy loads, making it an important factor for optimal functionality.

Importance of the Impeller

The impeller plays a crucial role in the efficiency and performance of any machine designed for snow removal. Its primary function is to facilitate the movement and discharge of snow, ensuring that the area is cleared effectively. Understanding its significance can greatly enhance user experience and operational effectiveness.

Key reasons for the importance of the impeller include:

- Efficient Snow Displacement: The impeller generates the force needed to push snow out of the chute, allowing for rapid and thorough clearing.

- Impact on Performance: A well-functioning impeller directly correlates with the overall efficiency of the equipment, affecting how quickly and effectively snow can be removed.

- Durability: The quality and construction of the impeller influence the lifespan of the equipment, as a robust design can withstand harsh conditions.

- Adaptability: Modern impellers are designed to handle various types of snow, whether wet or dry, making them versatile for different weather conditions.

In summary, the impeller is not just a component; it is fundamental to the successful operation of snow clearing machinery. Proper maintenance and understanding of its function can significantly improve the user experience and efficiency in snow management tasks.

Snow Discharge Mechanisms

Understanding the systems responsible for the expulsion of frozen precipitation is crucial for effective operation and maintenance. These mechanisms play a vital role in determining how efficiently the accumulated ice is cleared from driveways and pathways. Various components work in unison to achieve optimal performance, ensuring that the snow is directed away from the working area.

Typically, these systems utilize an impeller and chute configuration to manage the flow and trajectory of the snow. The design and functionality of these elements greatly influence the efficiency and speed at which the snow is cleared.

| Component | Description |

|---|---|

| Impeller | A rotating element that helps to propel the snow towards the discharge chute. |

| Chute | A channel that directs the snow away from the clearing area, allowing for controlled discharge. |

| Deflector | A movable part of the chute that adjusts the angle of discharge, influencing where the snow is thrown. |

| Auger | A component that gathers and feeds the snow into the impeller for effective processing. |

Proper understanding and maintenance of these mechanisms can enhance performance and extend the lifespan of the equipment, making snow removal tasks more efficient and manageable.

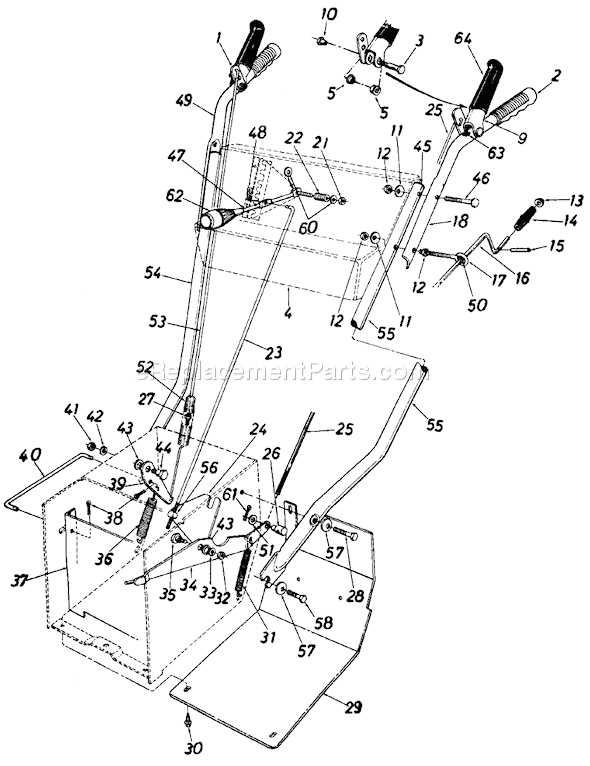

Control Mechanisms Overview

The functionality of any outdoor equipment hinges on its operational controls, which enable users to navigate various tasks efficiently. These systems are designed to enhance usability and provide precise management of the machine’s performance, ultimately leading to an improved user experience.

Operational levers serve as the primary interface, allowing for adjustments in speed and direction. Each lever is engineered to respond intuitively to user input, ensuring a seamless operation. Furthermore, electronic components may be integrated to facilitate automated functions, reducing manual effort and increasing precision.

Another critical aspect is the safety features embedded within the control framework. These mechanisms are designed to prevent accidental activation and ensure that the operator can maintain complete control at all times, enhancing overall safety during use.

