Exploring the intricacies of small engine mechanics reveals a world of essential elements that work in harmony to ensure optimal performance. Each segment plays a vital role in the overall functionality, contributing to efficiency and reliability.

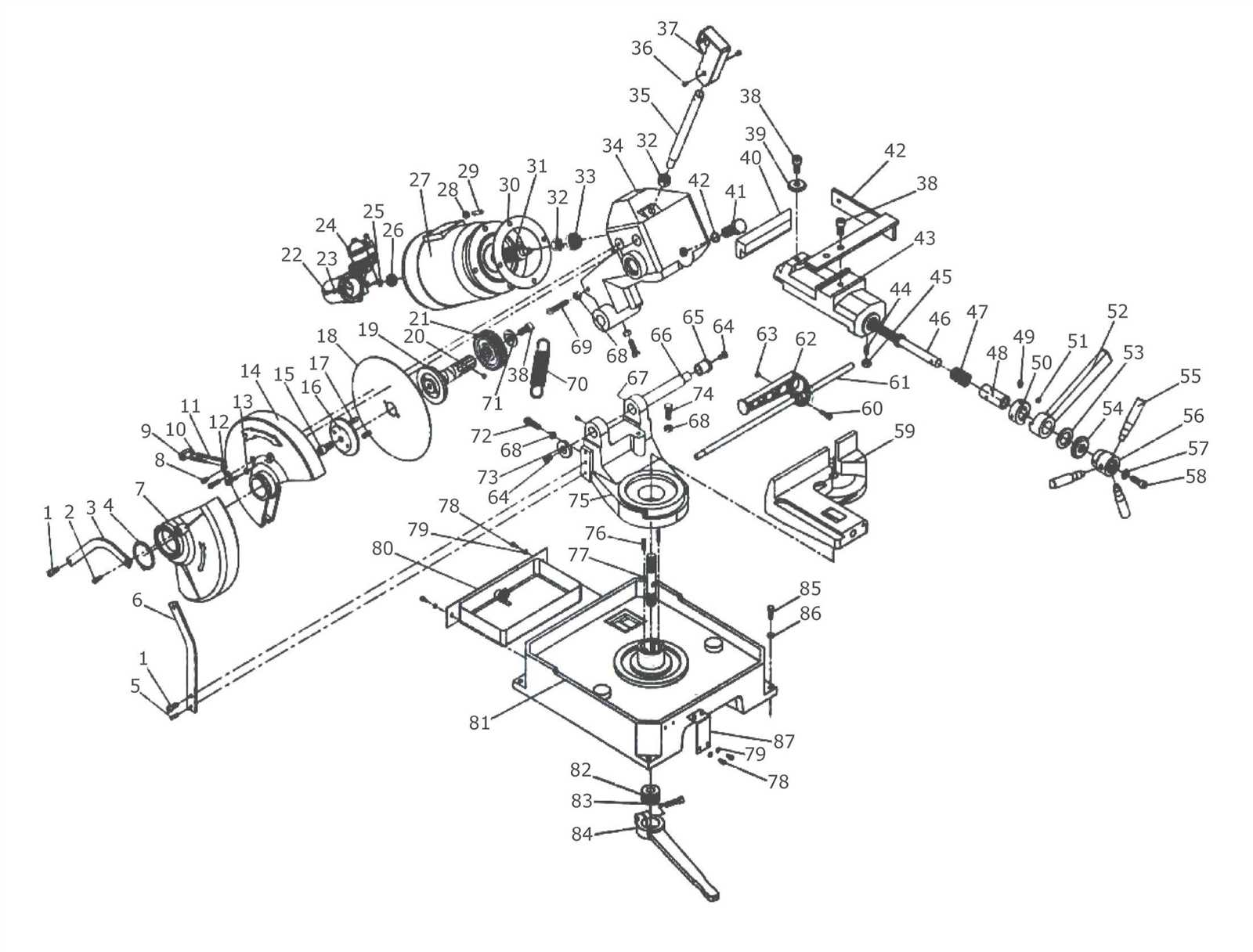

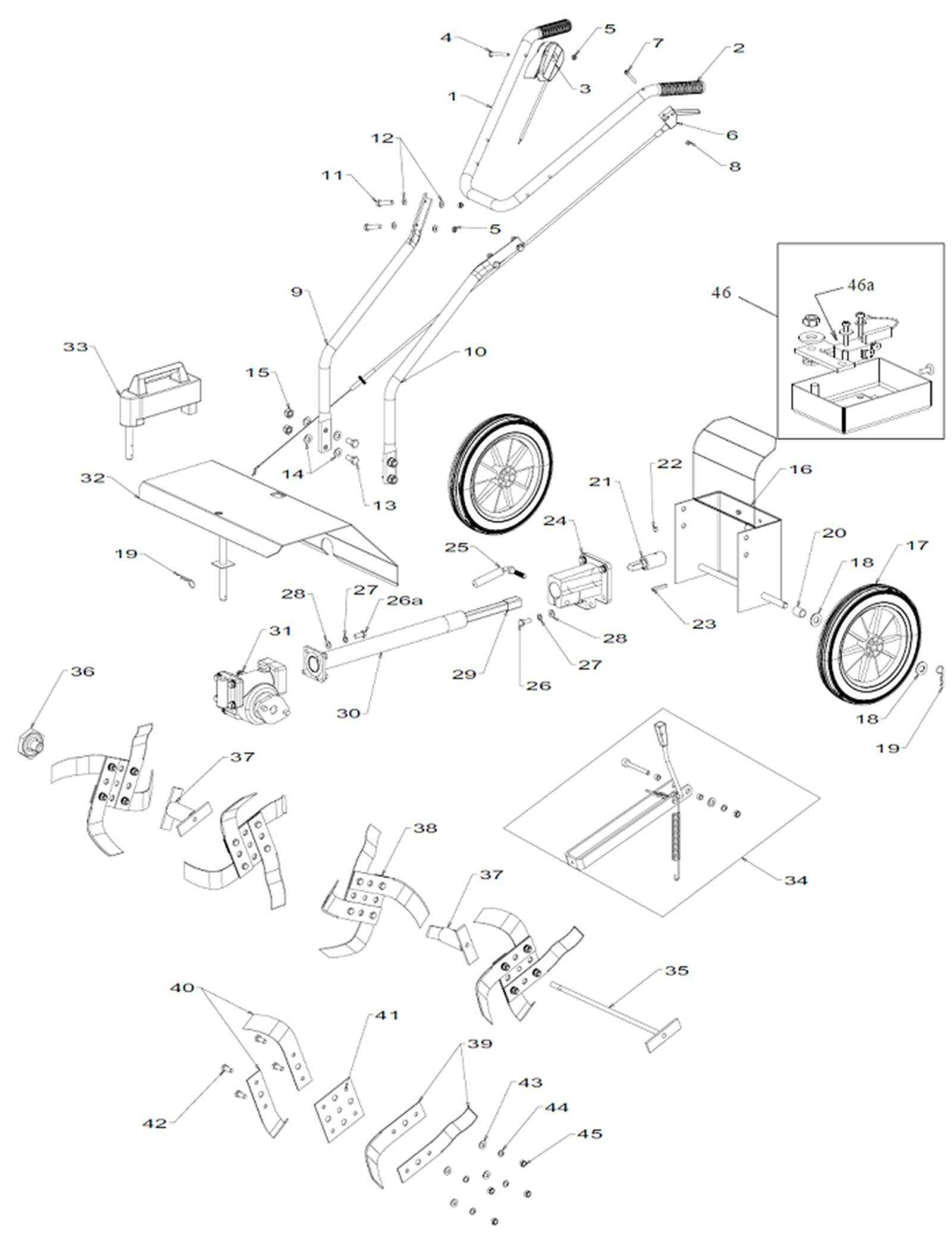

When faced with maintenance or repairs, having a clear visual representation of these crucial components becomes indispensable. An organized view of the various sections aids in identifying parts, facilitating troubleshooting, and ensuring correct reassembly.

This resource aims to empower users with detailed insights into the configuration of engine parts. By delving into this visual guide, enthusiasts and professionals alike can enhance their understanding and tackle challenges with confidence.

Understanding Briggs and Stratton 550

This section aims to provide insight into a widely used small engine model, highlighting its features and functionality. Understanding the components that contribute to its performance can enhance maintenance and repair efforts, ensuring longevity and efficiency.

