In the world of all-terrain vehicles, comprehending the intricate design and functionality of various components is essential for both enthusiasts and mechanics alike. A well-structured overview of these elements not only enhances maintenance practices but also fosters a deeper appreciation for the engineering involved in these robust machines.

Detailed illustrations serve as invaluable resources, allowing users to visualize the relationships between different sections and parts. These visual guides can aid in troubleshooting issues, performing upgrades, or simply gaining a better understanding of how the vehicle operates as a cohesive unit.

By examining these schematics, one can uncover the meticulous planning that goes into the design of off-road vehicles, ensuring durability and efficiency. Such knowledge empowers owners to make informed decisions about repairs and enhancements, ultimately prolonging the life of their vehicles and improving performance on rugged terrains.

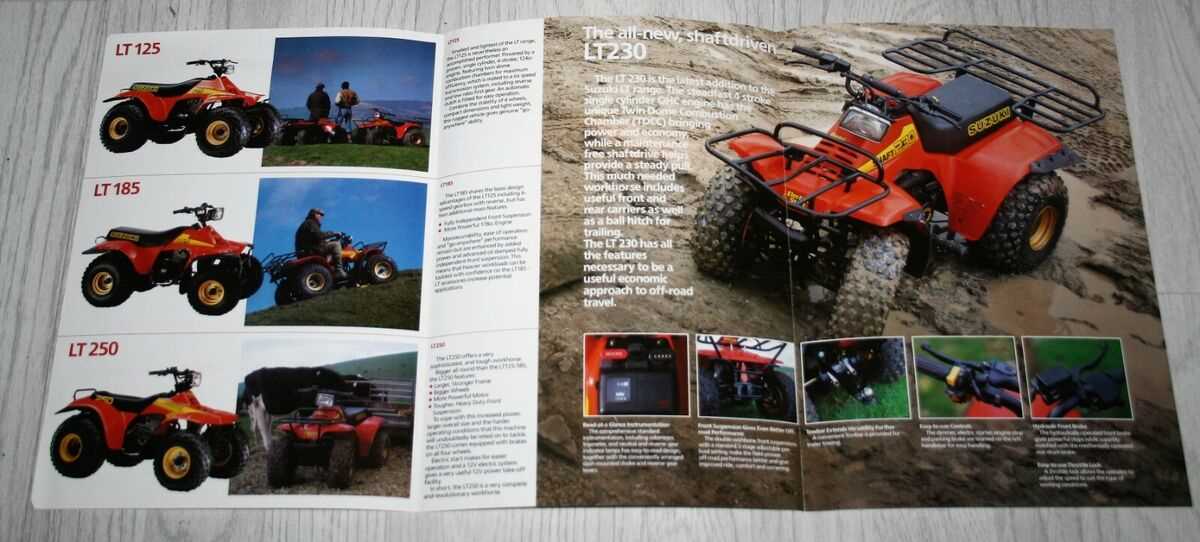

This model stands out for its robust design and reliable performance, making it a preferred choice among enthusiasts. Its engineering emphasizes versatility, catering to various terrains while ensuring comfort for the rider. The combination of advanced technology and durable components enhances its functionality, appealing to both recreational users and those needing a dependable utility vehicle.

Durability and Performance

The strength of this vehicle lies in its construction, featuring high-quality materials that withstand rigorous use. Its powerful engine provides ample torque, enabling smooth navigation across challenging landscapes. This capability ensures that users can rely on it for both work and leisure activities.

Comfort and Usability

Designed with the user in mind, this model incorporates ergonomic seating and intuitive controls, enhancing the overall experience. The layout allows for easy operation, making it accessible for both seasoned riders and newcomers alike. Moreover, its maintenance-friendly design simplifies servicing, ensuring that it remains in optimal condition over time.

