Understanding the structure and functionality of equipment is crucial for maintaining its efficiency and longevity. A clear breakdown of each component can provide insight into the mechanics behind it, enabling quick identification and addressing of potential issues. With the right knowledge, users can easily locate and replace elements to keep their machine running smoothly.

The internal organization of any machinery can seem complex at first, but it becomes more accessible when broken down into its individual elements. Recognizing how different sections interconnect allows for seamless troubleshooting and ensures optimal performance. Knowing which piece fits where is key to mastering the operational details of the equipment.

In this guide, we will walk through the various mechanisms and their connections, highlighting their functions and significance. This will offer users the confidence to perform necessary adjustments or replacements without confusion, promoting better upkeep and longer life for the machine.

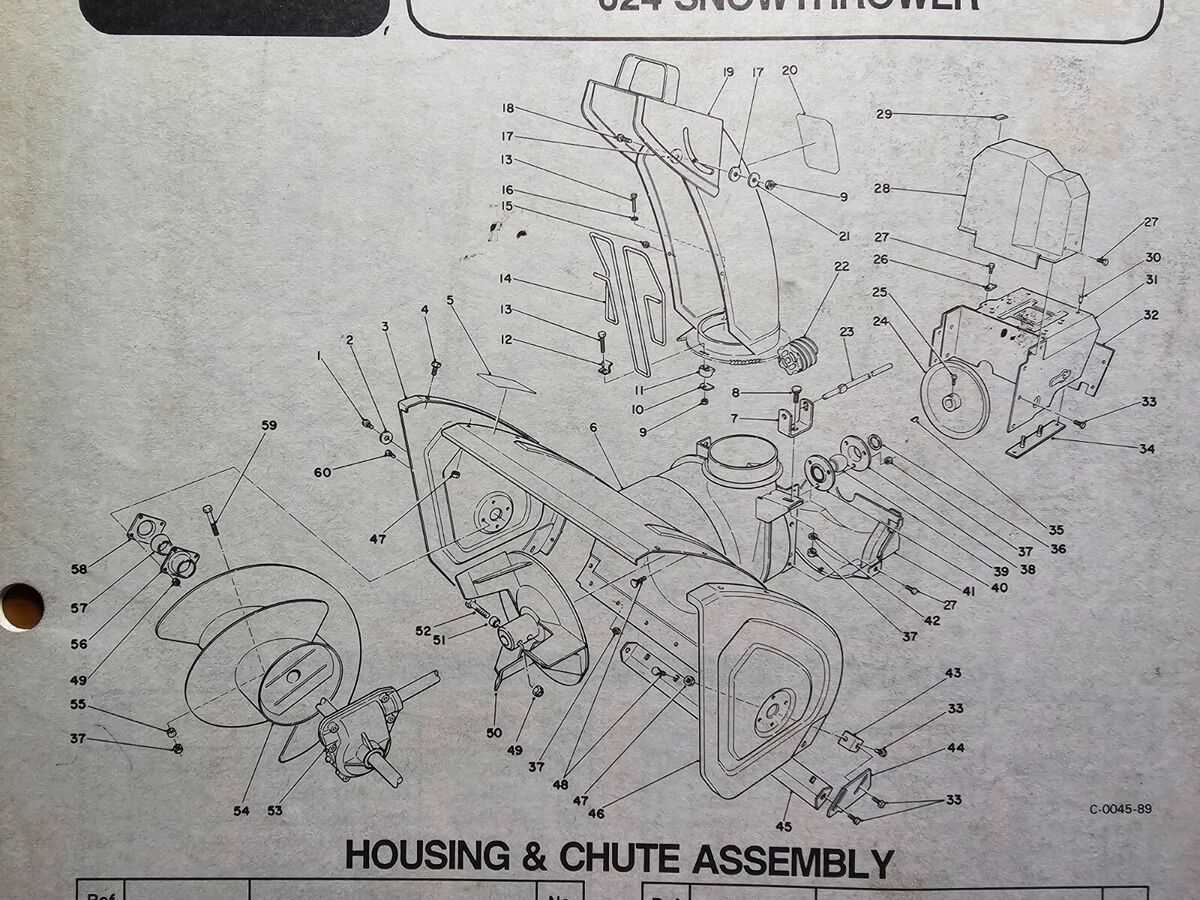

Comprehensive Overview of Snow Blower Components

Understanding the key mechanisms and their arrangement is essential for ensuring the optimal functionality of outdoor machinery designed to handle cold-weather conditions. Each element plays a vital role, working together to provide efficient operation and control over challenging environments.

Key Mechanical Systems

The primary systems involve a combination of rotating mechanisms, control levers, and propulsion systems. These work together to effectively handle various types of outdoor surfaces, ensuring steady movement and consistent performance. Proper maintenance of these areas is crucial for long-term durability and effectiveness.