Key Features

The engine in question is known for its reliability and versatility. With a robust design, it supports a variety of applications, making it a popular choice among users. Key attributes include fuel efficiency, ease of starting, and user-friendly maintenance requirements.

Components Overview

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts fuel energy into mechanical work. |

| Carburetor | Mixes air and fuel for optimal combustion. |

| Ignition System | Ignites the air-fuel mixture at the right moment. |

Key Components of the Engine

Understanding the essential elements of an engine is crucial for anyone interested in maintenance or repair. Each component plays a vital role in ensuring smooth operation and overall performance. Familiarity with these parts not only aids in troubleshooting but also enhances the efficiency of the machine.

1. Cylinder Assembly

The cylinder assembly is fundamental to the combustion process. It houses the piston and facilitates the compression of the air-fuel mixture. A well-functioning cylinder is critical for maintaining power output and efficiency.

2. Carburetor

The carburetor regulates the mixture of air and fuel entering the engine. Its proper operation ensures optimal performance and fuel efficiency. A malfunctioning carburetor can lead to poor engine response and increased fuel consumption.

Maintaining these key elements is essential for longevity and reliability. Regular checks and timely replacements can prevent more significant issues down the line.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. These illustrations serve as valuable tools for both professionals and enthusiasts, enabling them to navigate complex systems with ease.

Enhancing Understanding

Such visual aids simplify the intricate details of various elements, making it easier to identify their relationships and functions. Key benefits include:

- Clear identification of each component.

- Understanding of how parts interact.

- Facilitation of troubleshooting processes.

Streamlining Maintenance

Effective maintenance is vital for the longevity of equipment. Visual guides contribute to this by:

- Providing precise locations for replacement items.

- Offering step-by-step instructions for assembly or disassembly.

- Minimizing the risk of errors during repairs.

Overall, these illustrations are indispensable resources that empower users to maintain, repair, and optimize their machines efficiently.

Common Issues with Briggs and Stratton 550

Engines of this type often face various challenges that can hinder performance. Understanding these issues is essential for effective maintenance and longevity.

Typical Problems Encountered

Common malfunctions include starting difficulties, poor fuel efficiency, and unusual noises. Identifying these signs early can prevent further complications.

Maintenance Tips

Regular upkeep is vital. Ensuring clean air filters, checking spark plugs, and monitoring oil levels can significantly reduce operational issues.

| Issue | Possible Cause | Solution |

|---|---|---|

| Hard starting | Clogged fuel line | Clean or replace fuel line |

| Poor performance | Dirty air filter | Replace air filter |

| Unusual noise | Worn components | Inspect and replace parts |

How to Read Parts Diagrams

Understanding visual schematics can greatly enhance your ability to identify components and their relationships in machinery. These illustrations serve as valuable tools for both troubleshooting and repair, allowing you to quickly locate specific elements within a system. By familiarizing yourself with the symbols and layouts used in these representations, you can streamline your maintenance processes and make informed decisions.

Begin with the Legend: Most visuals include a legend or key that explains the symbols used throughout the illustration. Take a moment to review this section, as it will clarify what each symbol represents, making the entire schematic easier to interpret.

Identify the Layout: Pay attention to how the elements are arranged. Understanding the flow of the system, whether it’s linear or more complex, will help you visualize how parts interact with one another. Look for groupings that may indicate related components.

Follow the Connections: Trace the lines that connect different elements. These lines often represent pathways for energy, fluids, or other interactions. Recognizing these connections can provide insight into how components work together and where potential issues may arise.

Note the Numbering: Components are typically numbered for easy reference. Ensure you familiarize yourself with these numbers, as they correspond to part lists that can assist you in ordering replacements or understanding specifications.

Consult the Manufacturer: If you encounter difficulty interpreting a schematic, don’t hesitate to consult the manufacturer’s resources. They often provide additional guidance, such as service manuals or online tutorials, to aid in understanding the visuals.

Essential Tools for Maintenance

Proper upkeep of small engines requires a set of fundamental instruments to ensure efficiency and longevity. Having the right tools on hand can simplify routine tasks and facilitate timely repairs, ultimately enhancing the performance of your equipment.