| Feature | Description |

|---|---|

| Engine | High-performance engine for enhanced power and efficiency. |

| Chassis | Sturdy frame designed for durability and stability. |

| Comfort | Ergonomically designed seating for long rides. |

| Controls | User-friendly layout for easy handling. |

| Maintenance | Accessible design for straightforward servicing. |

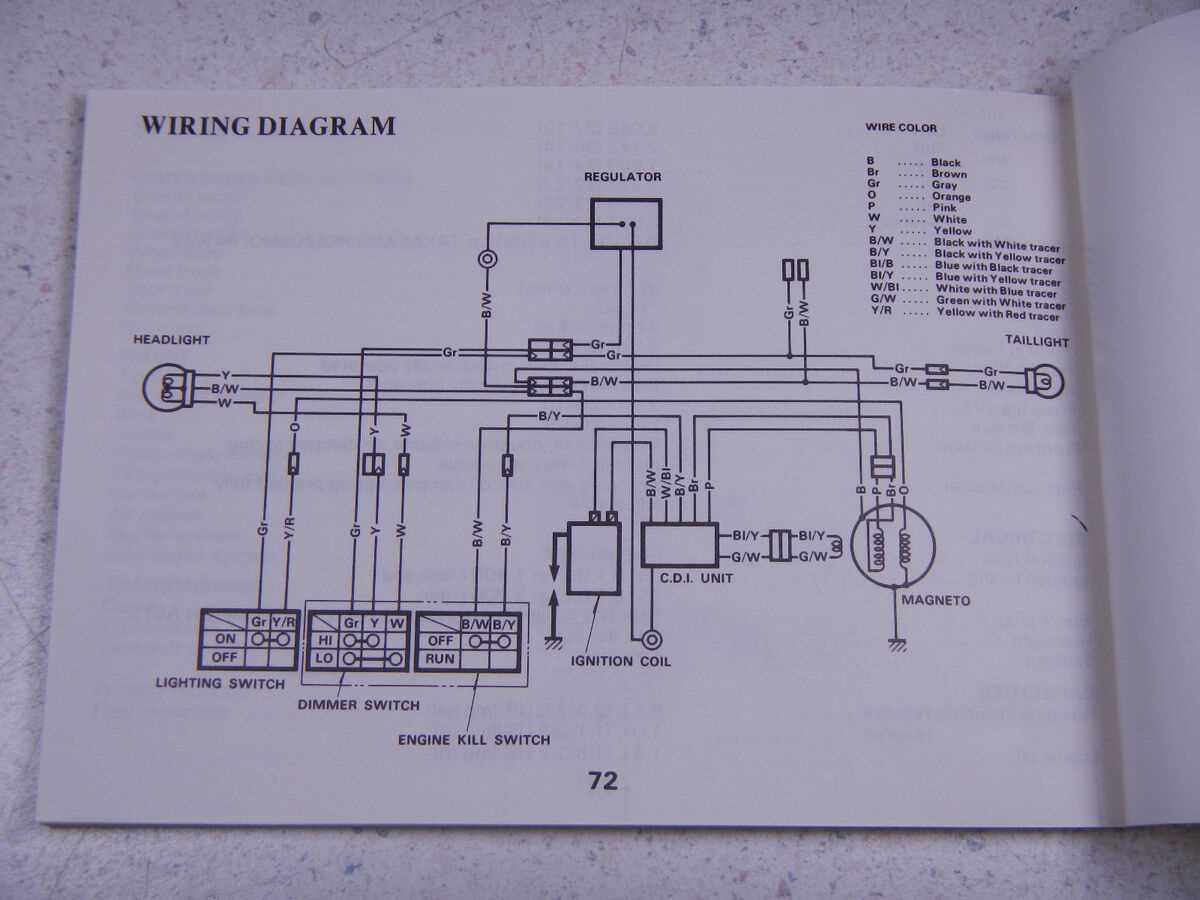

Understanding the Parts Diagram

Grasping the layout of components is crucial for effective maintenance and repair of any vehicle. A well-structured illustration of individual elements helps enthusiasts and technicians identify and understand how different pieces interact within the system. This knowledge not only facilitates troubleshooting but also enhances overall performance by ensuring that all parts function harmoniously.

Importance of Component Identification

Recognizing each element within the assembly can significantly streamline repair processes. By knowing the specific roles and connections of various units, one can quickly diagnose issues, replace faulty components, and perform routine maintenance more efficiently. Moreover, understanding the positioning of parts can aid in preventing common problems caused by improper installation or neglect.

How to Use the Illustration Effectively

To maximize the benefits of the component layout, it’s essential to study it carefully before undertaking any work. Focus on understanding the relationships between different units, as this will enable you to anticipate potential complications. Additionally, consulting the layout during assembly or disassembly can serve as a valuable reference, ensuring that everything is put together correctly. Familiarizing yourself with the arrangement will ultimately lead to a smoother and more successful maintenance experience.