Ultimately, a thorough understanding of these control systems not only contributes to efficient operation but also empowers users to troubleshoot and maintain their equipment effectively.

Maintenance Tips for Snowblowers

Keeping your winter equipment in top condition is essential for optimal performance during the snowy months. Regular upkeep not only extends the lifespan of your machine but also ensures it operates efficiently when you need it most.

Here are some key maintenance tips to consider:

- Regular Cleaning: After each use, remove any snow and ice buildup to prevent corrosion and blockages.

- Inspect the Belts: Check for wear and tear on the belts. Replace them if you notice cracks or fraying.

- Oil Changes: Follow the manufacturer’s recommendations for oil changes. Fresh oil improves performance and reduces engine wear.

Additionally, you should perform seasonal checks:

- Check the Spark Plug: Ensure it’s clean and functioning. Replace if it appears worn or damaged.

- Fuel Maintenance: Use fresh fuel and consider adding a stabilizer if storing for an extended period.

- Inspect the Tires: Ensure they are properly inflated and in good condition for traction.

By following these simple tips, you can enhance the reliability and efficiency of your equipment, ensuring you’re prepared for whatever winter brings.

Safety Features to Consider

When operating outdoor equipment designed for clearing snow, it is essential to prioritize safety. Understanding the various protective mechanisms can significantly reduce the risk of accidents and injuries. This section outlines key safety considerations that users should keep in mind.

Essential Safety Mechanisms

- Emergency Shut-off Switch: A quick-access feature that halts operation instantly.

- Safety Guards: Barriers designed to prevent accidental contact with moving parts.

- Operator Presence Control: This mechanism requires the user to maintain a hold on the equipment for it to operate.

- Adjustable Chassis: Ensures stability and reduces the risk of tipping during use.

Best Practices for Safe Operation

- Always wear appropriate protective gear, including gloves and eye protection.

- Read the manufacturer’s instructions thoroughly before use.

- Perform regular maintenance checks to ensure all safety features are functional.

- Avoid operating in adverse weather conditions, such as heavy winds or low visibility.

Comparing Electric and Gas Models

When it comes to clearing away winter’s white blanket, enthusiasts often debate the merits of different power sources. Each option presents unique advantages and considerations, influencing user experience and efficiency. Understanding these differences is essential for making an informed choice.

Advantages of Electric Models

- Quiet Operation: Electric units tend to operate more quietly than their gas counterparts, making them ideal for residential areas.

- Low Maintenance: With fewer mechanical components, electric machines generally require less upkeep.

- Environmentally Friendly: They produce no emissions during use, contributing to a cleaner environment.

- Easy Start: Simply plug in and press a button, eliminating the hassle of fuel preparation.

Benefits of Gas Models

- Powerful Performance: Gas engines often provide greater power, making them suitable for heavier tasks and deeper snow.

- Greater Mobility: Without the need for a power outlet, these machines offer enhanced maneuverability across larger areas.

- Versatile Use: Ideal for various outdoor tasks beyond snow removal, including yard work and landscaping.

- Longer Run Time: Typically, gas units can operate longer on a single tank than electric units can on a charge.

Ultimately, the choice between electric and gas models depends on individual needs, preferences, and the specific conditions of the environment where they will be used.

Choosing the Right Snowblower

Selecting the appropriate machine for clearing snow can significantly impact your winter experience. With various models available, it’s essential to understand your specific needs and the features offered by each option. Factors such as the size of your property, the typical snowfall in your area, and your physical capabilities should guide your decision.

Consider the following key aspects when making your choice:

| Feature | Description |

|---|---|

| Type of Drive | Single-stage models are best for light snowfall on paved surfaces, while two-stage variants handle heavier snow and rough terrain. |

| Clearing Width | A wider clearing path can save time but may be less maneuverable in tight spaces. |

| Power Source | Electric options are quieter and require less maintenance, while gas-powered models offer greater independence. |

| Weight | Lighter units are easier to handle but may struggle with heavy snow; heavier ones provide more power. |

| Additional Features | Look for models with heated handles, headlights, and adjustable chutes for added convenience. |

By evaluating these elements, you can make an informed decision that suits your winter maintenance needs. Choose wisely to ensure efficient snow removal and a smoother winter season.