Basic Hand Tools

Among the most crucial instruments are basic hand tools. A reliable set of wrenches, screwdrivers, and pliers will enable you to perform various adjustments and replacements. Socket wrenches are particularly useful for accessing hard-to-reach areas, while a good screwdriver set ensures you can handle different fasteners.

Specialized Equipment

In addition to standard tools, having specialized equipment can make a significant difference. A spark plug wrench is essential for checking and replacing ignition components. Moreover, an oil extractor allows for easy and clean oil changes, promoting better engine health. Investing in these tools can save time and enhance the quality of your maintenance routine.

Replacing Engine Parts Safely

Ensuring the safe replacement of mechanical components is crucial for optimal performance and longevity. Following proper guidelines can prevent accidents and enhance the efficiency of the machinery.

- Always disconnect the power source before starting any repairs.

- Use appropriate tools for the job to avoid damage to components.

- Wear protective gear such as gloves and goggles to safeguard against debris.

When handling sensitive elements, take extra precautions to maintain their integrity:

- Refer to the user manual for specific instructions.

- Label parts and screws during disassembly for easy reassembly.

- Dispose of old components responsibly to minimize environmental impact.

By following these steps, you can delve into the task with confidence, ensuring that every replacement contributes to the ultimate efficiency of your engine.

Finding Replacement Parts Easily

Locating suitable components for your machinery can often be a daunting task. However, with the right approach and resources, you can streamline the process significantly. Understanding where to look and what to consider can save you time and effort.

Utilize Online Resources: Numerous websites specialize in providing detailed listings of components for various machines. These platforms often feature search tools that allow you to input specific model numbers or descriptions, ensuring you find the correct items quickly.

Consult User Manuals: The documentation that accompanies your equipment is a valuable asset. Manuals typically include comprehensive lists of necessary components and their specifications, which can guide you in your search.

Join Community Forums: Engaging with online communities can yield helpful insights. Fellow users often share their experiences, recommendations, and even direct links to reliable suppliers, making your search more efficient.

Local Retailers: Don’t overlook the potential of nearby hardware or specialty shops. Many local businesses stock a range of essential components and can offer personalized assistance in finding what you need.

By leveraging these resources, you can navigate the process of sourcing replacements with greater ease and confidence.

Upgrading Your Engine’s Performance

Enhancing your engine’s capabilities can significantly improve efficiency and power output. Various modifications and upgrades can lead to better fuel consumption, increased speed, and overall improved functionality. Understanding the right components and adjustments is key to achieving the best results.

Key Modifications

Consider upgrading the air intake and exhaust systems for improved airflow. Replacing standard components with high-performance alternatives can reduce restrictions and enhance combustion. Additionally, tuning the engine’s fuel delivery system can optimize performance, ensuring the right mixture for peak power.

Maintenance Matters

Regular maintenance is essential for optimal performance. Replacing worn parts, checking spark plugs, and maintaining clean filters will prevent potential issues. A well-maintained engine not only runs smoother but also maximizes the benefits of any upgrades implemented.

Best Practices for Engine Care

Ensuring the longevity and efficiency of your machinery requires consistent maintenance and attention. By following effective strategies, you can enhance performance, reduce wear, and prevent costly repairs. This guide offers essential practices that any operator should adopt for optimal care.

Regular Inspections

Conduct routine checks on your engine components to identify any signs of wear or damage early. Look for leaks, unusual noises, or irregular vibrations. Keeping a close eye on these factors helps in addressing potential issues before they escalate.

Proper Lubrication

Using the correct type and amount of lubricant is crucial for reducing friction and heat within the engine. Regularly check and change the oil according to the manufacturer’s recommendations. Clean filters and appropriate fuel also contribute to smoother operation and longevity.

Resources for Additional Information

Accessing comprehensive resources can significantly enhance your understanding of engine components and their functionalities. These materials can provide insights into assembly, maintenance, and troubleshooting, ensuring optimal performance and longevity of your machinery.

Official Manufacturer Resources

Visit the official website of the engine manufacturer for the most accurate and detailed information. There, you will find manuals, maintenance guides, and technical support that can assist you in resolving any issues you may encounter.

Online Communities and Forums

Engaging with online forums and communities dedicated to engine enthusiasts can be invaluable. Users share their experiences, tips, and solutions, allowing you to delve into practical advice and gain a deeper understanding of various engine aspects.