Commonly Replaced Components

In the realm of all-terrain vehicles, certain components tend to wear out more quickly than others due to their frequent use and exposure to harsh conditions. Understanding which parts are commonly replaced can aid owners in maintaining optimal performance and extending the lifespan of their machines. Regular maintenance and timely replacements ensure a smoother ride and reduce the risk of unexpected breakdowns.

Engine and Transmission Elements

Key components within the engine and transmission systems often require replacement to maintain efficiency. This includes items such as gaskets, which can wear down and cause leaks, and filters that need regular changes to ensure proper lubrication and clean airflow. Addressing these elements promptly can prevent more extensive damage and costly repairs.

Suspension and Brake Parts

The suspension system is crucial for comfort and handling, making its components vital for replacement as they degrade over time. Commonly replaced items include shocks and springs, which are essential for absorbing bumps and maintaining stability. Similarly, brake components, such as pads and rotors, require attention to ensure safety and performance on diverse terrains.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your off-road vehicle involves a series of essential maintenance practices. By adopting a proactive approach to upkeep, you can enhance performance, prevent potential issues, and save on costly repairs. Regular attention to key components will not only improve functionality but also provide a more enjoyable riding experience.

Here are some fundamental maintenance tips to consider:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil to ensure optimal lubrication and performance. |

| Air Filter Cleaning | Every 50 hours | Inspect and clean the air filter to maintain airflow and engine efficiency. |

| Tire Pressure Check | Monthly | Regularly check tire pressure for improved handling and safety. |

| Battery Maintenance | Every 3 months | Inspect battery terminals for corrosion and ensure a secure connection. |

| Brake Inspection | Every 100 hours | Examine brake pads and fluid levels to ensure reliable stopping power. |

Locating Authentic Replacement Parts

Finding genuine components for your vehicle can be a challenging yet rewarding task. It is essential to ensure that the parts you acquire meet the required specifications and quality standards. This section will guide you through the process of sourcing reliable replacements, enhancing your machine’s performance and longevity.

Understanding Quality Standards

When searching for replacements, it is crucial to familiarize yourself with industry standards and certifications. Authentic components are typically manufactured with precision and undergo rigorous testing to guarantee their durability and reliability. Always verify that the parts you consider align with the specifications outlined by the manufacturer.

Where to Purchase Authentic Components

There are several avenues for obtaining genuine replacements. Authorized dealerships offer a wide range of options, ensuring that you receive high-quality components. Online marketplaces also provide a platform to compare various suppliers, but caution is advised. Always read reviews and check the seller’s reputation to avoid counterfeit products.

Importance of OEM vs. Aftermarket Parts

When it comes to maintaining and repairing vehicles, the choice between original components and those produced by third parties can significantly impact performance, durability, and overall value. Understanding the differences between these options is crucial for making informed decisions that will ensure the longevity and reliability of your machinery.

Original Equipment Manufacturer (OEM) components are designed and manufactured by the same company that produced the vehicle. These items are typically held to higher quality standards and specifications, ensuring they fit seamlessly and perform as intended. On the other hand, aftermarket components are produced by various independent manufacturers and may offer a broader range of options, often at lower prices. However, the quality and compatibility of these products can vary widely, making it essential to research and evaluate their reliability.

Choosing between OEM and aftermarket options involves weighing factors such as cost, quality, warranty, and availability. While OEM parts may be more expensive, their proven reliability often justifies the investment. Conversely, aftermarket options can be cost-effective but may require careful scrutiny to avoid potential issues. Ultimately, the decision should align with the vehicle owner’s priorities regarding maintenance and performance.

How to Interpret Parts Diagrams

Understanding assembly visuals is crucial for effective maintenance and repairs. These representations provide detailed information about components and their relationships, enabling users to identify necessary elements for specific tasks. Grasping how to read these visuals can significantly enhance the efficiency of any repair or replacement project.

Here are some key aspects to consider when analyzing these illustrations:

- Symbols and Labels: Familiarize yourself with the symbols used, as they indicate various elements such as screws, bolts, and connectors. Labels often accompany these symbols, providing additional context.

- Component Groupings: Notice how parts are categorized into groups. This organization helps in identifying sections of the assembly, making it easier to locate specific components.

- Reference Numbers: Each element typically has a unique identifier, allowing you to cross-reference it with a list or catalog. This is essential for ordering replacements or understanding assembly sequences.

- Orientation: Pay attention to the orientation of components in the visual. This information is vital for proper installation and alignment during assembly.

