In the realm of marine machinery, having a comprehensive overview of the internal configurations is essential for effective maintenance and repair. Each assembly comprises a variety of intricate elements, each serving a distinct function to ensure optimal performance. By familiarizing oneself with these configurations, users can enhance their understanding and ability to address potential issues.

Visual representations of engine structures play a crucial role in simplifying complex systems. These illustrations aid in identifying the various components and their respective placements within the overall system. Gaining insight into this layout can significantly improve troubleshooting efforts and facilitate more efficient repair processes.

Furthermore, grasping the arrangement of these vital components can empower users to undertake necessary adjustments and replacements with confidence. Whether for routine maintenance or addressing specific concerns, a clear understanding of the machinery’s configuration is invaluable for anyone looking to maximize the longevity and functionality of their equipment.

Overview of Mercury 40 HP Engine

This section provides a comprehensive look at a specific outboard motor known for its efficiency and reliability. Designed for a variety of marine applications, it offers a blend of performance and user-friendly features, making it a popular choice among boat enthusiasts.

The engine is notable for its robust construction and innovative technology, ensuring smooth operation in various water conditions. Below are some key aspects that highlight its strengths:

- Power and Performance: This motor delivers impressive horsepower, allowing for swift acceleration and excellent handling.

- Fuel Efficiency: Engineered to optimize fuel consumption, it ensures longer outings without frequent refueling.

- Durability: Built with high-quality materials, it is designed to withstand the rigors of marine environments.

- Ease of Maintenance: Its design allows for straightforward servicing, making upkeep simpler for owners.

In summary, this outboard motor represents a reliable choice for those seeking a balance of power, efficiency, and ease of use, making it suitable for various boating adventures.

Identifying Key Components and Functions

Understanding the essential elements of an outboard motor is crucial for effective maintenance and troubleshooting. Each component plays a specific role in ensuring the smooth operation of the engine, and recognizing these parts can significantly enhance performance and longevity. This section aims to highlight the primary elements involved and their respective functions.

Major Elements and Their Roles

- Engine Block: The core of the engine where combustion occurs, responsible for housing various internal parts.

- Fuel System: Comprises the fuel tank, lines, and pump, delivering the necessary fuel for combustion.

- Cooling System: Maintains optimal operating temperatures by circulating coolant to prevent overheating.

- Ignition System: Includes spark plugs and coils, generating the spark needed to ignite the fuel-air mixture.

- Propulsion Unit: Converts the engine’s power into movement, including components like the propeller and gearbox.

Understanding Component Functions

- Engine Block: Provides structural integrity and houses cylinders, crankshafts, and camshafts.

- Fuel System: Ensures a consistent supply of fuel, optimizing combustion efficiency and engine response.

- Cooling System: Protects the engine from damage caused by excessive heat through efficient temperature regulation.

- Ignition System: Guarantees reliable engine start-up and operation by delivering electrical sparks at the right moment.

- Propulsion Unit: Translates engine power into motion, allowing for efficient movement across water.

Understanding the 4-Stroke Mechanism

The operation of a combustion engine involves a sequence of processes that convert fuel into mechanical energy. This efficient cycle is fundamental in many engines, facilitating power generation through a systematic approach. Each phase plays a crucial role in optimizing performance and ensuring smooth functioning.

Phases of Operation

This mechanism comprises four distinct phases: intake, compression, power, and exhaust. During the intake phase, a mixture of air and fuel is drawn into the combustion chamber, preparing for ignition. Next, the compression phase increases the mixture’s pressure and temperature, setting the stage for a powerful reaction.

Significance of the Cycle

Following compression, the power phase initiates a controlled explosion, pushing the piston down and generating energy. Finally, in the exhaust phase, the remaining gases are expelled, allowing for fresh air and fuel to enter for the next cycle. Understanding this structured approach highlights its importance in achieving efficiency and reliability in engine performance.