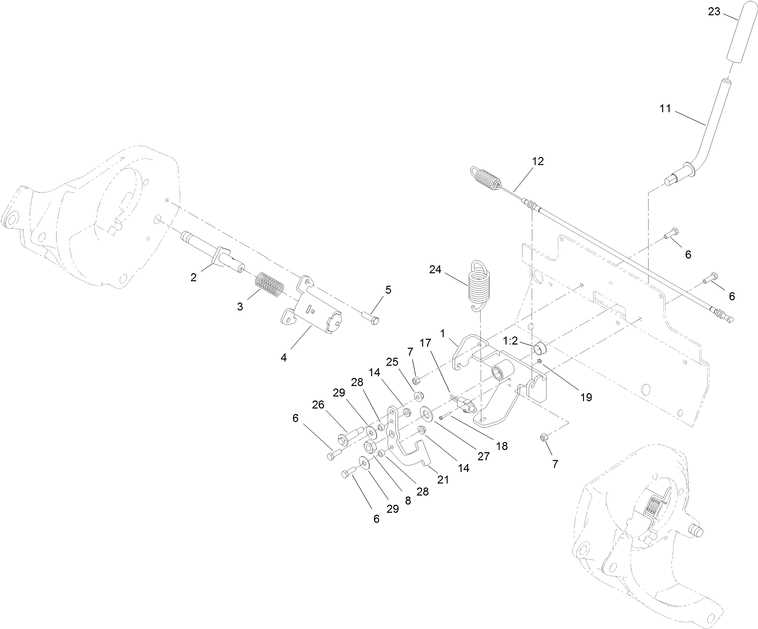

Operational Controls and Adjustment Mechanisms

Operational controls are vital for adjusting the machinery’s settings and guiding its movement. These include ergonomic levers, directional controls, and adjustment mechanisms that allow for customization based on the operator’s needs. Keeping these controls in good condition enhances ease of use and precision during operation.

Identifying Essential Mechanisms for Smooth Operation

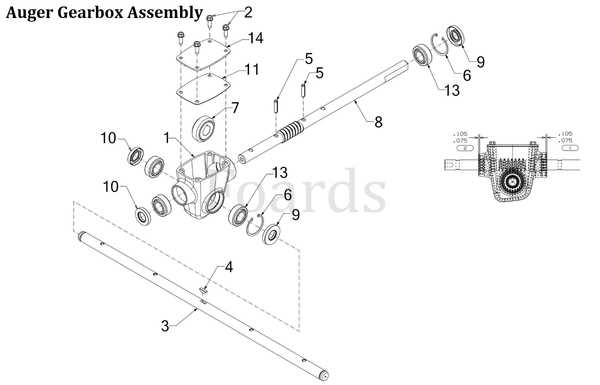

Understanding the fundamental components and their interactions is crucial to maintaining optimal performance. Every machine relies on several key elements working in harmony to ensure efficiency and longevity. When these mechanisms function properly, the entire system operates seamlessly, preventing potential breakdowns and ensuring reliable performance over time.

Key Moving Parts and Their Role

Among the most important elements are the components that directly influence movement and power transfer. These include various gears, belts, and bearings, all of which need to be regularly checked and maintained. If any of these parts wear out or malfunction, the smoothness of the machine’s operation can be compromised, leading to potential inefficiencies.

Maintenance for Longevity

To keep the equipment in top condition, regular upkeep of vital systems is essential. This includes not only inspecting mechanical parts but also ensuring proper lubrication, tension adjustment, and timely replacement of worn elements. Proper care significantly extends the life of

Understanding the Functionality of Key Engine Parts

Engines play a vital role in powering various mechanical systems, each part designed to contribute to overall performance. Familiarity with the components allows for better maintenance and troubleshooting. By understanding the purpose of each element, users can ensure efficient operation and prolong the lifespan of their equipment.

Critical Components and Their Roles

There are several essential components that collaborate to keep the engine running smoothly. These parts interact seamlessly, each performing a distinct function to convert energy and keep the system in motion.

| Component | Function | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Piston | Moves within the cylinder, converting pressure into rotational force. | ||||||||||||||||||||

| Crankshaft | Transforms the linear motion of the piston into rotational motion, driving other mechanical processes. |

| Feature | Description |

|---|---|

| Height Adjustment | Allows customization to fit different operator heights for improved comfort. |

| Ergonomic Grip | Soft-touch materials enhance comfort and reduce hand strain. |

| Anti-Vibration | Reduces shock transmitted to hands, increasing user comfort during operation. |

| Secure Hold | Prevents slipping to ensure precise control and safety. |

Electrical System Parts and Their Functions

The electrical system of a mechanized device plays a vital role in ensuring smooth operation and efficient performance. Understanding the various components and their respective roles can greatly enhance troubleshooting and maintenance efforts. This section outlines the essential elements of the electrical assembly and their functionalities.

Main Components

- Motor: The driving force behind the entire mechanism, converting electrical energy into mechanical power.

- Battery: Provides the necessary energy to power the device, enabling startup and continuous operation.

- Wiring Harness: A network of wires that connects various electrical elements, ensuring proper communication and power distribution.

Control Mechanisms

- Switches: Act as the interface for the user, allowing for control over the operation and settings of the machine.