By honing your skills in interpreting these visuals, you’ll be better equipped to tackle repair tasks with confidence and accuracy.

Essential Tools for Repairs

When it comes to maintaining and fixing your vehicle, having the right tools at your disposal is crucial. A well-equipped workshop not only makes the repair process more efficient but also ensures that tasks are completed correctly, reducing the risk of future issues. Whether you are a professional mechanic or a DIY enthusiast, knowing the essential tools can save time and effort.

Basic Hand Tools

Basic hand tools are fundamental for any repair task. They include items that help in loosening, tightening, and manipulating various components. Here is a list of essential hand tools:

| Tool | Purpose |

|---|---|

| Wrenches | For tightening and loosening nuts and bolts |

| Screwdrivers | For driving screws into place or removing them |

| Pliers | For gripping, twisting, or cutting wires and small components |

| Socket Set | For easier access to fasteners in tight spaces |

Specialized Equipment

In addition to basic hand tools, specialized equipment can significantly enhance your repair capabilities. Investing in high-quality tools tailored for specific tasks can lead to better results. Consider the following:

| Tool | Purpose |

|---|---|

| Torque Wrench | For applying precise torque to fasteners |

| Multimeter | For diagnosing electrical issues |

| Brake Bleeder | For ensuring proper brake fluid flow in the system |

| Lift or Jack | For safely raising the vehicle during repairs |

Step-by-Step Assembly Guide

This section provides a comprehensive approach to reassembling the components of your vehicle. Following a systematic process not only enhances efficiency but also ensures that every part is correctly positioned for optimal performance. Each step is designed to guide you through the assembly with clarity and precision.

Begin by organizing all components to ensure easy access during assembly. Lay out each piece in the order you will be working on them. This practice minimizes confusion and reduces the likelihood of missing any crucial elements.

Next, refer to your assembly instructions or guidelines specific to your model. These documents serve as a roadmap, detailing the proper sequence and techniques for putting everything together. Pay close attention to torque specifications and alignment markers.

Start the assembly process with the foundational elements. Secure them firmly to create a stable base for additional components. Utilize the appropriate tools, ensuring they are in good condition, to avoid damaging any parts during the installation.

As you progress, double-check each connection to ensure everything is fitting snugly. Take your time and don’t rush through the steps. If something feels off, stop and reassess the alignment and placement of the parts.

Finally, once the assembly is complete, conduct a thorough inspection of the entire unit. Look for any loose connections or misaligned components. This final check is crucial to ensure that your vehicle operates safely and efficiently.

Common Issues and Solutions

When working with off-road vehicles, certain technical challenges often arise. These challenges may stem from prolonged use, tough terrain, or insufficient maintenance. Addressing these problems quickly is essential to ensuring continued reliability and performance.

Engine Misfires: One frequent issue is inconsistent engine performance. This can lead to erratic behavior, such as sudden power loss or uneven acceleration. Checking the fuel system and spark components is a good first step to resolve this.

Transmission Problems: Another challenge involves difficulty in shifting gears, which may cause delayed response or jerky movements. Regular inspection of the gearbox and clutch system can prevent these issues from escalating.

Electrical Malfunctions: Many off-road machines experience intermittent electrical issues, such as faulty wiring or unresponsive controls. Ensuring that all connections are secure and free of corrosion often resolves this issue.

By addressing these common problems promptly, you can maintain optimal vehicle performance and extend its lifespan.

Upgrades and Modifications Available

When considering improvements for this vehicle, there are various performance and aesthetic modifications that can enhance its functionality and appearance. Many components can be replaced or upgraded to achieve better handling, power, and overall durability, tailored to the specific needs of the rider. Whether it’s optimizing the suspension system or adding new technology for better control, numerous options are available.

| Upgrade Type | Description |

|---|---|

| Suspension Tuning | Improving the suspension can result in smoother rides and better off-road performance. Different kits are available depending on terrain preferences. |

| Engine Enhancements | Engine modifications can increase power and efficiency, allowing for a more aggressive performance on challenging trails. |

| Brake Upgrades | Upgrading the brake system ensures better stopping power and

Resources for LT230 EnthusiastsFor those passionate about maintaining and upgrading their off-road vehicle, having access to the right tools and guides is essential. Whether you’re looking to improve performance or simply ensure your ride stays in top condition, there are a variety of resources available to help.

By leveraging these resources, you can enhance your vehicle’s performance, reliability, and overall riding |