Parts Replacement for Enhanced Performance

Upgrading components in a marine engine can significantly improve its efficiency and overall functionality. By selecting high-quality replacements, boat enthusiasts can ensure their vessels operate at peak performance. This process not only enhances speed but also increases fuel efficiency and prolongs the lifespan of the engine.

Benefits of Upgrading Components

- Improved fuel efficiency, leading to cost savings over time.

- Enhanced horsepower and torque, allowing for better acceleration.

- Reduced emissions, contributing to a cleaner environment.

- Increased reliability, minimizing the risk of breakdowns.

Key Components to Consider for Replacement

- Filters: Regularly replacing oil and fuel filters helps maintain optimal fluid flow and engine cleanliness.

- Ignition System: Upgrading spark plugs and ignition coils can lead to better combustion and improved performance.

- Fuel System: Replacing fuel injectors with high-performance options ensures efficient fuel delivery.

- Cooling System: A new water pump and thermostat can help regulate engine temperature, preventing overheating.

Investing in quality replacements not only boosts performance but also enhances the overall enjoyment of boating experiences. Regular maintenance and upgrades are essential to keep your engine running smoothly and efficiently.

Common Issues and Troubleshooting Steps

When operating marine engines, users often encounter various challenges that can impact performance and reliability. Identifying these issues early and understanding the necessary corrective measures can help maintain efficiency and longevity. This section outlines frequent problems that may arise, along with practical steps to address them effectively.

Overheating Concerns

One of the prevalent issues is overheating, which can stem from several factors, including inadequate coolant flow or blocked cooling passages. To troubleshoot this problem, first check the coolant levels and ensure there are no obstructions in the intake system. If the issue persists, inspect the water pump and thermostat for proper functionality.

Starting Difficulties

Another common challenge is difficulty starting the engine. This can result from issues such as a weak battery, faulty ignition components, or fuel supply problems. Begin by testing the battery’s charge and connections. Next, examine the ignition system, including spark plugs and wiring. If fuel delivery is suspected, ensure that the fuel lines are clear and that the filter is not clogged.

Maintenance Tips for Longevity

Ensuring the prolonged efficiency of your watercraft engine requires a dedicated approach to upkeep. Regular maintenance not only enhances performance but also extends the life of essential components, allowing for a smoother and more enjoyable experience on the water.

Here are some key practices to consider for optimal care:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours or annually | Replace engine oil and filter to prevent buildup and ensure smooth operation. |

| Fuel System Inspection | Annually | Check and clean fuel filters, lines, and injectors to ensure proper fuel delivery. |

| Cooling System Check | Every 50 hours | Examine water intake screens and replace the water pump impeller to avoid overheating. |

| Battery Maintenance | Monthly | Inspect connections and clean terminals; ensure the battery is charged and free from corrosion. |

| Visual Inspection | Every outing | Check for leaks, cracks, or any visible damage to ensure safe operation. |

Implementing these maintenance strategies will significantly contribute to the reliability and efficiency of your marine engine, allowing for countless memorable journeys on the water.