- Relays: Function as electromagnetic switches, enabling control of larger electrical loads through low-power signals.

- Sensors: Monitor conditions such as temperature and position, providing feedback to enhance safety and efficiency.

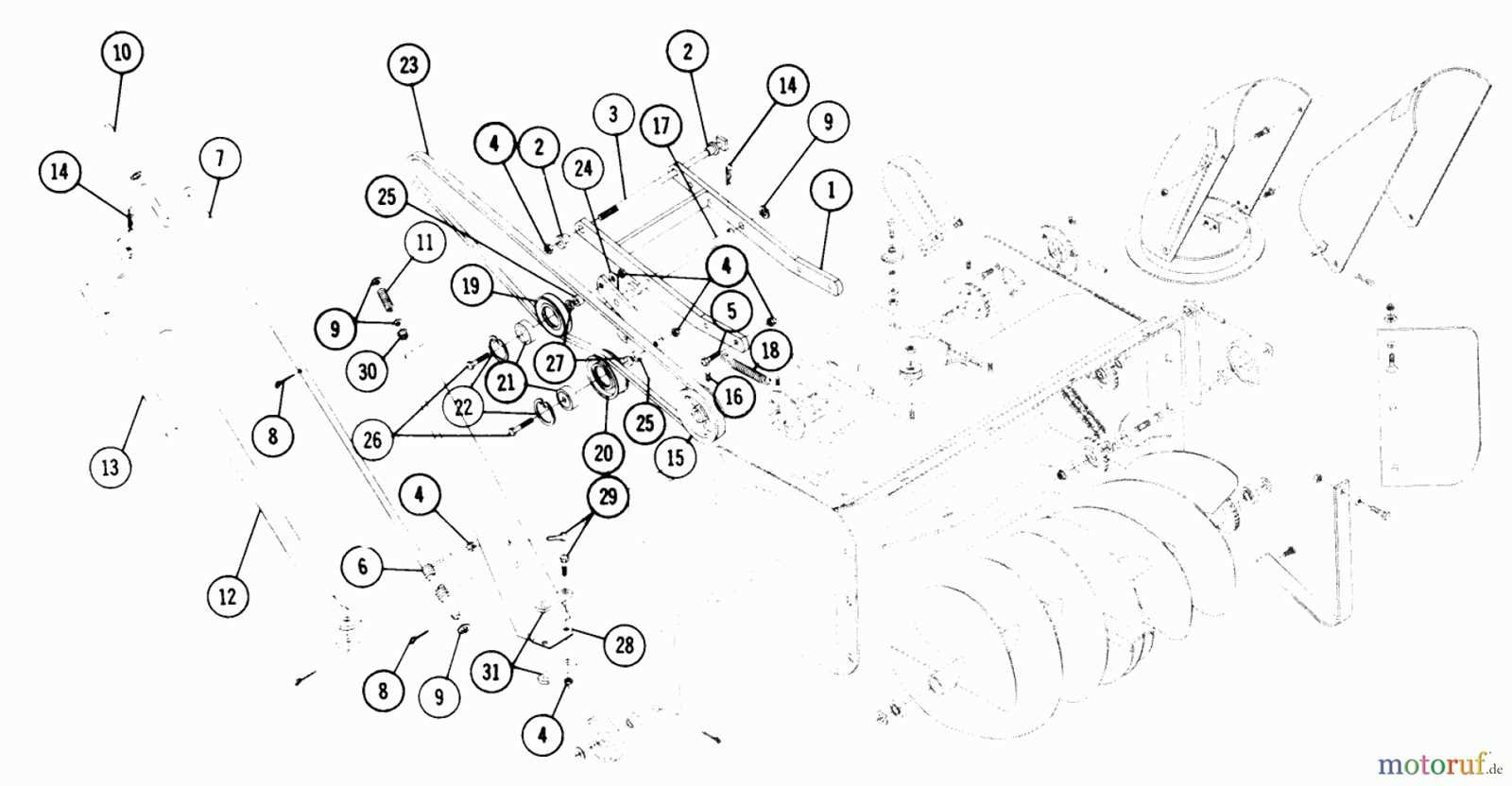

Understanding the Belt System for Power Transfer

The belt mechanism serves as a crucial component in the transmission of energy within various machinery, playing an essential role in converting motor output into functional movement. This system facilitates the efficient transfer of force between different elements, ensuring that operations proceed smoothly and effectively.

Typically, the belt assembly comprises multiple elements that work together to deliver power from the engine to the functional parts of the equipment. Understanding how this mechanism operates is vital for troubleshooting and maintenance, as it can significantly impact overall performance.

| Component | Function |

|---|---|

| Belt | Transmits power from the engine to various operational parts. |

| Pulleys | Guide and support the belt, allowing for efficient power transfer. |

| Tensioner | Maintains appropriate tension on the belt to prevent slippage. |

| Idler | Adjusts the belt path and aids in tension regulation. |

By familiarizing oneself with each component’s role, operators can ensure that the entire system functions optimally. Regular inspections and timely replacements of worn elements contribute to the longevity and reliability of the entire machinery.