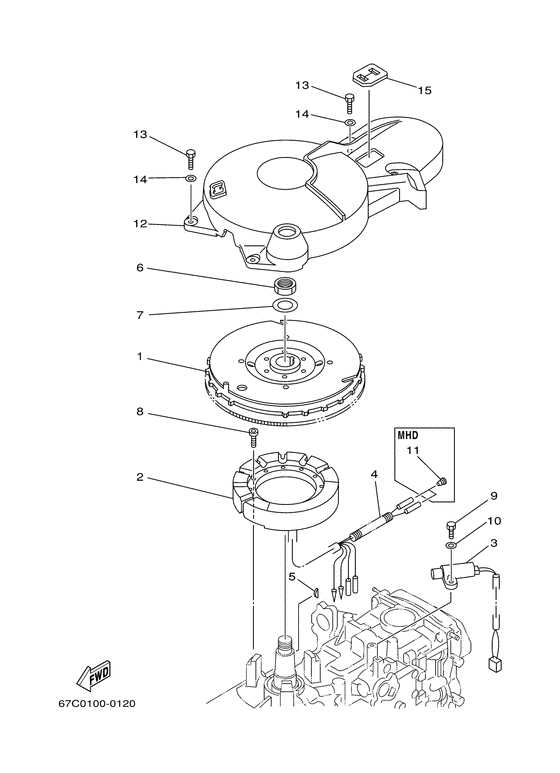

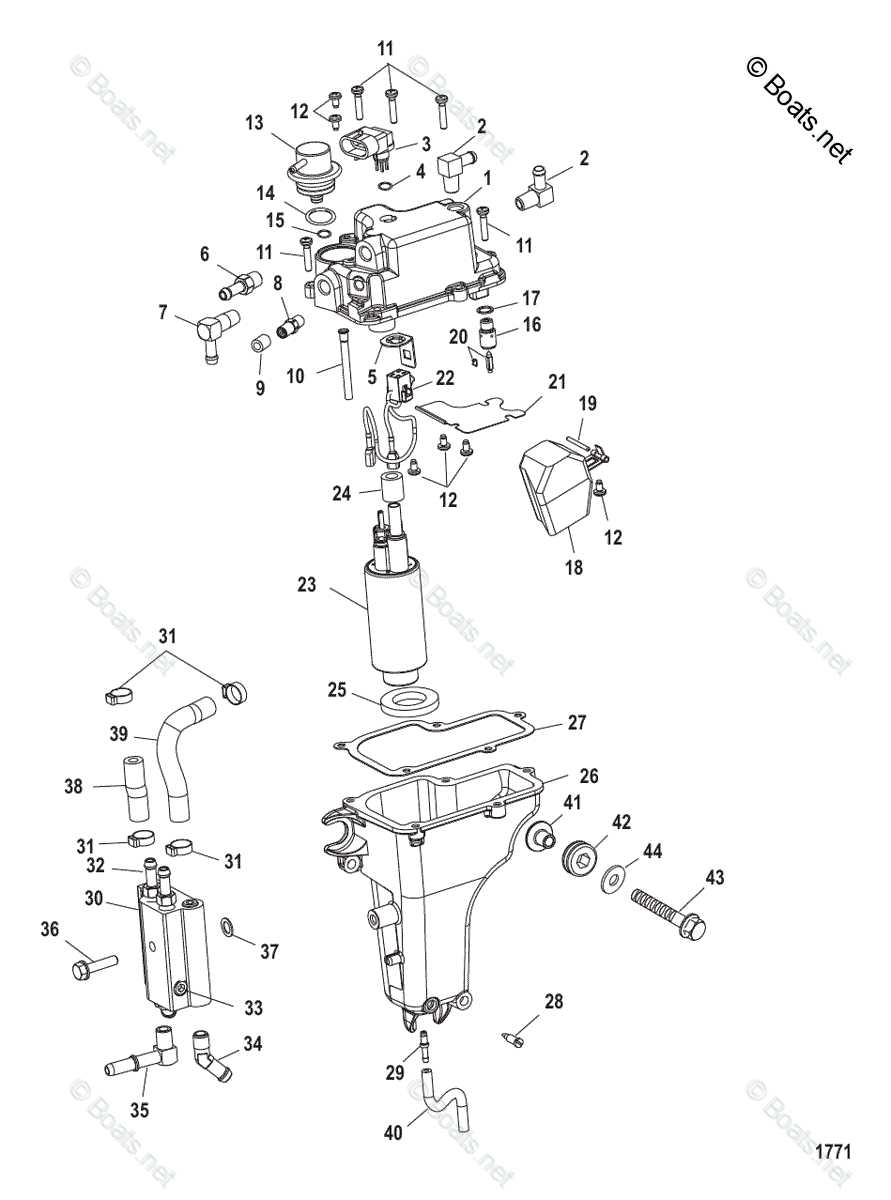

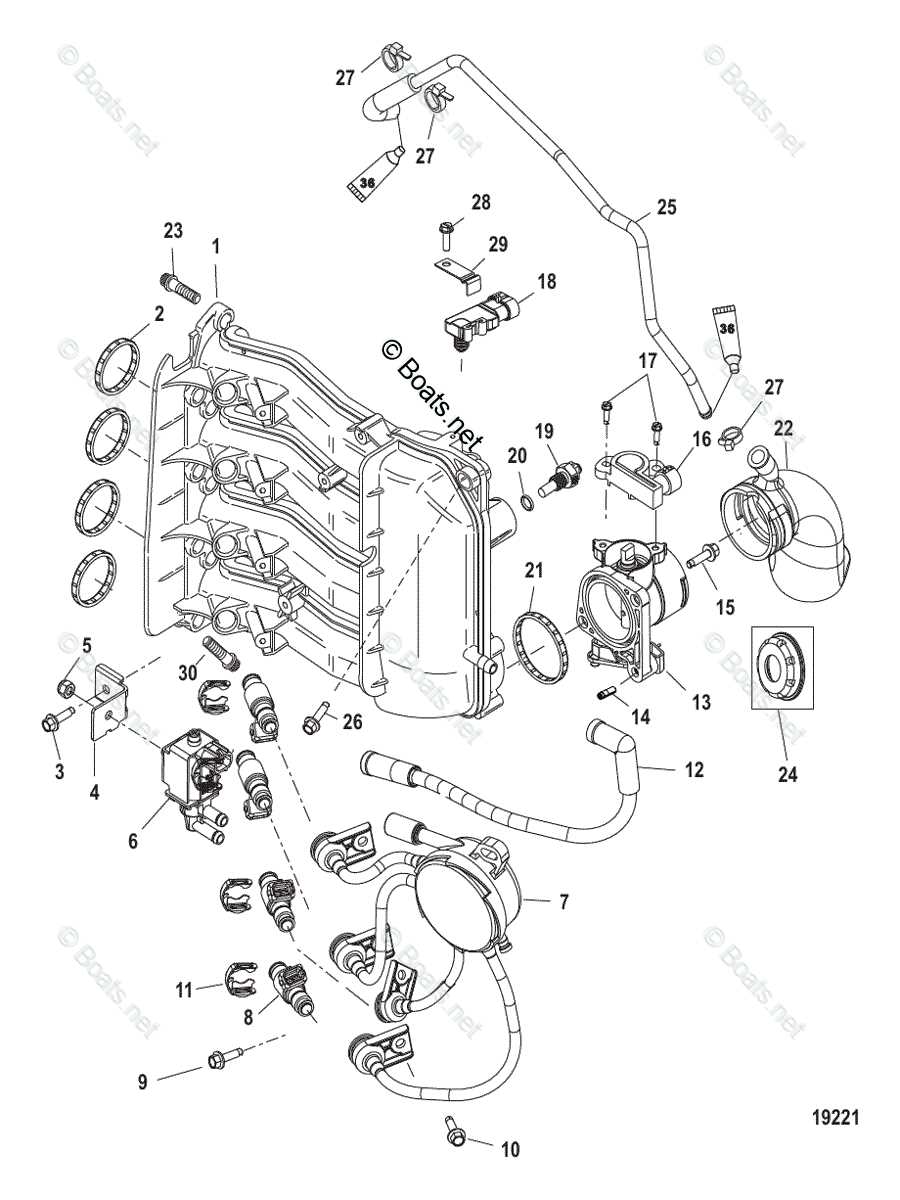

Parts Diagram for Easy Reference

This section serves as a visual guide, showcasing essential components and their arrangements for straightforward identification. A well-organized layout enhances understanding and facilitates quick access to necessary information for maintenance and repairs.

Understanding Component Layout

Having a clear overview of each element’s positioning is vital for effective servicing. This reference material enables users to familiarize themselves with the configuration, ensuring that anyone working with the machinery can efficiently locate and address any issues that may arise.

Benefits of Visual References

Utilizing a visual reference not only streamlines the troubleshooting process but also improves overall familiarity with the equipment. By consulting the layout, operators can enhance their confidence when performing inspections or replacements, ultimately leading to better performance and longevity of the machinery.

Fuel System Components Explained

The fuel system plays a crucial role in the overall performance and efficiency of an engine. Understanding its various elements can help ensure optimal functionality and maintenance. This section delves into the essential components that contribute to the fuel delivery process, ensuring a seamless operation.

| Component | Description |

|---|---|

| Fuel Tank | A container that stores the fuel required for engine operation. |

| Fuel Pump | Transfers fuel from the tank to the engine, maintaining the necessary pressure. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine, protecting sensitive components. |

| Fuel Lines | Hoses or tubes that transport fuel between the tank, pump, and engine. |

| Injector | Sprays a fine mist of fuel into the combustion chamber, ensuring efficient mixing with air. |

| Throttle Body | Controls the amount of air and fuel entering the engine, affecting power and efficiency. |

Cooling System Essentials

The cooling mechanism is fundamental to maintaining optimal performance in any engine. It prevents overheating by regulating the temperature, ensuring smooth operation even during prolonged use. A well-maintained cooling system extends the longevity of the engine by reducing wear caused by excessive heat. Understanding the components involved can help in identifying potential issues and performing routine maintenance.

- Water Pump: A vital part that circulates coolant through the engine, helping to dissipate heat efficiently.

- Thermostat: Monitors temperature and controls the flow of coolant, allowing the engine to reach the ideal operating temperature.

- Hoses and Fittings: These transport the coolant to different parts of the system, requiring regular inspection for any leaks or blockages.

- Heat Exchanger: Responsible for transferring heat from the engine to the surrounding environment, ensuring temperature control during operation.

Regular checks of these elements are essential to prevent overheating, l

Electrical Components and Their Roles

The electrical system is essential in ensuring smooth functionality of various devices and mechanisms within the engine. Each component plays a specific role in powering, regulating, and maintaining optimal operation, working together as an integrated network.

Main Power Sources

The power generation begins with key elements that produce and distribute electricity. This ensures that all systems receive the required energy for proper function.

- Battery: The main source of energy that supplies power to the entire system, even when the engine is not running.

- Alternator: Generates electricity while the engine is in operation, recharging the battery and powering other components.

Control and Regulation Devices

These components ensure the proper flow and distribution of electricity, preventing overloads and ensuring stable performance.

- Regulator: Manages the voltage output from the alternator to protect the system from surges.

- Fuses

Choosing Quality Replacement Parts

When it comes to maintaining the performance and longevity of your equipment, selecting high-grade components is essential. Ensuring that the replacements are durable, reliable, and built to withstand tough conditions can make a significant difference in functionality. Careful selection will prevent frequent repairs and help maintain optimal operation for a longer time.

Key Considerations for Selection

Before making a choice, it’s crucial to assess the compatibility of the new component with your existing setup. Checking the material quality, manufacturer reputation, and product reviews can provide valuable insight. Ensure that the selected part meets industry standards to avoid compromising safety and efficiency.

Comparison of Replacement Options

Component Type Durability Rating Average Lifespan Engine Component A High 5-7 years Upgrades to Improve Efficiency

Improving the overall performance of your equipment can lead to better fuel economy, longer lifespan, and smoother operation. With the right enhancements, you can optimize functionality while reducing maintenance needs. Here are some of the most effective upgrades to consider for better performance.

Fuel System Enhancements

Modernizing the fuel system can significantly boost operational efficiency. Implementing advanced components designed for precise fuel delivery ensures a cleaner burn, which can reduce fuel consumption and emissions.

- Upgrade fuel injectors for better atomization.

- Install a high-performance fuel pump to maintain consistent pressure.

- Use fuel additives that promote a cleaner combustion process.

Propeller Adjustments

Changing the propeller can lead to more efficient power transfer and improved handling. Choosing the right model tailored to your needs can minimize resistance and increase thrust.

- Select a propeller with a pitch suited to your desired speed range.

- Consider lightweight materials like stainless steel for better durability and efficiency.